Water-based durable erasable ink and preparation method thereof

An ink and long-lasting technology, applied in the field of water-based long-lasting erasable ink and its preparation, can solve the problem of writing trace reproduction and other problems, and achieve the effect of bright writing and high storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

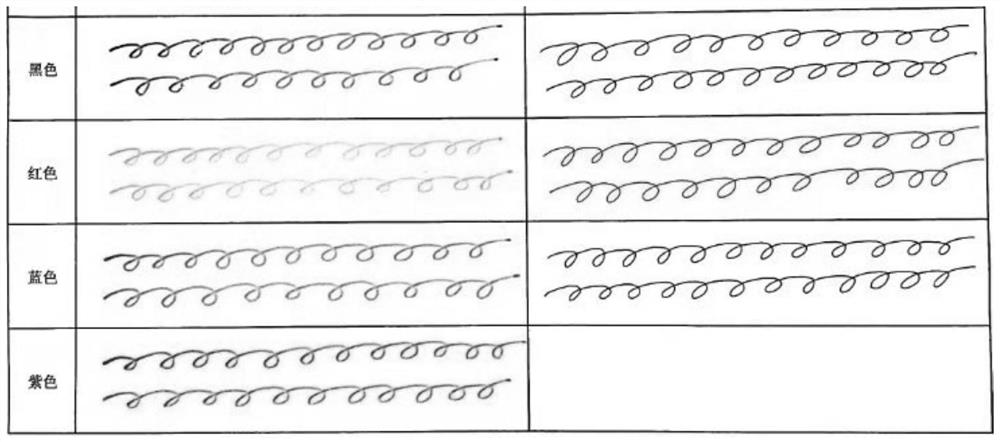

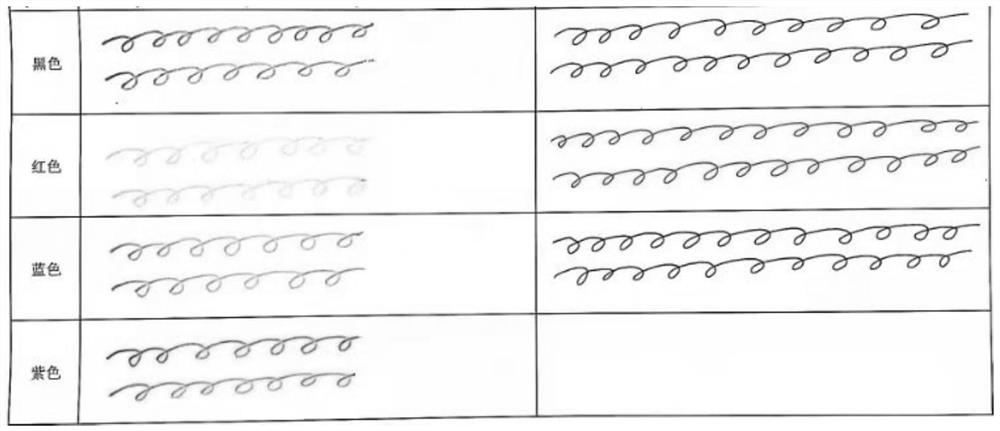

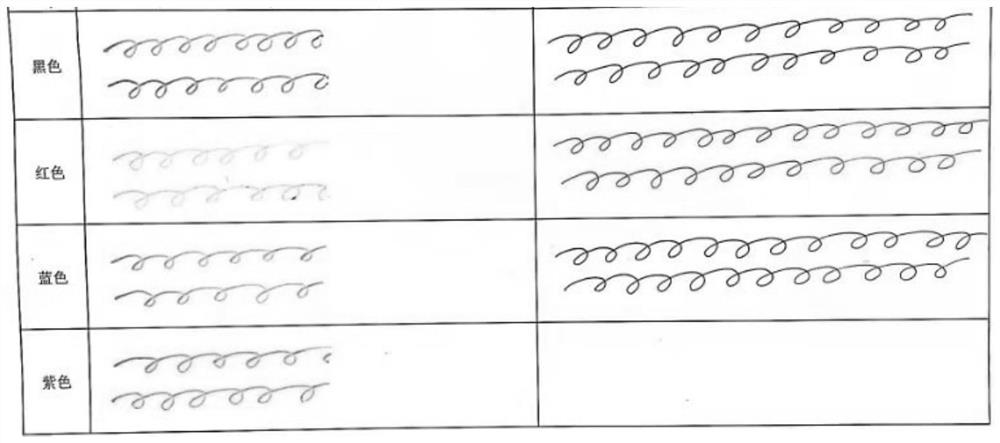

Image

Examples

Embodiment 1

[0045] Example 1: Red ink

[0046] (a) Add 2% glycerin, 19% peelable resin PRIMAL PC-25, 4% dispersant DISPERBYK-2080 and 70% deionized water to the reaction kettle at the same time, then stir at room temperature for 10 minutes, Then add 2% GW-G25, and continue stirring for 1.5 hours;

[0047] (b) Under the condition of stirring, add 1% xanthan gum and 1% fumed silica successively, stir at room temperature for 1 hour, transfer to a sand mill after stirring, and grind until the average particle diameter is 600nm , D90 is 900nm.

[0048] (c) Under the condition of stirring, finally add 1% of wetting and leveling agent BYK-346, and stir at room temperature for 1 hour. Water-based ink that can be wiped on paper can be obtained by filtering with a 400-mesh filter cloth.

Embodiment 2

[0049] Example 2: Green ink

[0050] (a) Add 2.5% glycerin, 30% peelable resin PRIMAL PC-25, 4% dispersant DISPERBYK-2096 and 56.7% deionized water into the reaction kettle at the same time, stir at room temperature for 10 minutes, and then Add 4% GW-G21, and continue stirring for 1.5 hours;

[0051](b) Under the condition of stirring, add 0.8% xanthan gum and 1.2% fumed silica successively, stir at room temperature for 1 hour, transfer to a sand mill after stirring and grind until the average particle diameter is 580nm , D90 is 950nm.

[0052] (c) Under the condition of stirring, finally add 0.8% of wetting and leveling agent BYK-348, and stir at room temperature for 1 hour. Water-based ink that can be wiped on paper can be obtained by filtering with a 400-mesh filter cloth.

Embodiment 3

[0053] Embodiment 3: yellow ink

[0054] (a) 2% propylene glycol, 40% peelable resin NeoPac E-251, 5% dispersant DISPERBYK-2096 and 42.5% deionized water were simultaneously added to the reactor, then stirred at room temperature for 10 minutes, Then add 6% GW-G22, and continue stirring for 1.5 hours;

[0055] (b) Under stirring conditions, add 1.5% xanthan gum and 1.5% silicon dioxide successively, stir at room temperature for 1 hour, transfer to a sand mill after stirring and grind until the average particle size is 550nm, D90 is 880nm.

[0056] (c) Under the condition of stirring, finally add 1.5% of wetting and leveling agent BYK-348, and stir at room temperature for 1 hour. Water-based ink that can be wiped on paper can be obtained by filtering with a 400-mesh filter cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com