Sealing device for gas isolation of furnace sections

A sealing device and atmosphere technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of small sealing gas area, easy loosening, poor sealing performance, etc., to achieve convenient disassembly and installation, simple manufacturing and processing, and extended use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

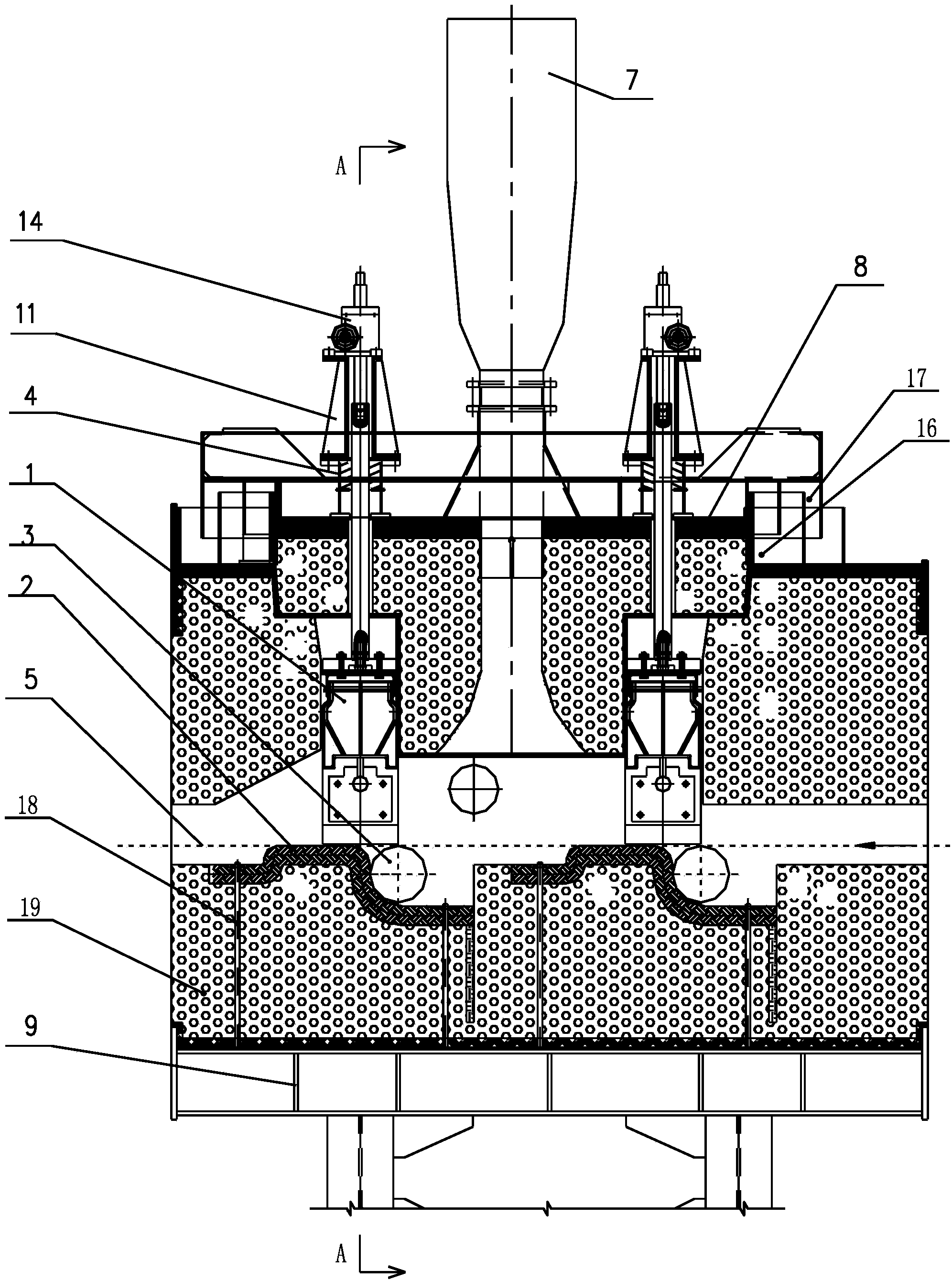

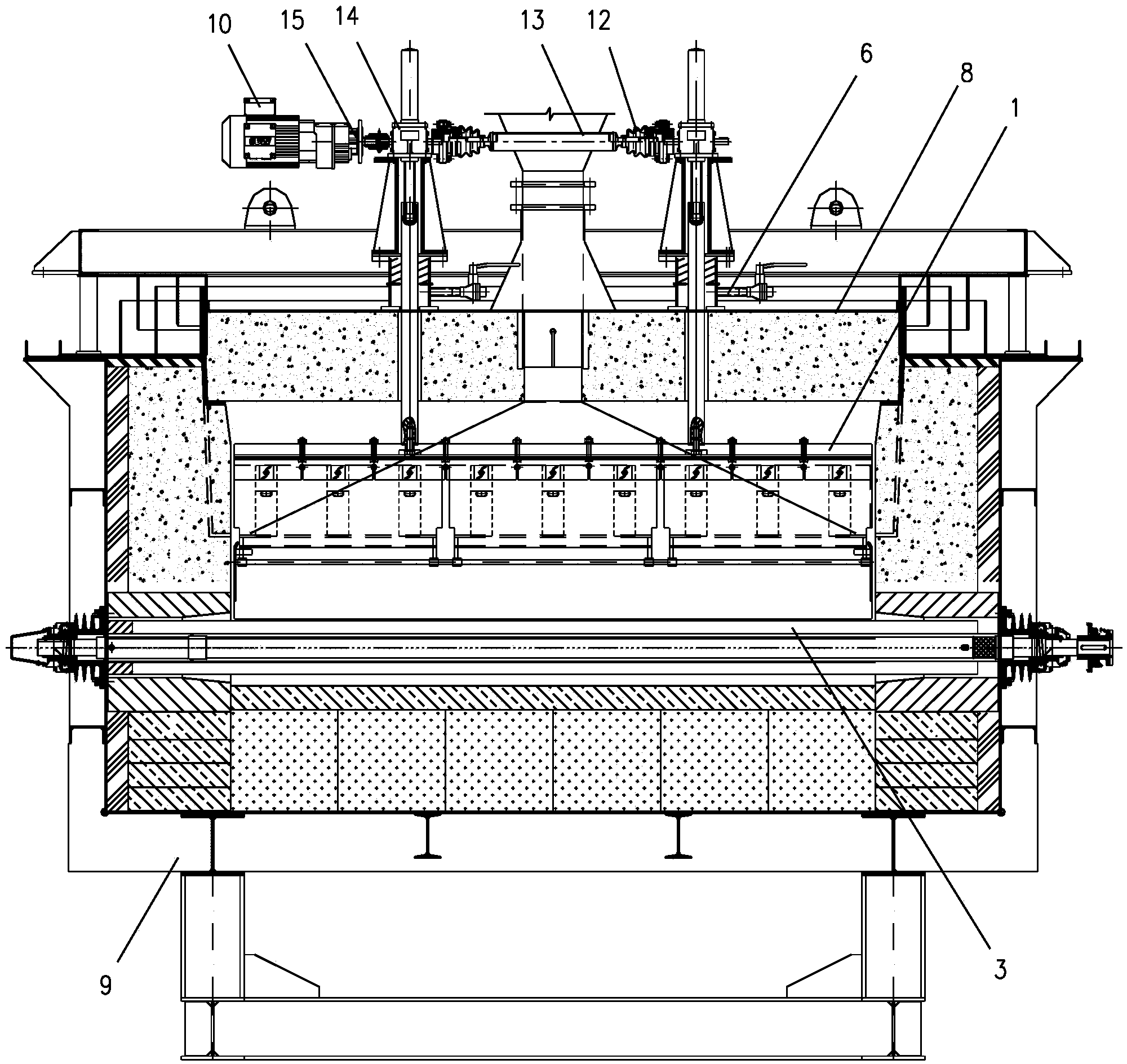

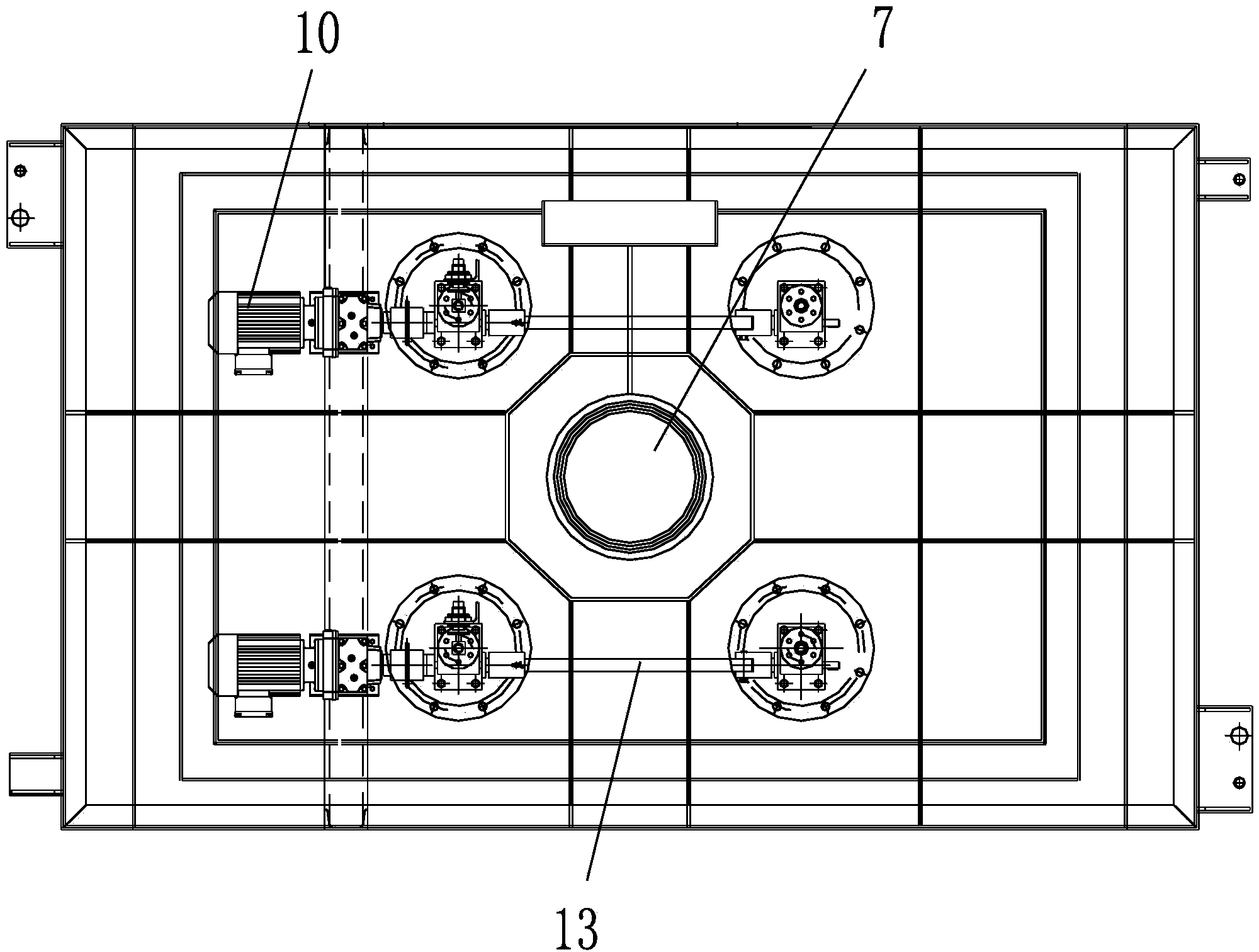

[0026] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0027] A sealing device for the atmosphere isolation of the furnace section (the device is arranged between the dry atmosphere and the wet atmosphere furnace section or between the heating section and the cooling section), which is mainly composed of a furnace shell steel structure 9 and a seal cover on the furnace shell steel structure 9 Furnace roof cover 8, refractory castables 19 are provided around the inside of the furnace shell steel structure 9, and a channel for the strip steel 5 to pass is provided in the middle. The passing line coincides; the lower surface of the furnace roof 8 is provided with an inverted "convex" shaped refractory castable 19, and a release channel 7 is provided in the middle of it (the gas flow between the two baffles is controlled by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com