Neutral erasable ink composition and preparation method thereof

An ink composition and neutral technology, applied in the direction of ink, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of insufficient ball milling, low ball mill efficiency, uneven particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

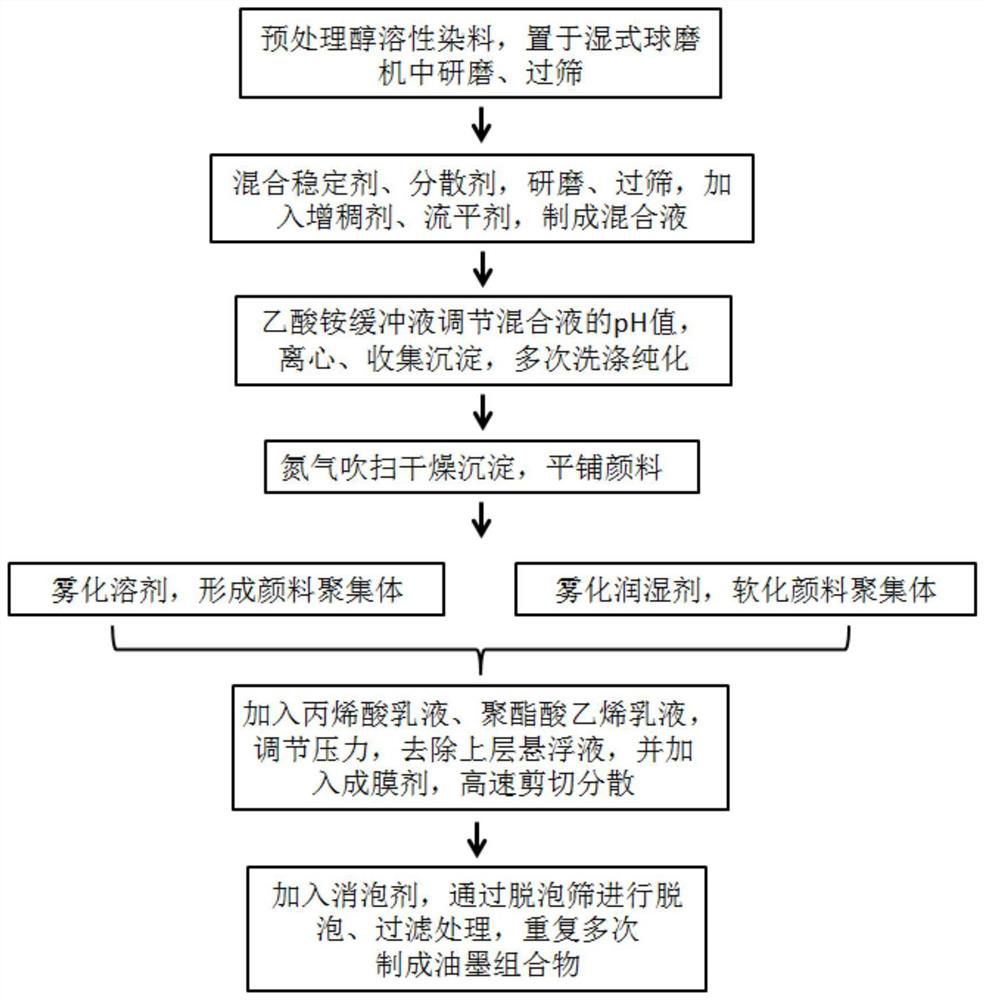

[0072] S1, pre-treating the alcohol-soluble dye, weighing 3% alcohol-soluble nigrosine in a proportion by weight, placing it in a wet ball mill, grinding for 10 minutes, and then passing through a 100-mesh sieve;

[0073] S2. Prepare a mixed solution, weigh the stabilizer and dispersant in parts by weight, 0.5% sodium alginate, and 10% sodium methylene dinaphthalene sulfonate, mix them in a wet ball mill, grind for 10 minutes, and then pour them again Add 0.5% polyacrylic acid, 0.5% polyacrylamide, and 0.5% octylphenol, adjust the stirring rate to 400rpm, and stir for 10min, so that the viscosity of the mixture is 0.01-0.05cP;

[0074] S3, centrifuge and wash the mixed solution, use ammonium acetate buffer to adjust the pH value of the mixed solution in the range of 7.0-7.5, then let it stand at room temperature for 1-2h, place the mixed solution in a centrifuge for centrifugation, and adjust the centrifugal speed Centrifuge at 3000rpm for 10min, repeat the centrifugation thre...

Embodiment 2

[0083] S1, pretreating the alcohol-soluble dye, weighing 5% alcohol-soluble nigrosine, placing it in a wet ball mill, grinding for 15 minutes, and then passing through a 100-mesh sieve;

[0084] S2. Prepare the mixed solution, take the stabilizer and dispersant in parts by weight in proportion, 0.8% sodium alginate, 12% sodium methylene dinaphthalene sulfonate, mix them in a wet ball mill, grind for 15min, and then pour Add 0.75% polyacrylic acid, 0.75% polyacrylamide, and 0.75% octylphenol, adjust the stirring rate to 500rpm, and stir for 15min, so that the viscosity of the mixture is 0.01-0.05cP;

[0085]S3, centrifuge and wash the mixed solution, use ammonium acetate buffer to adjust the pH value of the mixed solution in the range of 7.0-7.5, then let it stand at room temperature for 1-2h, place the mixed solution in a centrifuge for centrifugation, and adjust the centrifugal speed Centrifuge at 4000rpm for 12min, repeat the centrifugation three times, collect the precipita...

Embodiment 3

[0094] S1, pretreating the alcohol-soluble dye, weighing 7% alcohol-soluble nigrosine, placing it in a wet ball mill, grinding for 20 minutes, and then passing through a 100-mesh sieve;

[0095] S2. Prepare a mixed solution, weigh the stabilizer and dispersant in parts by weight, 1.0% sodium alginate, 15% sodium methylene dinaphthalene sulfonate, mix them in a wet ball mill, grind for 20min, and then pour them again Add 1.0% polyacrylic acid, 1.0% polyacrylamide, and 1.0% octylphenol, adjust the stirring rate to 600rpm, and stir for 20min, so that the viscosity of the mixture is 0.01-0.05cP;

[0096] S3, centrifuge and wash the mixed solution, use ammonium acetate buffer to adjust the pH value of the mixed solution in the range of 7.0-7.5, then let it stand at room temperature for 1-2h, place the mixed solution in a centrifuge for centrifugation, and adjust the centrifugal speed Centrifuge at 5000rpm for 15min, repeat the centrifugation three times, collect the precipitate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com