Spiral casing pile pulling equipment and spiral casing pile pulling system

A technology of spiral casing and equipment, applied in the field of construction machinery, can solve the problems of low equipment requirements, unsatisfactory pile pulling effect, low pile pulling success rate, etc., and achieves rapid isolation action, good pile pulling effect, and pile pulling efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

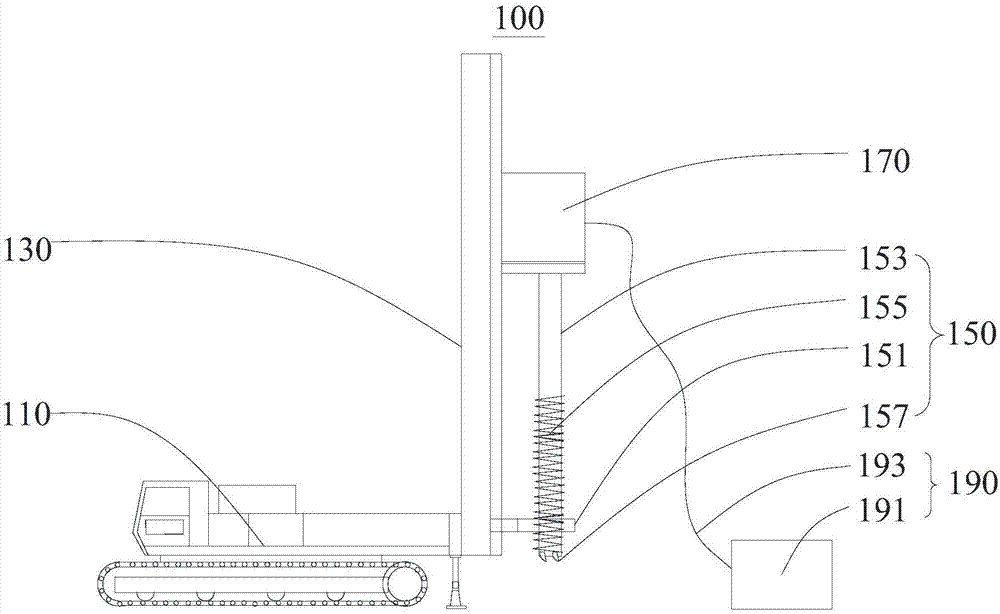

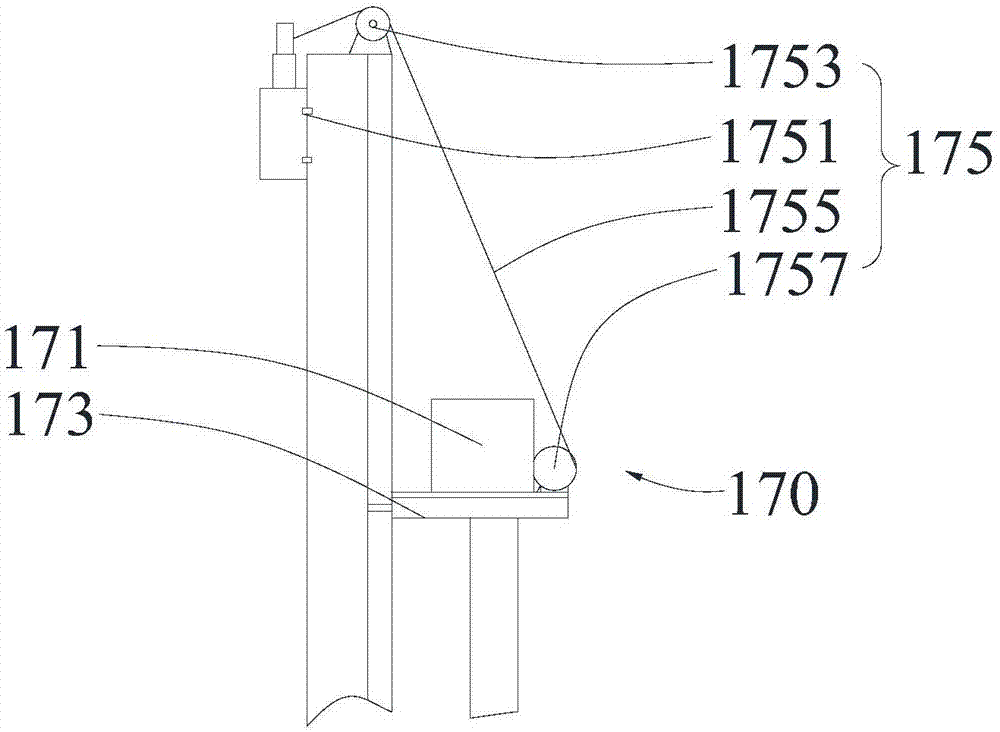

[0033] see figure 1, the present embodiment provides a spiral casing pile pulling device 100 for pulling out pipe piles, the spiral casing pile pulling device 100 includes a pile digger 110, a boom 130, a hole forming device 150, a power device 170 and a mud Circulation device 190, arm frame 130 is connected to an end of pile excavator 110, has slide rail on the arm frame 130, and power unit 170 is slidably connected to slide rail, and one end of mud circulation device 190 stretches into power unit 170 and with hole forming device 150 Connection for injecting mud into the hole forming device 150.

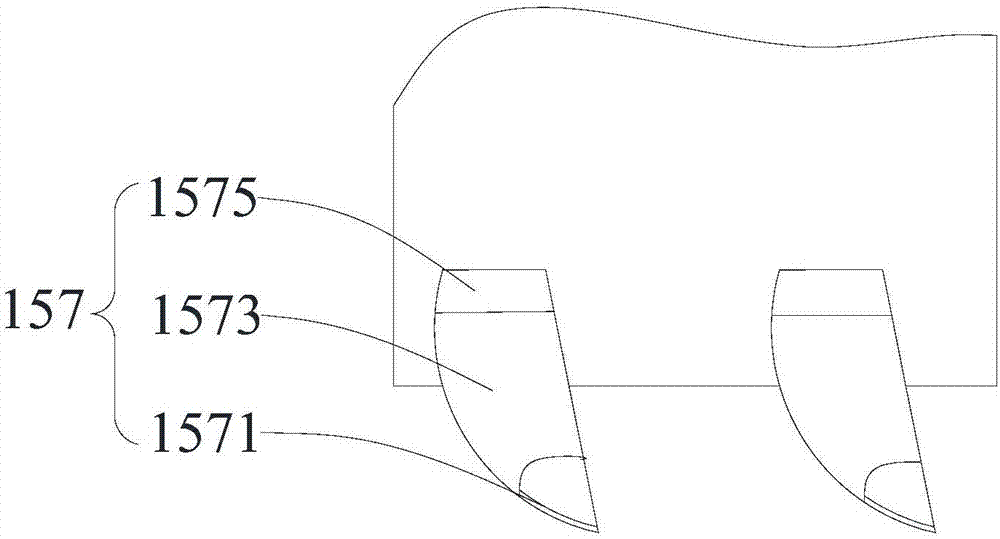

[0034] The hole-forming device 150 includes a positioning sleeve 151, a casing 153, a spiral guide blade 155 and a plurality of cutting cutter heads 157. The positioning sleeve 151 is fixedly connected to one end of the boom 130 close to the pile digger 110, and one end of the casing 153 is detachable. The ground is connected to the power unit 170 and communicates with one end of t...

no. 2 example

[0048] A spiral casing pile pulling system (not shown in the figure) provided in this embodiment is used for pulling out pipe piles, including mud sedimentation circulation equipment (not shown in the figure) and a spiral casing pile pulling device 100, wherein the spiral casing pulling The basic structure, principle and technical effect of the pile equipment 100 are the same as those of the first embodiment. For a brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0049] The spiral casing pile pulling equipment 100 includes a pile digging machine 110, a hole forming device 150, a power unit 170, and a mud circulation device 190. The pile digging machine 110 includes a boom 130 and a hydraulic walking base 111. The boom 130 is connected to the hydraulic walking One end of the base 111 has a slide rail on the boom 130, and the power unit 170 is slidably connected to the slide rail. One end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com