High-performance decrosslinked rubber asphalt and preparation method thereof

A rubber asphalt and decrosslinking technology, which is applied in building components, building insulation materials, plastic recycling, etc., to achieve the effects of improving dissolving capacity, improving economic and social benefits, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

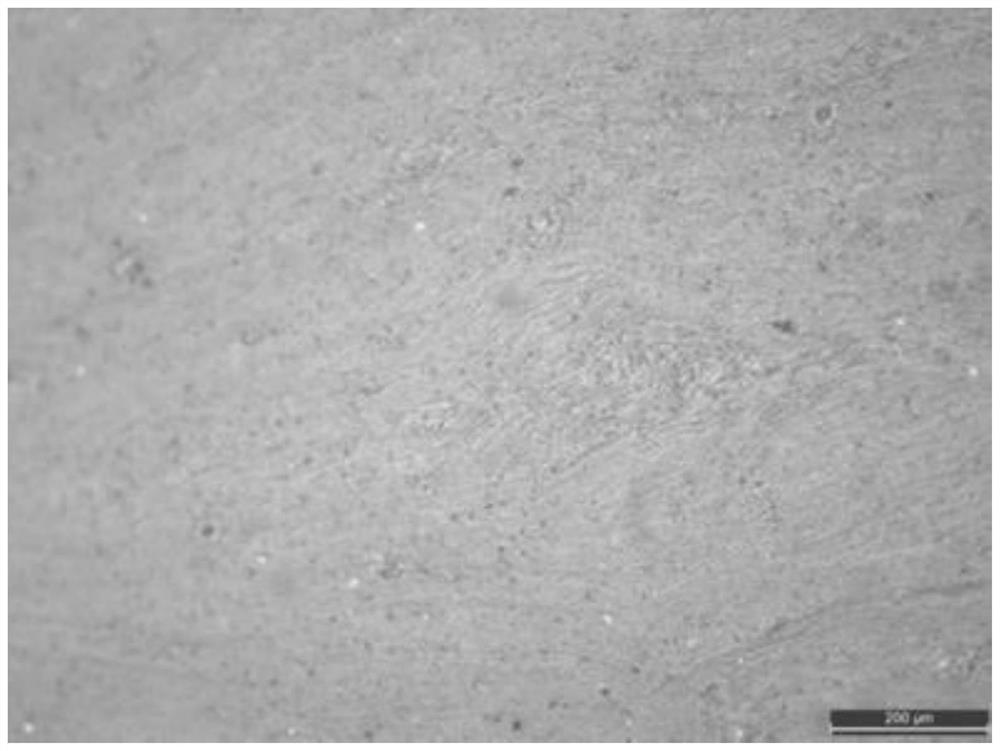

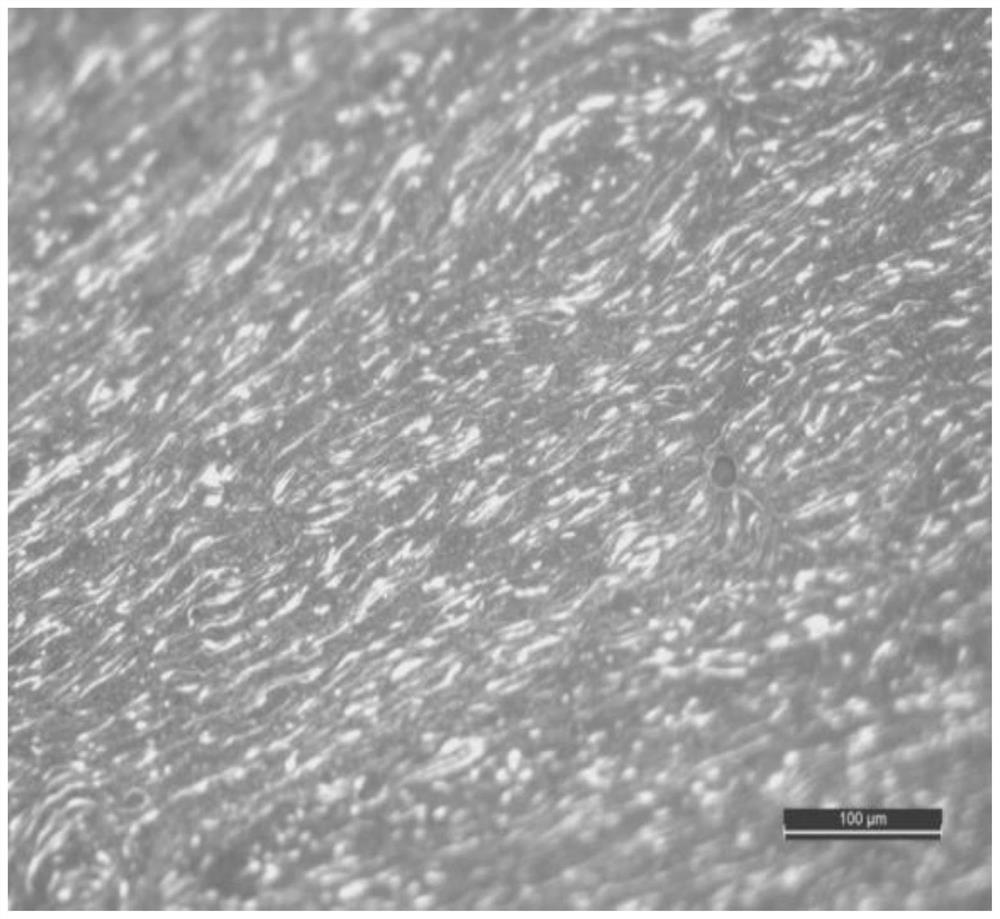

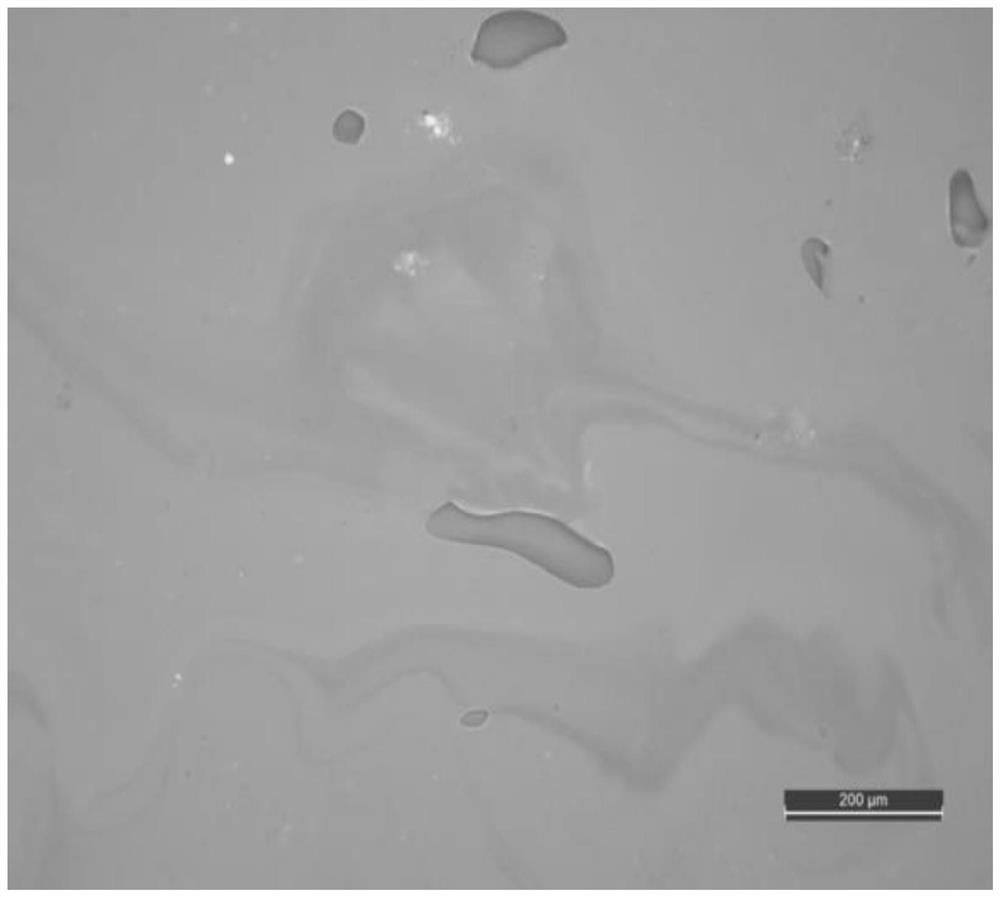

Image

Examples

Embodiment 1

[0044] Example 1: The method of the present invention is used to prepare decrosslinked rubber powder, the method of the present invention is used to prepare asphalt rubber, and then the performance test of asphalt and asphalt mixture is carried out.

[0045] First, use a single-screw extruder to carry out preliminary decrosslinking treatment on rubber powder, mix 97.5% by mass of 40 mesh waste tire rubber powder and 2.5% by mass of aromatic oil, and pass through the first stage of the screw at 280°C in a sealed oxygen barrier , the passage time is 6min, and then pass through the second cooling screw, the passage time is 5min, and the discharge temperature is 60°C;

[0046] Then, the rubber powder was decrosslinked again and premixed with the isolation modifier by using an internal mixer: the above-mentioned pretreated rubber powder of 88% by mass, 5% by mass of linear SBS791-H modifier and 7 % mass of polyethylene wax is added to the internal mixer, set the internal mixer spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com