Fuel dealkalization device and method thereof and circulating fluidized bed gasification device and method thereof

A circulating fluidized bed, fuel gas technology, applied in the direction of granular/powder fuel gasification, etc., can solve the problems of enhanced slagging risk, low utilization efficiency of high-alkali coal, slagging, etc. Fuel gas efficiency, solving large water consumption, reducing alkali metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

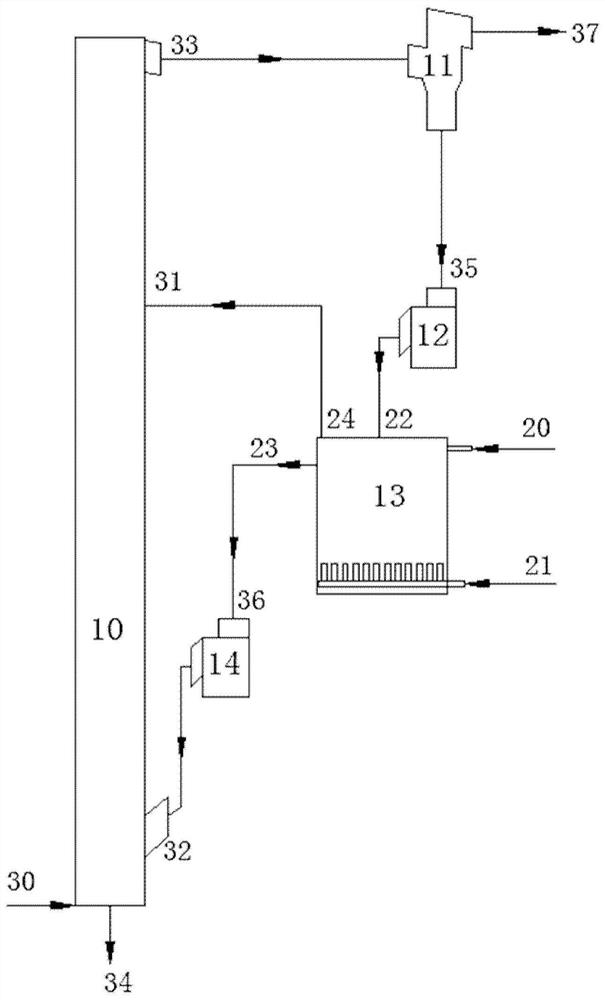

[0070] The following combination figure 1 , taking high-alkali coal as an example to illustrate a circulating fluidized bed gasification device suitable for high-alkali coal, which includes a main bed 10, a gas-solid separator 11, an upper return device 12, an auxiliary bed 13 and Lower feeder 14.

[0071] The main bed 10 communicates with the gas-solid separator 11, the gas-solid separator 11 communicates with the upper feeder 12, the upper feeder 12 communicates with the auxiliary bed 13, the auxiliary bed 13 communicates with the main bed 10 through a connecting pipe, and the auxiliary bed 13 It communicates with the lower feeder 14 , and the lower feeder 14 communicates with the main bed 10 .

[0072] The auxiliary bed 13 is provided with a fuel inlet 20 , an auxiliary gasification agent inlet 21 , a high-temperature circulating semi-coke inlet 22 , a high-temperature dealkalization solid fuel overflow port 23 and an alkali-rich crude fuel gas outlet 24 .

[0073] The ma...

Embodiment 2

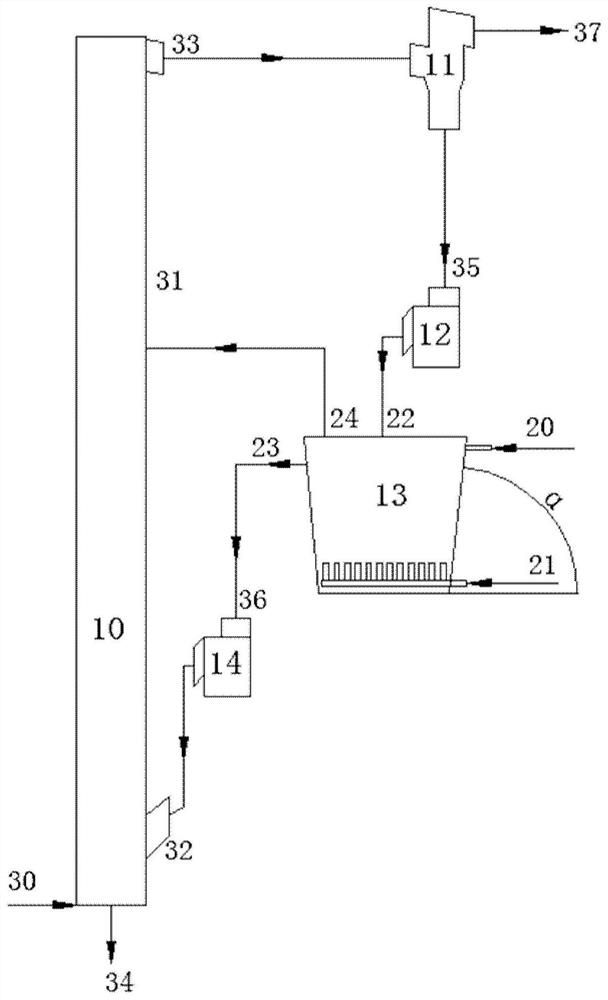

[0079] see figure 2 , is a preferred embodiment of the present invention, similar in structure to Embodiment 1, the main difference is that the auxiliary bed 13 has a certain inclination angle. The angle α between the wall surface of the auxiliary bed 13 and the horizontal plane is between 45° and 90°. The auxiliary gasification agent is passed into the bottom of the auxiliary bed 13 from the auxiliary gasification agent inlet, and is mixed with fresh high-alkali coal and high-temperature semi-coke transported by the upper return device 12 during the process of moving upward with the bottom material of the auxiliary bed 13 1. During the reaction process, a certain amount of pyrolysis gas and gasification gas are formed. Due to the volume expansion, the velocity in the middle and upper part of the auxiliary bed 13 is higher than the velocity at the bottom, which will increase the escape of fine particles and affect the residence time and desorption of fresh high-alkaline fuel....

Embodiment 3

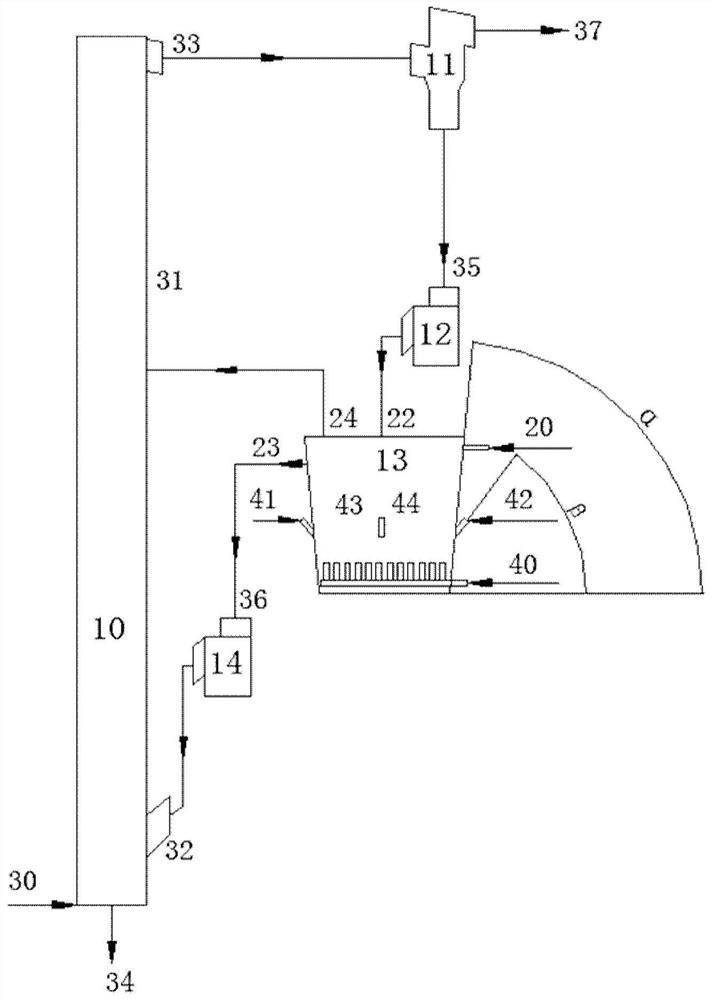

[0081] see image 3 , is another preferred embodiment of the present invention, similar to the structure of embodiment 1, the main difference is that the auxiliary bed 13 has a secondary air nozzle, and the structure of the secondary air nozzle is as follows Figure 4 shown. The angle β between the secondary air gasification agent inlet of the auxiliary bed 13 and the horizontal plane is between 0° and 60°. The introduction of the secondary air will strengthen the particle disturbance and reaction in the auxiliary bed 13, thereby promoting the dealkalization process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com