Automatic pipeline acid adding apparatus

A pipeline and automatic technology, which is applied in the fields of casein production, dairy beverage processing and biological product production, can solve the problems of uneven mixing and high local acidity, and achieve the effects of simple process, reduced denaturation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

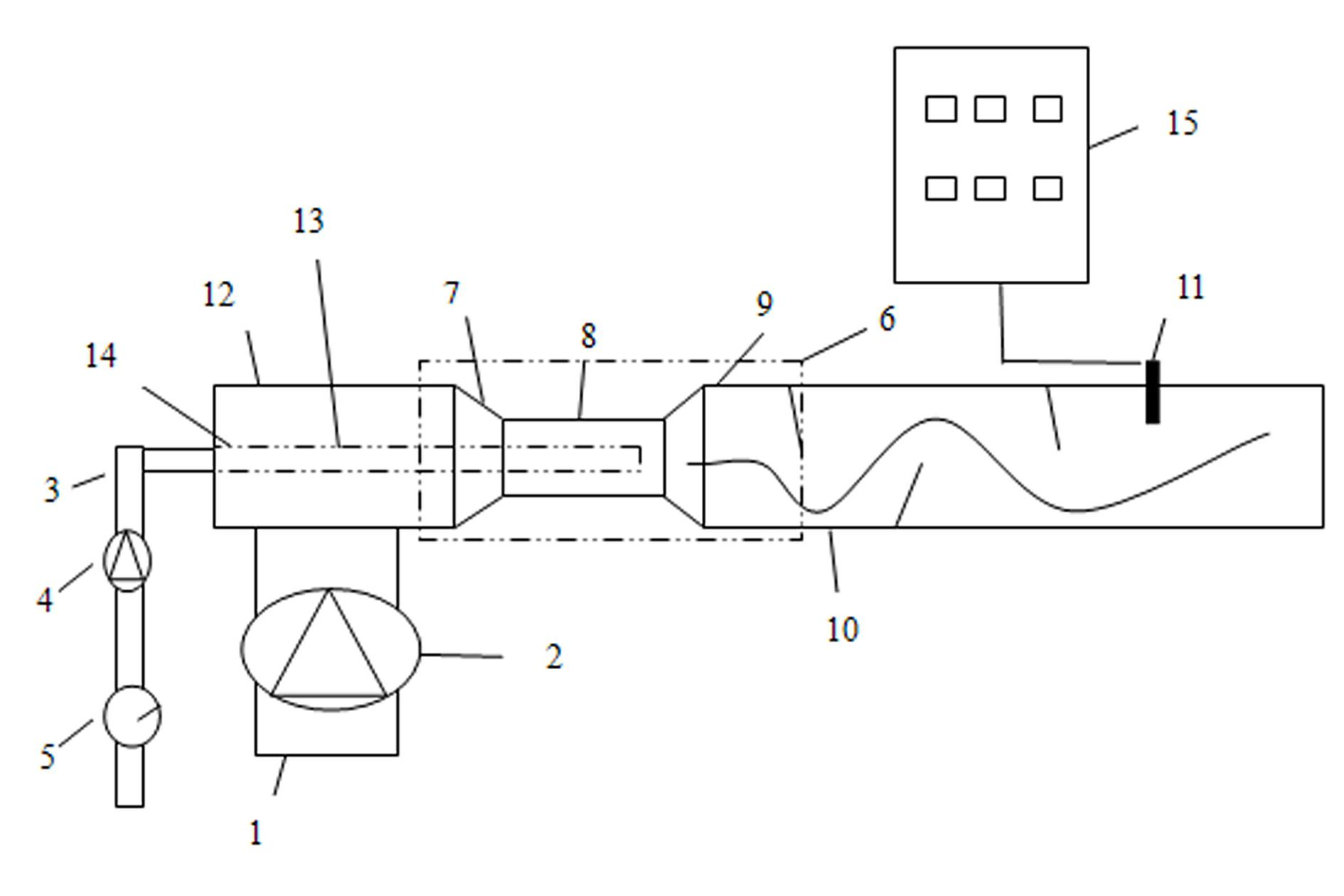

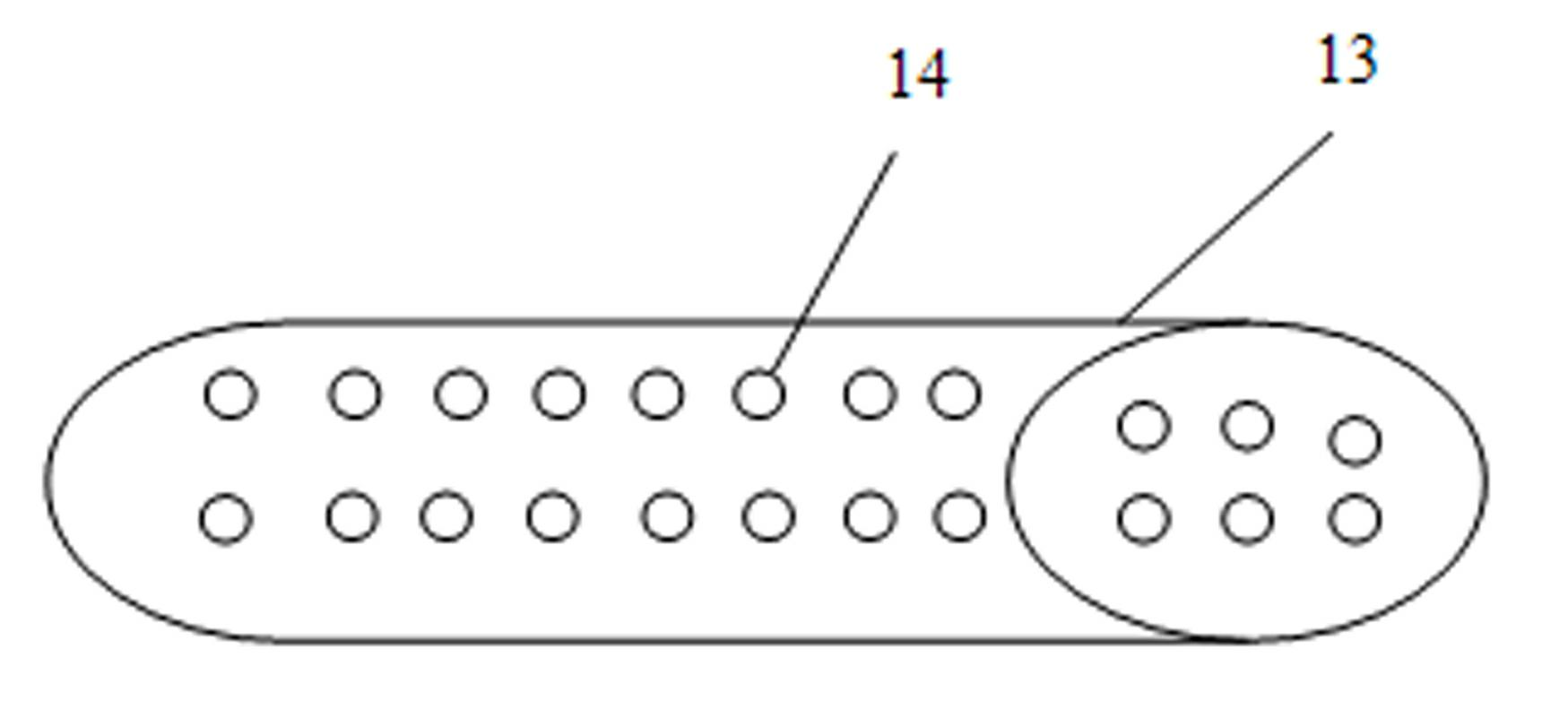

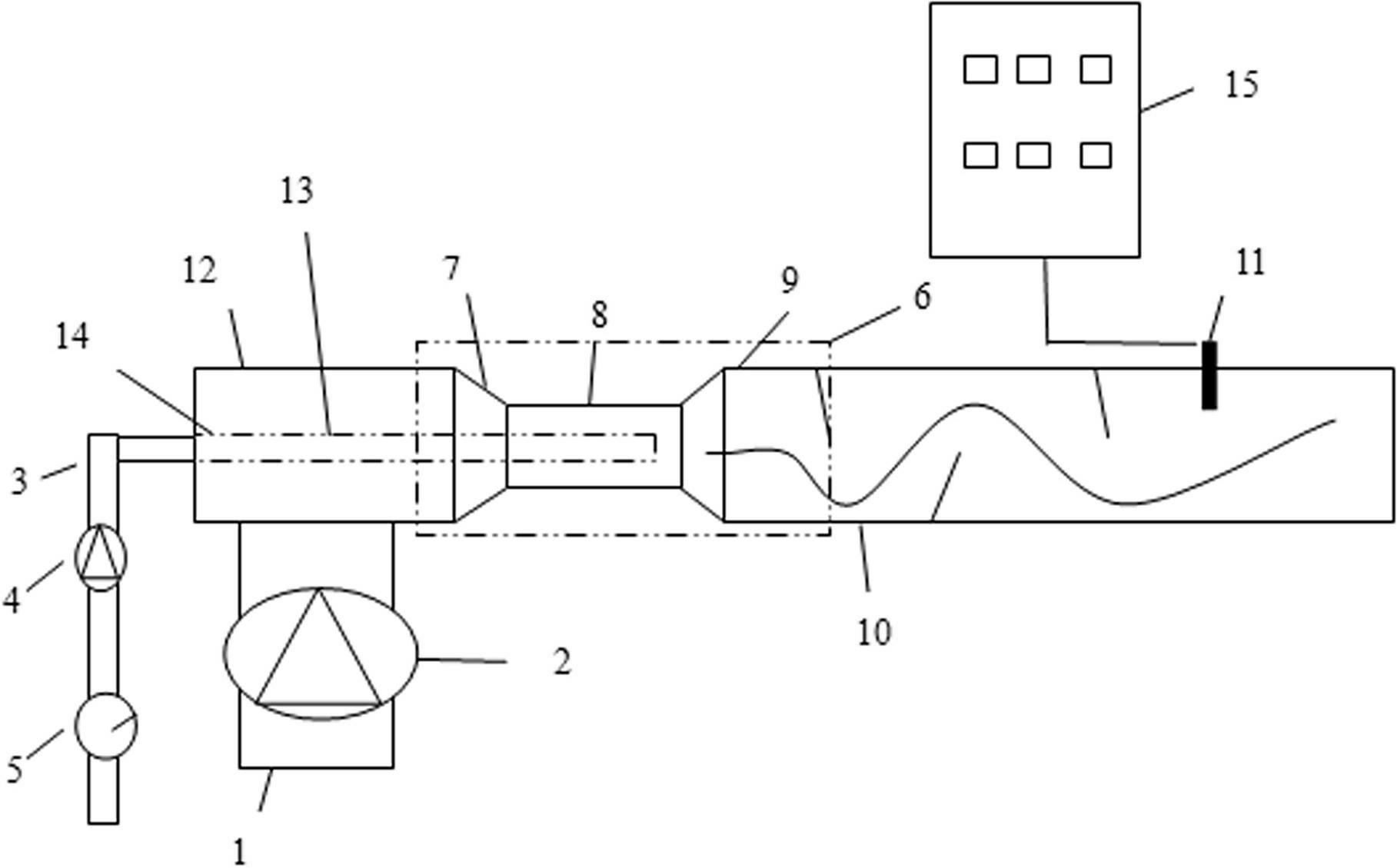

[0013] Automatic pipeline acid point device, including material pipeline 1, material frequency conversion pump 2, acid pipeline 3, dilute acid frequency conversion pump 4, filter 5 and Venturi tube 6 are installed at the front end of the dilute acid frequency conversion pump 4 on the acid pipeline 3 , a mixer 10, the Venturi tube 6 includes an inlet section 7, a throat 8, a diffuser section 9, the diffuser section 9 is connected to the mixer 10, and the inlet section 7 of the Venturi tube 6 is connected There is a pre-mixer 12, the inlet of the pre-mixer 12 is respectively connected with the acid pipeline 3 and the material pipeline 1, the acid spray pipeline 13 is arranged in the said pre-mixer 12, and one end of the acid spray pipeline 13 is connected with the acid pipeline. 3 connected, the other end of the acid spraying pipe 13 extends into the thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com