Circulating type powder grinding device

A circulating and grinding technology, which is applied in the field of grinding equipment, can solve the problems of blockage of the grinding mouth and difficulty for grinding materials to enter the grinding teeth, and achieve the effects of energy saving and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The circulating milling device of this embodiment will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

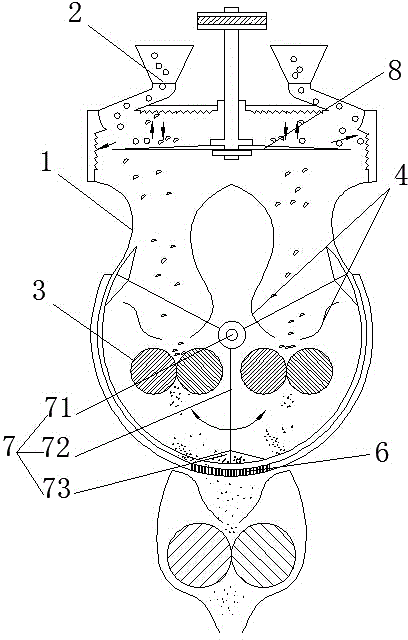

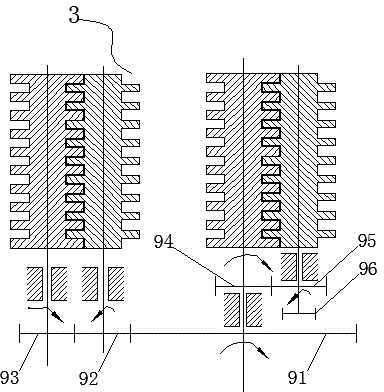

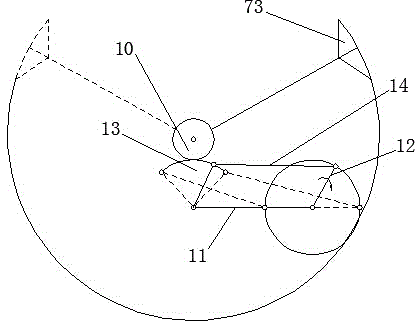

[0029] A kind of circulating milling device of the present embodiment, such as figure 1 As shown, it includes a main body 1 provided with a grinding chamber, a hopper 2 arranged on the upper part of the main body 1, and a grinding mechanism. Its grinding mechanism includes coarse grinding mechanism and fine grinding mechanism, and its rough grinding mechanism is as follows: figure 2 As shown, two pairs of roller mechanisms 3 arranged symmetrically to each other are included. The above-mentioned roller mechanism 3 is arranged inside the milling chamber of the main body 1, and the roller mechanism 3 is also provided with a guide plate 4 for guiding the raw materials to the corresponding rollers respectively. Preferably, in order to increase the meshing area between the roller mechanisms 3, the roller mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com