Fabricated cofferdam structure and construction method

A prefabricated and cofferdam technology, which is applied in the direction of infrastructure engineering, construction, sheet pile walls, etc., can solve the problem of material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

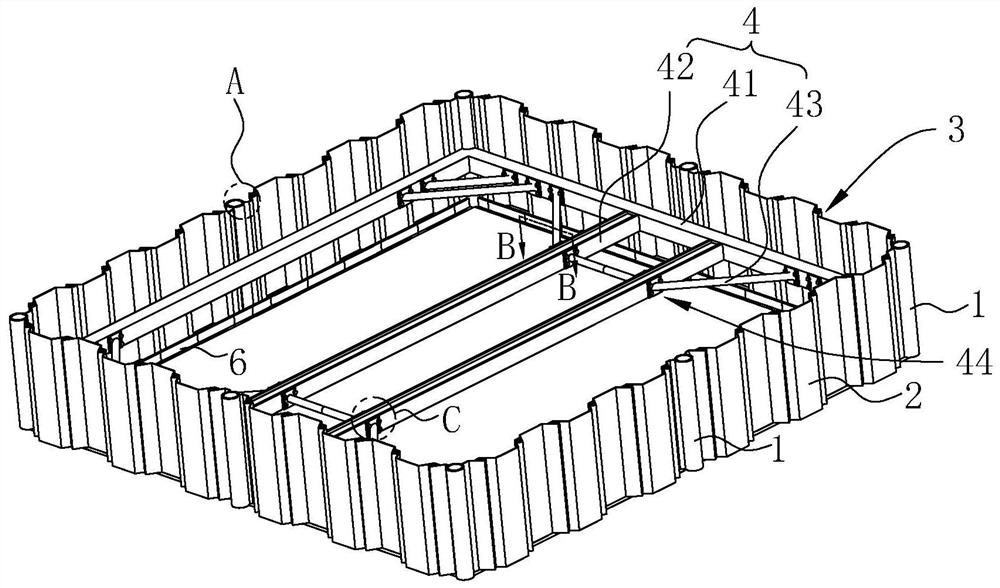

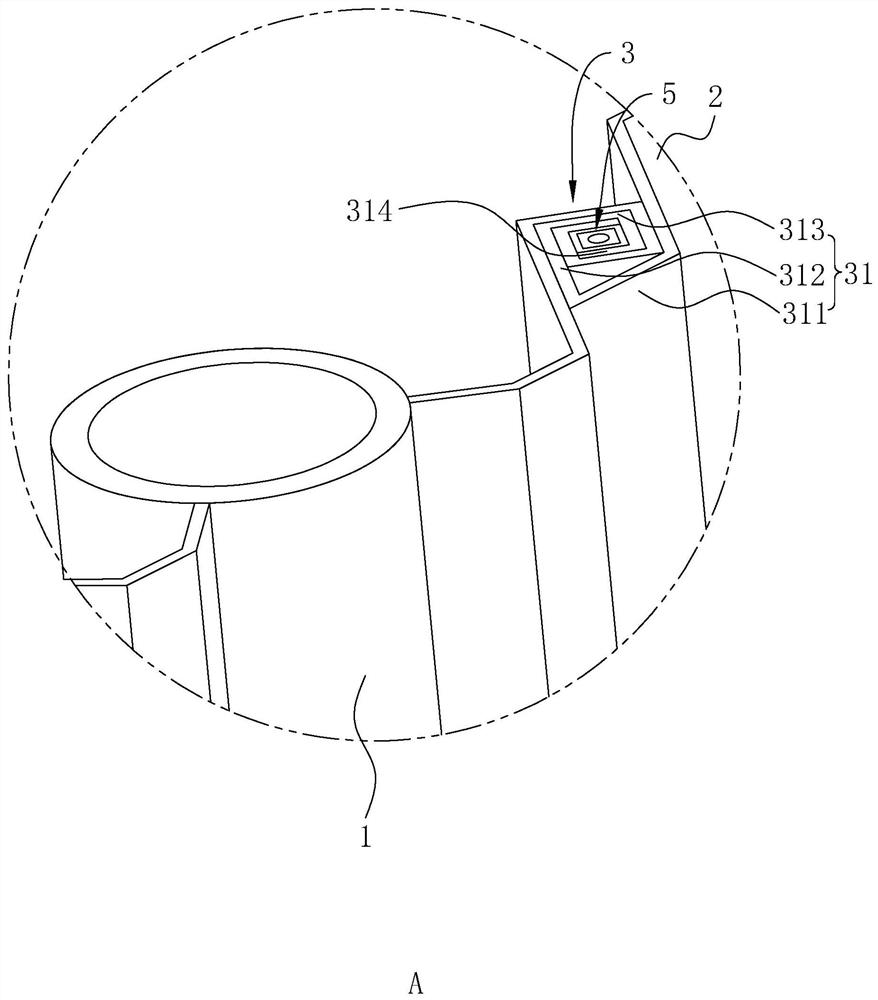

[0036] The following is attached Figure 1-6 The application is described in further detail.

[0037] The embodiment of the application discloses a prefabricated cofferdam structure.

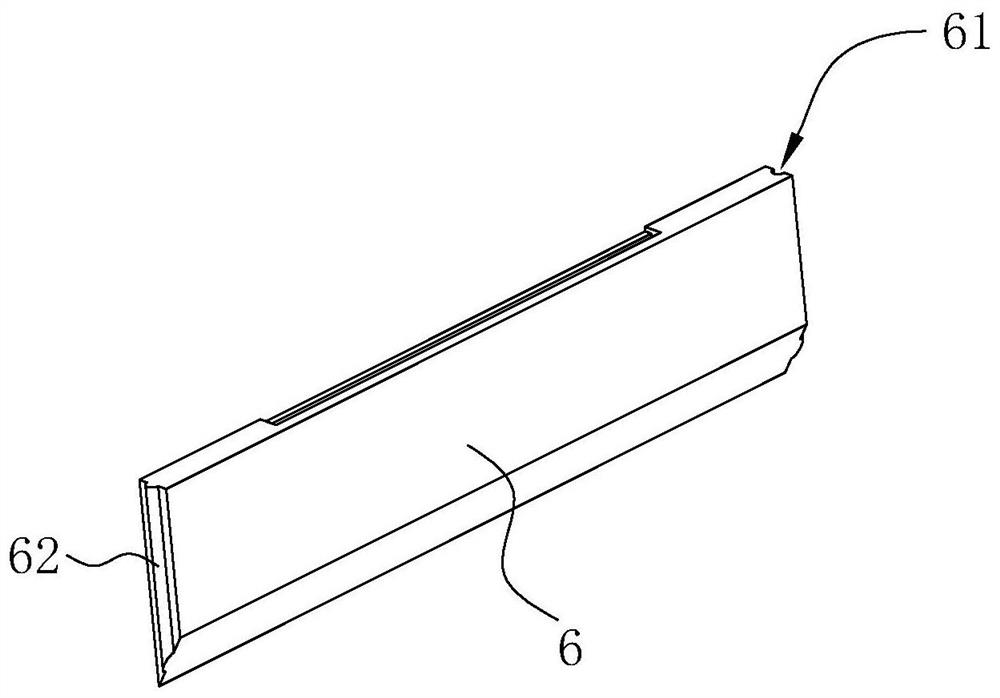

[0038] refer to figure 1 with figure 2 , The assembled cofferdam structure includes a plurality of vertically arranged steel casings 1 and at least one hanging box in a ring structure. A plurality of steel casings 1 are distributed along the circular contour of the suspension box, the suspension box includes a plurality of cofferdam steel plates 2, and the plurality of cofferdam steel plates 2 are divided into multiple groups, and each group contains a plurality of cofferdam steel plates 2 and multiple cofferdam steel plates 2 in the same group A cofferdam steel plate 2 is arranged between two adjacent steel casings 1 .

[0039] In addition, in order to facilitate the disassembly of the cofferdam steel plate 2 relative to the back cover concrete in the later stage, the bottom of the cofferdam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com