Patents

Literature

60results about How to "To achieve the effect of isolation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

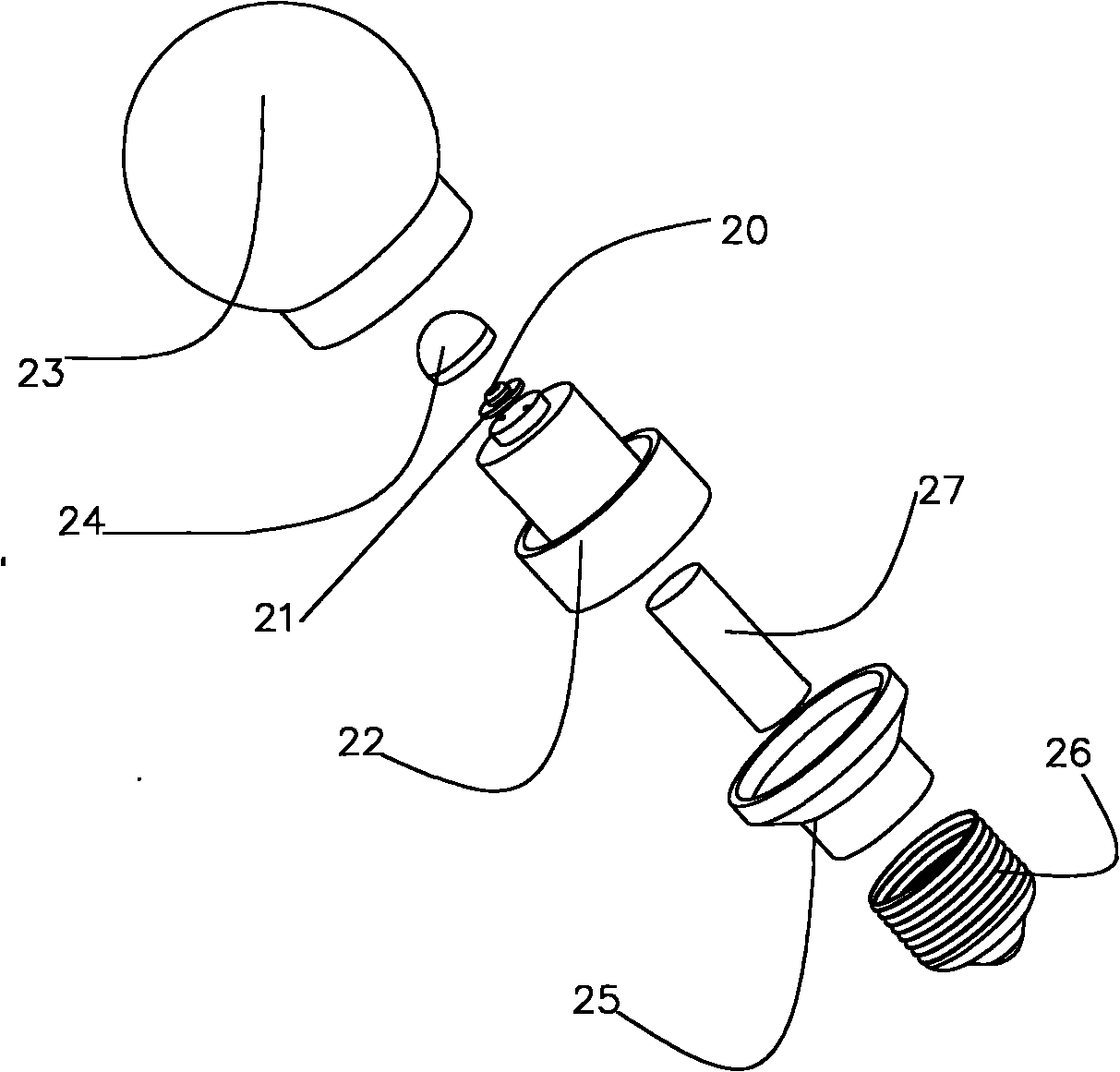

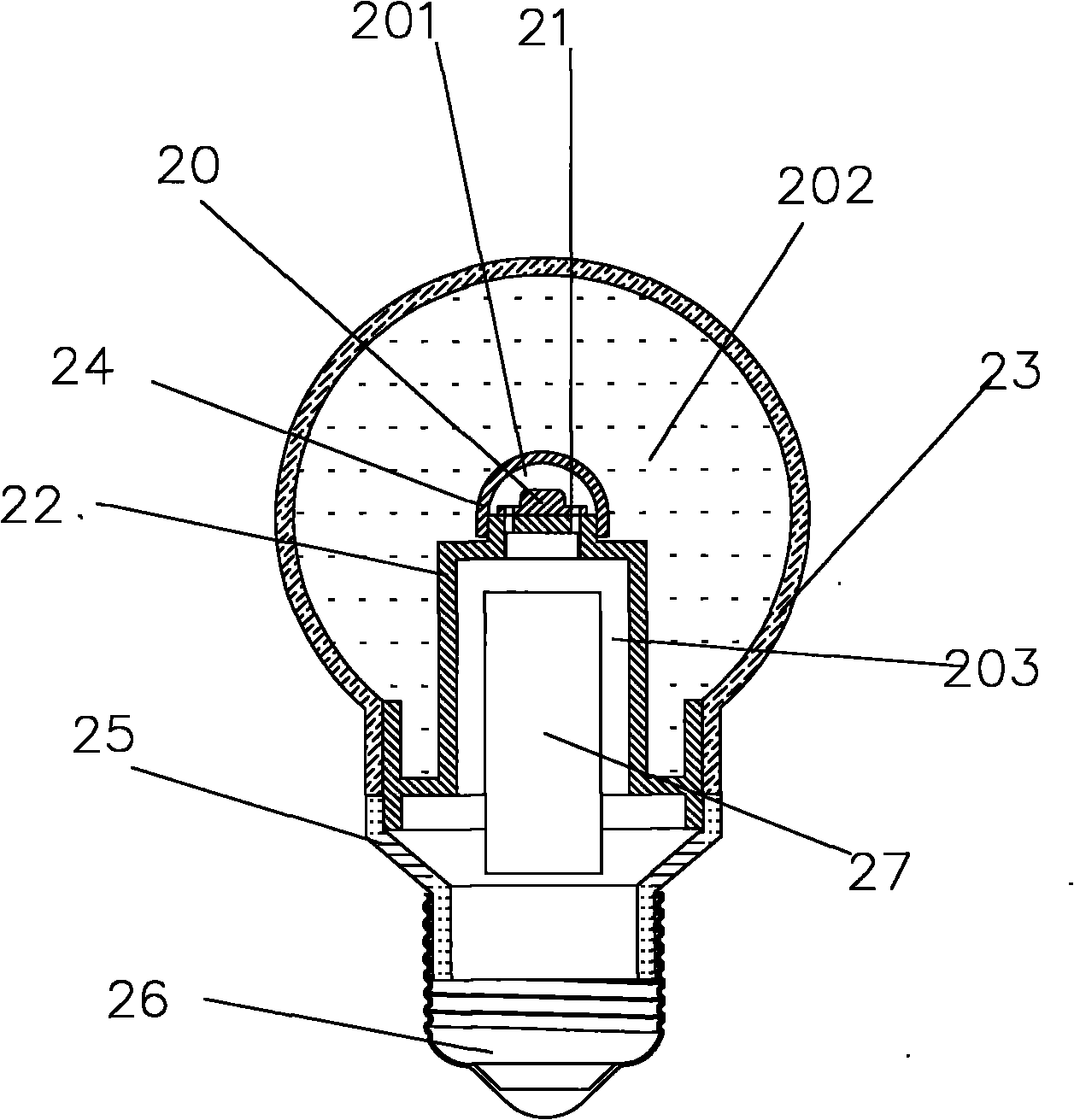

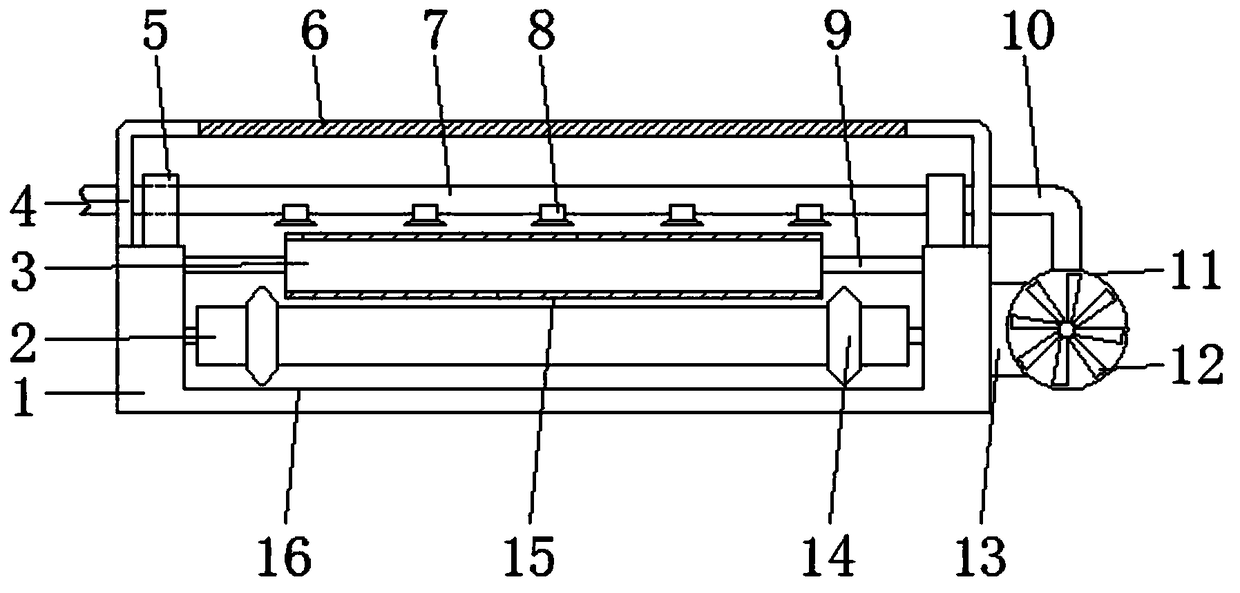

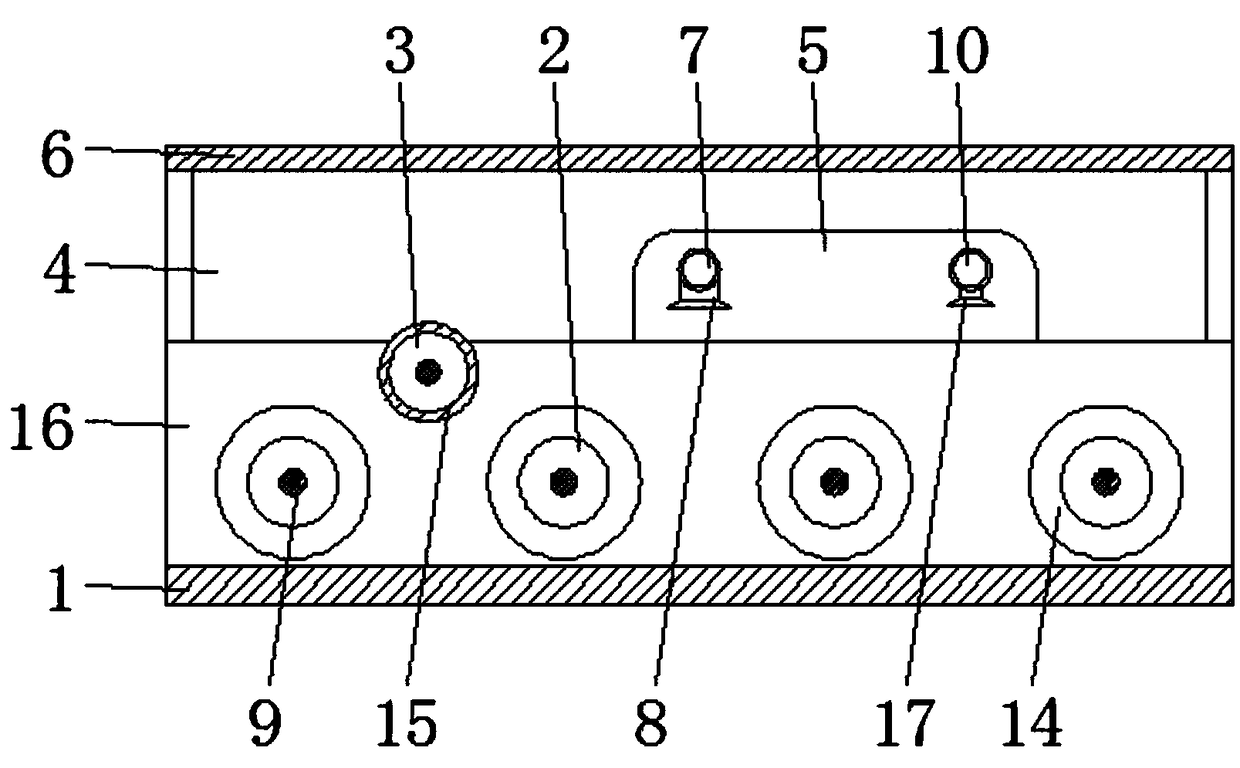

Hollow liquid-cooled light-emitting diode (LED) lamp

ActiveCN102313161AAvoid corrosionPrevent penetrationLighting heating/cooling arrangementsElectric lightingEngineeringLED lamp

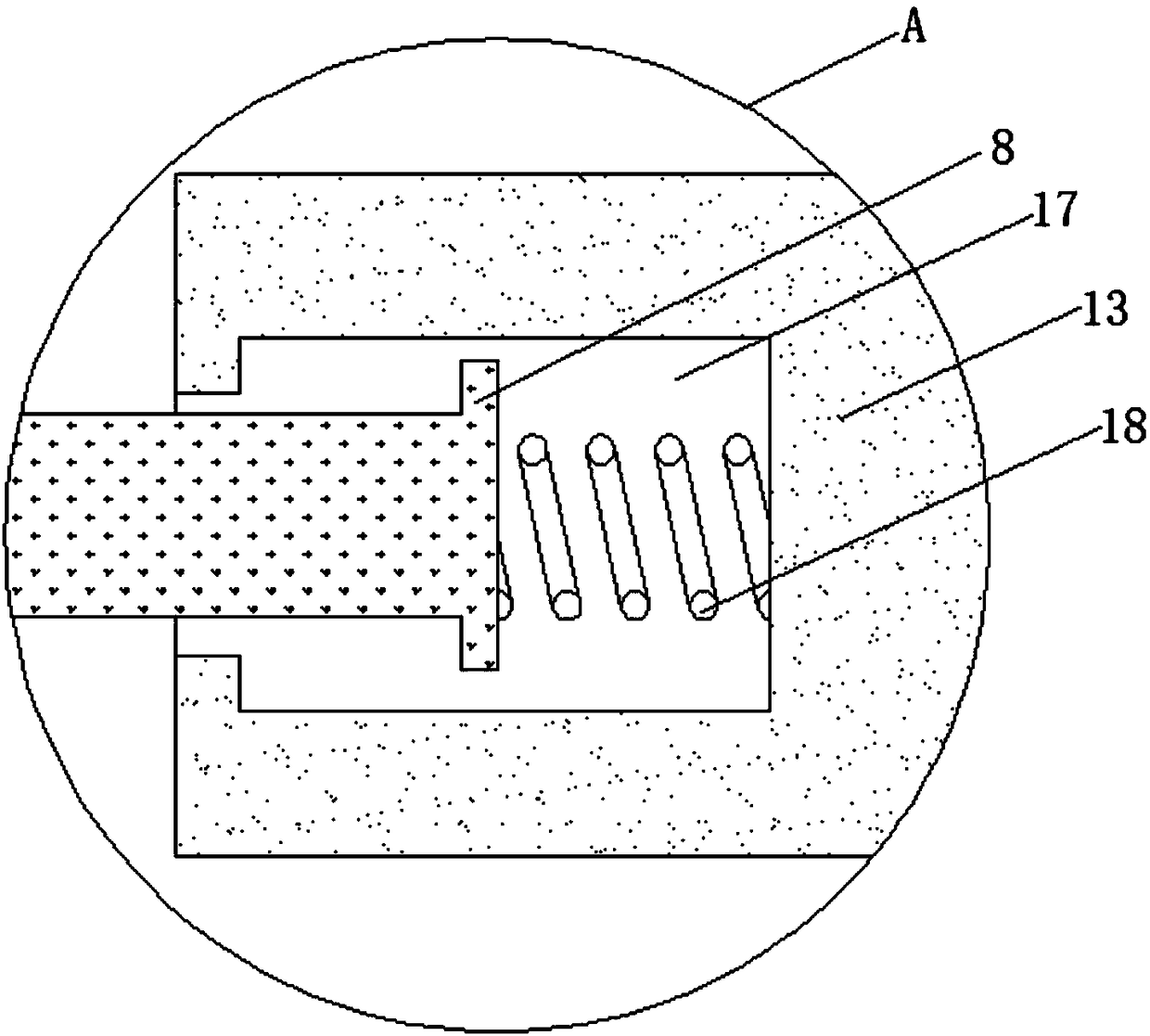

The invention discloses a hollow liquid-cooled light-emitting diode (LED) lamp. The hollow liquid-cooled LED lamp comprises an LED substrate light source which consists of an LED light source and an LED substrate, a substrate seat, an external light distributing cover and an internal sealing cover, wherein the internal sealing cover is arranged on the top of the substrate seat; the inner surface of the internal sealing cover and the top of the substrate seat form a first sealing cavity; the LED substrate light source is sealed in the first sealing cavity; the external light distributing cover is arranged on the outer side of the substrate seat; and the outer surface of the external light distributing cover, the outer surface of the substrate seat and the outer surface of the internal sealing cover form a second sealing cavity which is filled with radiator liquid. The problem that the LED substrate is corroded by the radiator liquid can be solved by the embodiment of the invention.

Owner:FOSHAN CITY NANHAI DISTRICT LIANHE GUANGODNG XINGUANGYUAN IND INNOVATION CENT

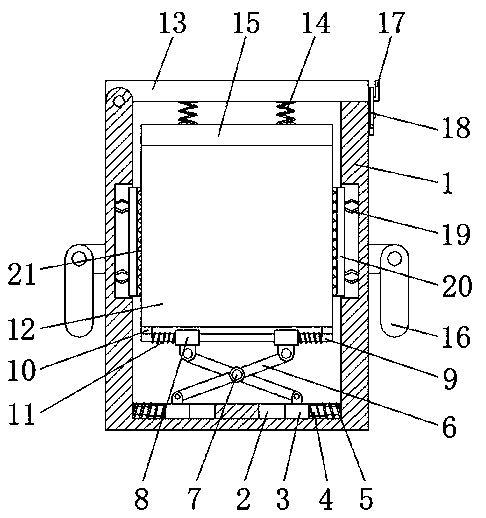

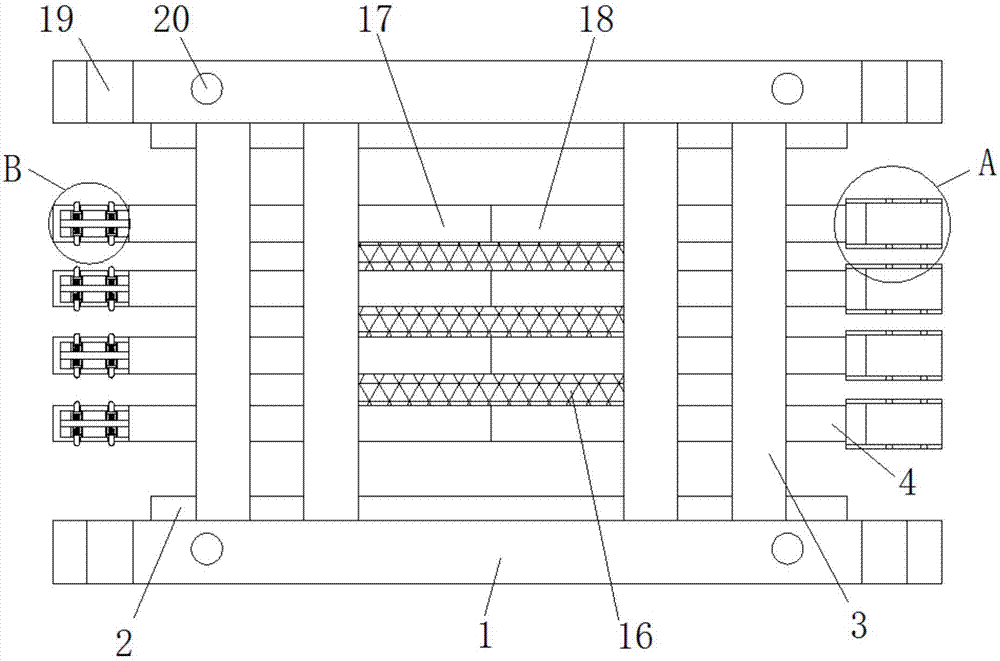

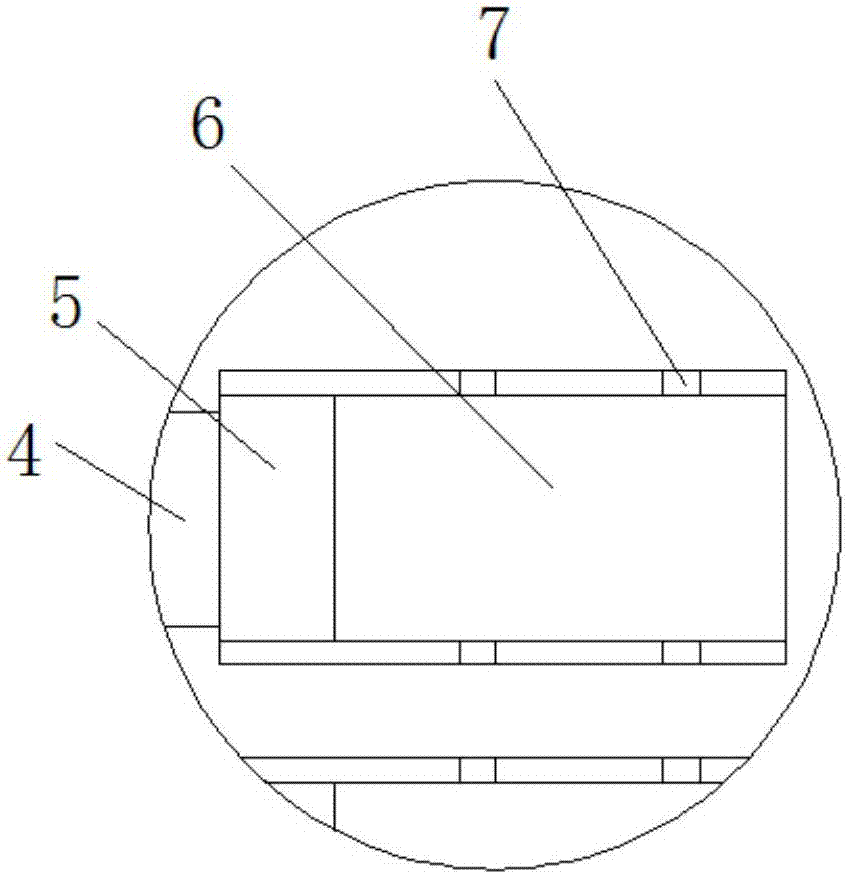

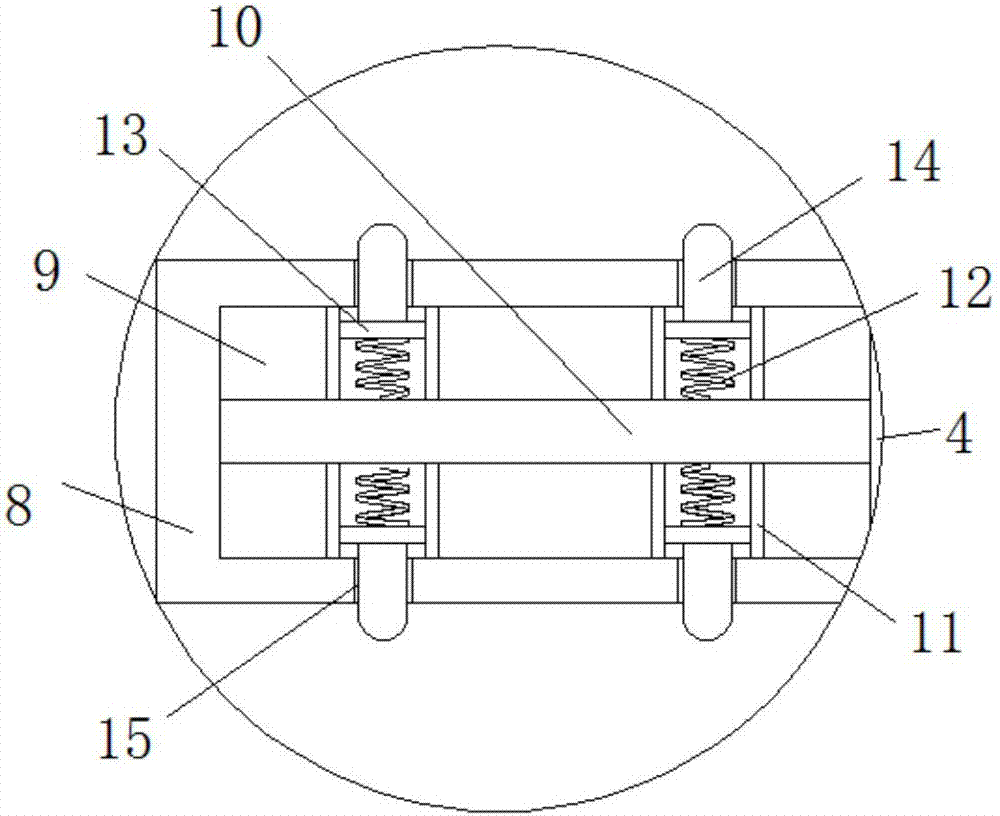

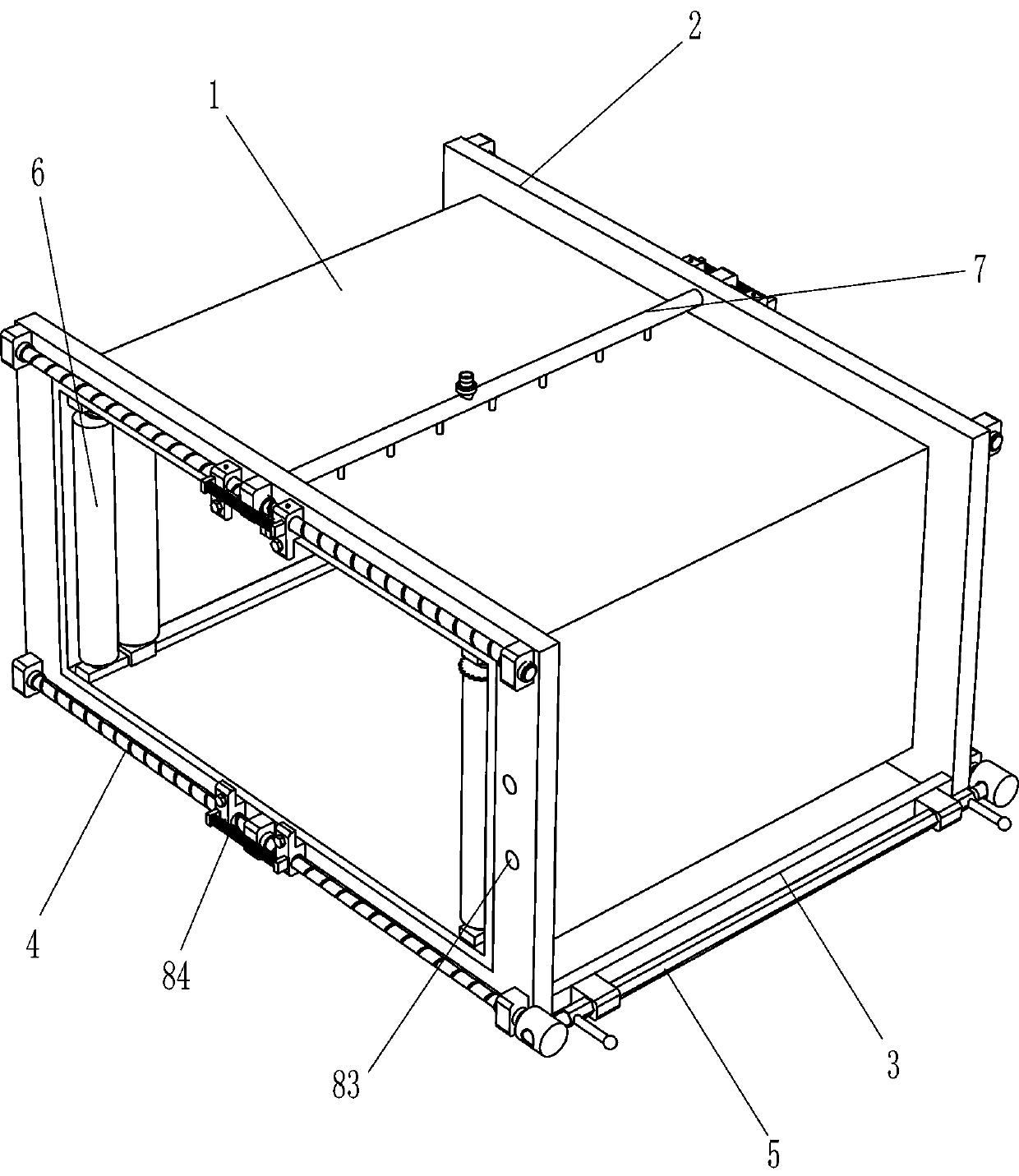

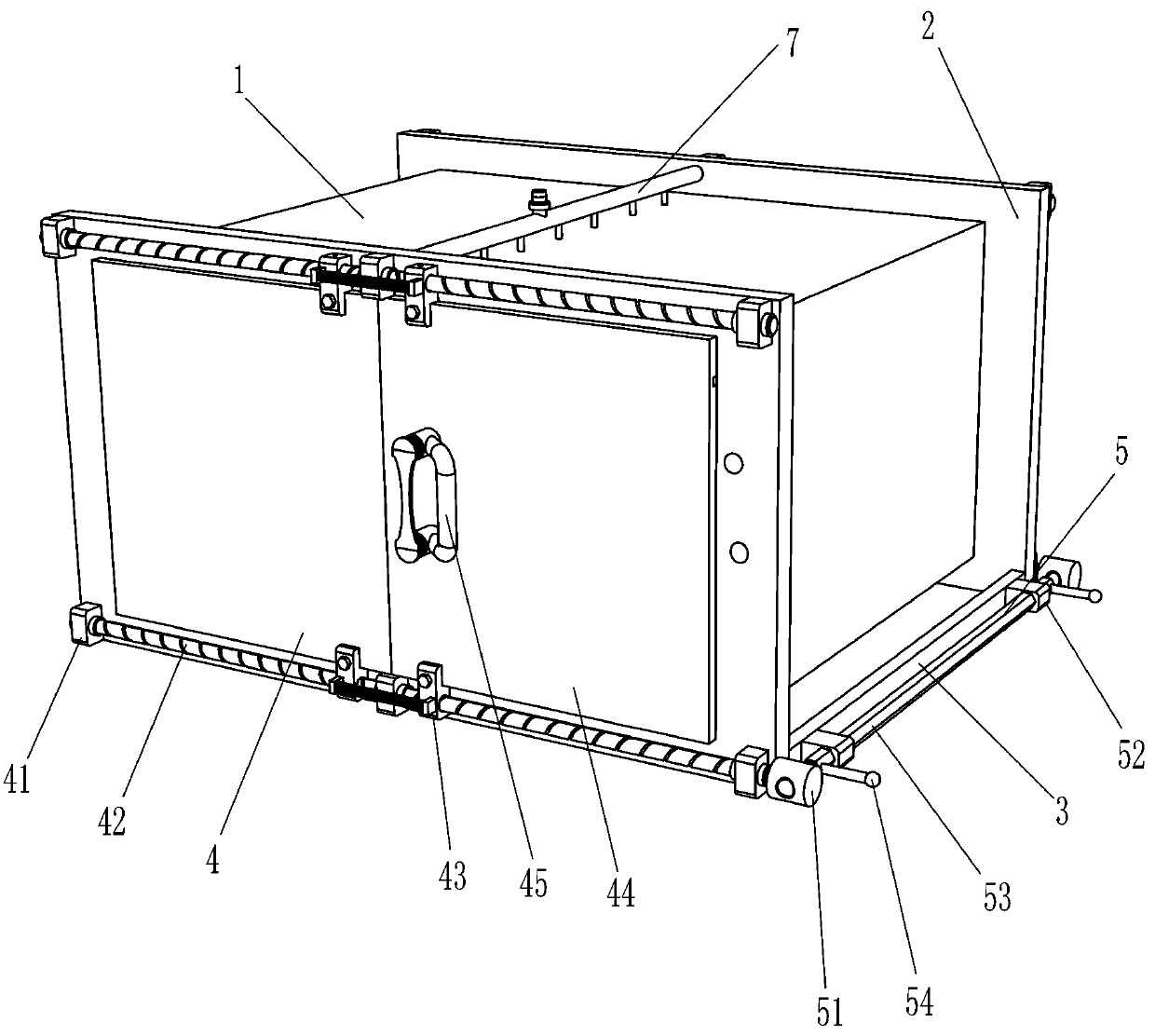

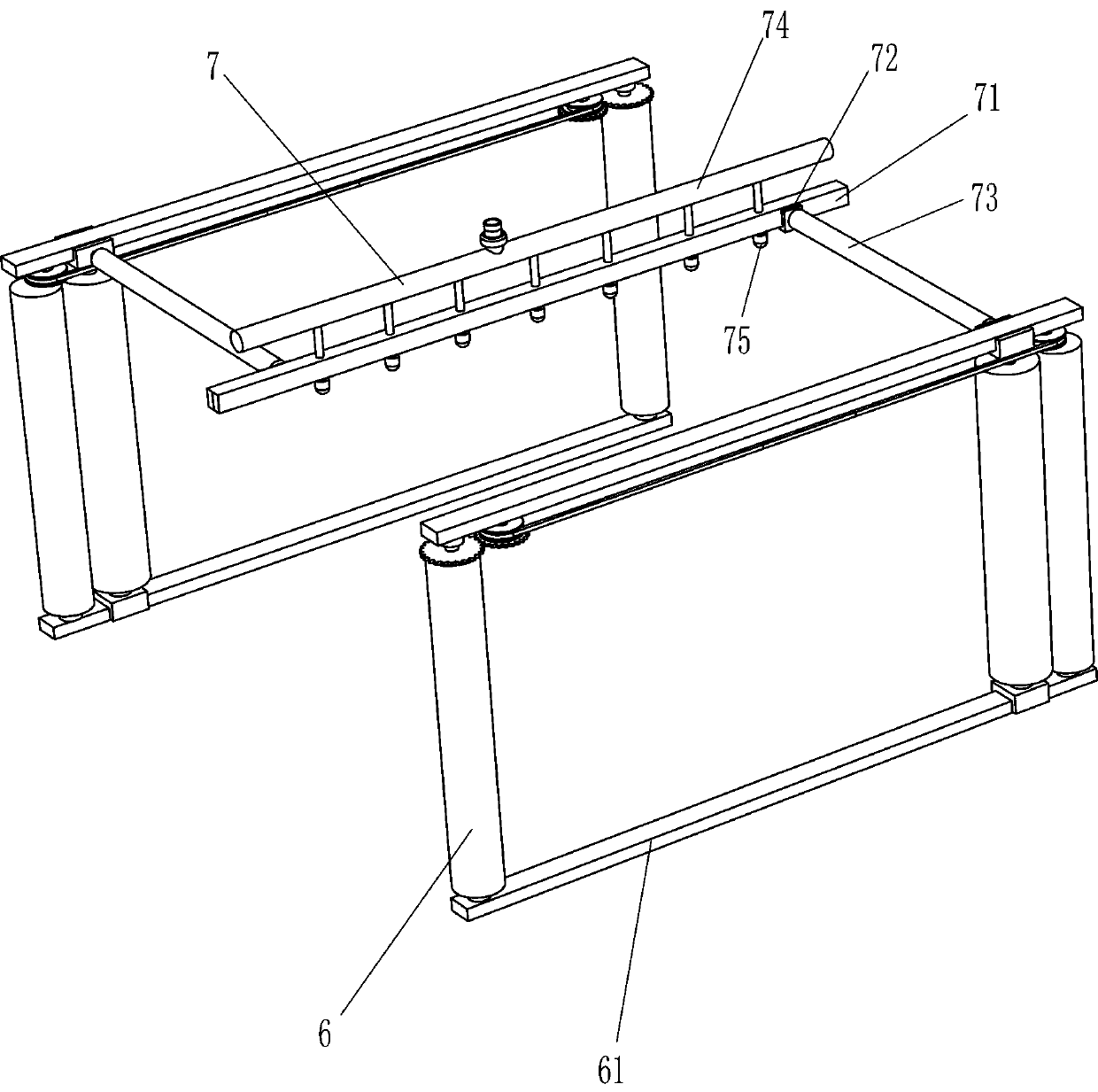

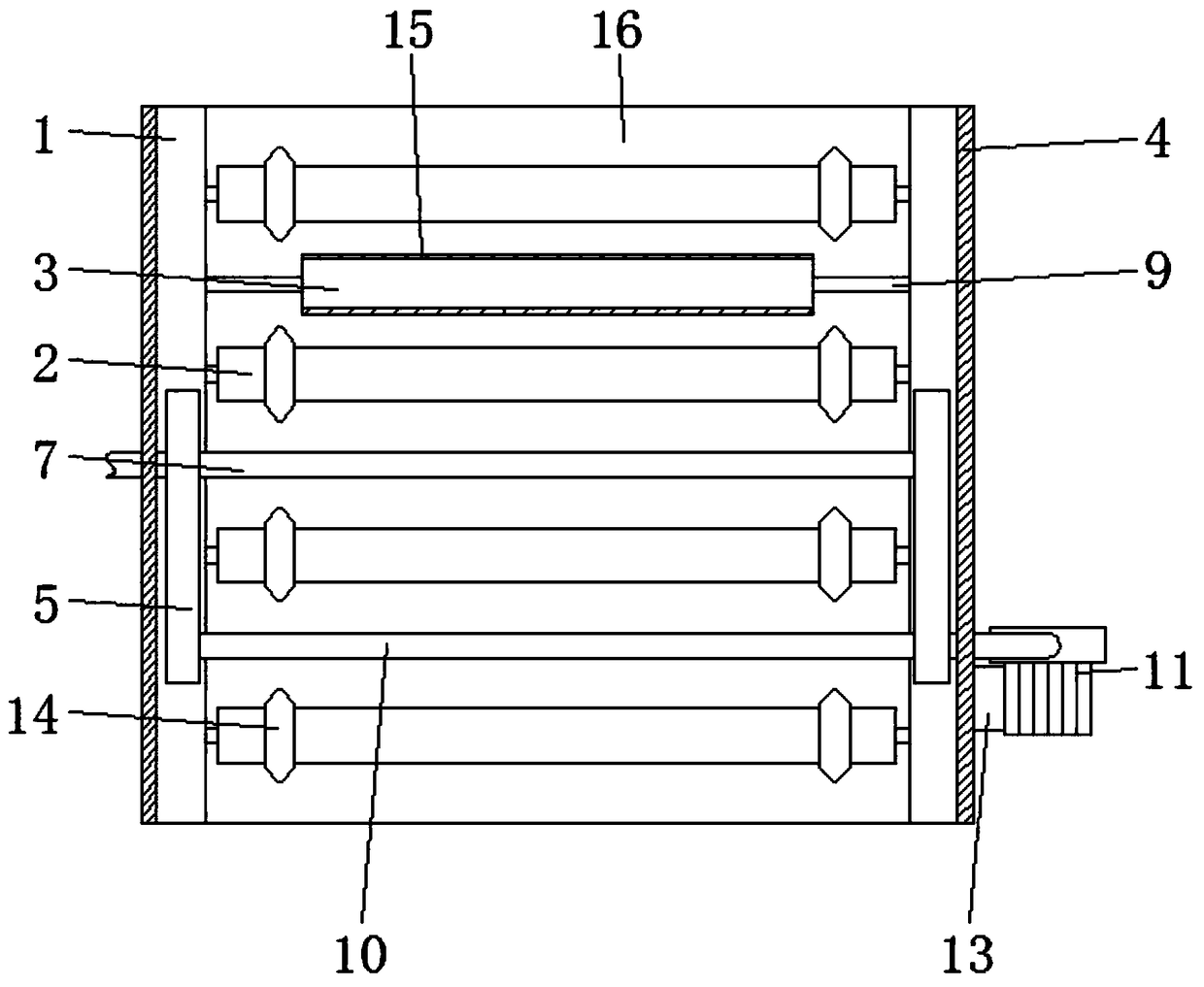

A lithium battery shock absorb box

InactiveCN109065773ASolve the function that does not have shock absorption and bufferingAchieve the advantages of shock absorption and cushioningLi-accumulatorsCell component detailsCushioningEngineering

A lithium battery shock absorb box comprises a transport box, wherein both sides of the bottom of the inner cavity of the transport box are provided with sliding grooves, the inner wall of the slidinggroove is slidably connected with a sliding block, the outer side of the sliding block is fixedly connected with a telescopic rod, an end of the telescopic rod away from the sliding block is welded with the inner wall of the transport box, and the surface of the telescopic rod is sleeved with a first spring. In accordance with that present invention, Slider, telescopic bar, First spring, strut, movable shaft, sliding sleeve, Fixing block, second spring, storage box, the arrangement of the third spring and the pressing plate, so that the lithium battery can be cushioned by a spring when the lithium battery is transported, The invention achieves the advantages of shock absorbing and cushioning, and solves the problem that the traditional battery storage box does not have the shock absorbingand cushioning function, and the shell of the lithium battery is mostly plastic products, so that the lithium battery is easy to be damaged and economic loss is caused by bumping during transportation.

Owner:许昌政德能源科技有限公司

Method for forming air-isolated air curtain

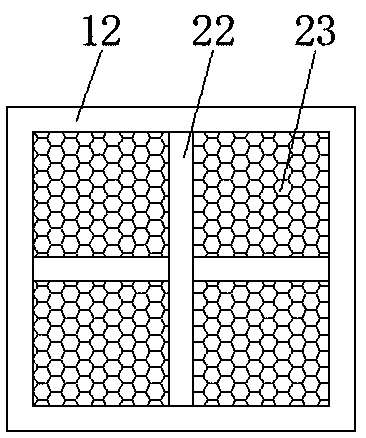

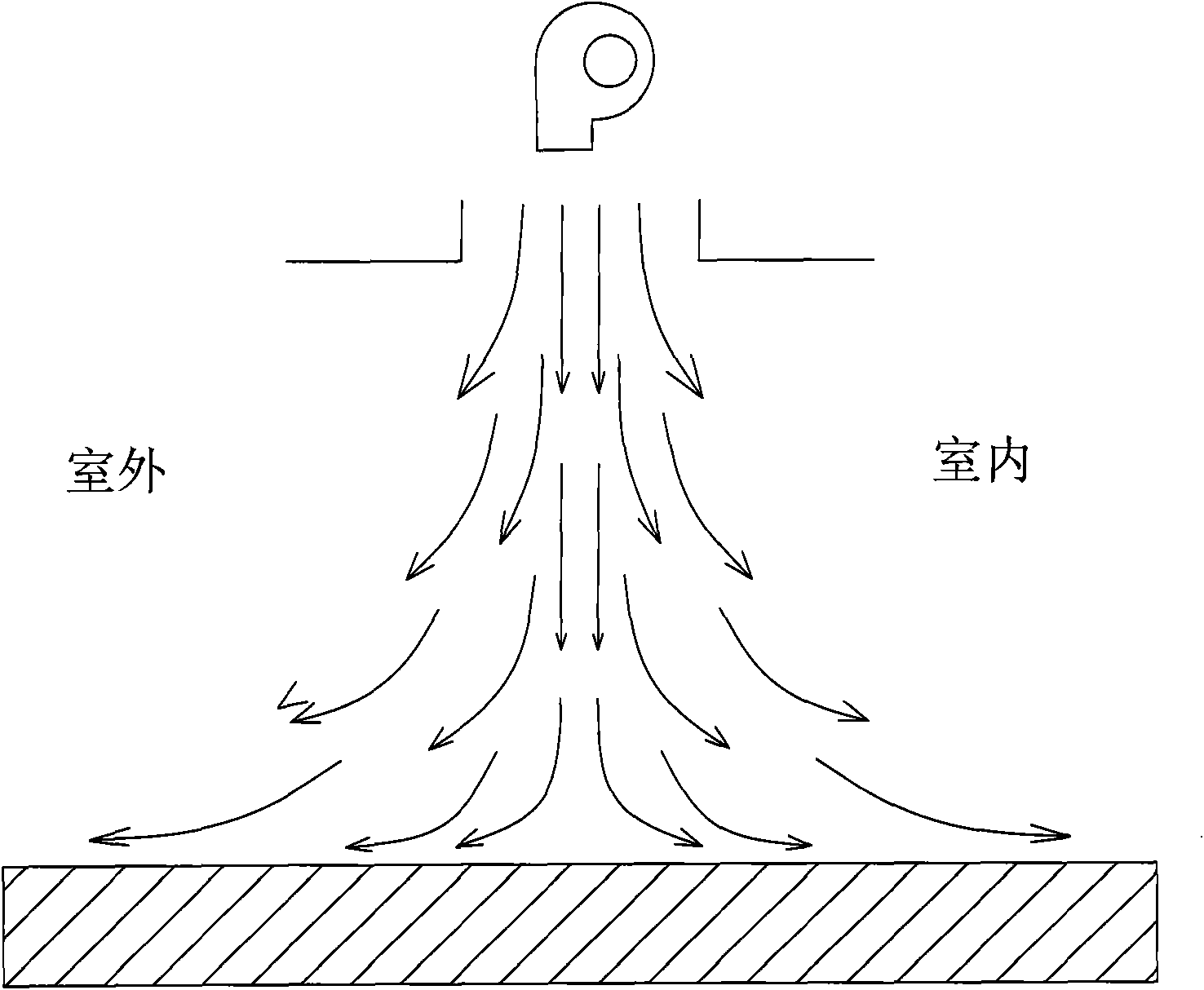

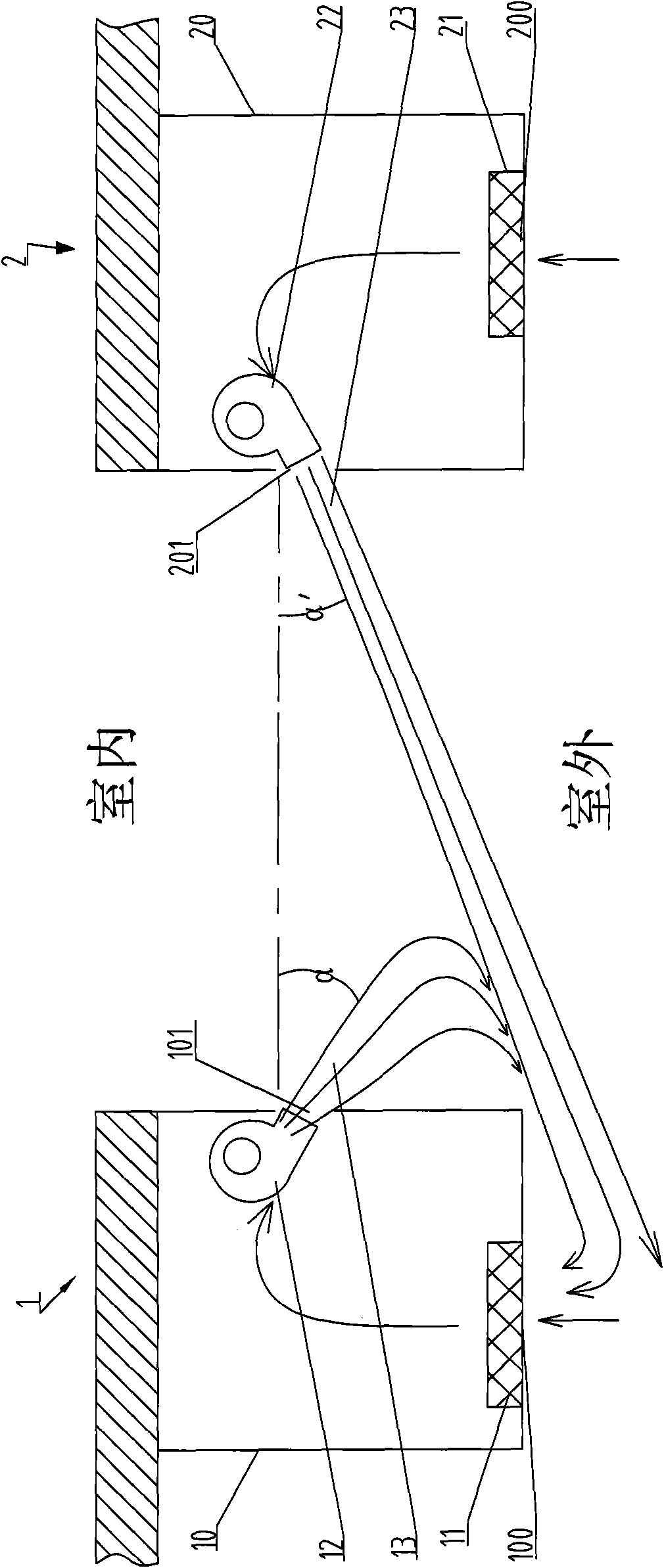

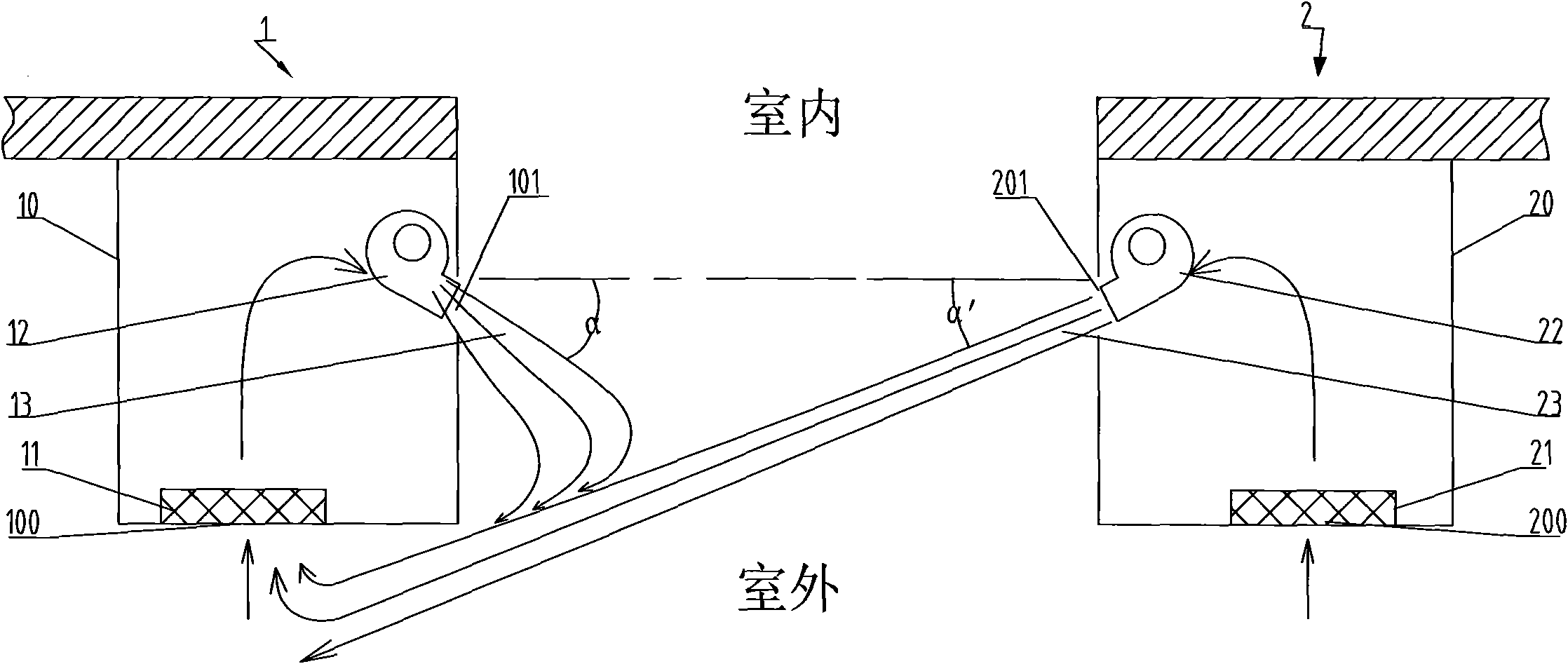

InactiveCN101915447AImprove cleanlinessImprove the isolation effectLighting and heating apparatusAir currents for screeningEngineeringOutdoor temperature

The invention relates to a method for forming an air-isolated air curtain, which comprises the following steps of: a, respectively arranging a first air spraying device and a second air spraying device on two sides of the intersection of indoor and outdoor positions, and controlling an included angle between an air outlet direction of a first centrifugal fan and the horizontal plane to be more than that between an air outlet direction of a second centrifugal fan and the horizontal direction, wherein the first air spraying device comprises a first box body and the first centrifugal fan; the second air spraying device comprises the second centrifugal fan; and the included angles are set between 10 and 45 degrees; b, regulating the air outlet speed of the first centrifugal fan and the second centrifugal fan to be 12-16m / s and 20-26m / s respectively, wherein the air outlet speed of the first centrifugal fan is higher than that of the second centrifugal fan; and c, starting a first centrifugal motor and a second centrifugal motor to form the air-isolated air curtain. The formed air-isolated air curtain can effectively isolate the mixture of indoor and outdoor air so as to achieve the effects of keeping indoor cleanliness and isolating indoor and outdoor temperature difference, and the like.

Owner:苏州安泰空气技术有限公司

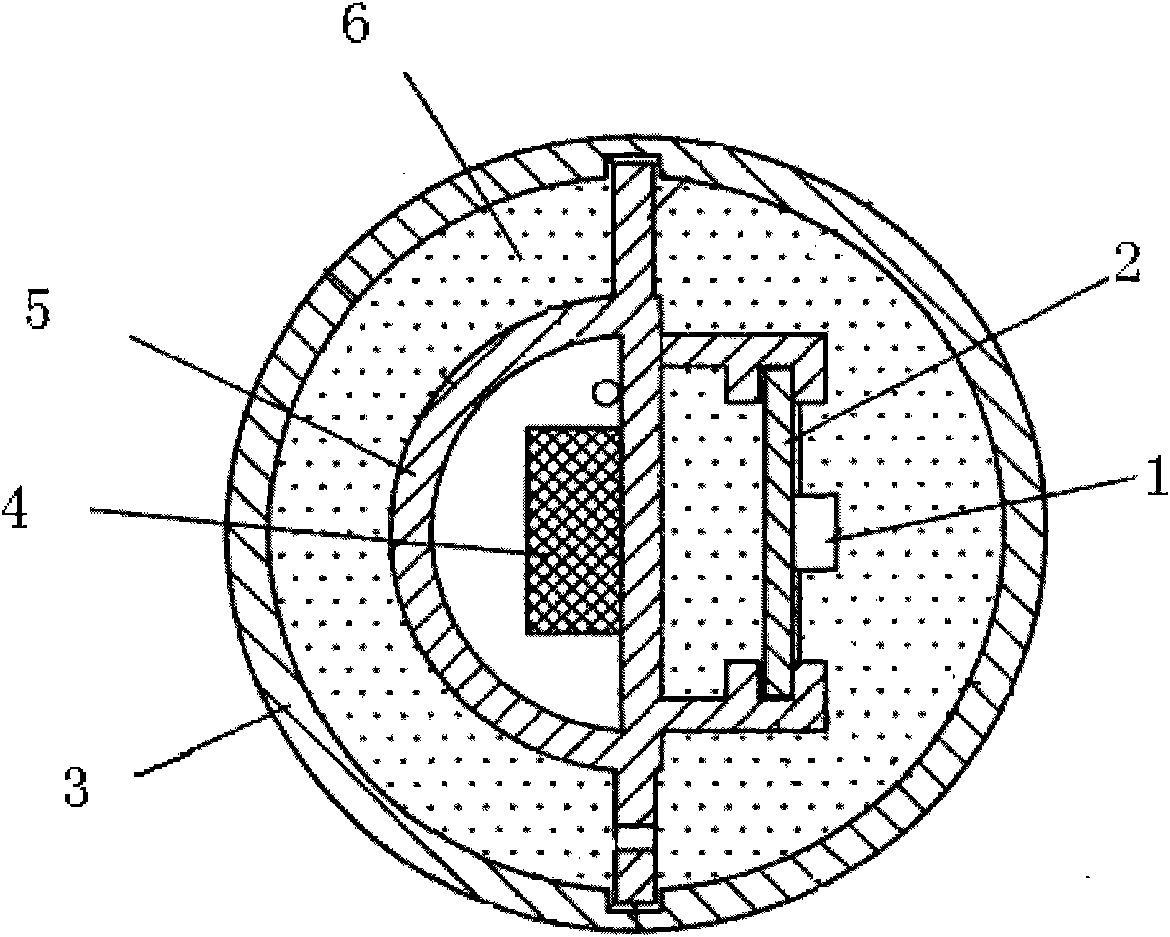

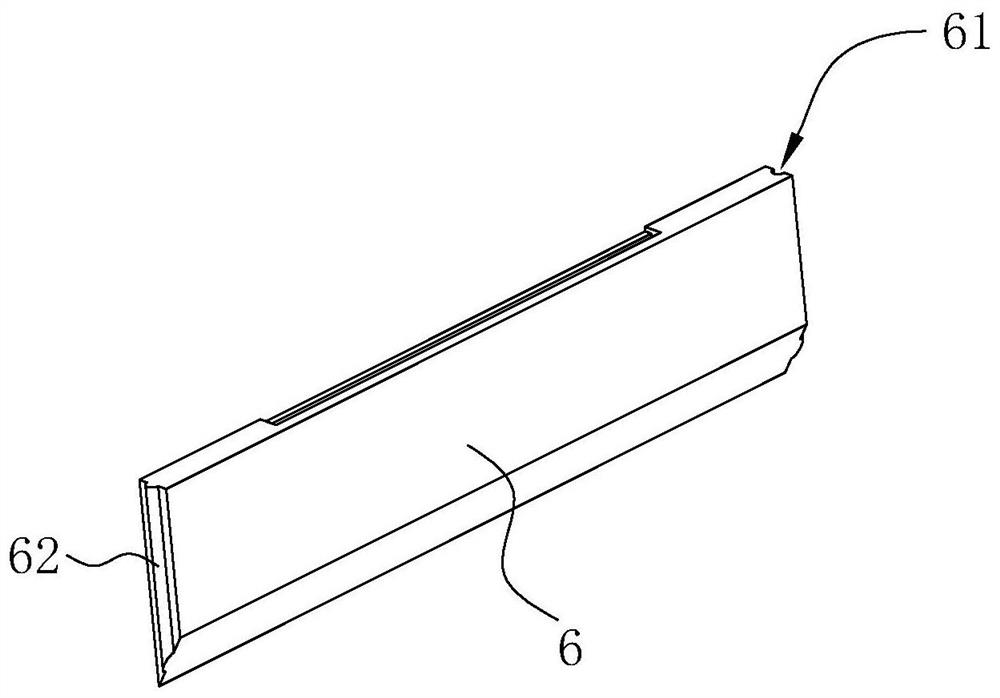

Pouring type waterproof bus duct

InactiveCN107508228AFirmly connectedImprove work efficiencyTotally enclosed bus-bar installationsCopper conductorStructural engineering

The present invention relates to a bus duct technology field, and discloses a pouring type waterproof bus duct. The pouring type waterproof bus duct comprises a fixing side plate, a ceramic silicone rubber body is fixedly connected at the inner side of the fixing side plate, and a flame retardant clapboard is fixedly connected inside the fixing side plate. A copper conductor is fixedly connected inside the flame retardant clapboard, penetrates and extends to the outer side of the flame retardant clapboard, one end of the copper conductor is fixedly connected with a fixing joint, and a jack is arranged at one side of the fixing joint. According to the pouring type waterproof bus duct, by the cooperative usage of the fixing joint and a fixing plug, and when the two pouring type waterproof bus ducts need to be connected together, the fixing plug can be plugged in the jack on the fixing joint, and a fixing rod extends in a fixing hole on the fixing plug under the action of a first compression spring, so that the copper conductors in the pouring type waterproof bus ducts can be connected conveniently, the connection is convenient, the time and the labor are saved, and the working efficiency is improved.

Owner:WETOWN ELECTRIC GRP CO LTD

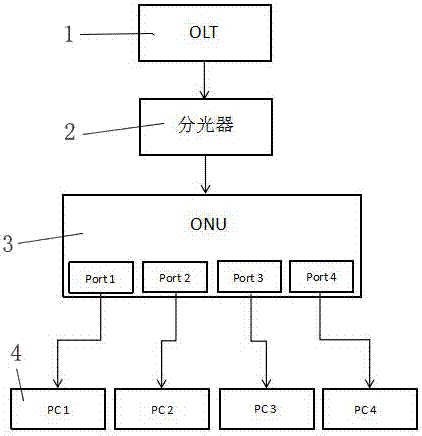

Port isolation and VLAN isolation switching method and application thereof in EPON (Ethernet Passive Optical Network)

InactiveCN107172101ATo achieve the effect of isolationAchieve isolationElectromagnetic transmission optical aspectsComputer terminalEthernet passive optical network

Owner:LOOTOM TELCOVIDEO NETWORK WUXI

Broadband low-noise analog front end circuit for optical fiber instant fracture detection system

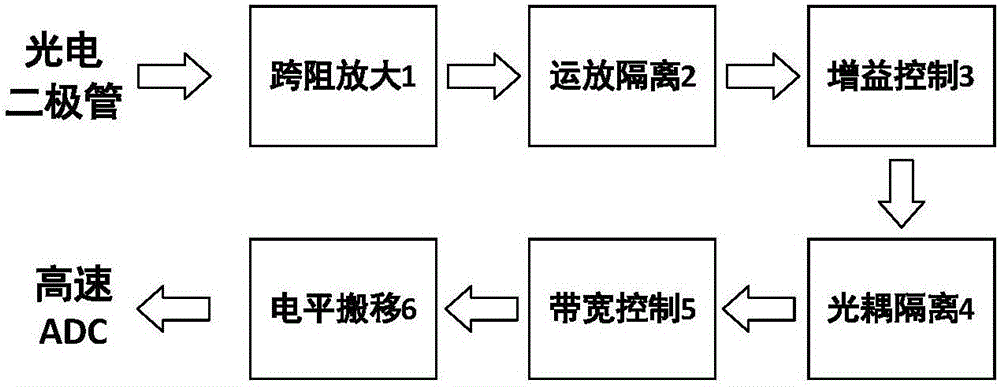

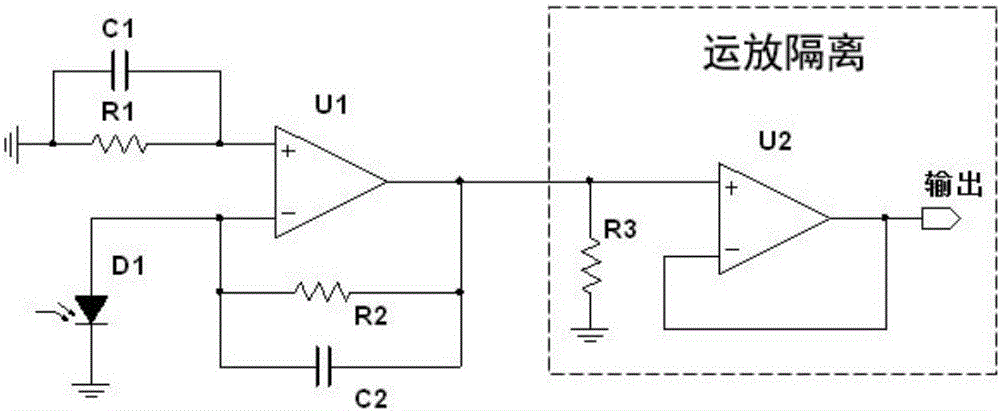

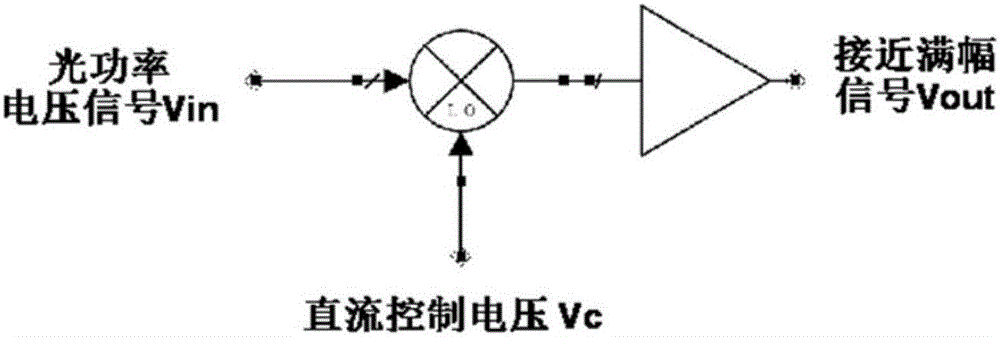

ActiveCN106850055ALower noise figureQuick responseGain controlLogic circuits using opto-electronic devicesBroadbandLarge dynamic range

The invention relates to a broadband low-noise analog front end circuit for an optical fiber instant fracture detection system. The circuit comprises a photodiode, a transimpedance amplifier module, a gain control module, a bandwidth control module and a level movement module. The system also is equipped with an isolation module which is connected with the transimpedance amplifier module, the gain control module and the bandwidth control module. Compared with the prior art, the circuit has the advantages of large dynamic range, simple control, fast response speed, low noise and satisfaction of a nanosecond level demand of the optical fiber instant fracture detection system.

Owner:SHANGHAI JIAO TONG UNIV

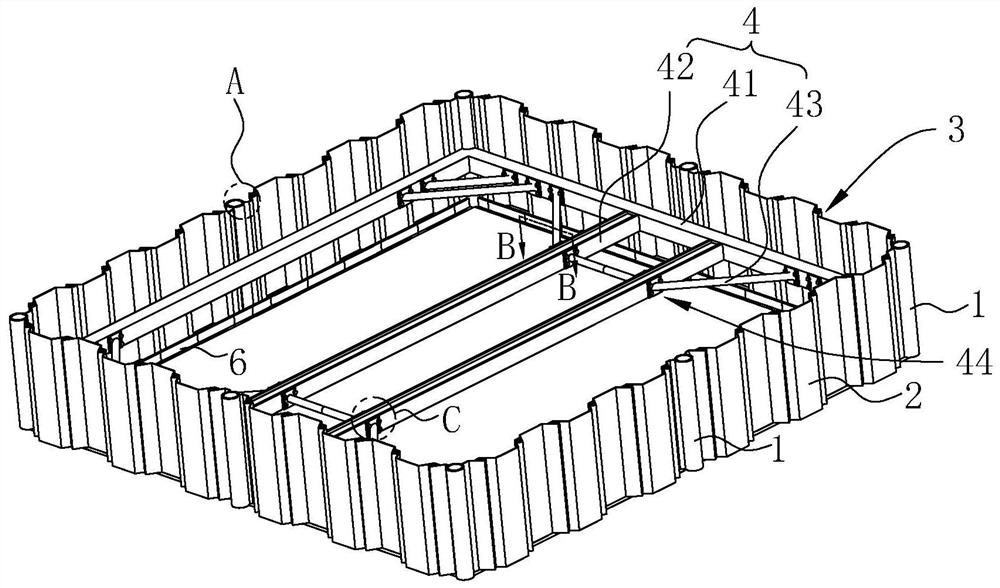

Fabricated cofferdam structure and construction method

The invention relates to a fabricated cofferdam structure and a construction method. The fabricated cofferdam structure comprises a plurality of vertically arranged steel casings and at least one hanging box of an annular structure, the multiple steel casings are distributed along the annular contour of the hanging boxes, each hanging box comprises a plurality of cofferdam steel plates, the multiple cofferdam steel plates are divided into a plurality of groups, and the multiple cofferdam steel plates in the same group are mutually spliced and arranged between every two adjacent steel casings. The cofferdam steel plates are parallel to the axial direction of the steel casings, and connecting assemblies used for connecting the adjacent cofferdam steel plates or the adjacent steel casings are arranged on the two vertical side edges of each cofferdam steel plate correspondingly. A supporting assembly used for supporting and serving as a construction platform is arranged in each hanging box. According to the fabricated cofferdam structure, the waste of materials can be effectively reduced.

Owner:北京华昊水利水电工程有限责任公司

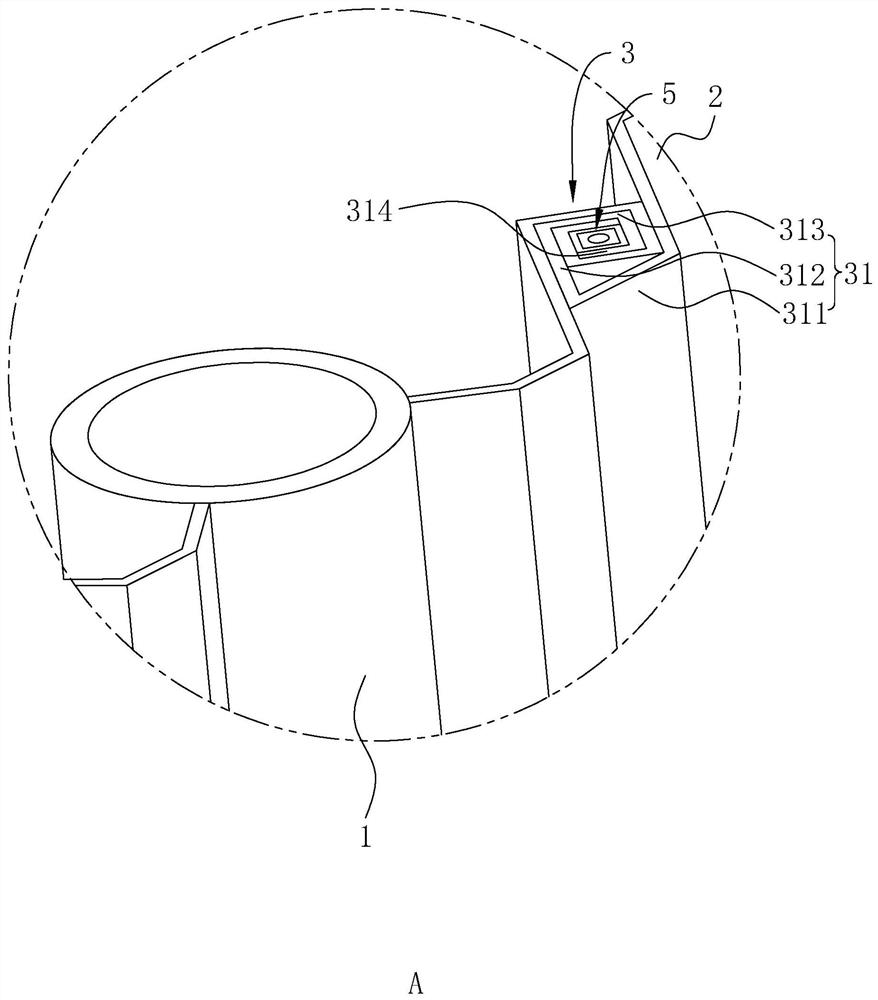

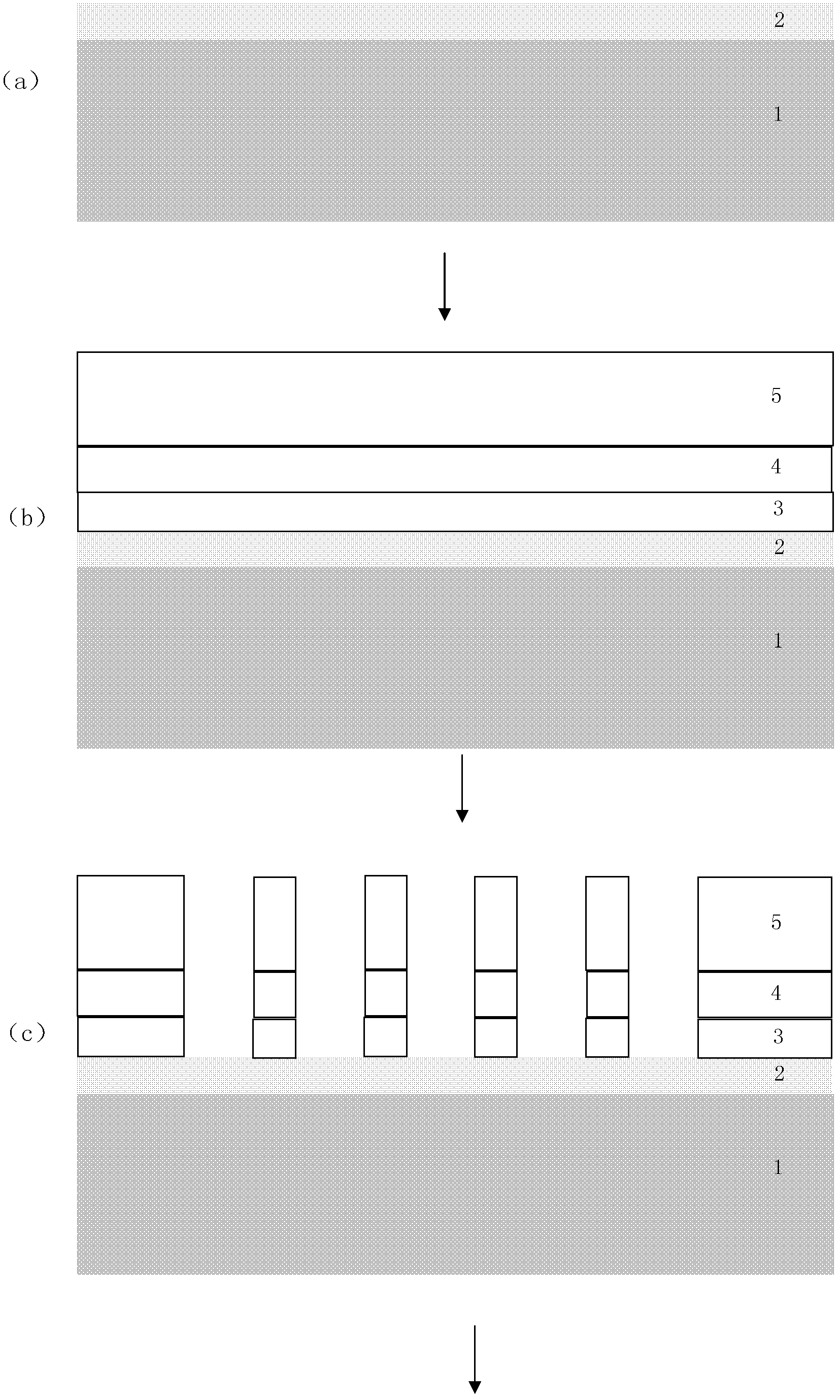

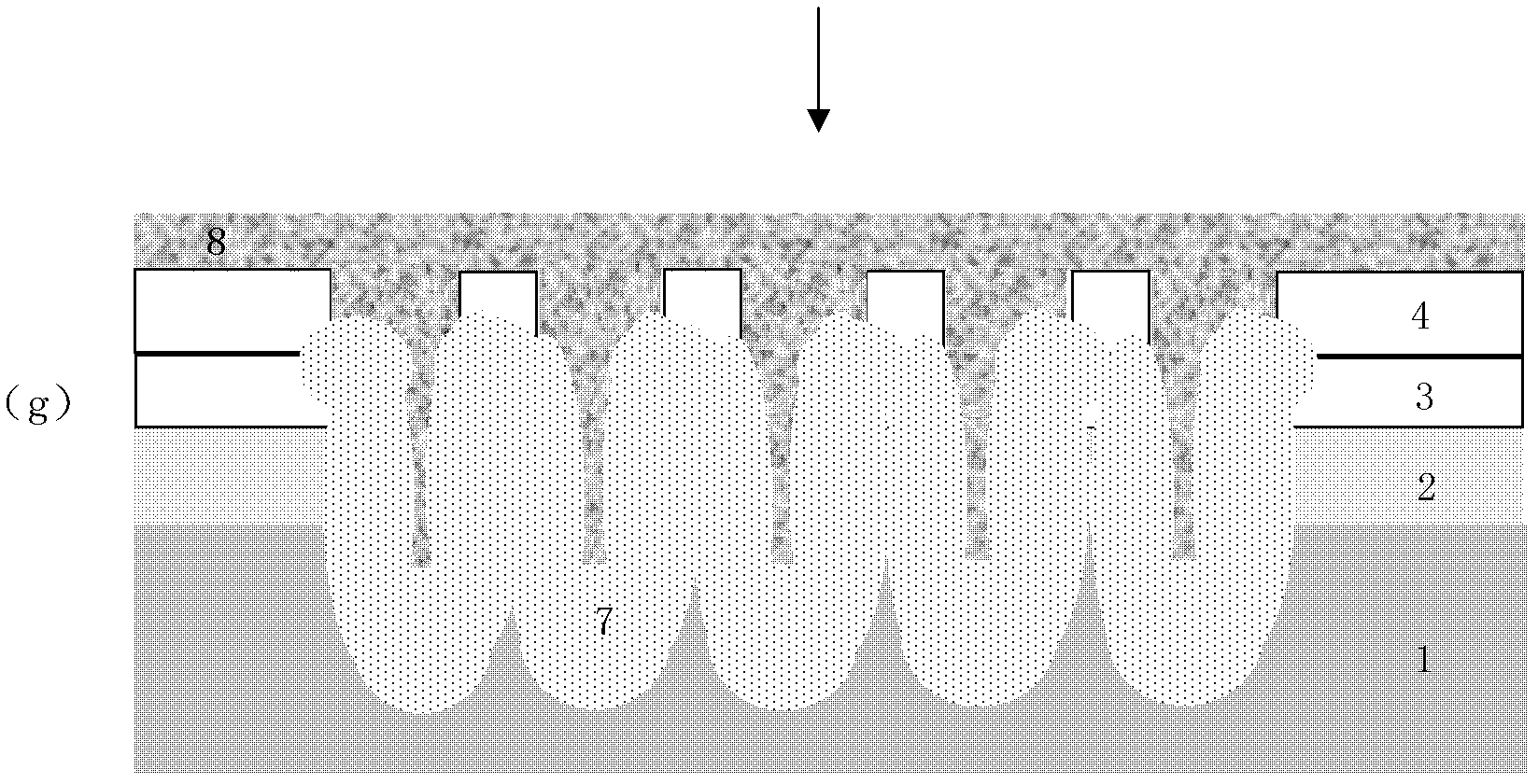

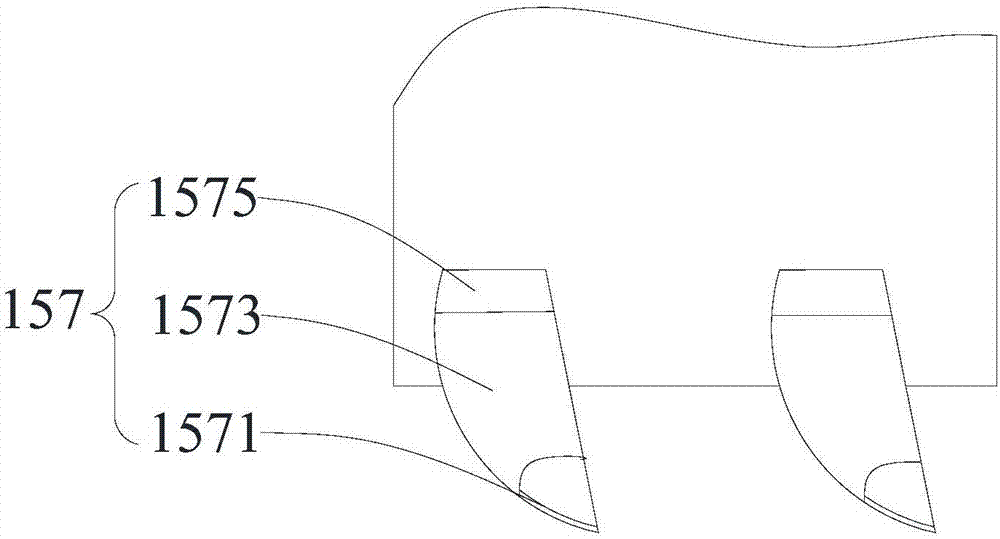

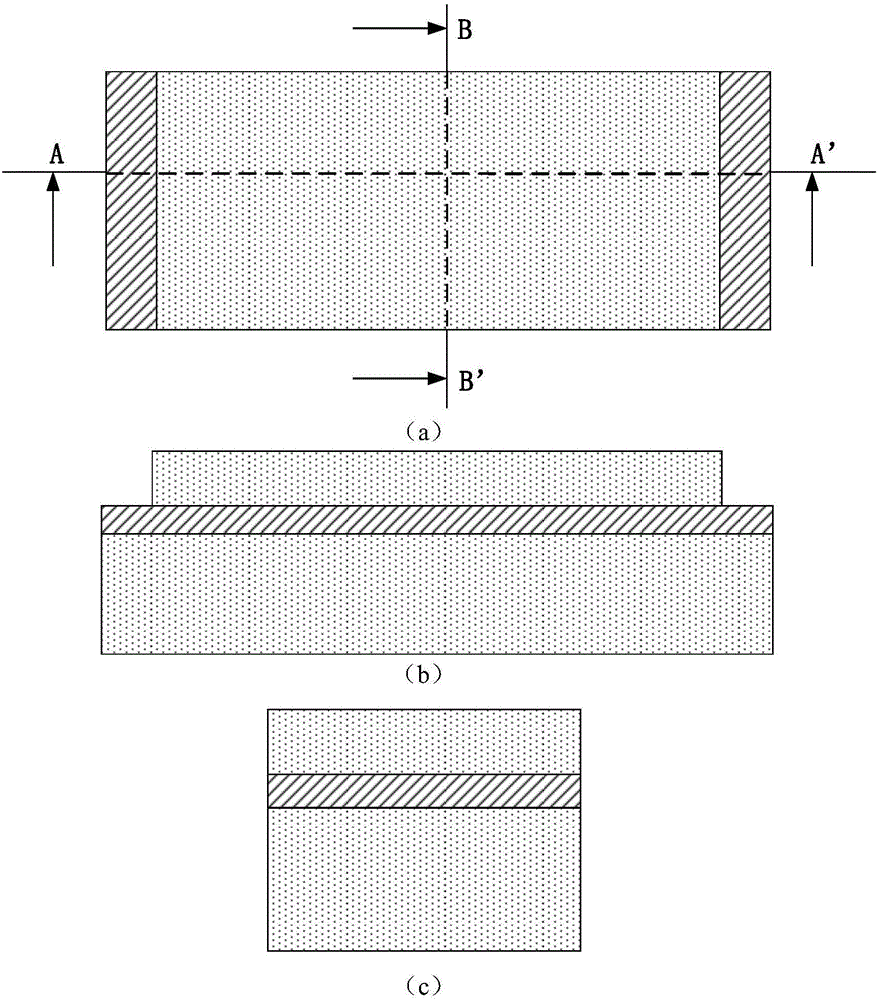

Production method of deep groove isolation structure

InactiveCN102522363AImprove in-plane uniformityTo achieve the effect of isolationSemiconductor/solid-state device manufacturingIsolation effectIsolation layer

The invention discloses a production method of a deep groove isolation structure. After an epitaxial layer is grown, the method produces the deep groove isolation structure in the following steps: 1) growing silicon dioxide and silicon nitride in a furnace tube, and depositing silicon dioxide on silicon nitride; 2) performing exposure and development, and opening an area where a deep groove is to be etched in a dry etching mode; 3) utilizing silicon dioxide-silicon nitride-silicon dioxide formed by the step 1) to serve as an etching blocking layer, and forming the deep groove in the dry etching mode; 4) performing furnace pipe oxidation again, growing silicon dioxide, and fully oxidizing silicon below silicon nitride of a deep groove isolation area; 5) depositing silicon dioxide and sealing an opening of the deep groove; and 6) carrying out planarization of the surface of the deep groove. The method forms an ultra-thick field oxidation isolation layer by means of a deep groove etching and oxidation technology, and utilizes silicon nitride to serve as the blocking layer of planarization, thereby not only achieving isolation effect, but also greatly improving evenness in the surface and reducing difficulty of rear-end process.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

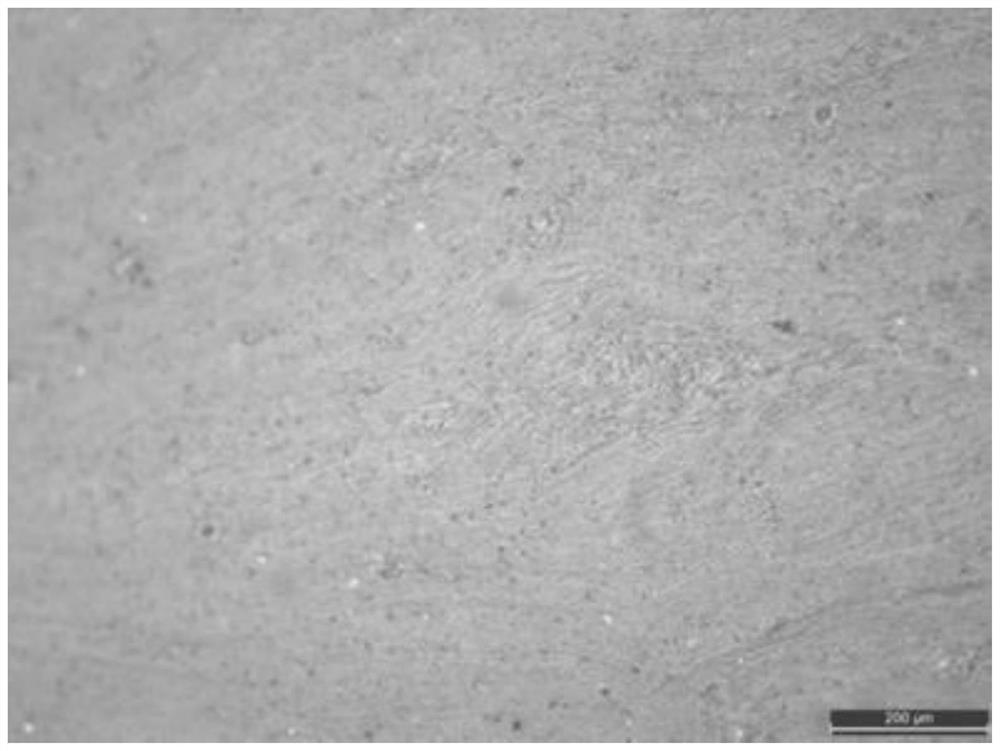

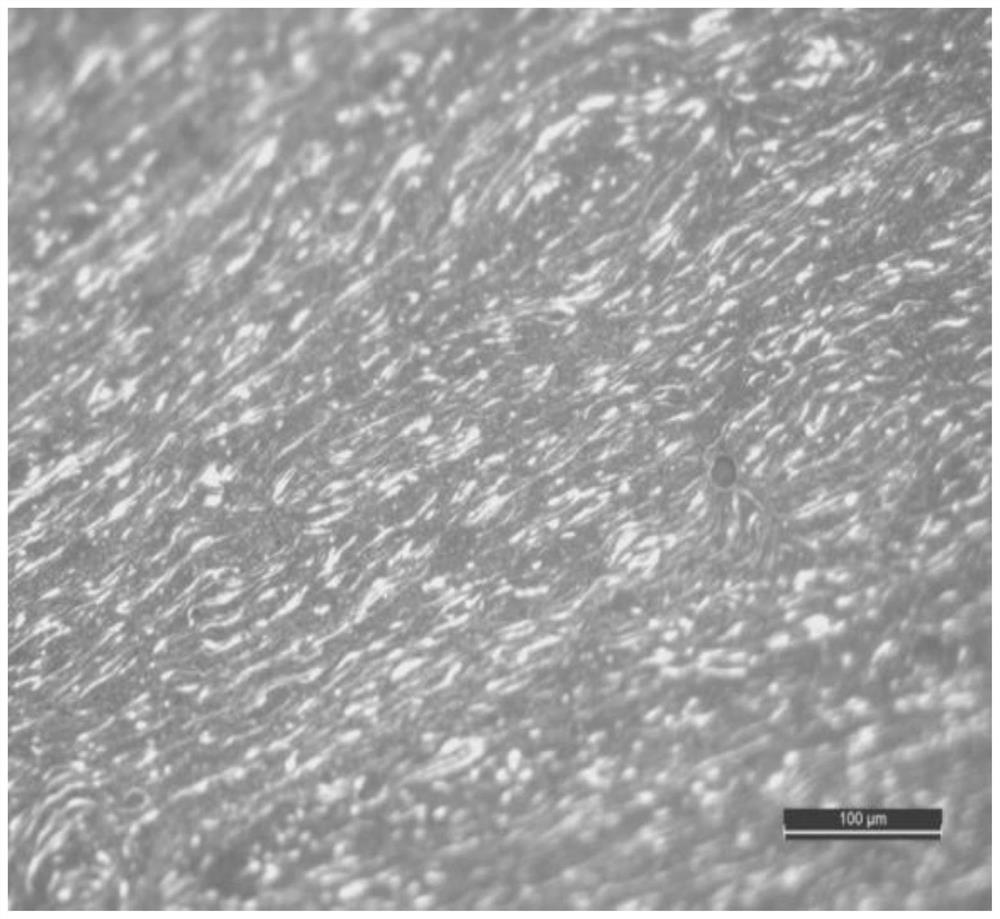

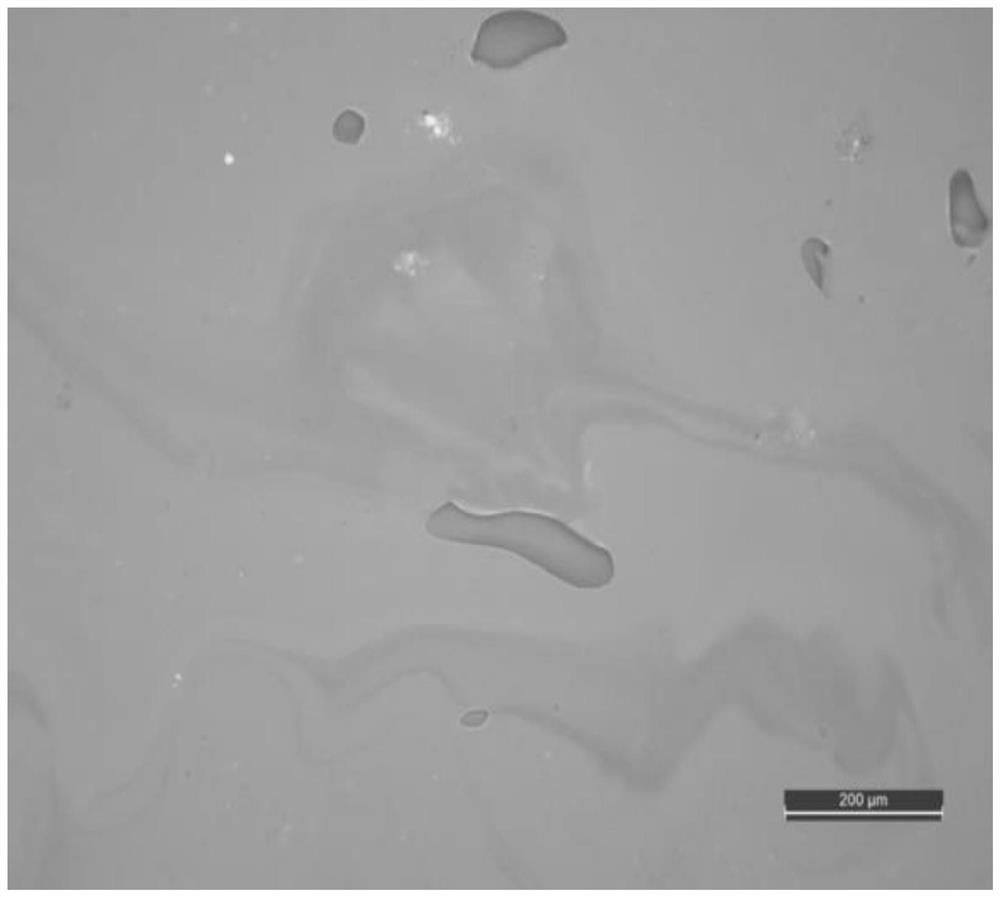

High-performance decrosslinked rubber asphalt and preparation method thereof

ActiveCN114058097AImprove solubilityPrevent popupPlastic recyclingBuilding insulationsPolymer sciencePolyolefin

The invention provides high-performance decrosslinked rubber asphalt and a preparation method thereof, when the rubber powder is deeply decrosslinked, a polyolefin modifier and an SBS modifier (styrene-butadiene block polymer) are doped as separants of decrosslinked rubber, so that the viscosity of the decrosslinked rubber can be reduced, the cohesion of the decrosslinked rubber is prevented, the polyolefin modifier is rapidly melted at high temperature, the rubber particles are rapidly opened, and thus the dispersity of the rubber particles can be remarkably enhanced. Meanwhile, the polyolefin and the SBS modifier can obviously improve the performance of the asphalt. The decrosslinked rubber is deeply degraded, so that the cohesive force of the rubber asphalt is improved, the Brookfield viscosity of the rubber asphalt is reduced, the construction performance is improved, and a relatively high rubber mixing amount is achieved.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

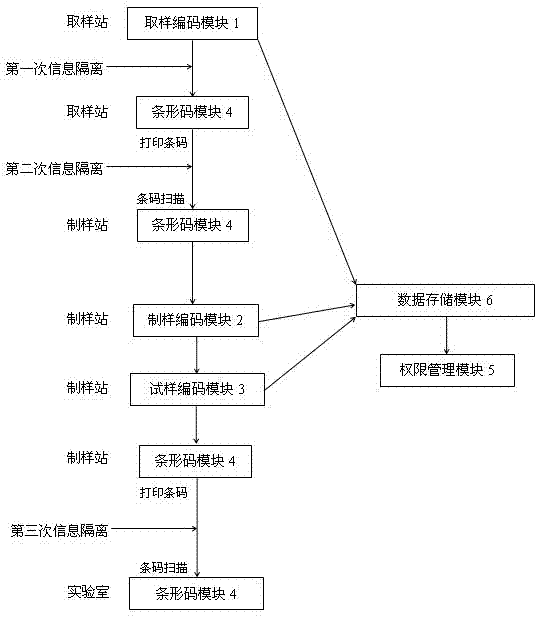

System and method for coded message circulation and isolation of sampling, sample preparation and sample test of raw materials

InactiveCN102930228ACan't colludeTo achieve the effect of isolationDigital data protectionRecord carriers used with machinesCode moduleBarcode

The invention discloses a system and a method for coded message circulation and isolation of sampling, sample preparation and sample test of raw materials, and relates to a sensitive data flow information isolating method for a large amount of raw materials for a quality system of an iron and steel enterprise. The system is composed of a sampling encoding module, a sample preparation encoding module, a sample test encoding module, a bar code module, an authority control module and a data storage module, wherein the data obtained by the sampling encoding module, the sample preparation encoding module, the sample test encoding module and the bar code module are stored by the data storage module and subjected to authority control management through the authority control module; and the data stored in the data storage module are circulated among the sampling encoding module, the sample preparation encoding module, the sample test encoding module and the bar code module through internet along with sample circulation. The system and the method have the advantages that suppliers are isolated from in-plant quality flow, the encoding is isolated from actual operation staff, therefore operation chains above and below cannot be linked, two-dimensional bar codes are used for circulation outside the system, encoding content cannot be seen, and information isolation effects are achieved.

Owner:WUKUN STEEL

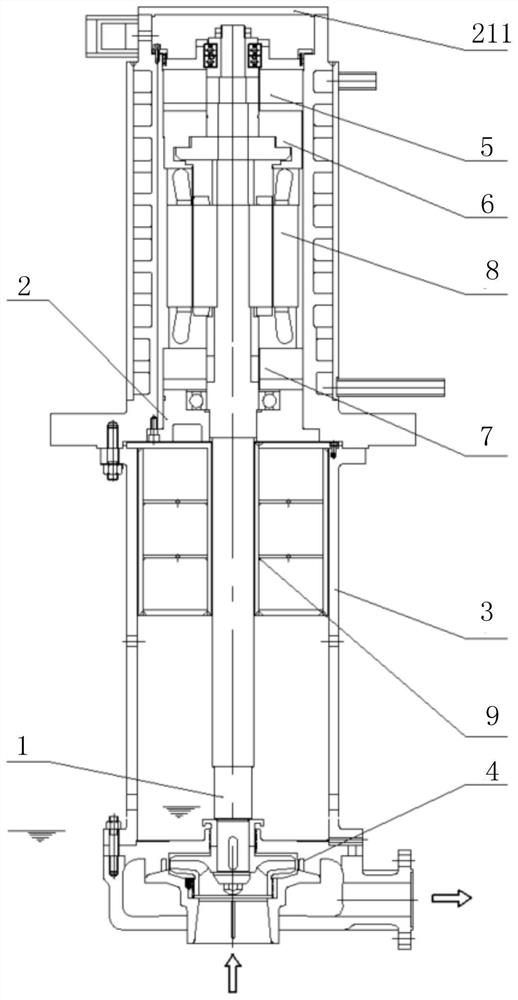

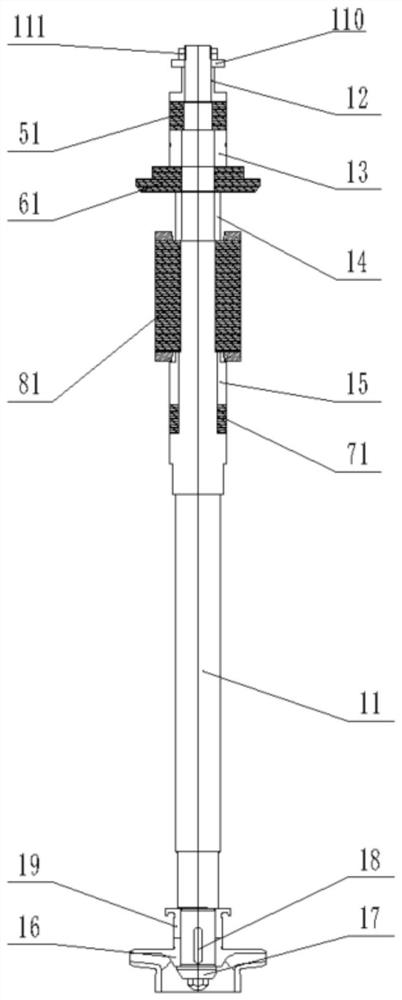

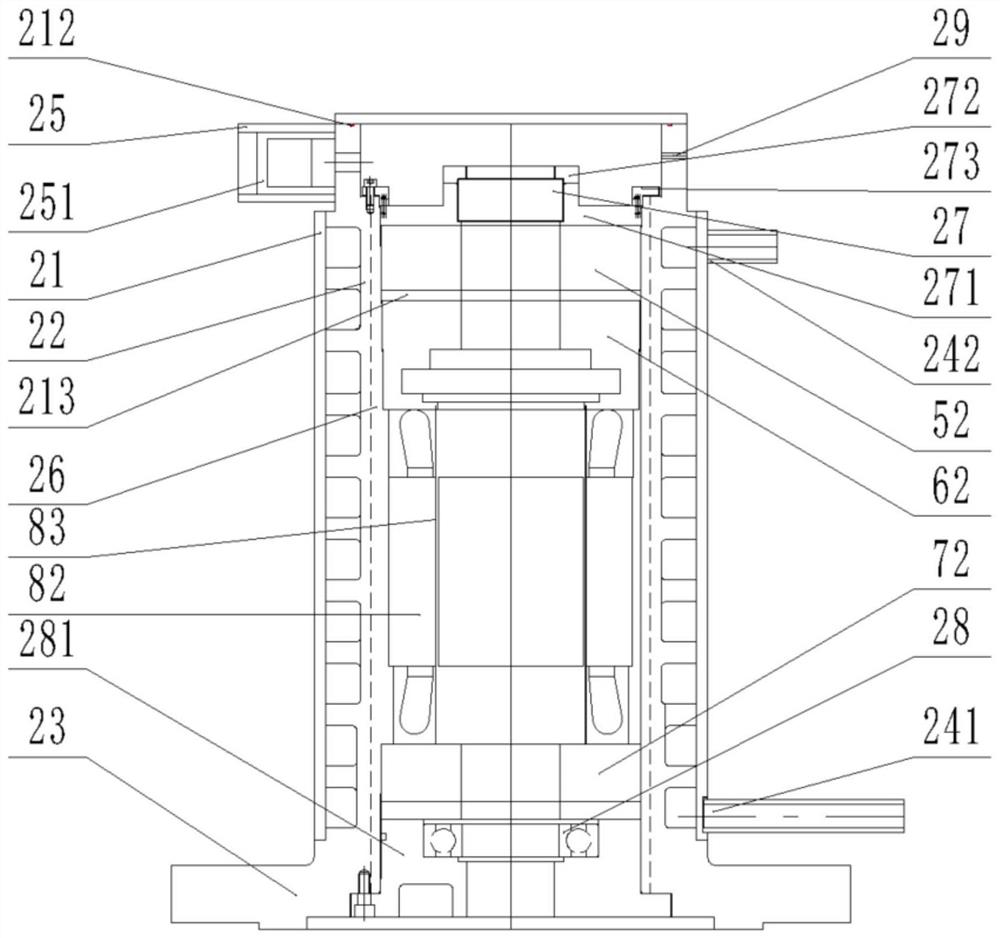

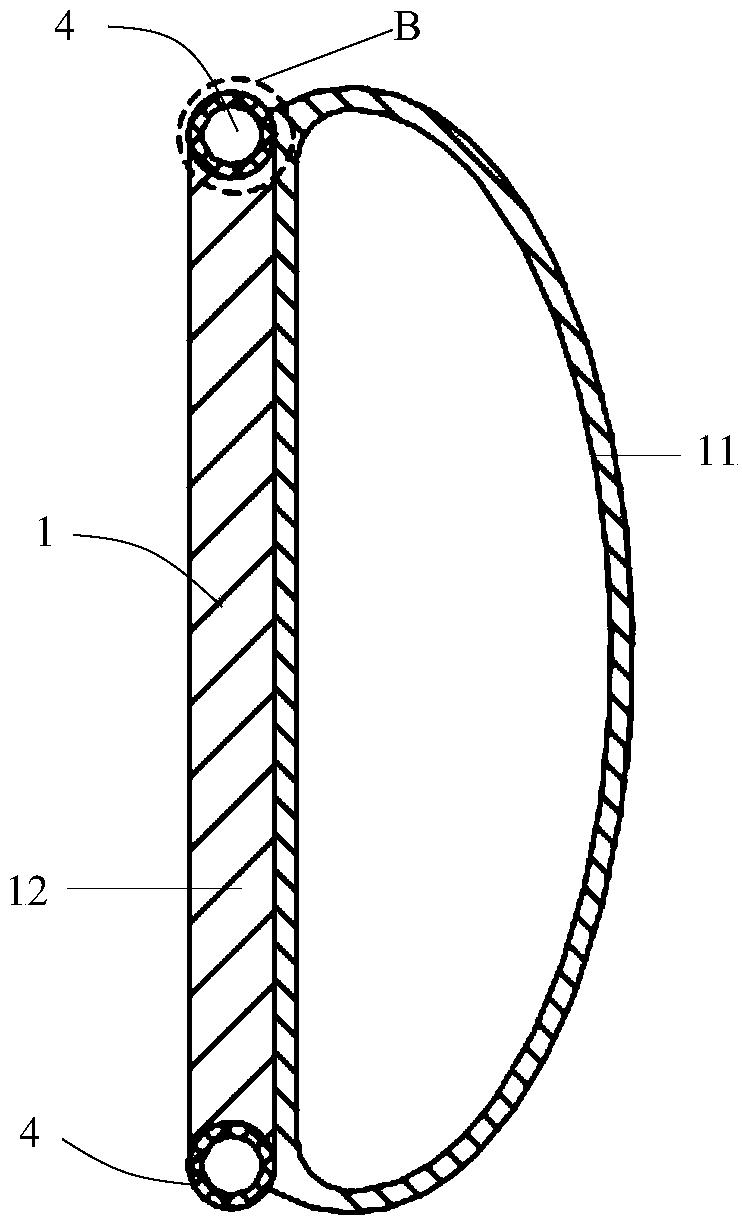

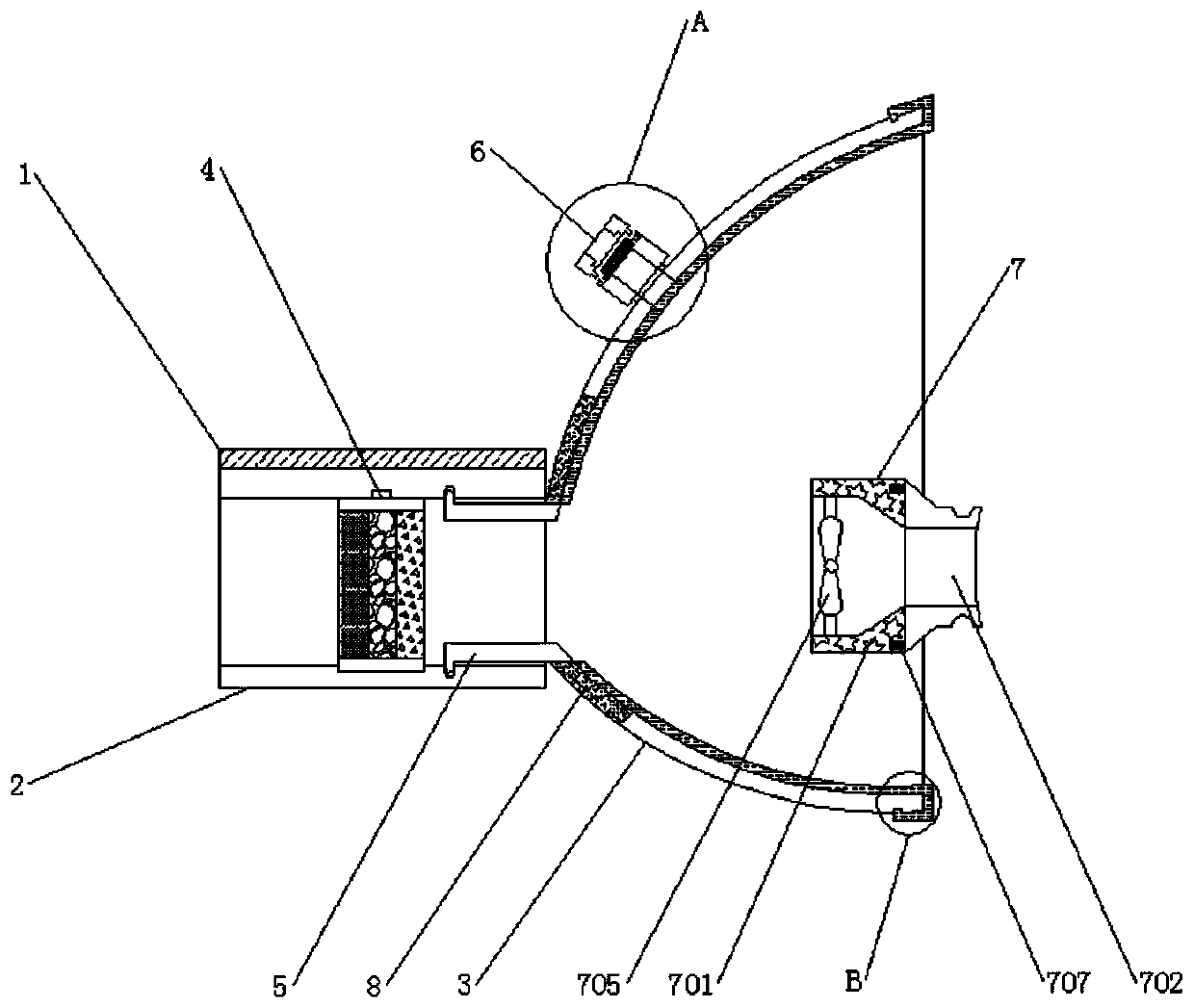

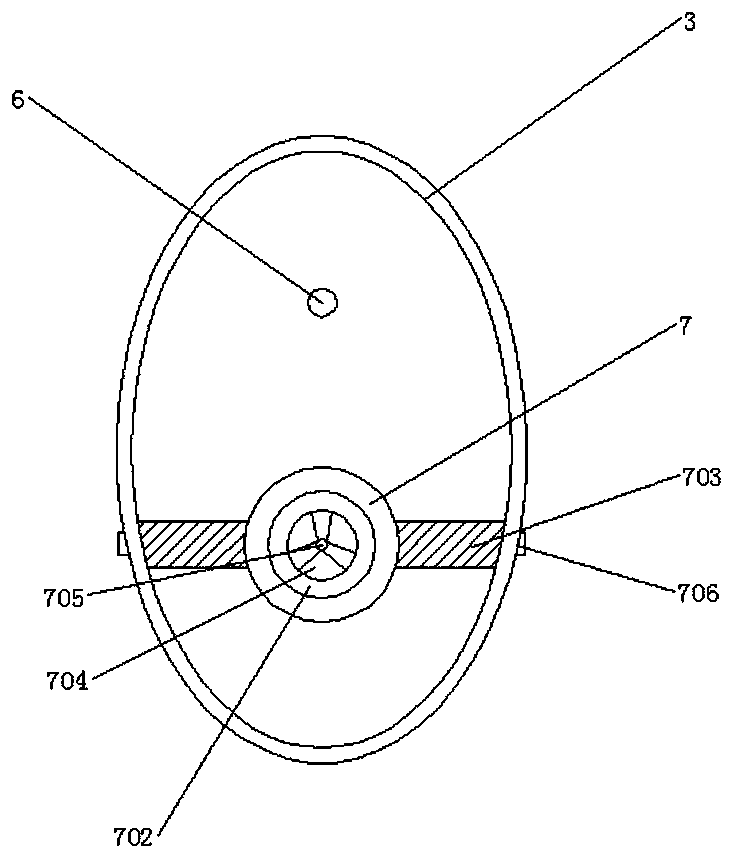

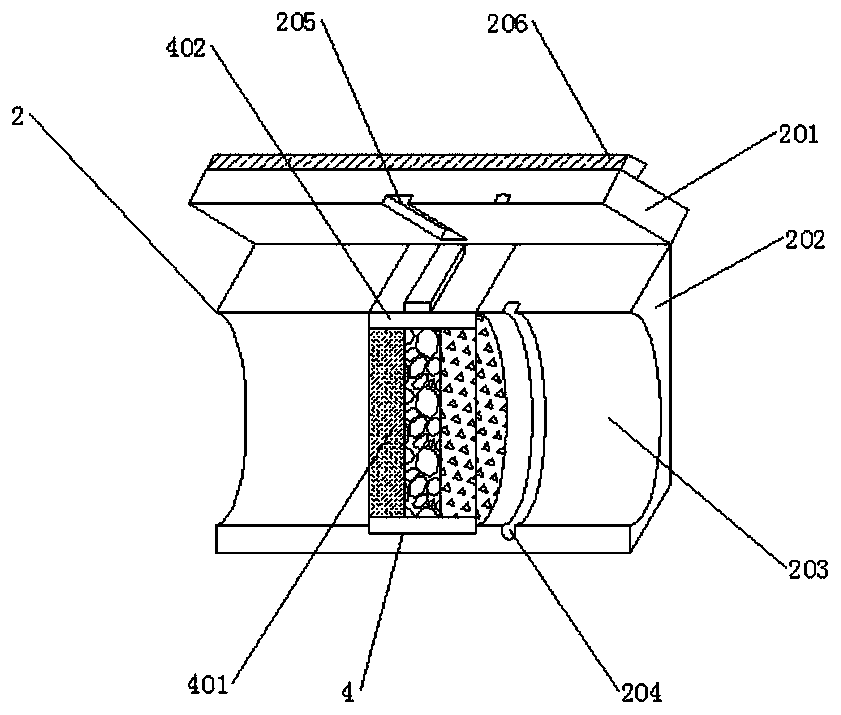

High-temperature shielded molten salt pump supported by magnetic levitation bearings

PendingCN113202780AEasy to disassembleCompact structureSpecific fluid pumpsPump componentsMolten saltElectric machinery

The invention relates to a high-temperature shielded molten salt pump supported by magnetic levitation bearings. The high-temperature shielded molten salt pump comprises a rotating assembly with a main shaft, a bearing cylinder, a connecting cylinder, an annular pump body, a first cover plate, a magnetic levitation bearing set, a shielding motor and a shielding plug, wherein the bearing cylinder, the connecting cylinder and the annular pump body are sequentially arranged from top to bottom; the main shaft penetrates through the connecting cylinder and extends into the bearing cylinder and the annular pump body; the first cover plate is hermetically connected to the top of the bearing cylinder; the magnetic levitation bearing set is arranged in the bearing cylinder and comprises an upper radial magnetic levitation bearing, an axial thrust magnetic levitation bearing and a lower radial magnetic levitation bearing; the shielding motor is arranged between the axial thrust magnetic levitation bearing and the lower radial magnetic levitation bearing; and the shielding plug is arranged in the connecting cylinder. The molten salt pump is compact in overall structure and stable in operation, meanwhile, the effect of complete isolation of internal and external atmosphere environments can be achieved, and the molten salt pump is convenient and efficient to maintain.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI +1

Convenient-to-disinfect article delivery window for isolation room

InactiveCN111544632ATo achieve the effect of isolationAvoid infectionLavatory sanitoryCleaning using toolsLocking mechanismEngineering

The invention relates to a delivery window, in particular to a convenient-to-disinfect article delivery window for an isolation room. The invention aims to design the article delivery window convenient to disinfect for the isolation room, which can disinfect the interior of the delivery window and prevent viruses from remaining in the delivery window. An article delivery window convenient to disinfect and used for an isolation room comprises a delivery window body, mounting frames are connected to the two sides outside the delivery window body, and a mounting plate is connected between the lower portions of the mounting frames on the two sides. The isolation mechanism is arranged on the mounting frame; and the locking mechanism is arranged between the mounting plate and the isolation mechanism. Through cooperation of the isolation mechanism and the locking mechanism, when the delivery window outside the isolation room is opened, the delivery window inside the isolation room cannot be opened, and when the delivery window inside the isolation room is opened, the delivery window outside the isolation room cannot be opened, so that the effect of isolating the two sides of the deliverywindow is achieved.

Owner:刘贤贤

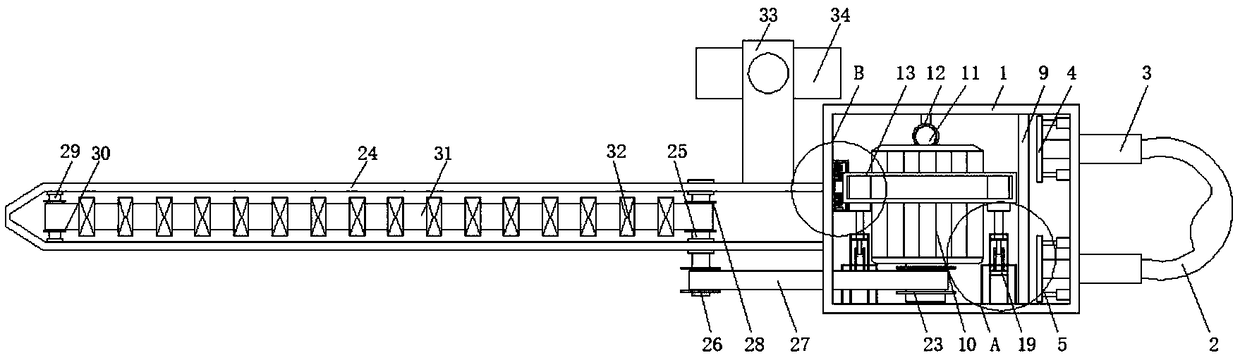

Hand-held branch pruning machine for garden maintenance

InactiveCN109041872ATo achieve the effect of isolationEasy to holdCuttersMotor driven pruning sawsArchitectural engineeringHand held

The invention relates to the technical field of garden maintenance equipment, and discloses a hand-held branch pruning machine for garden maintenance. The pruning machine comprises an installing box I, a handle fixedly sleeves one side of an inner cavity of the installing box I, and one side of the handle extends to the outer portion of one side of the installing box I; the outer wall of the handle is fixedly sleeved with a sleeve pipe located on one side of the installing box I, one end of the handle is fixedly connected with an installing plate located in the installing box I, and the top ofone side of the installing plate is fixedly connected with one end of a telescopic upper rod. According to the hand-held branch pruning machine for garden maintenance, by arranging the installing boxI, the handle, the sleeve pipe, the installing plate, the telescopic upper rod, a fixed box, a movable plate, a spring I and a partition plate, noises generated in the working process of a motor canbe isolated, by arranging the sleeve pipe, a user can conveniently hold the pruning machine by hand, and the user can be protected to avoid that the noises make the ears of the user uncomfortable.

Owner:杭州真树园林设计工程有限公司

Mixer with uniform mixing

InactiveCN108582479AStir wellIncrease the stirring structureCement mixing apparatusFixed frameEngineering

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

Memory allocation method, device and system for virtual machine

PendingCN113377490ATo achieve the effect of isolationTroubleshooting Technical Issues Encroaching on Virtual Machine ContentSoftware simulation/interpretation/emulationOut of memoryTerm memory

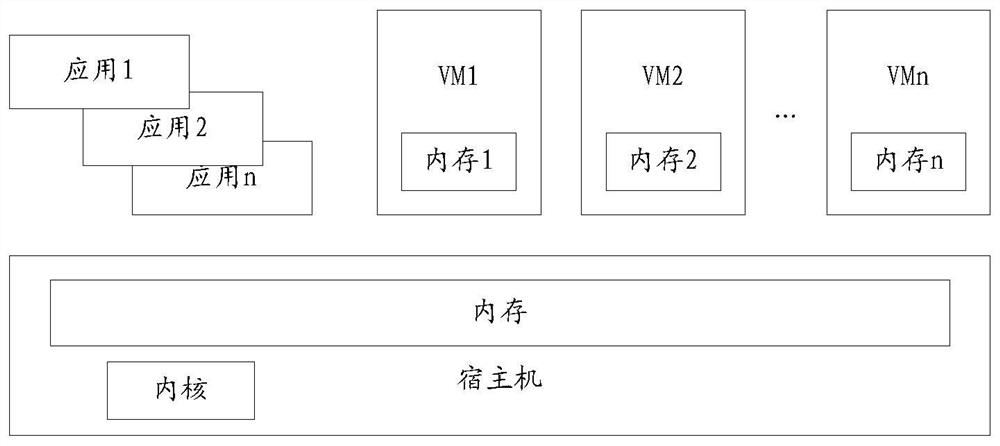

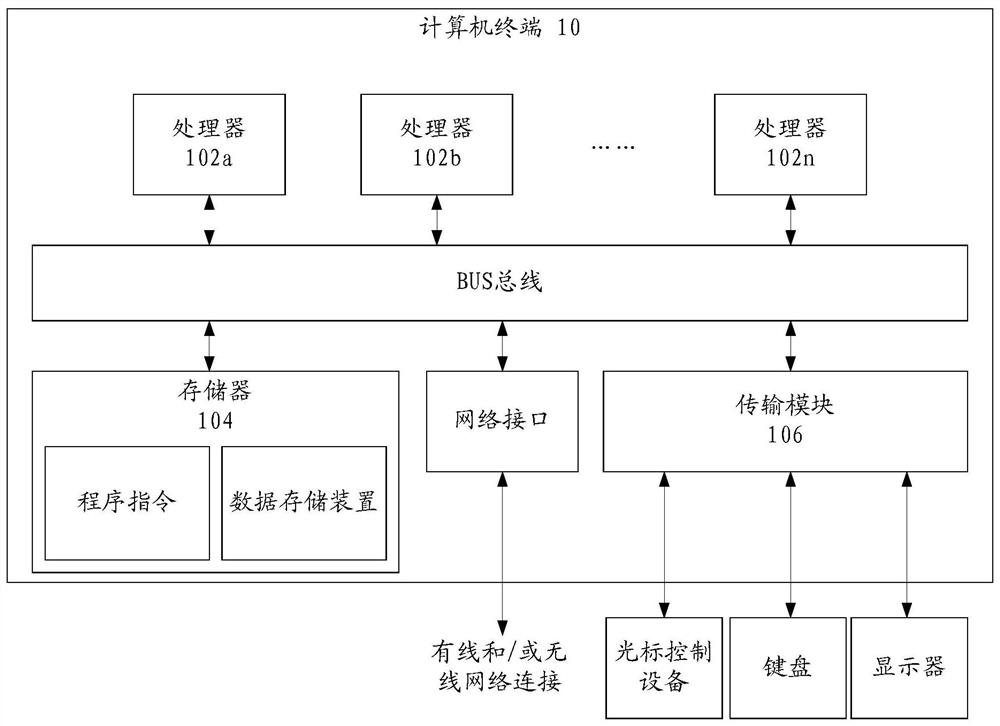

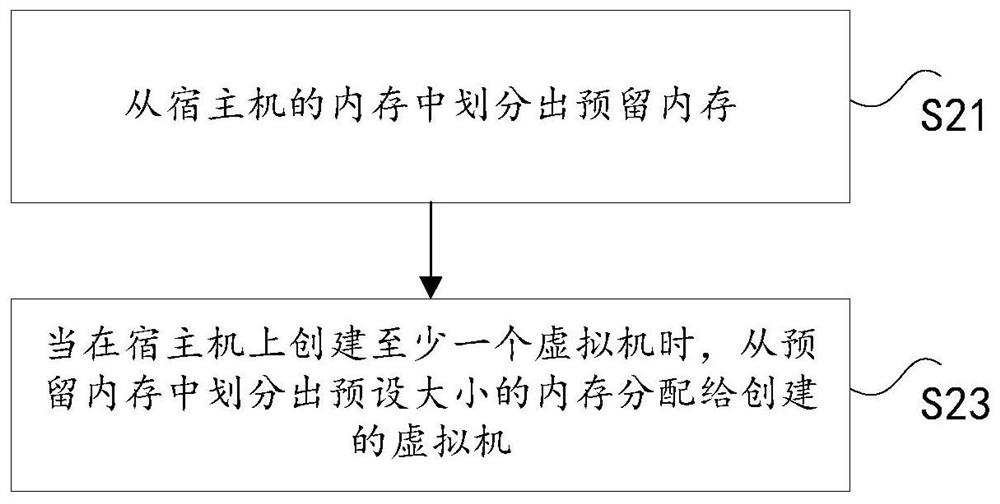

The invention discloses a memory allocation method, device and system for a virtual machine. The method comprises the steps of dividing a reserved memory from a memory of a host machine, allowing a first process running on a virtual machine of the host machine to use the reserved memory, and allowing a second process running on the host machine to use other memories except the reserved memory; and when at least one virtual machine is created on the host machine, dividing a memory with a preset size from the reserved memory, and allocating the memory to the created virtual machine. The technical problem that the content of the virtual machine is occupied under the condition that the memory is insufficient is solved.

Owner:ALIBABA GRP HLDG LTD

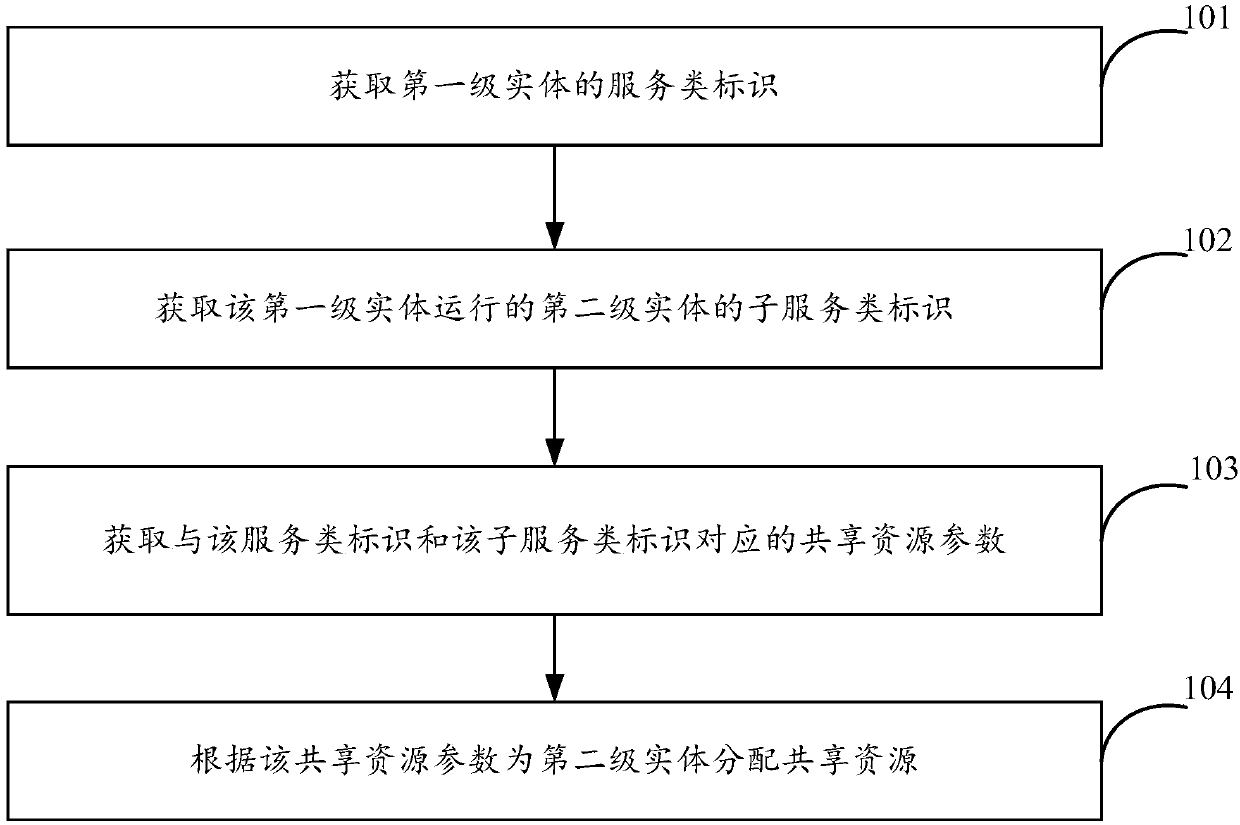

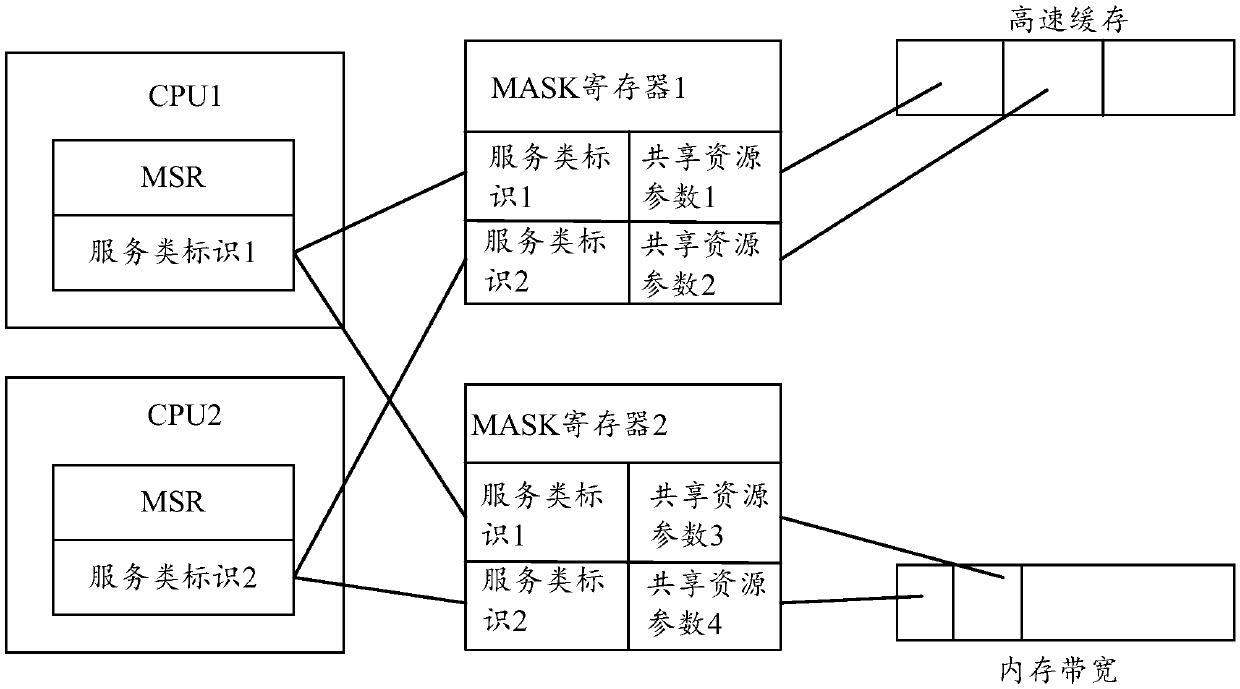

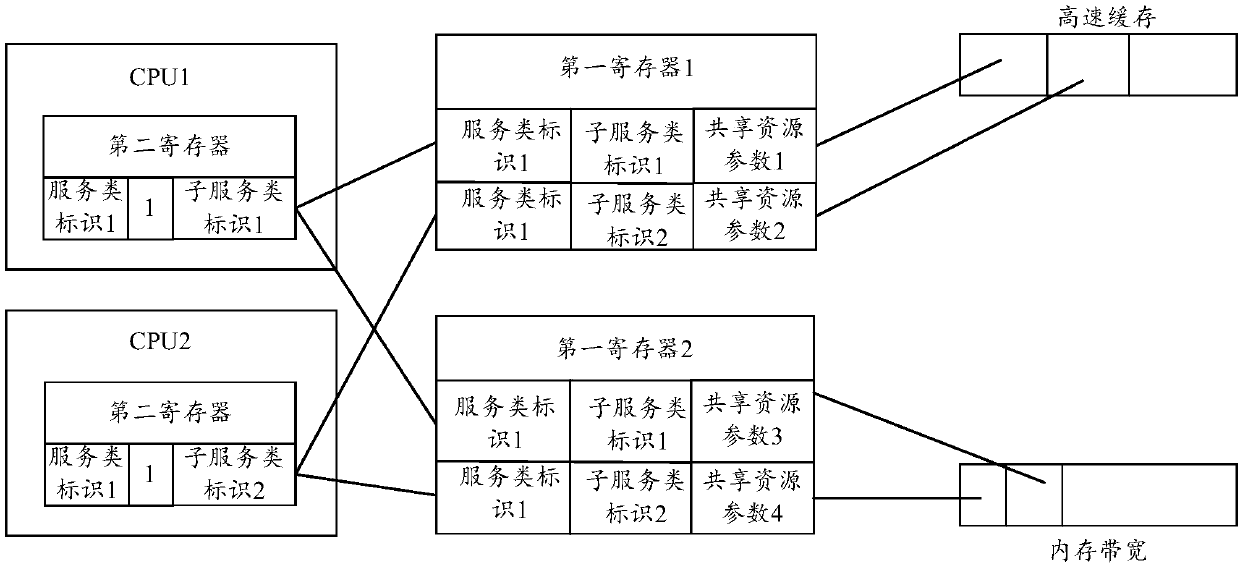

Shared resource allocation method, device and equipment

ActiveCN110879748AAvoid mutual influenceIncrease profitResource allocationInterprogram communicationResource assignmentResource isolation

The invention provides a shared resource allocation method, a device and equipment. The method comprises the steps of obtaining a service class identifier of a first-level entity; obtaining a sub-service class identifier of a second-level entity operated by the first-level entity; obtaining shared resource parameters corresponding to the service class identifiers and the sub-service class identifiers; and allocating shared resources to the second-level entity according to the shared resource parameters. Through the method of the invention, the effect of shared resource isolation can be achieved, the mutual influence of a plurality of second-level entities is avoided, and the resource utilization rate is improved.

Owner:ALIBABA GRP HLDG LTD

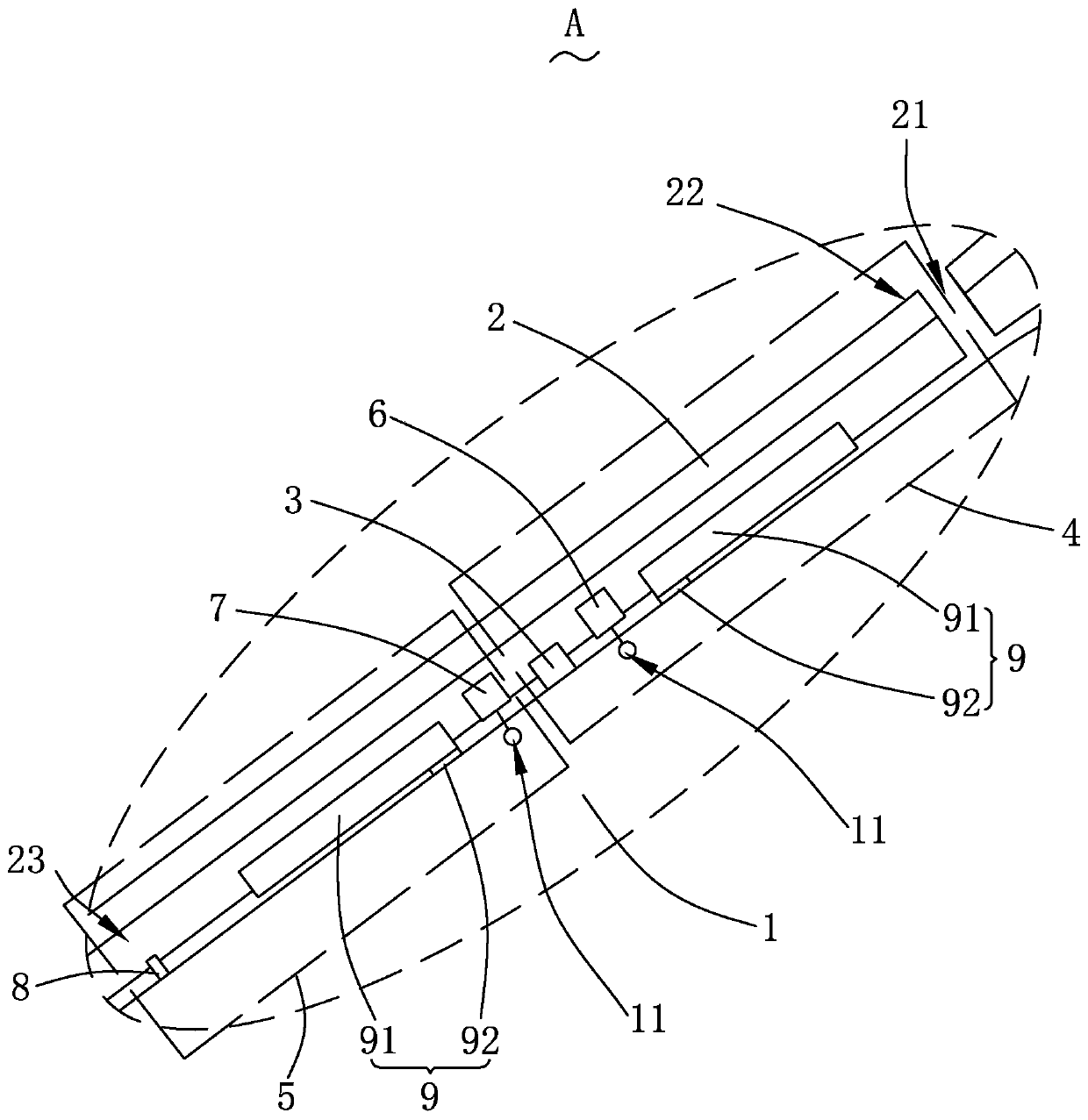

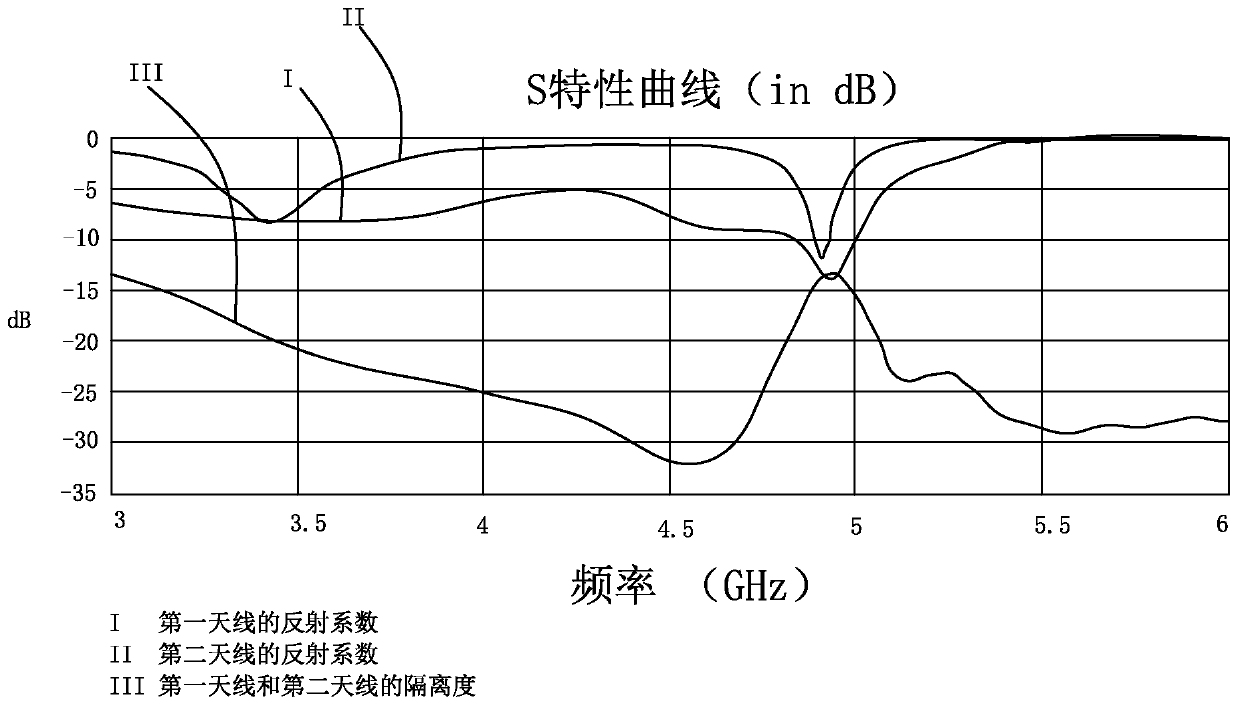

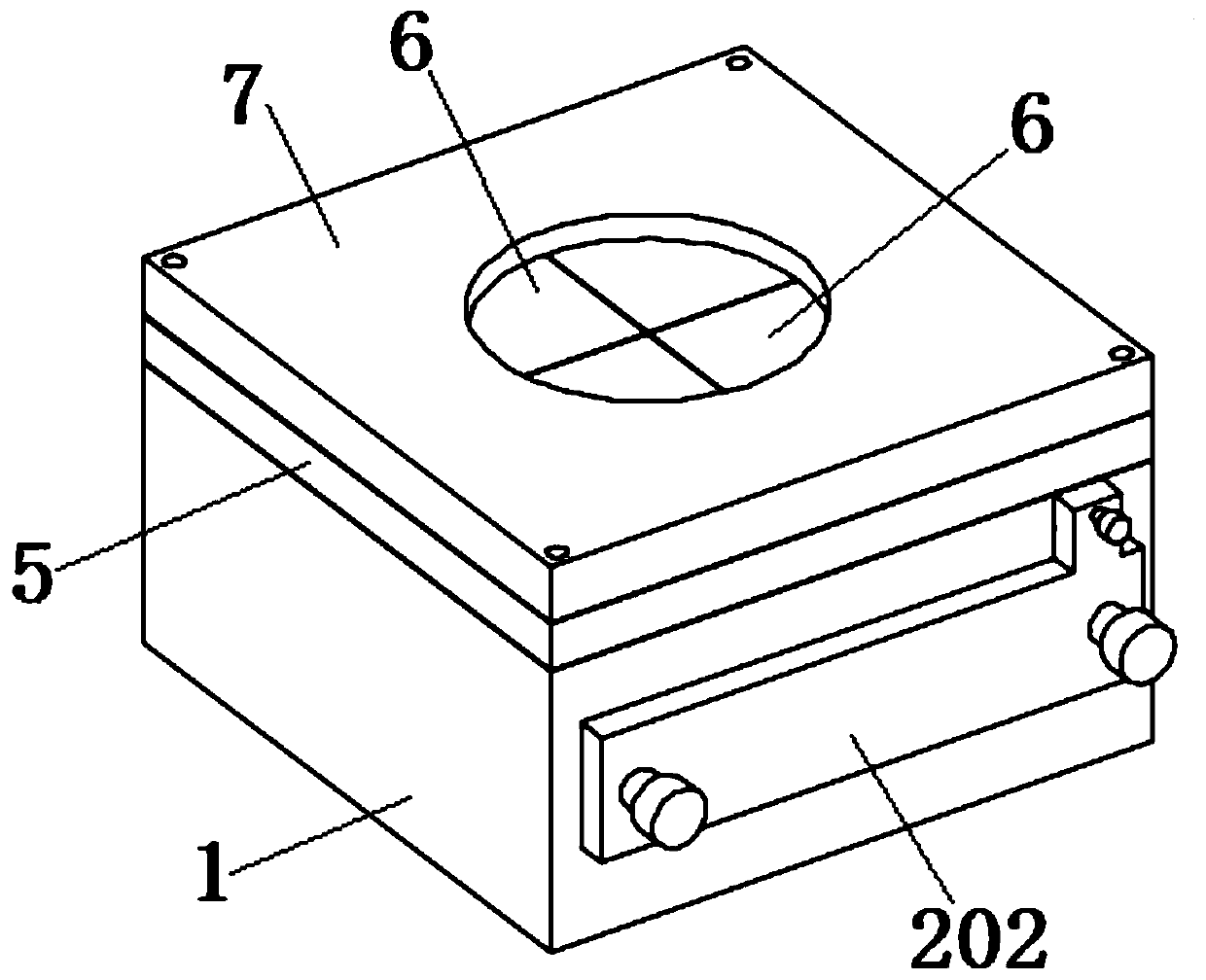

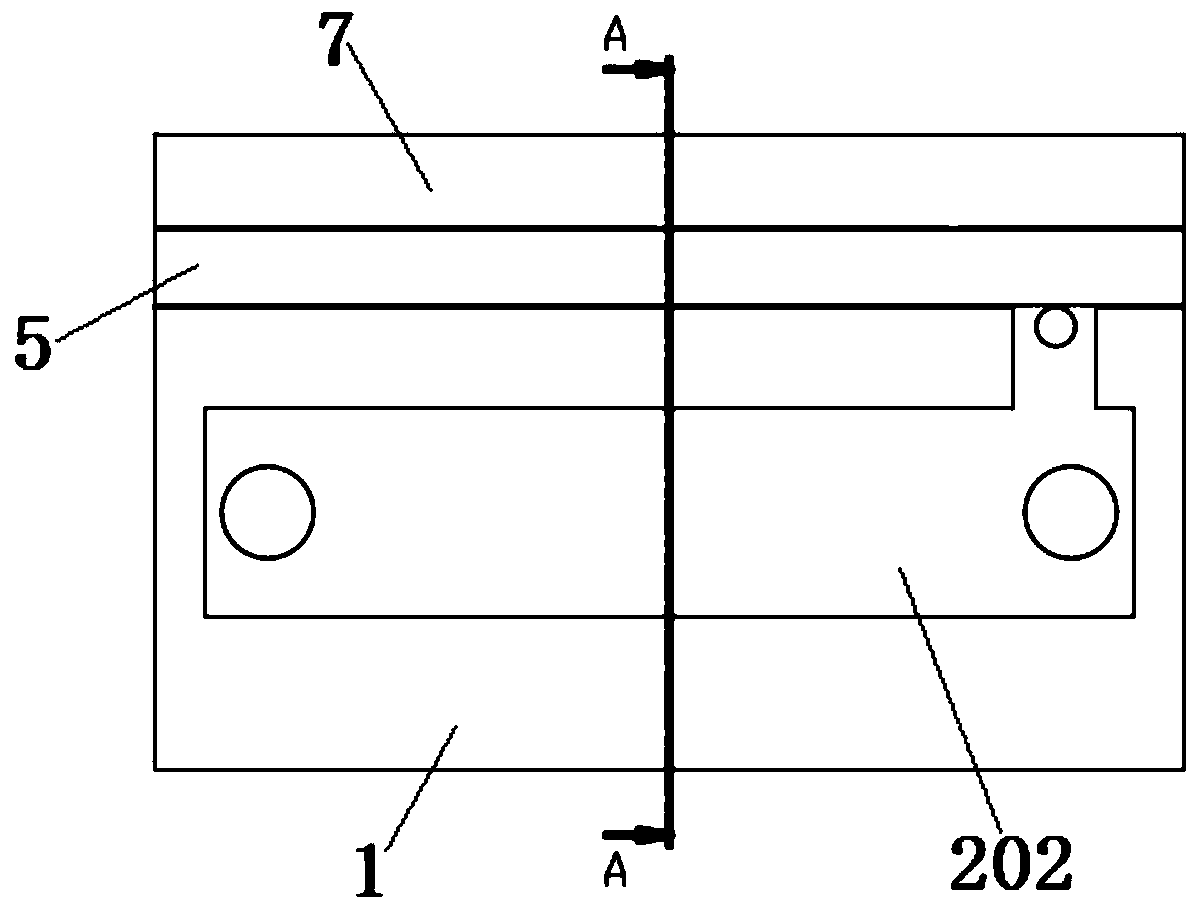

MIMO antenna system

InactiveCN109742513ATo achieve the effect of isolationImprove reliabilityAntenna arraysSimultaneous aerial operationsElectricityMimo antenna

The invention provides an antenna system, comprising a system ground unit having a feed point, a metal frame disposed adjacent to the system ground unit, a grounding line extending from the metal frame to the system ground unit and forming a grounding connection, and a first antenna and a second antenna at least having the metal frame as a partial radiator, wherein the metal frame is spaced apartfrom the system ground unit to form a clearance area; the first antenna and the second antenna are electrically connected to the feed point of the system ground unit respectively, and are respectivelydisposed at both sides of the grounding line in a spaced manner and radiate orthogonal modes. Compared with the related art, the antenna system of the invention has a wide frequency band, a good overall aesthetic appearance and high strength.

Owner:AAC TECH NANJING

Focusing lens protecting device for laser cutting machine

InactiveCN110328457ARealize opening and closingTo achieve the effect of isolationLaser beam welding apparatusLaser cuttingLens plate

The invention discloses a focusing lens protecting device for a laser cutting machine and relates to the technical field of laser cutting machines. The focusing lens protecting device comprises a mounting base, wherein the mounting base is provided with a lens protecting mechanism through a slot; the upper surface of the mounting base is in sliding fit with a rotating ring through an annular sliding chute; one side of the mounting base is provided with a T-shaped groove; the T-shaped groove is in sliding fit with a T-shaped strip; a laminate is fixedly connected to the upper surface of the mounting base; a plurality of sector plates are rotationally connected to the upper surface of the laminate; and a cover plate is fixedly connected to the upper surface of the laminate. According to thefocusing lens protecting device disclosed by the invention, a rack on the mounting base is utilized to drive a gear ring to rotate and realize opening and closing between the sector plates; the effectof isolating a focusing lens is achieved, the protecting effect of the focusing lens is improved, and service life of the focusing lens is effectively prolonged; and meanwhile, the position of the rack is controlled by using an adjusting screw on the lens protecting mechanism, and the operations of changing protective lenses and opening and closing the sector plates are synchronously finished, and thereby the use convenience of the protecting device is improved.

Owner:YANGZHOU JIANGFENG MACHINERY MFG

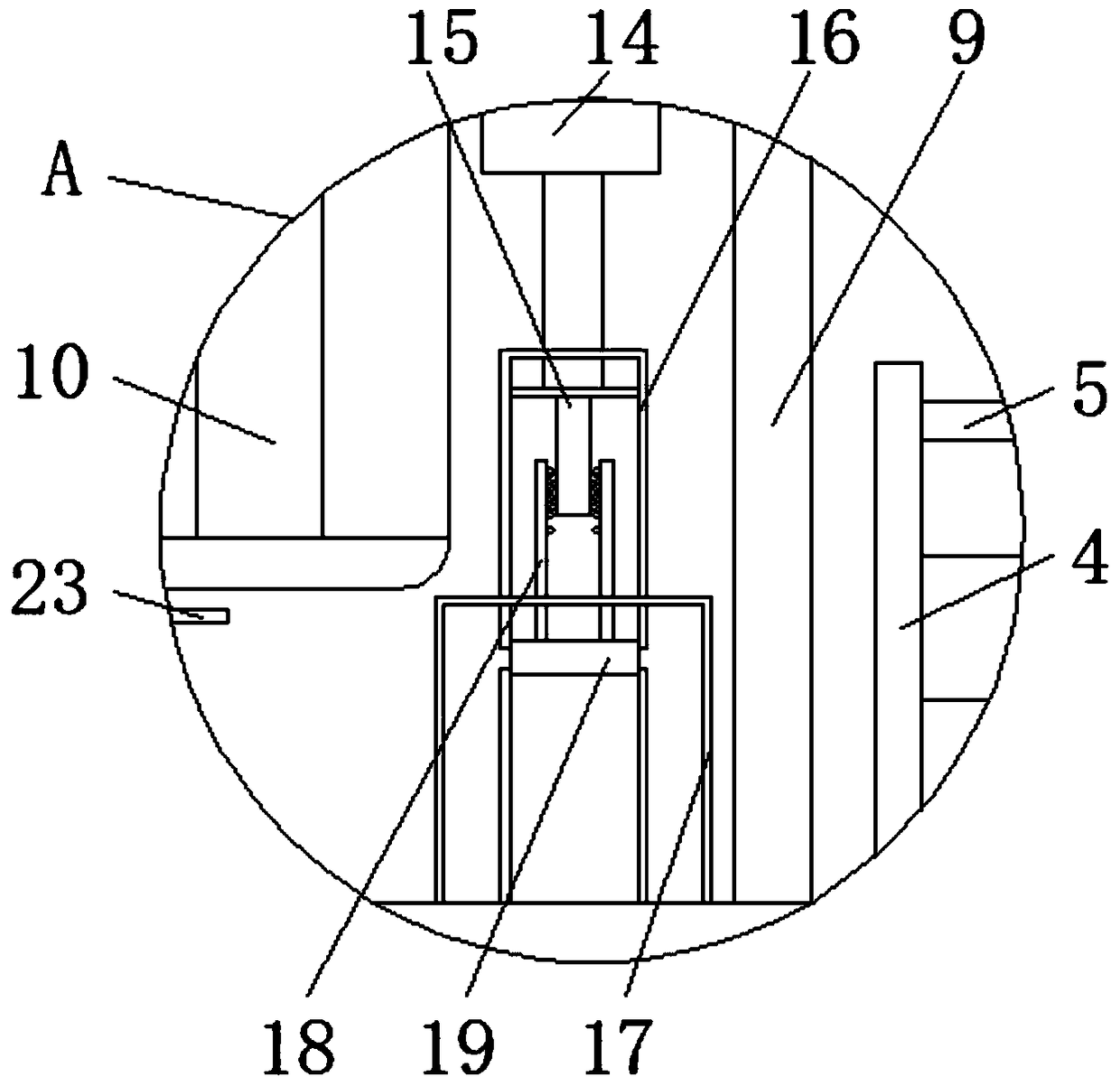

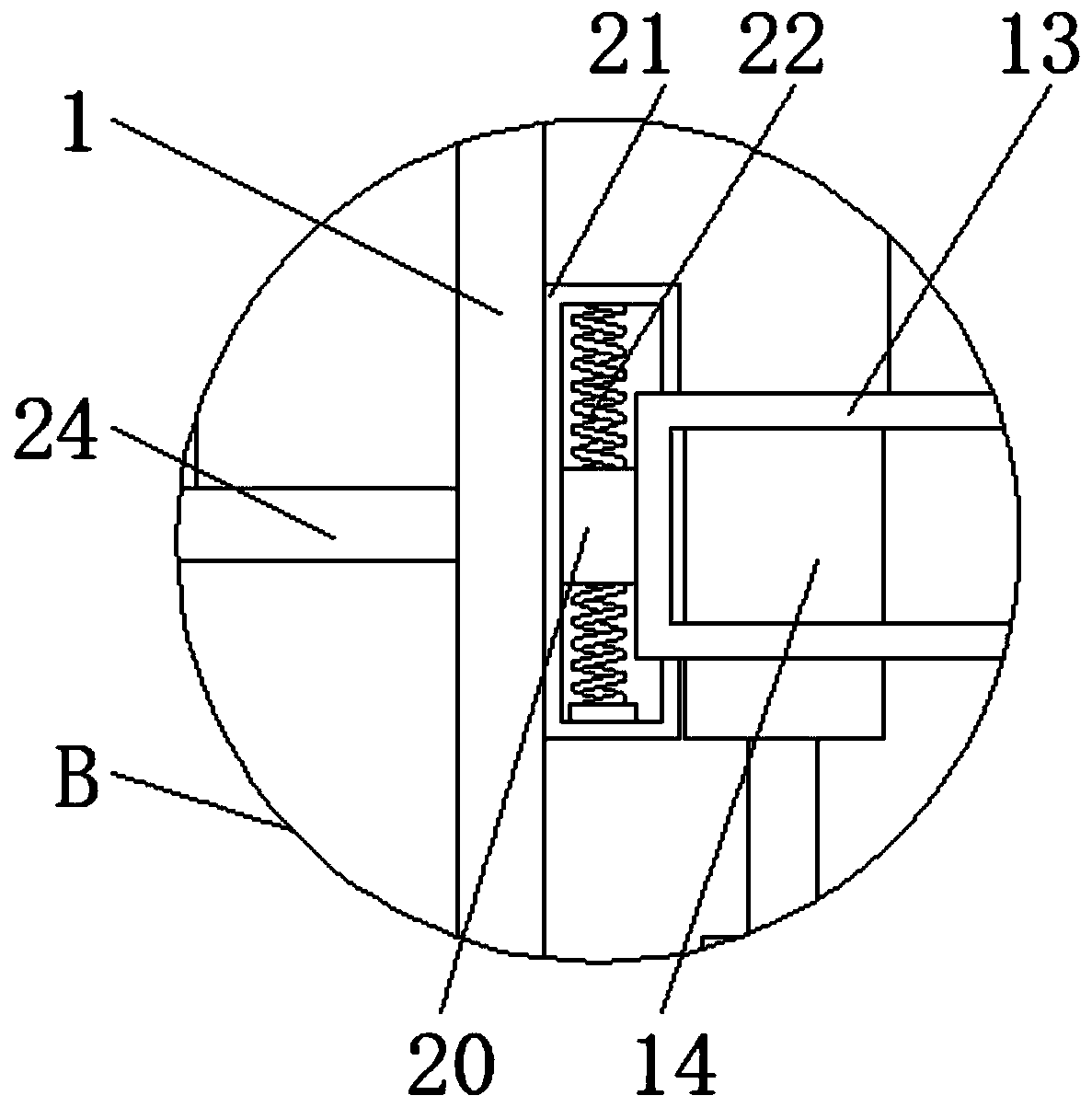

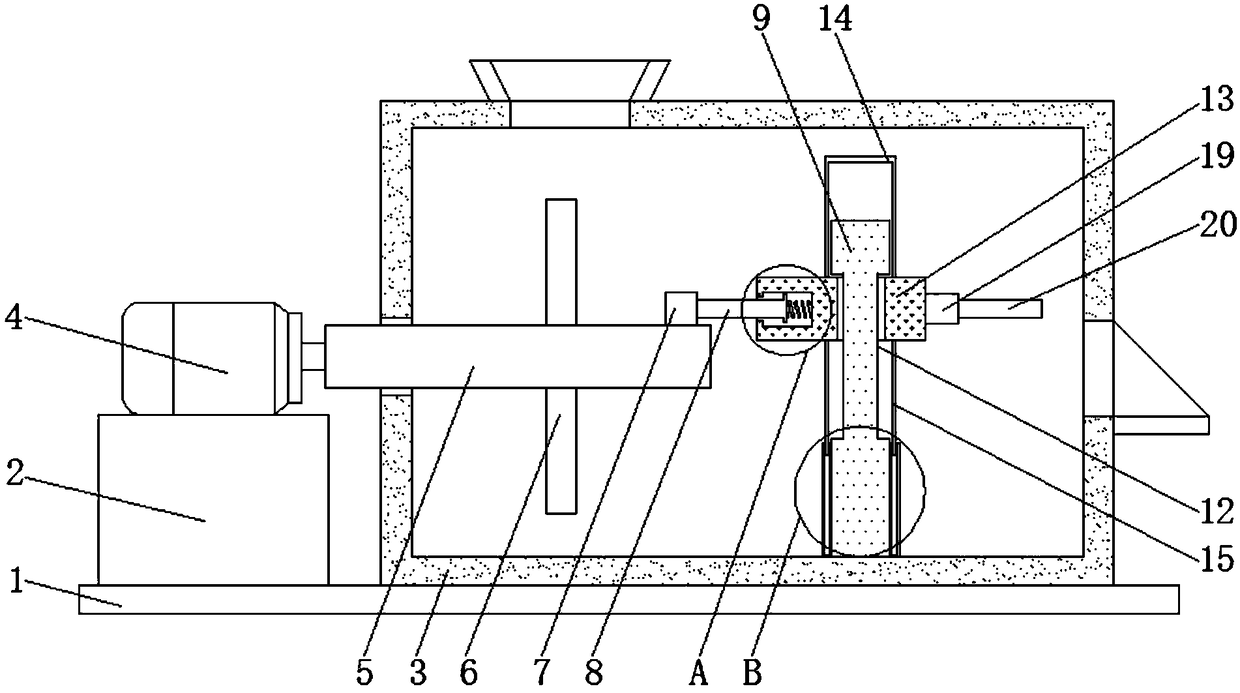

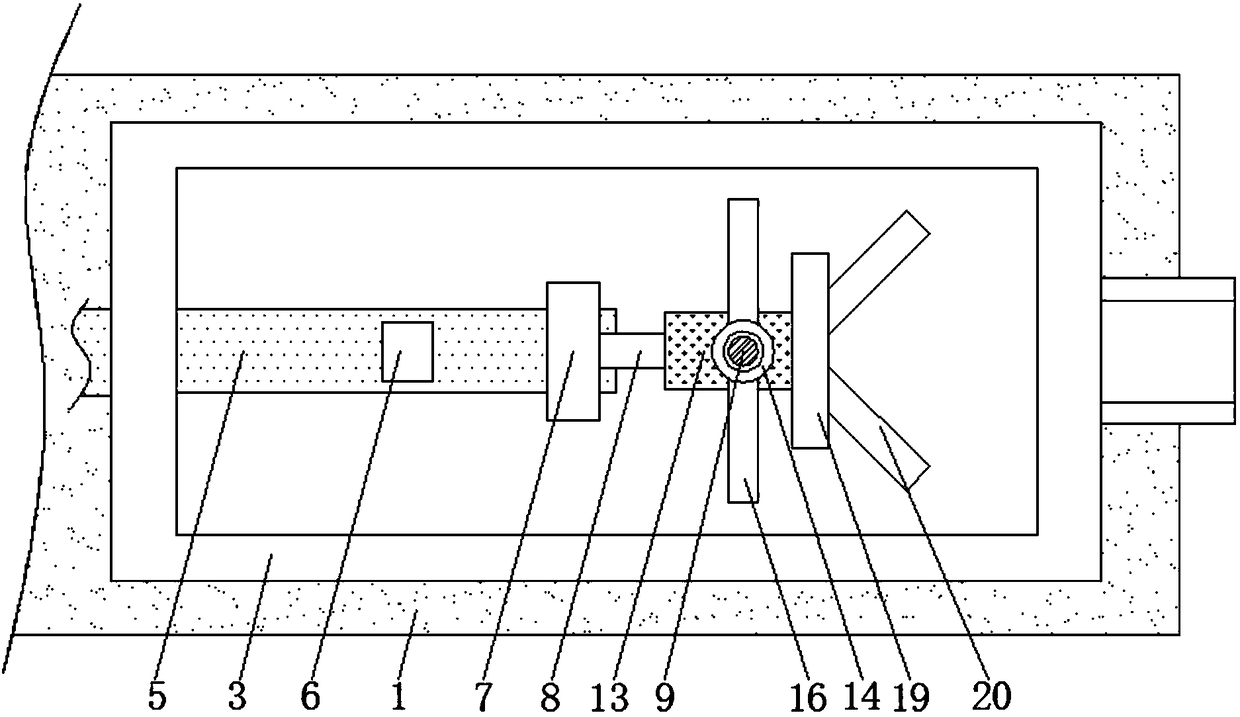

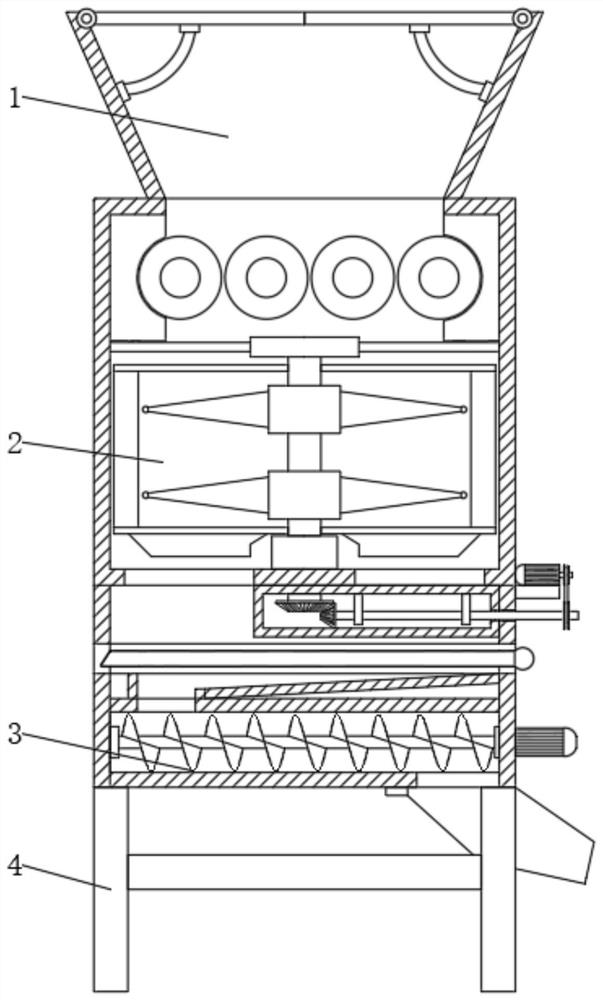

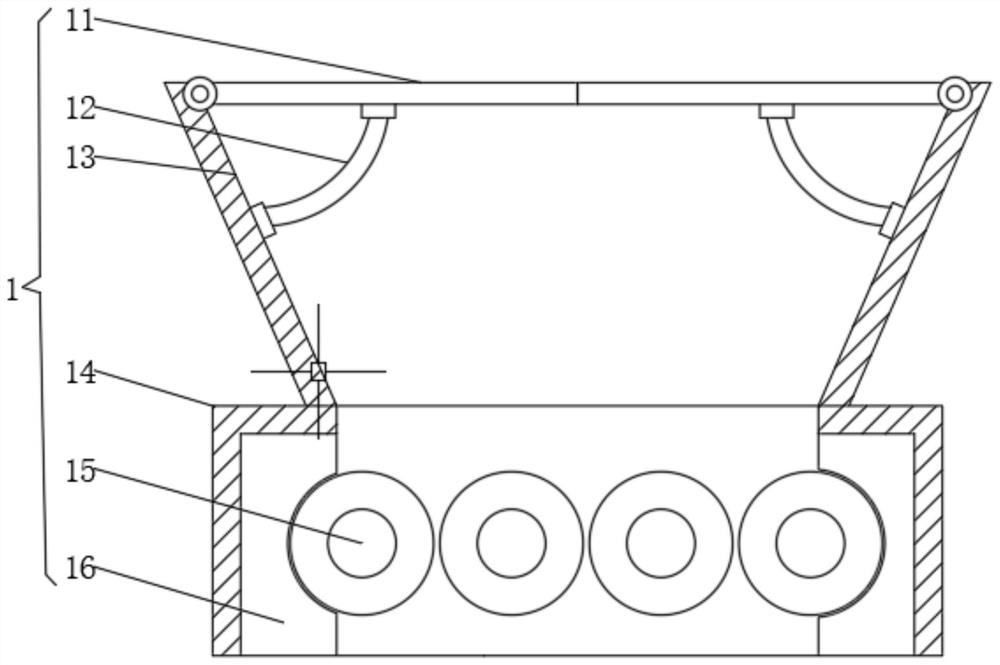

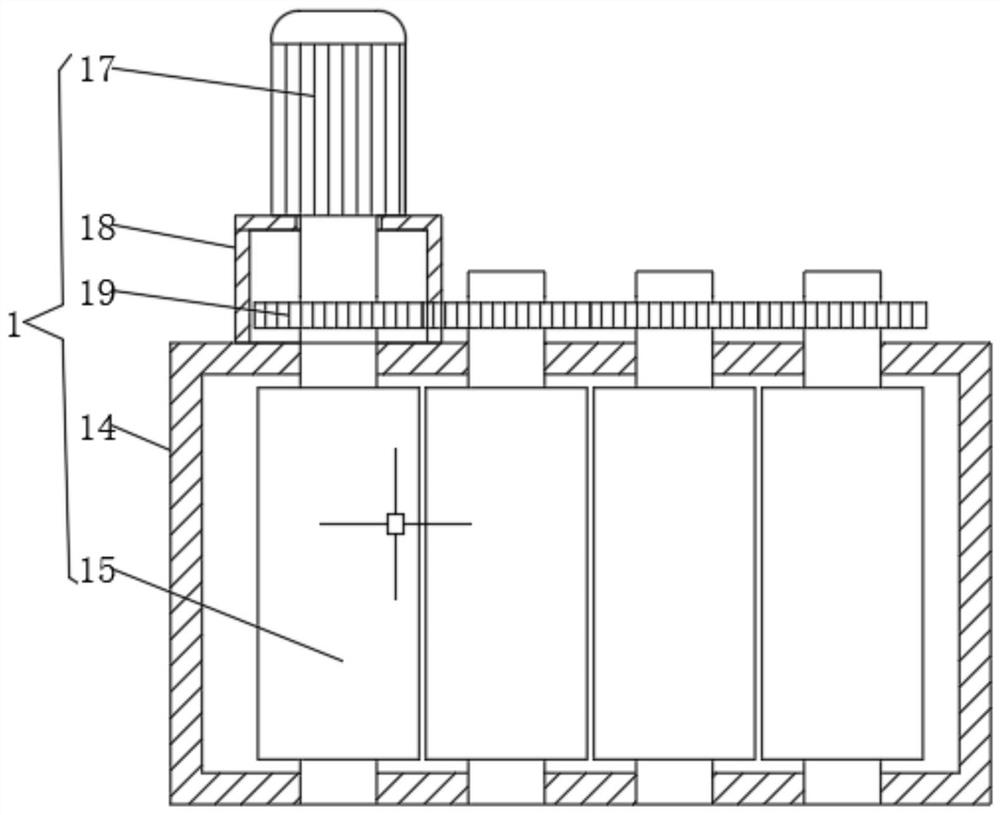

Flying-dust-free production and manufacturing equipment for PVC grinding powder

InactiveCN112549360ATo achieve the purpose of dust-free grindingTo achieve the effect of isolationElectric machineryEngineering

The invention discloses flying-dust-free production and manufacturing equipment for PVC grinding powder. The flying-dust-free production and manufacturing equipment comprises a grinding mechanism, a powder grinding mechanism, an output mechanism and a supporting frame. The top of the supporting frame is fixedly connected with the bottom of the output mechanism, the top of the output mechanism is fixedly connected with the bottom of the powder grinding mechanism, the top of the powder grinding mechanism is fixedly connected with the bottom of the grinding mechanism, the inner top of a feeding hopper is hinged to one side of a dust-free plate through a hinge, and the bottom of the dust-free plate is fixedly connected with the top of a spring strip. According to the flying-dust-free production and manufacturing equipment for the PVC grinding powder, by arranging the grinding mechanism, PVC materials enter a grinding shell through the feeding hopper, a first motor is started, four grindingrollers rotate under cooperation of gears to flatten and grind PVC passing through the four grinding rollers, and the purpose of dust-free powder grinding can be effectively achieved; and meanwhile,the dust-free plate can enable the feeding port of the feeding hopper to directly fall off when feeding is needed and return to the original position when no material enters the feeding port, and theisolation effect is achieved.

Owner:德清江明新材料有限公司

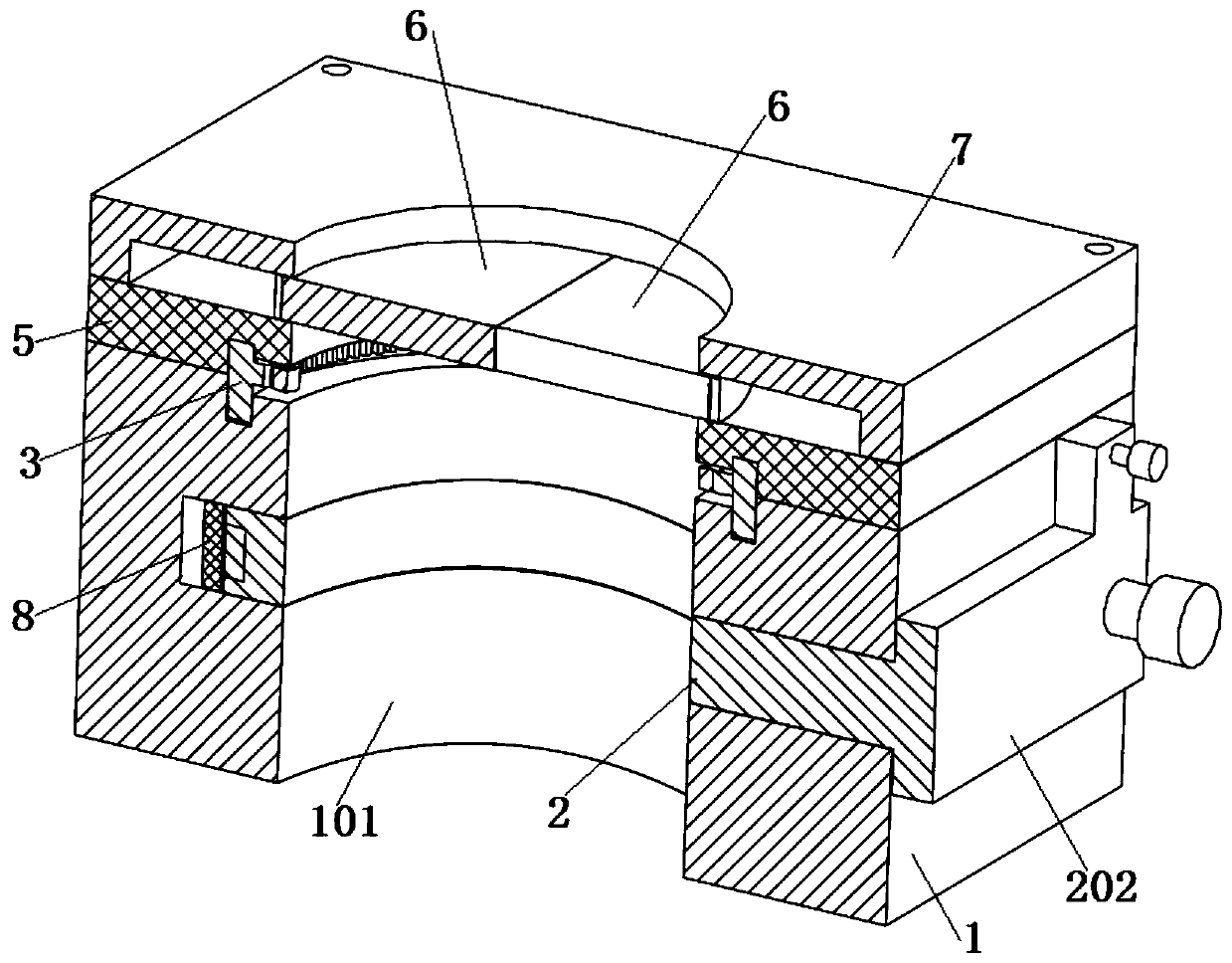

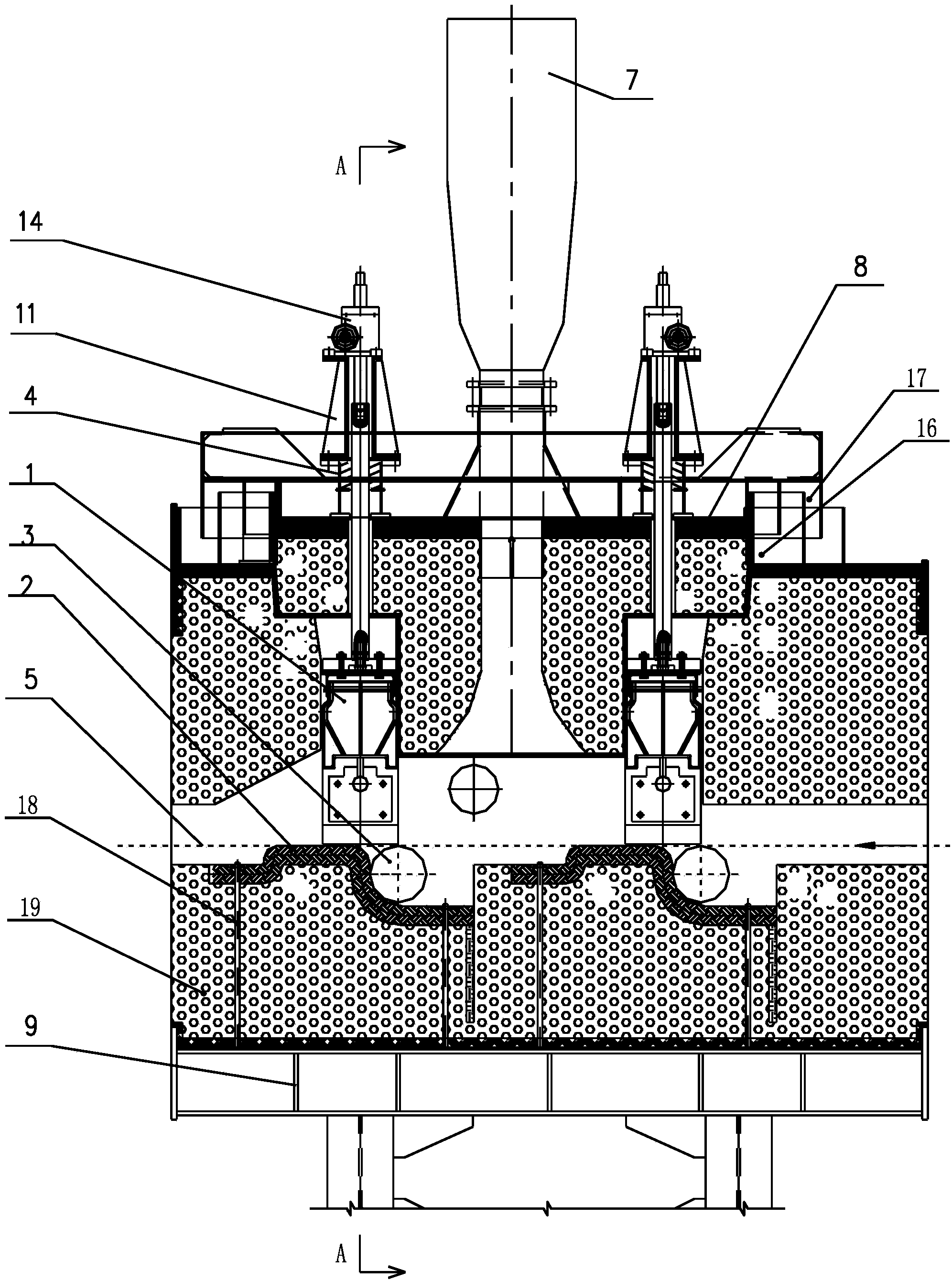

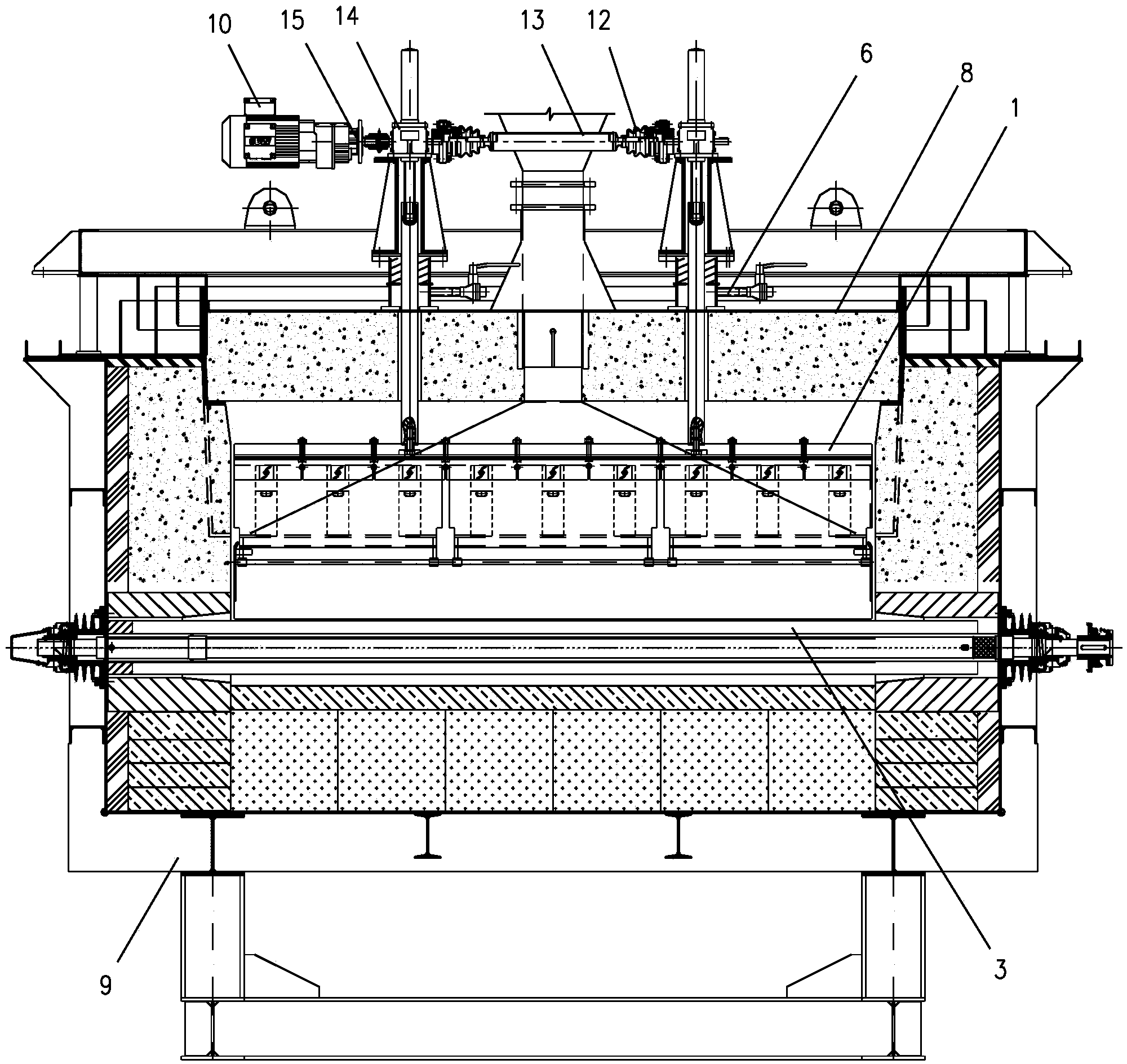

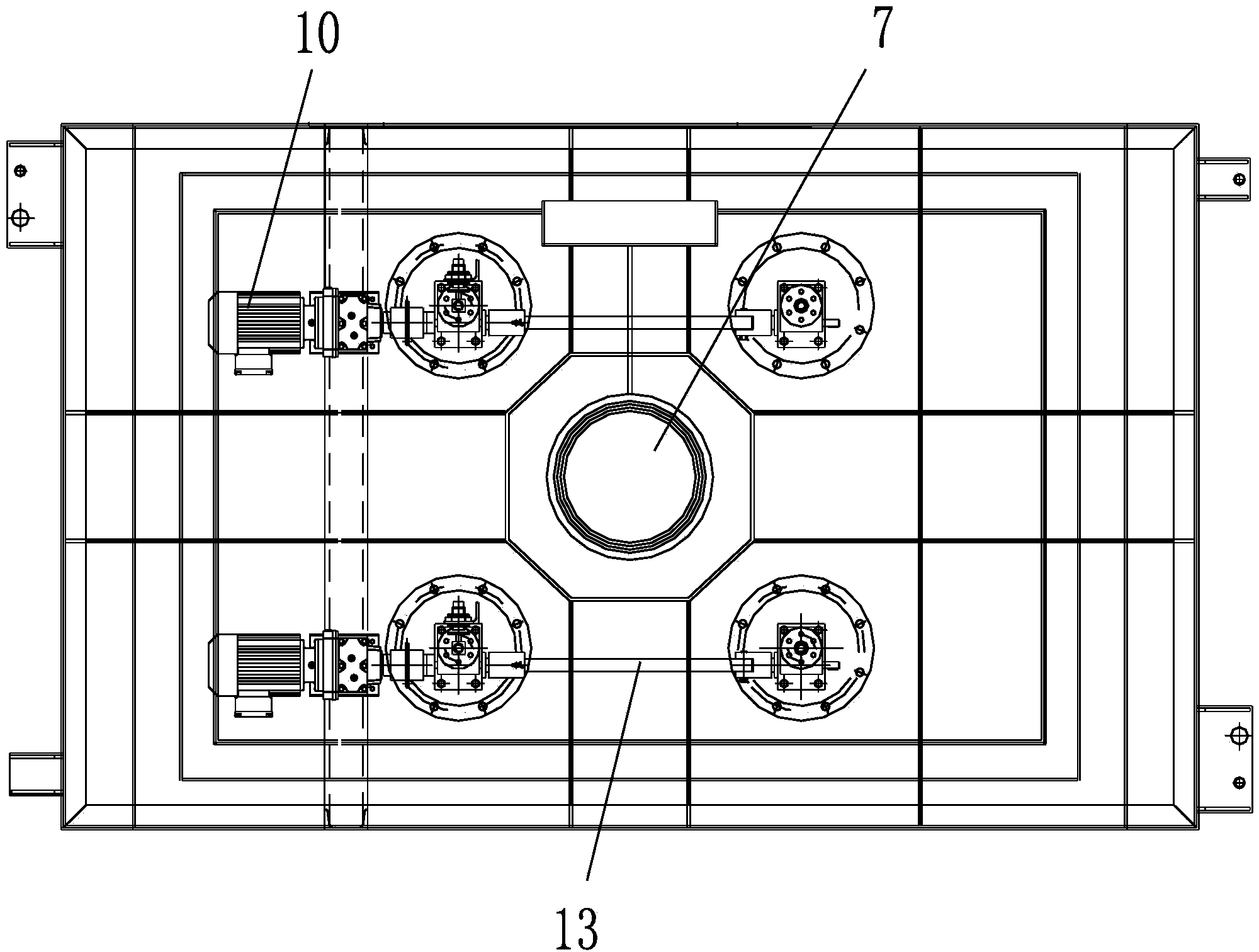

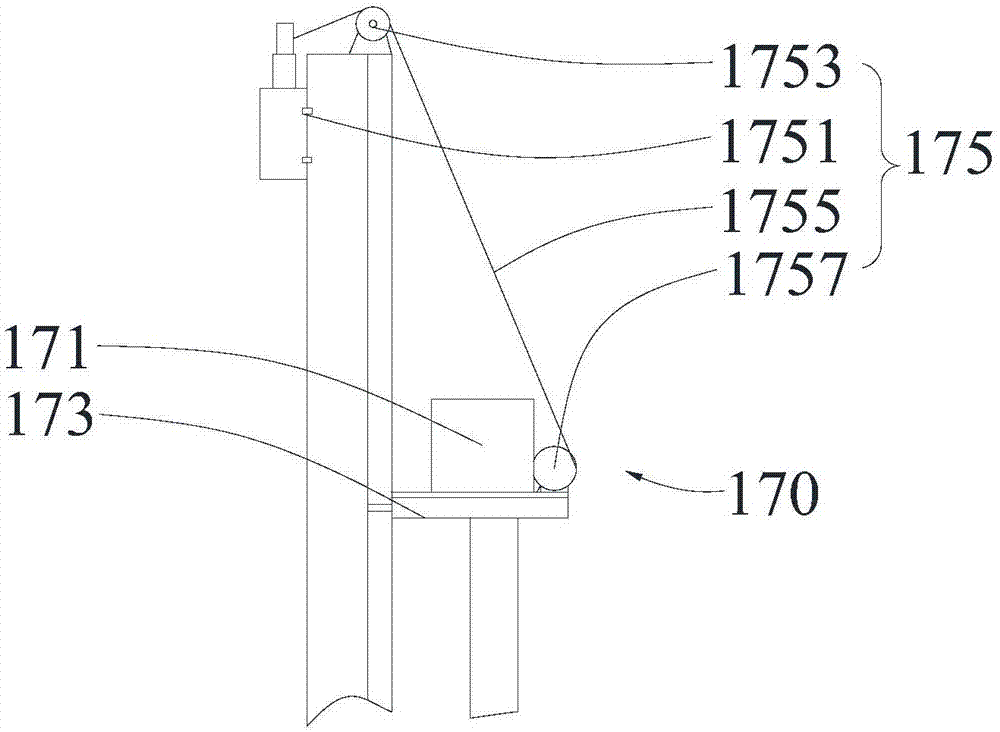

Sealing device for gas isolation of furnace sections

ActiveCN104099449AStable structureExtended service lifeHeat treatment process controlRefractoryStrip steel

The invention belongs to the field of sealing equipment for gas isolation of furnace sections in silicon steel heat processing technology, and particularly to a sealing device for gas isolation of furnace sections, especially for gas isolation of furnace sections of a high grade oriented silicon steel continuous annealing furnace. The sealing device for gas isolation of furnace sections comprises a furnace shell steel structure and a furnace top cover covered on the furnace shell steel structure in a sealing manner, wherein refractory cast materials are internally arranged around the furnace shell steel structure; a passage allowing a steel strip to penetrate through is arranged at the middle of the furnace shell steel structure; a pair of rollers are arranged in the passage; the upper surfaces of the rollers are overlapped with the steel strip through a line; T-shaped refractory cast materials are arranged on the lower surface of the furnace top cover; a diffusing passage is arranged at the middle of the furnace top cover; two baffles are arranged on the two sides of the diffusing passage; lifting devices are arranged at the upper ends of the baffles and mounted on the upper surface of the furnace top cover. According to the sealing device, gas flow in a front furnace section and a rear furnace section can be effectively controlled, the required furnace pressure can be precisely controlled, and the required isolating effect can be achieved.

Owner:WISDRI WUHAN WIS IND FURNACE

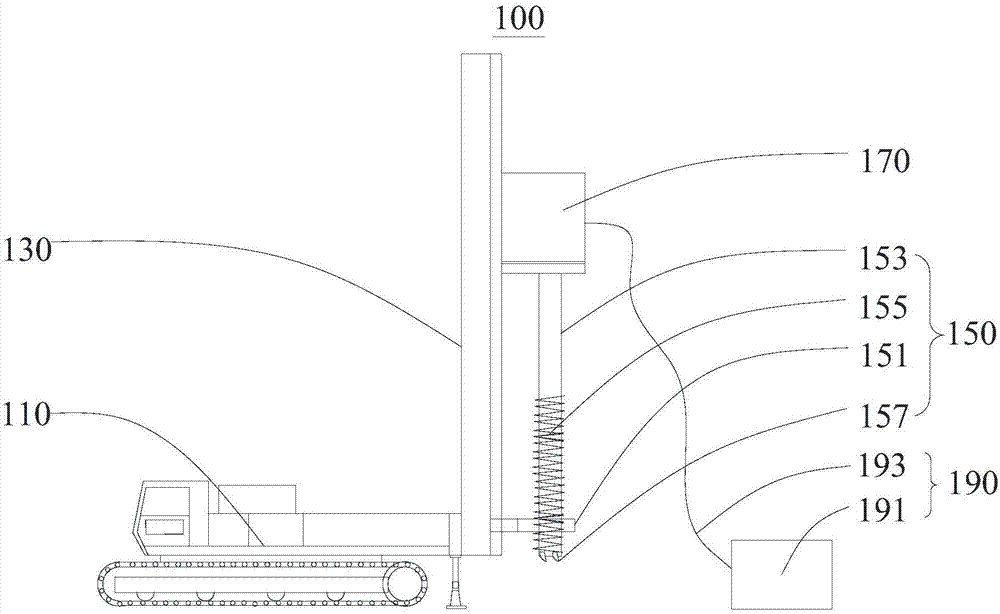

Spiral casing pile pulling equipment and spiral casing pile pulling system

PendingCN107354945ASimple structureEasy to useDrilling rodsDrilling casingsSedimentArchitectural engineering

The invention provides spiral casing pile pulling equipment and a spiral casing pile pulling system, and relates to the field of construction machines. The spiral casing pile pulling system comprises slurry sediment circulating equipment and the spiral casing pile pulling equipment. The spiral casing pile pulling equipment comprises a pile excavation machine, an arm support, a pore forming device, a power device and a mud circulating device; the pore forming device comprises a locating sleeve, a casing and a spiral diversion blade; the locating sleeve is fixedly connected with one end, close to a hydraulic travelling base, of the arm support; one end of the casing is detachably connected with the power device, and communicates with one end, stretching into the power device, of the mud circulating device; the other end of the casing penetrates through the locating sleeve; and the spiral diversion blade is fixed at the peripheral surface of the casing spirally. Compared with the prior art, the spiral casing pile pulling equipment is simple in structure, convenient to use and high in pile pulling efficiency, has the excellent pile pulling effect and can rapidly complete isolation movement.

Owner:中铁十一局集团桥梁有限公司 +1

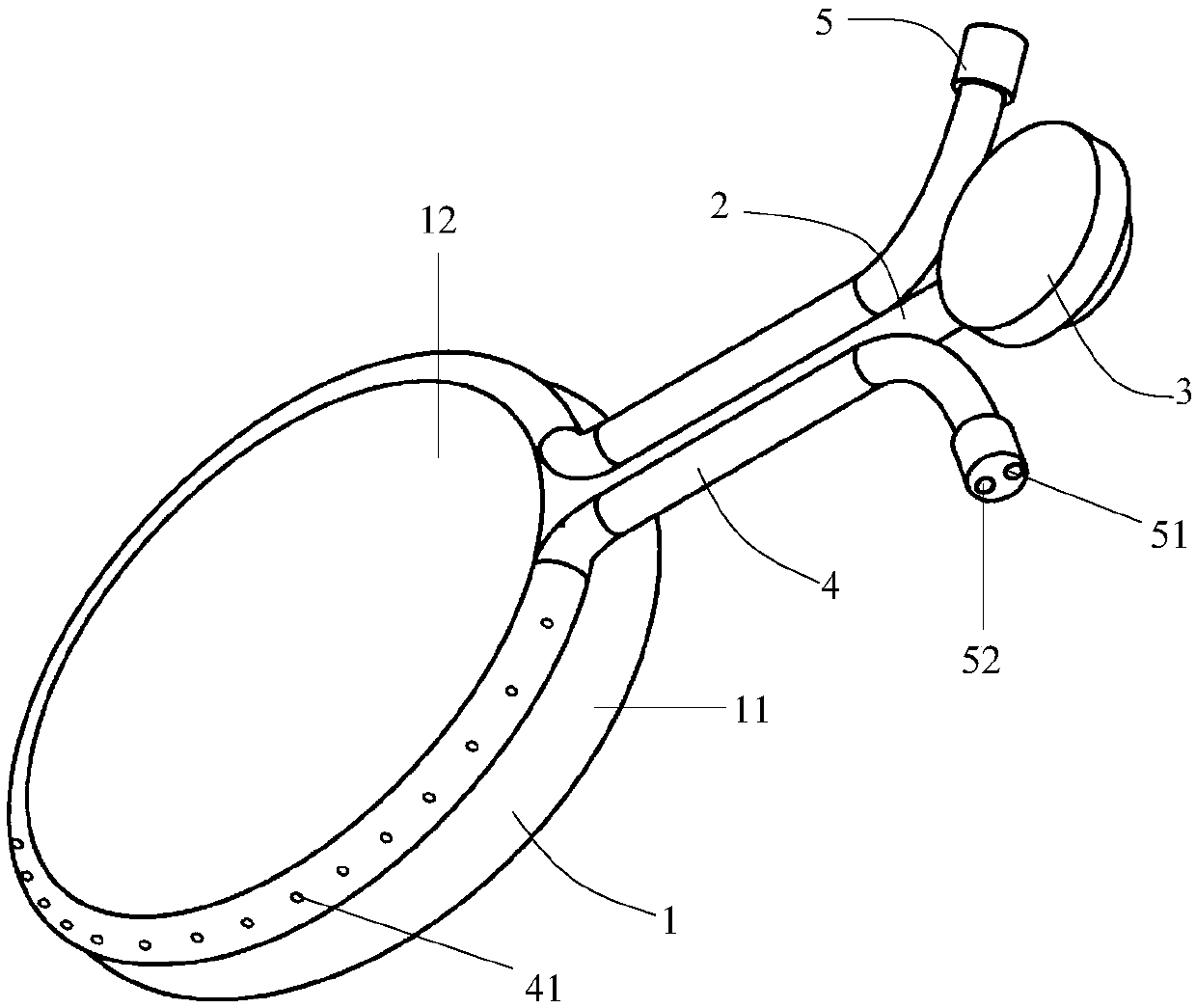

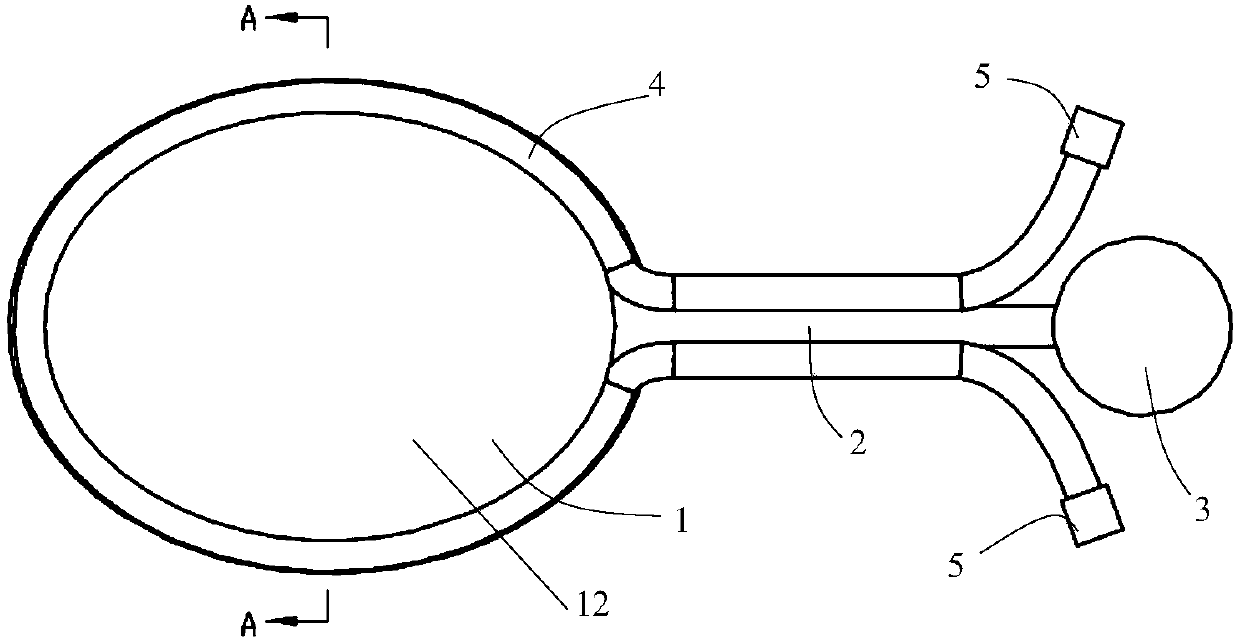

Anti-infection expander

ActiveCN108670431AReduce the risk of infectionStrong anti-infection effectCannulasEnemata/irrigatorsGuide tubeVALVE PORT

The invention discloses an anti-infection expander. The anti-infection expander comprises a connecting catheter, an expanding bag, an external injection pot and a flushing catheter, wherein the expanding bag and the external injection pot are connected to the two ends of the connecting catheter; the materials of the expanding bag, the connecting catheter and the flushing catheter are modified silicone rubber of which the surface is injected with silver ions; the expanding bag comprises a bag body and a thickened base arranged on the bottom surface of the bag body; the edge of the bag body is protruded out of the edge of the thickened base; the middle section of the flushing catheter is wound on the outer side of the thickening base; a flushing hole is formed in the outer side wall of the middle section of the flushing catheter; two side sections of the flushing catheter extend out of the expanding bag; and two ends of the flushing catheter are separately connected with a one-way injection valve. The anti-infection expander is convenient to use and operate, and the infection probability of skin soft tissues in an expanding process can be reduced effectively.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

Isolation device for respiratory emergency and severe diseases

ActiveCN110613878AShortness of breath reliefNot easy to bite offRespiratory masksPatient affectedEngineering

The invention discloses an isolation device for respiratory emergency and severe diseases. The isolation device comprises an isolation device main body filter, a mask, a venthole and an anti-biting opening, a filter is fixedly connected to the other side of an isolation device main body, the outer wall of the periphery of the filter is connected with the outer wall of the periphery of the isolation device main body, the mask is movably connected to one side of the filter, the outer wall of the periphery of the mask is connected with the inner wall of the inner side of one side of the filter inan overlapped mode, the venthole is fixedly connected to the top of the mask, filter cotton is placed in the venthole, harmful gases can be effectively absorbed, thus the situation that some untreated gases are absorbed into the body by a patient through the venthole is prevented, at the same time, when the patient is breathing, the filter cotton in the venthole absorbs the harmful gases exhaledby the patient, then other harmless gases are discharged outward through the venthole, thus the situation that the harmful gases exhaled by the patient affect other human bodies is prevented, and broad development prospects in the future are achieved.

Owner:SHANGQIU INST OF TECH

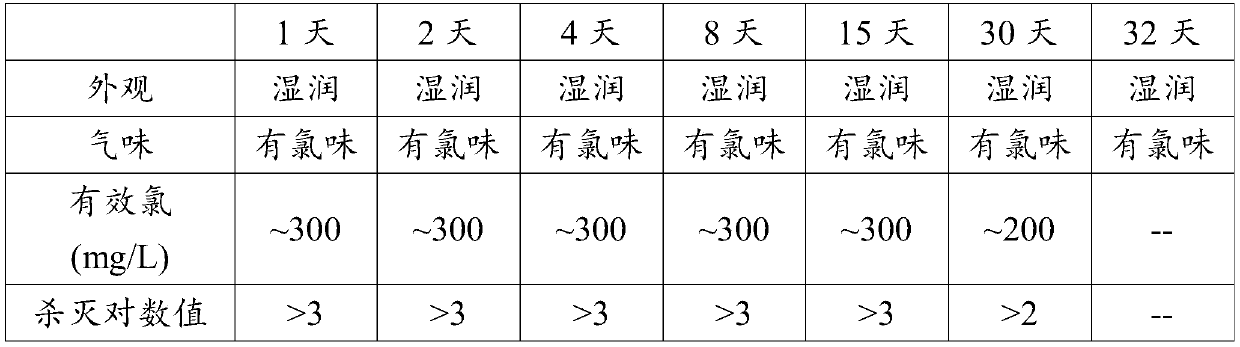

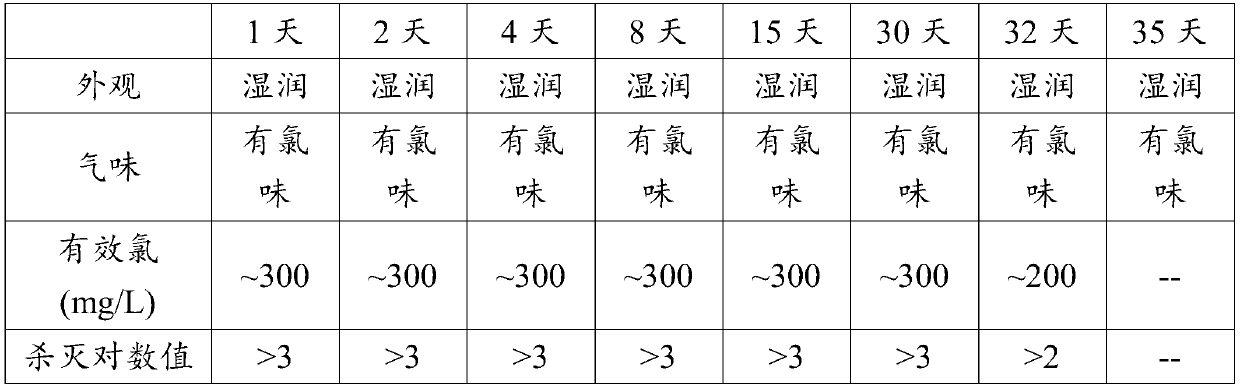

Disinfectant and preparation method and application thereof

ActiveCN111493091AStay hydratedExtended use timeBiocideGaseous substancesPolyvinyl alcoholDisinfectant

The invention provides a disinfectant and a preparation method and application thereof, the disinfectant is gel-like, water is used as a solvent, and the disinfectant comprises or is prepared from thefollowing raw materials: 10-30 wt% of sodium hypochlorite, 2-10 wt% of polyvinyl alcohol and the balance of an additive. The disinfectant provided by the invention has high stability, can realize continuous, effective and slow release of available chlorine, has a good air disinfection effect, and especially has a good disinfection effect on suspended bacteria and / or viruses in air. Moreover, thedisinfectant provided by the invention is simple and convenient to use.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

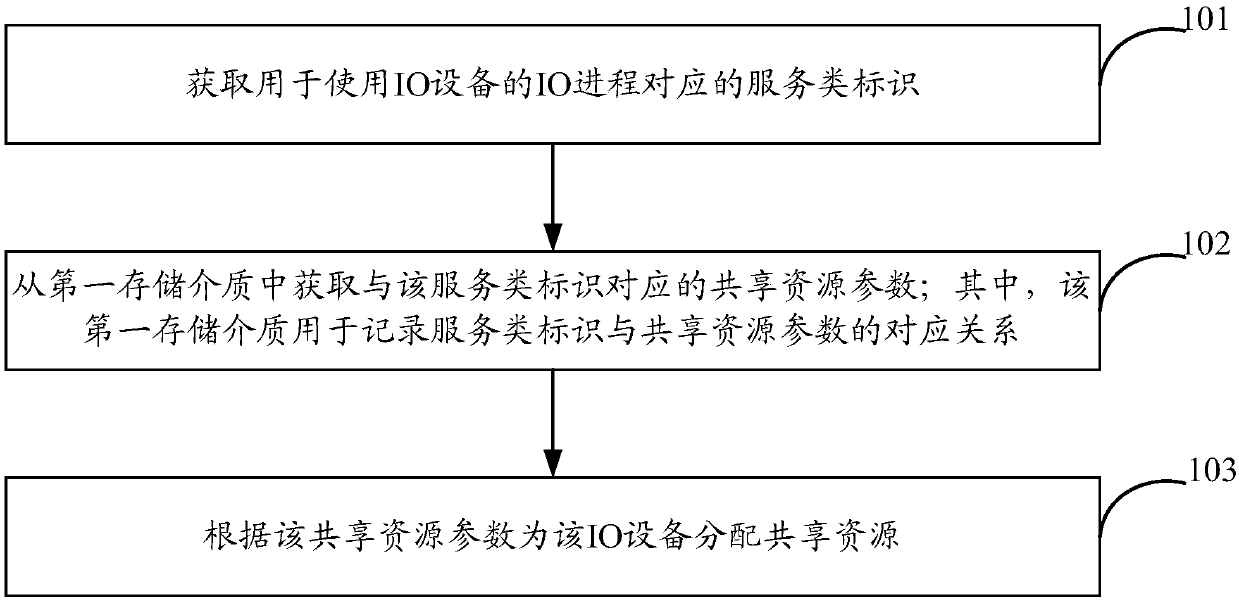

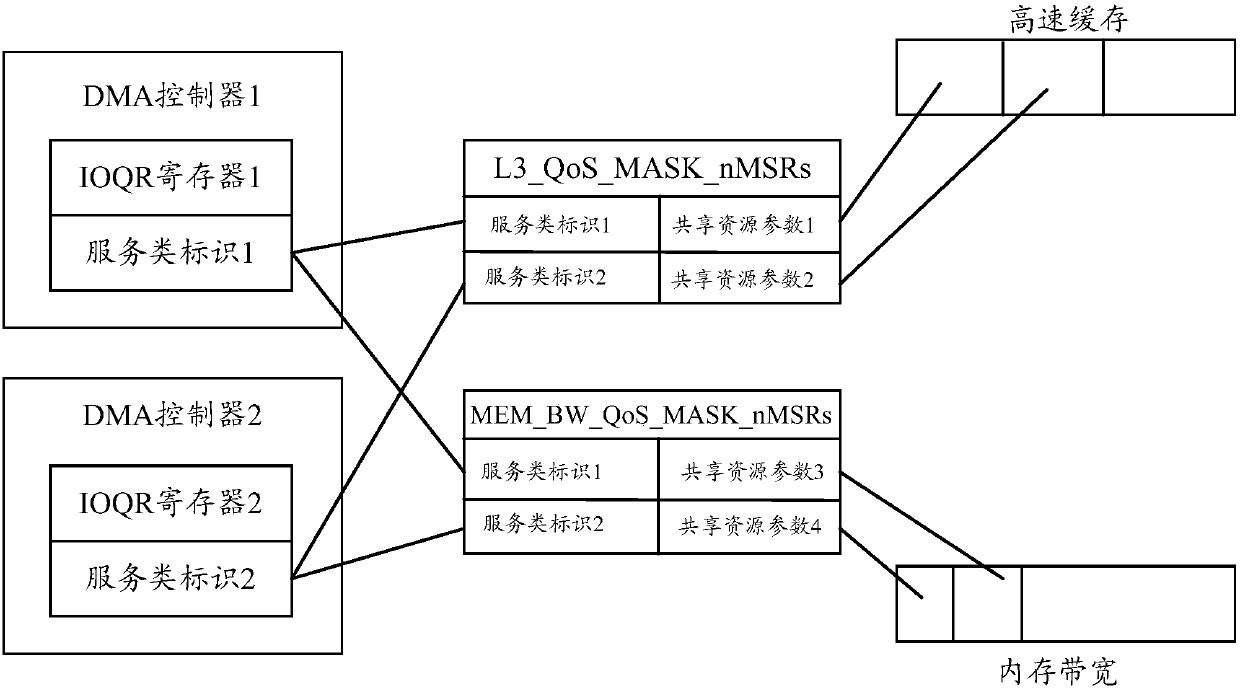

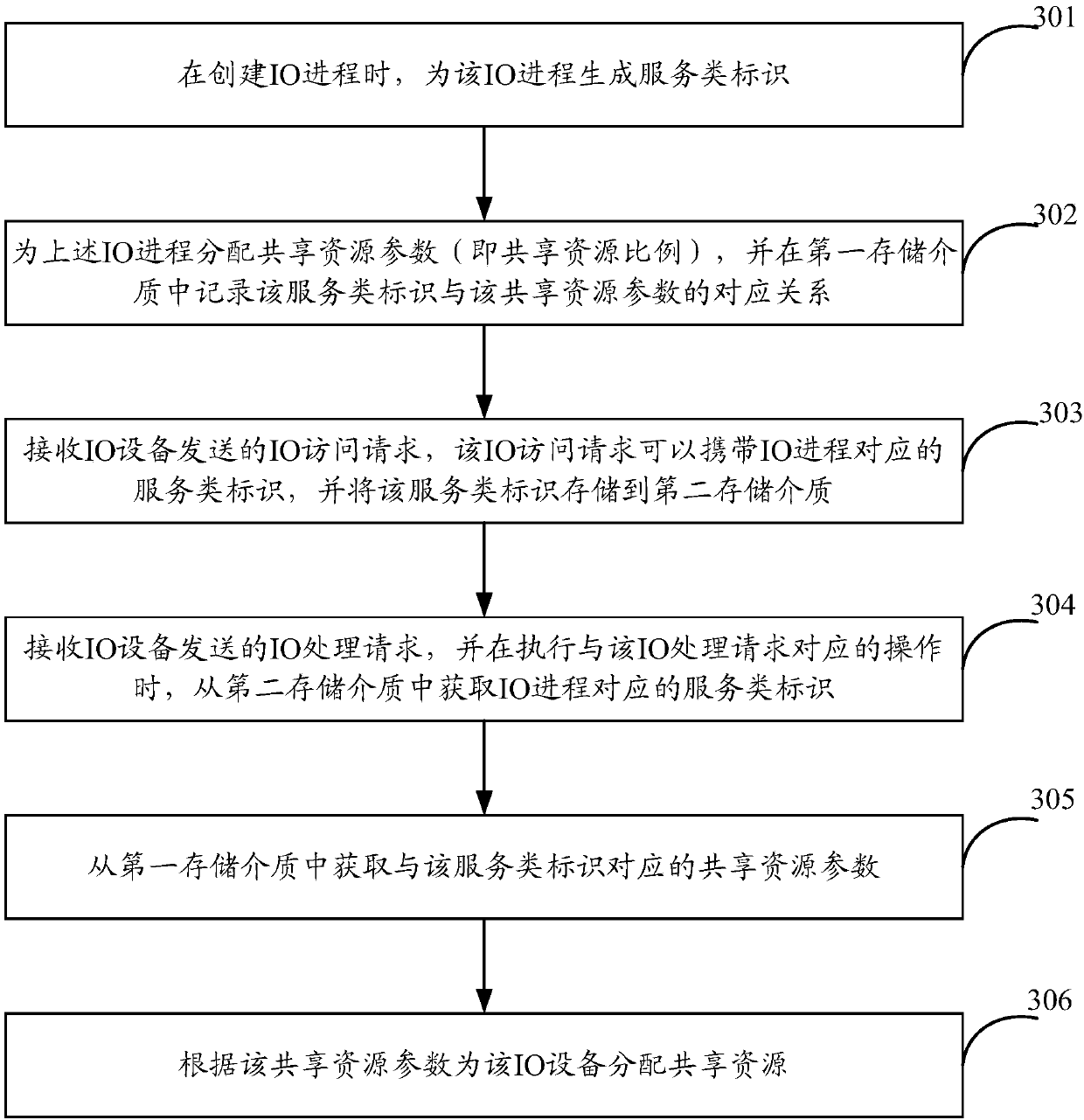

Shared resource allocation method and device and equipment

PendingCN110096355ATo achieve the effect of isolationIncrease profitResource allocationSoftware simulation/interpretation/emulationDistribution methodShared resource

The invention provides a shared resource distribution method and device and the equipment. The method comprises the steps of obtaining the service class identifiers corresponding to the IO processes used for using the IO devices; obtaining the shared resource parameters corresponding to the service class identifiers from a first storage medium, wherein the first storage medium is used for recording a corresponding relation between the service class identifiers and the shared resource parameters; and distributing the shared resources to the IO devices according to the shared resource parameters. According to the technical scheme of the invention, the plurality of IO devices do not compete for the shared resources together, so that the effect of isolating the shared resources is achieved, the mutual influence among the plurality of IO devices is avoided, the utilization rate of the shared resources is improved, the influence of the competition of the shared resources on the service performance is avoided, and the jitter of the application performance is avoided.

Owner:ALIBABA GRP HLDG LTD

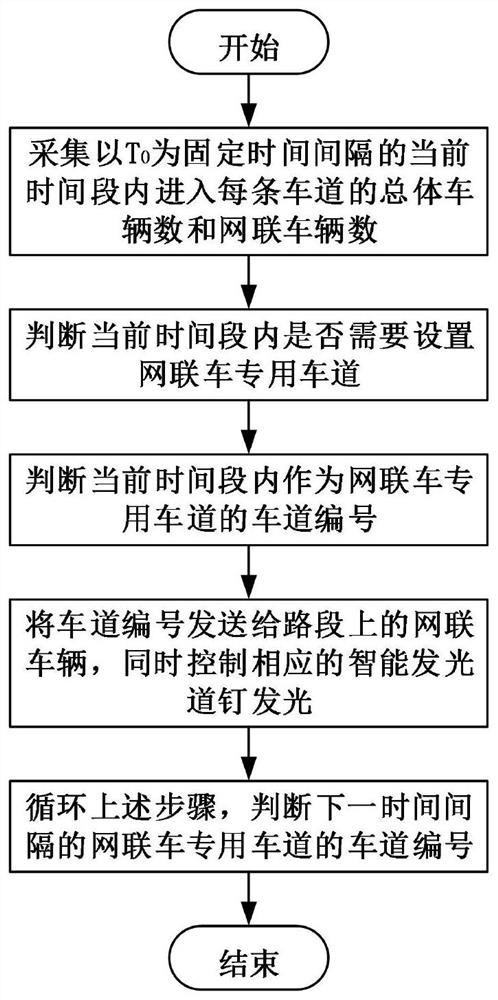

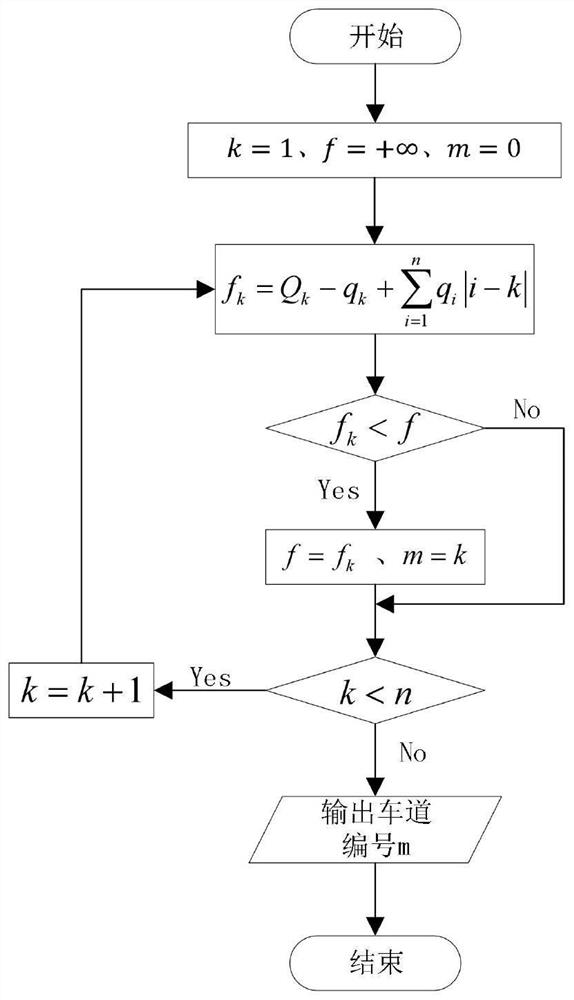

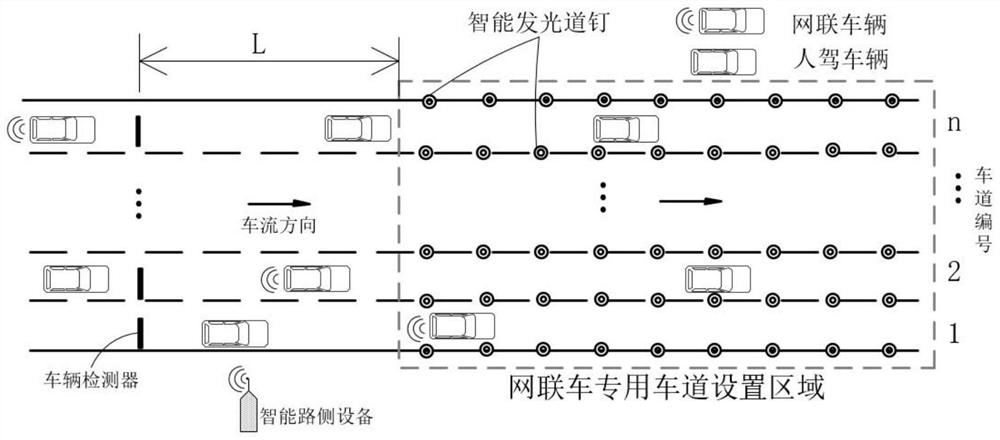

Dynamic regulation and control method for special lane of network-connected vehicle based on permeability

ActiveCN113744539AAvoid Lane Change ConflictsLane changing conflicts reducedControlling traffic signalsArrangements for variable traffic instructionsNetwork connectionSimulation

The invention discloses a dynamic regulation and control method for a special lane for network-connected vehicle based on permeability. The method comprises the following steps of: 1, acquiring the total number of vehicles entering each lane and the number of network-connected vehicles in a current time period; 2, judging whether a special lane for the network-connected vehicle needs to be set in the current time period; 3, judging the lane number of the special lane for the network connection vehicle in the current time period through an algorithm; 4, sending the serial number of the special lane for the network-connected vehicle to the network-connected vehicle in the road section, and meanwhile controlling the intelligent light-emitting spikes on the corresponding lane marking lines to emit light; and 5, circulating the steps, and judging the lane number of the special lane for the network connection vehicle in the next time period. According to the invention, the position of the special lane for the network-connected vehicle can be dynamically selected in real time according to the network-connected vehicle permeability of each lane, the necessary lane changing times of the vehicles are reduced, the lane changing conflicts among the vehicles are reduced, and the traffic flow operation safety and the traffic flow operation efficiency are improved.

Owner:HEFEI UNIV OF TECH

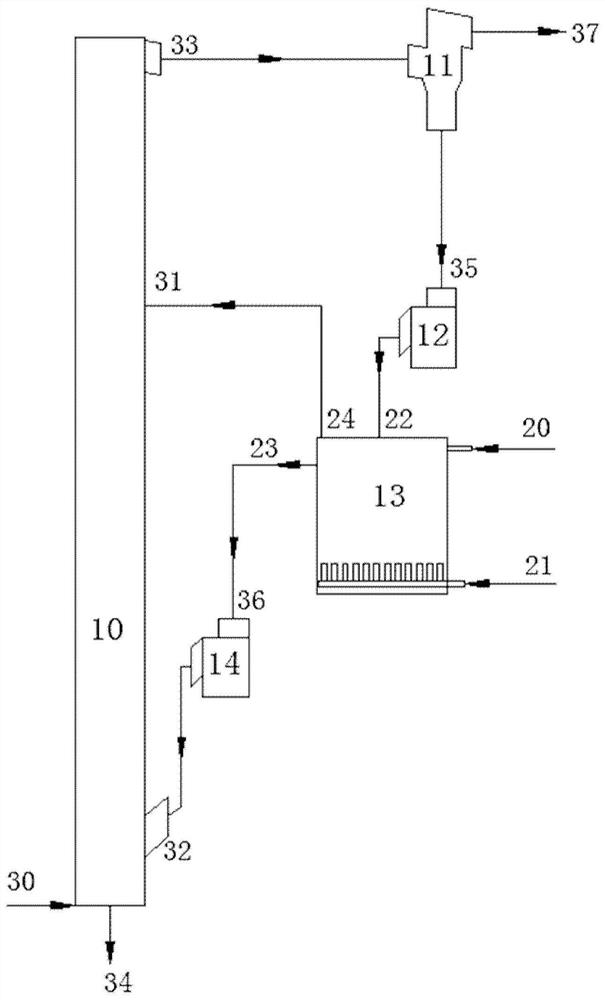

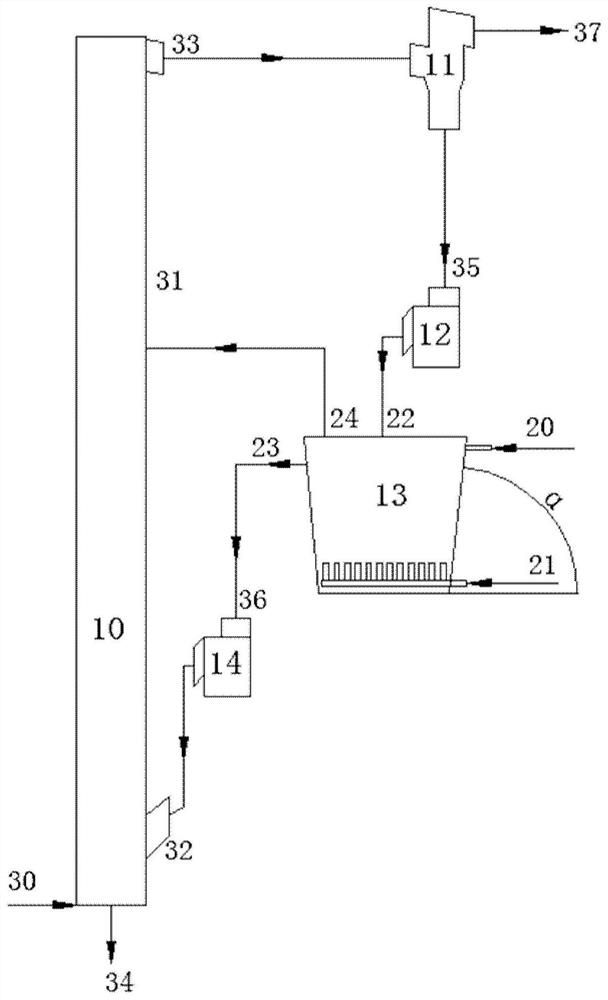

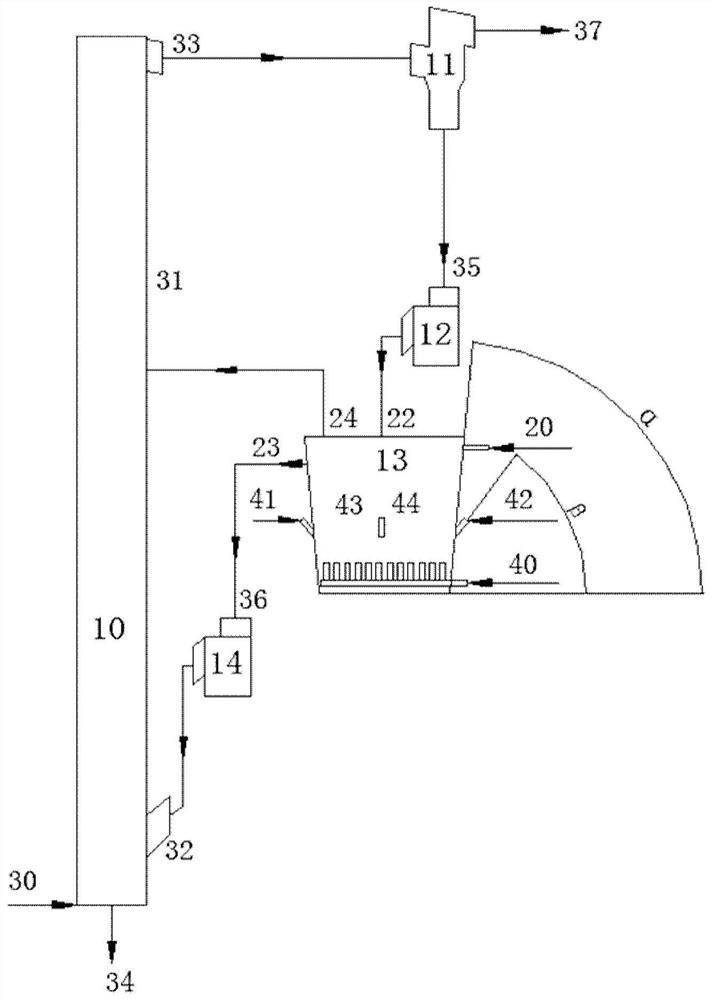

Fuel dealkalization device and method thereof and circulating fluidized bed gasification device and method thereof

ActiveCN112852498ASimplify dealkalization processRun at scaleGranular/pulverulent flues gasificationSlagSolid fuel

The invention discloses a fuel dealkalization device and a method and a circulating fluidized bed gasification device and a method thereof, and the fuel dealkalization device is a bubbling fluidized bed and comprises a fuel inlet which is located at the upper part of the fuel dealkalization device and is used for conveying fuel to the fuel dealkalization device; an auxiliary gasifying agent inlet positioned at the lower part of the fuel dealkalization device and used for conveying an auxiliary gasifying agent to the fuel dealkalization device, wherein the fuel and the auxiliary gasifying agent are subjected to dealkalization reaction under heating; a dealkalized solid fuel overflow port positioned at the upper part of the fuel dealkalization device and used for outputting the dealkalized solid fuel generated by the dealkalization reaction; and an alkali-rich fuel gas outlet is positioned at the upper part of the fuel dealkalization device and used for outputting alkali-rich fuel gas generated by the dealkalization reaction. The invention further provides the fuel dealkalization method and the circulating fluidized bed gasification device and the method thereof. The method solves the technical problem of slag bonding caused by high alkali metal content of the high-alkali coal, realizes safe and reliable utilization of the high-alkali coal, and has a wide market application prospect.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Low-power fin type field effect transistor and manufacturing method thereof

ActiveCN106098783AAchieve separationTo achieve the effect of isolationSemiconductor/solid-state device manufacturingSemiconductor devicesVery large scale integrated circuitsBody area

The invention provides a low-power fin type field effect transistor and a manufacturing method thereof, and belongs to the technical field of super-large integrated circuit manufacture. The thickness of a sidewall channel layer and the thickness of a top channel layer of the field effect transistor are no greater than 10nm, and a fin-type isolation bar is formed on a deep body area far away from top gate control. Further shortening of a device trench length is facilitated, short channel effect control ability of the device is improved, and static power consumption is minimized. The source-drain area of the device is a monocrystalline active island, and has maller source-drain series resistance. Compared with a fin type field effect transistor employing lifting source-drain structure, the low-power fin type field effect transistor requires no epitaxial lifting source-drain to obtain rapidly high open-state current. The low-power fin type field effect transistor is compatible with conventional IC-manufacture technology and has the advantages of simple process and low manufacture cost.

Owner:PEKING UNIV +1

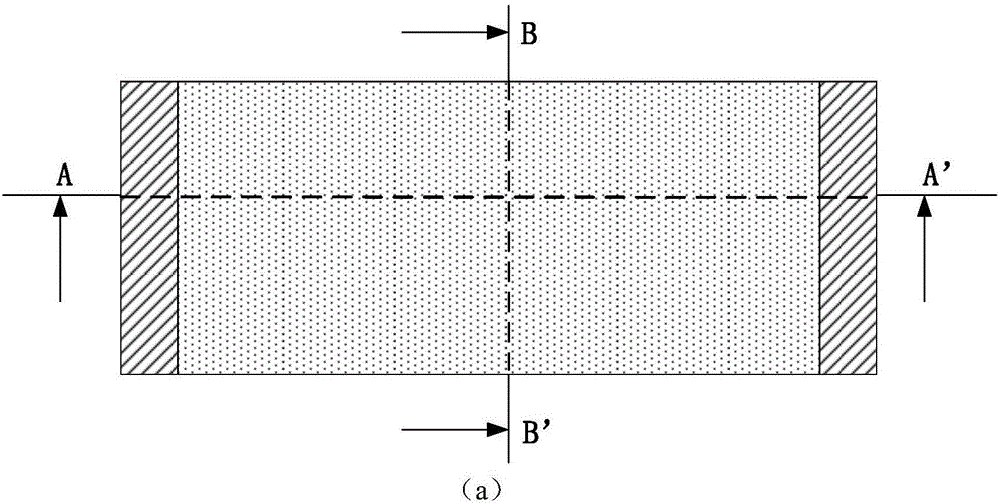

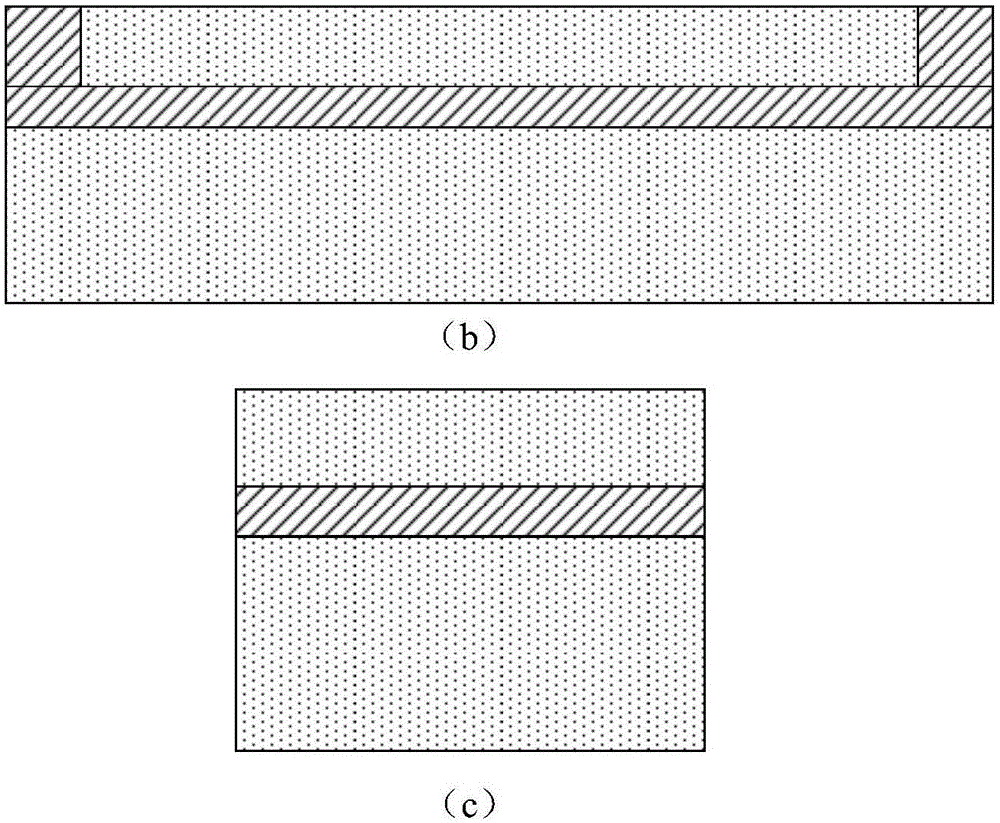

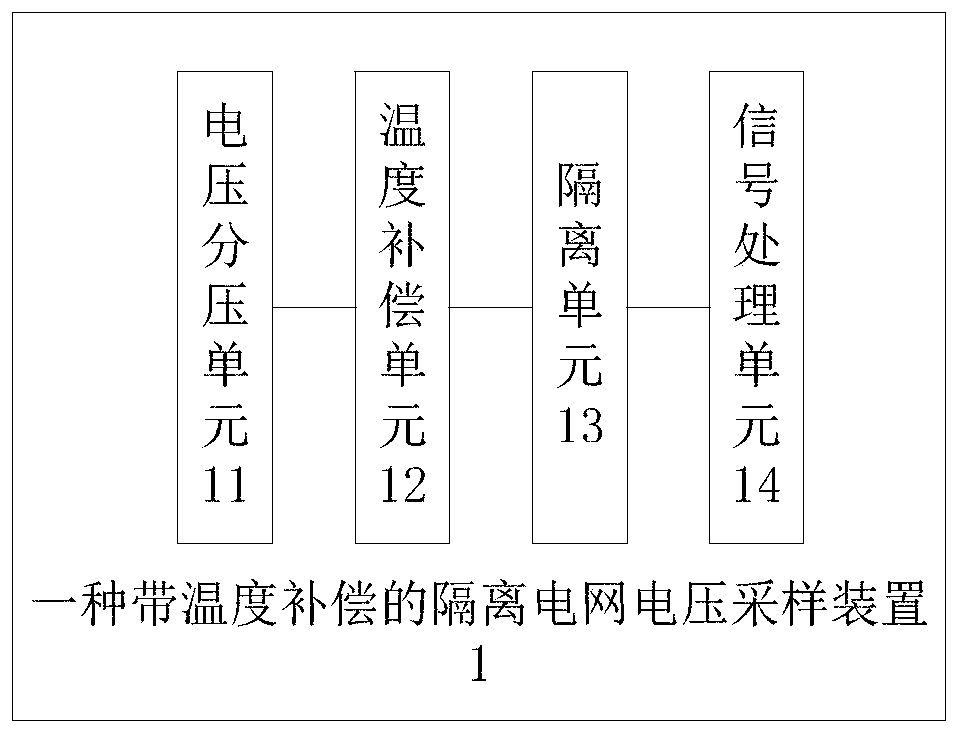

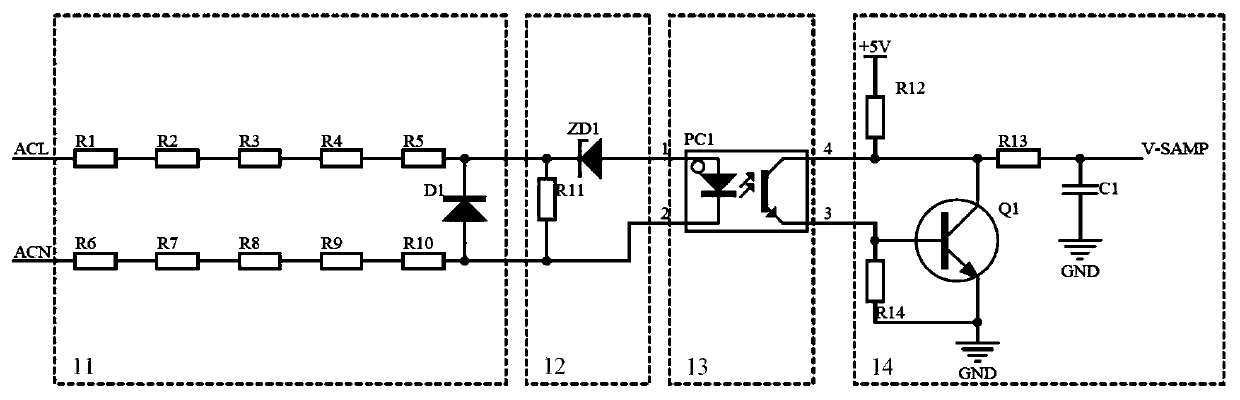

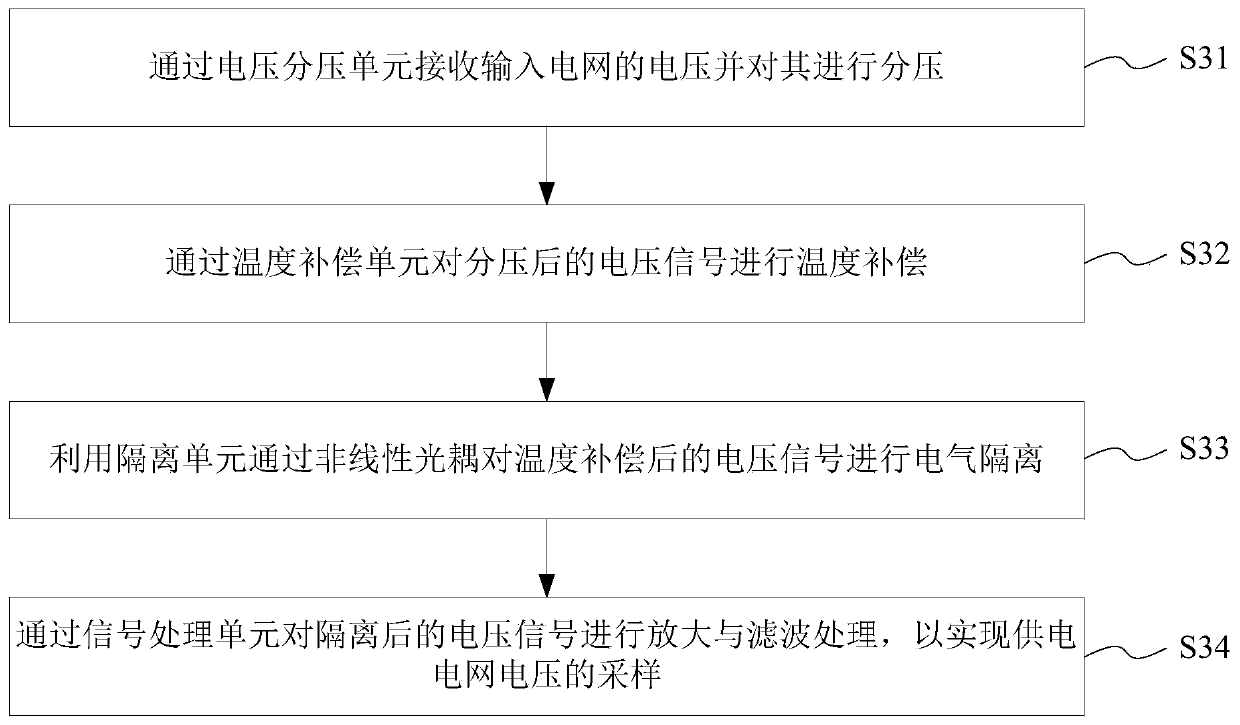

Isolated power grid voltage sampling device with temperature compensation and sampling method

PendingCN110865232ATo achieve the effect of isolationEasy transferCurrent/voltage measurementPower gridControl theory

The invention provides an isolated power grid voltage sampling device with temperature compensation and a sampling method, and the device comprises a voltage dividing unit which is used for receivinga voltage of an input power grid and dividing the voltage of the input power grid; a temperature compensation unit which is connected with the voltage dividing unit and is used for carrying out temperature compensation on the divided voltage signal; an isolation unit which is connected with the temperature compensation unit and is used for electrically isolating the voltage signal subjected to temperature compensation through a nonlinear optocoupler; and a signal processing unit which is connected with the isolation unit and is used for amplifying and filtering the isolated voltage signal so as to realize sampling of a power supply network. The sampling of the power grid voltage is achieved based on the nonlinear optocoupler and the mode of compensating the temperature drift of the nonlinear optocoupler, the precision requirement of voltage sampling is met, and the cost is reduced.

Owner:RUKING EMERSON CLIMATE TECH SHANGHAI CO LTD

Spraying equipment for color plate production

The invention discloses spraying equipment for color plate production. The spraying equipment comprises a bottom plate, first roller columns, a protection cover, fixing blocks and a guiding groove. The guiding groove is formed in the upper surface of the bottom plate. The first roller columns distributed in parallel at equal intervals are movably arranged in the guiding groove. The outer walls ofthe two ends of the first roller columns are sleeved with symmetrically-distributed limiting wheels. Second roller columns are arranged above the first roller columns. The surfaces of the second roller columns are sleeved with rubber sleeves. The symmetrically-distributed fixing blocks are welded to the two ends of the upper surface of the bottom plate, and a paint spraying pipe and an air guidingpipe are inserted and connected in the fixing blocks. An installing block is fixed to the outer wall of one side of the bottom plate. An air pump is fixed to the outer wall of the side, deviating from the bottom plate, of the installing block. The protection cover is arranged on the upper surface of the bottom plate. A glass plate is embedded and installed in the upper surface of the protection cover. Through rotation of the limiting wheels in clamping grooves of a color plate, the effect of color plate limiting is achieved, and it is guaranteed that the situation of deflection of the color plate during moving is avoided.

Owner:TIANJIN YIXUNYUAN METAL PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com