Production method of deep groove isolation structure

A technology of isolation structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor uniformity in the plane and residual liquid medicine, so as to reduce the difficulty of back-end process and reduce the stability of devices Hidden dangers, the effect of improving in-plane uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

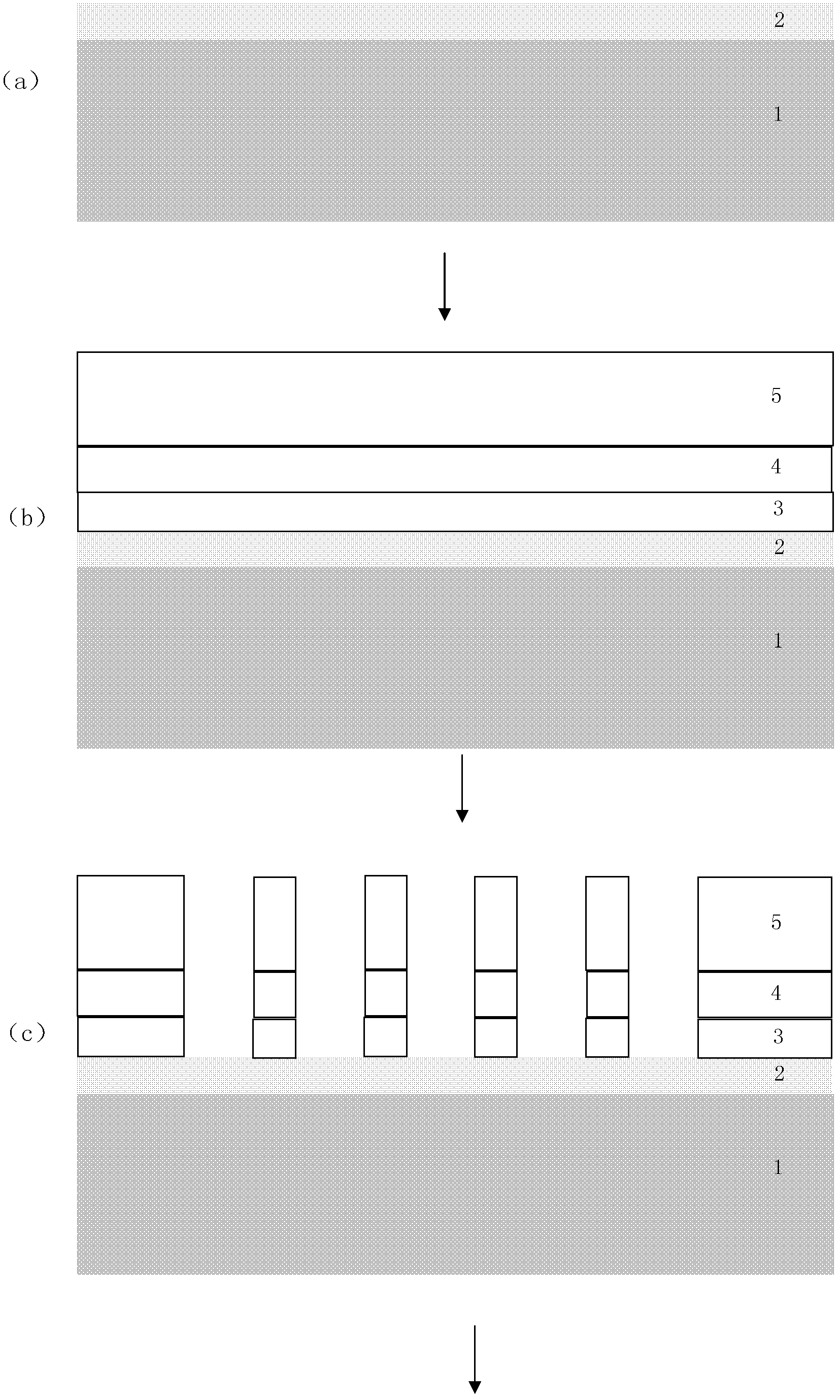

[0021] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, the manufacturing process flow of the deep trench isolation structure in the RFLDMOS device is described in detail as follows in conjunction with the illustrated embodiment:

[0022] Step 1, growing an epitaxial layer 2 on a silicon substrate 1, such as figure 1 (a) shown.

[0023] Step 2, enter the furnace tube to oxidize, and grow an oxide layer 3 with a thickness of 150-300 angstroms; then enter the furnace tube to grow a layer of silicon nitride 4 with a thickness of 500-800 angstroms; accumulate to form a layer of oxide layer 5 with a thickness of 2000-5000 angstroms, such as figure 1 (b) shown.

[0024] Step 3, exposure, development, using dry etching method, open the area to be etched deep groove, such as figure 1 (c) shown.

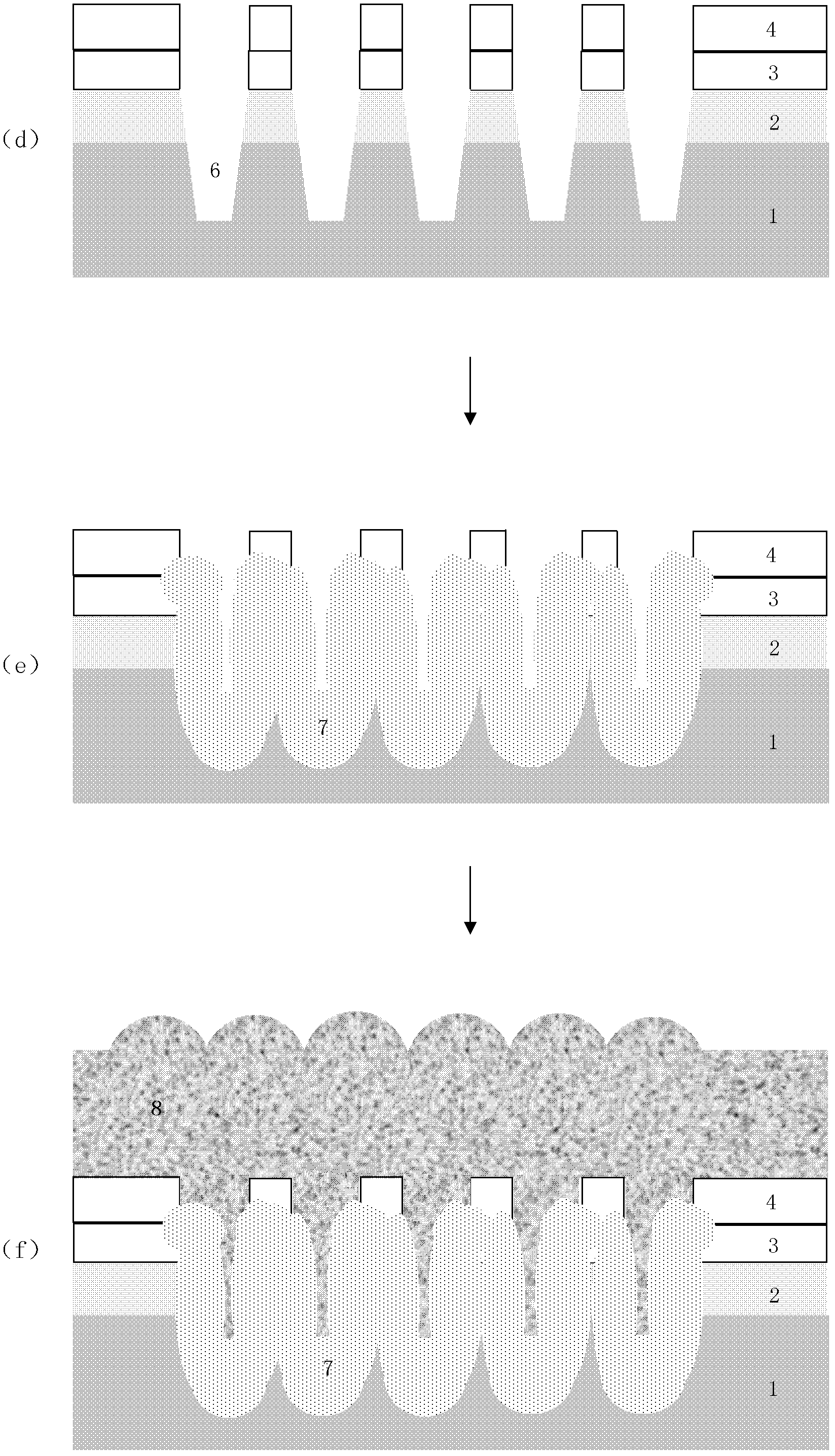

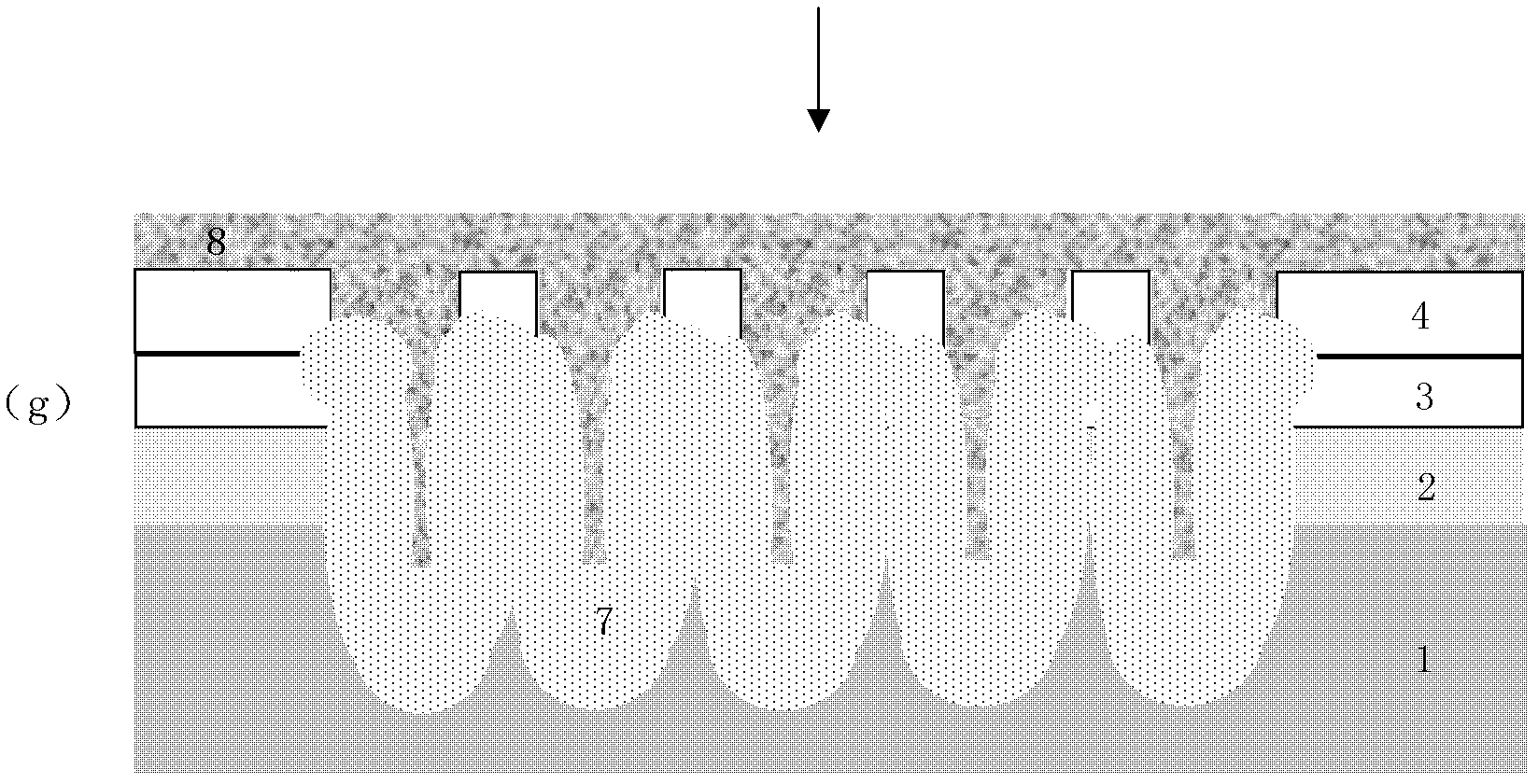

[0025] Step 4, using the oxide layer 3, the silicon nitride 4 and the oxide layer 5 as an etching barrier lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com