Microcapsule watercolor pen ink preparation method and preparation method of key materials

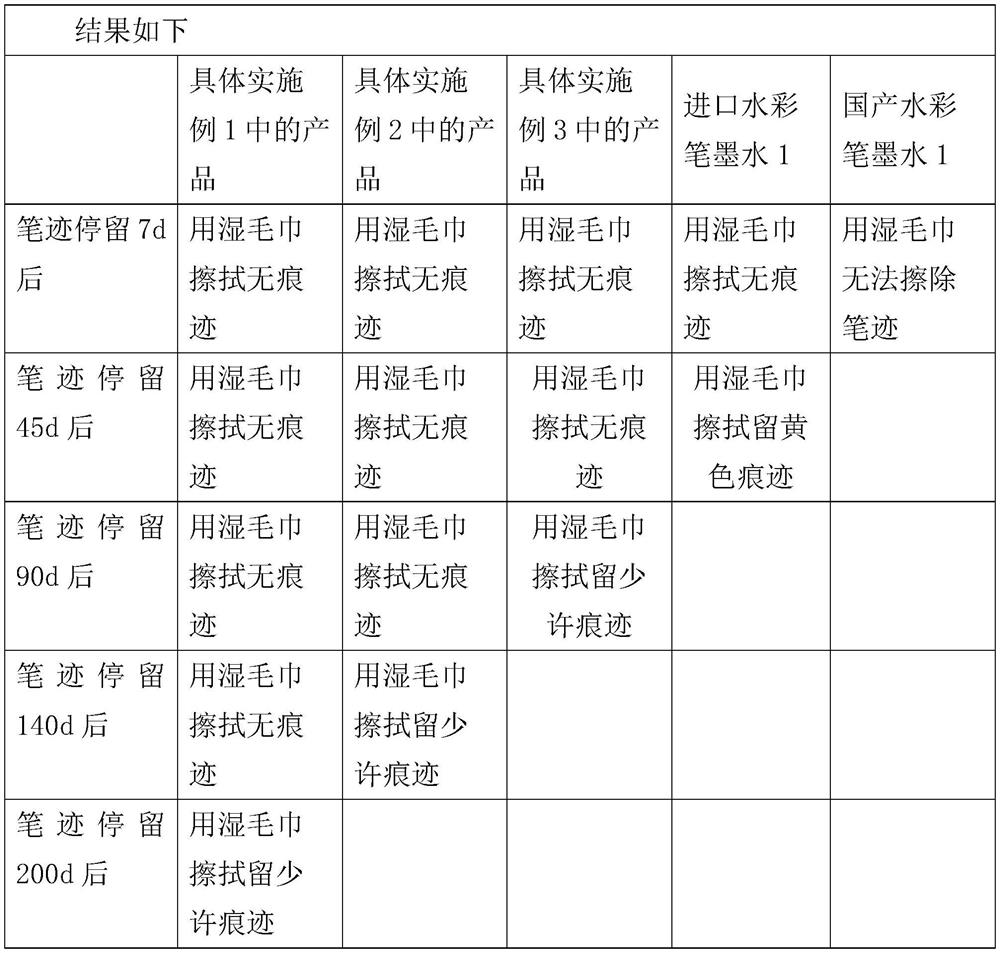

A pen-ink, capsule-type technology, applied in the field of new materials, can solve problems such as inability to erase cleanly, affecting the use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of color paste microcapsule core layer, comprises the steps:

[0015] Step 1: Mix sodium dodecylbenzenesulfonate, acrylic acid, ammonia water and water, add methyl methacrylate resin and organic pigment ultrafine powder under high shear emulsification and dispersion at 10000-20000r / min, and disperse for 10-40min , to prepare a nucleation seed emulsion, wherein, according to the mass percentage, sodium dodecylbenzenesulfonate is 2.5-5.5%, acrylic acid is 0.5-1.5%, ammonia water is 1-2%, and methyl methacrylate resin is 2.5-2.5% 5.5%, organic pigment superfine powder is 3-7%, and water is supplemented to 100%. The particle size of the organic pigment ultrafine powder is preferably 10-15 nm. The shearing time for dispersing the organic pigment ultrafine powder is preferably: 10-40min. Preferably, the mass percentages of organic pigment ultrafine powder, sodium dodecylbenzenesulfonate, methyl methacrylate resin, acrylic acid and ammonia water are 5:...

specific Embodiment

[0017] Step 1: Under high-speed dispersion conditions, add 4g of sodium dodecylbenzenesulfonate, 1g of acrylic acid, and 1.5g of ammonia in 50g of water in sequence, mix and emulsify and disperse. Methyl ester resin and 5 g of organic pigment ultrafine powder were slowly added, and after the addition of the pigment, the emulsification and dispersion were continued for 15 minutes, and the nucleation seed emulsion was prepared. The organic pigment ultrafine powder is preferably 10-15 nm. Stirring and mixing can be carried out by means of a Fluke high shear emulsification disperser with a rotating speed between 10000-30000r / min. In step 1, the organic pigment ultrafine powder can be added as required, and the color depth of the ink can be adjusted according to the addition amount of the organic pigment ultrafine powder, which can be carried out within 3-7%.

[0018] Step 2: Take a 500ml four-necked flask, install a tetrafluoro stirring paddle in the middle hole, a condenser tube...

specific Embodiment 1

[0024]Step 1: Under high-speed dispersion conditions, add 4g of sodium dodecylbenzenesulfonate, 1g of acrylic acid, and 1.5g of ammonia in 50g of water in sequence, mix and emulsify and disperse. Methyl ester resin and 5 g of organic pigment ultrafine powder were slowly added, and after the addition of the pigment, the emulsification and dispersion were continued for 15 minutes, and the nucleation seed emulsion was prepared. The organic pigment ultrafine powder is preferably 10-15 nm. Stirring and mixing can be carried out by means of a Fluke high shear emulsification disperser with a rotating speed between 10000-30000r / min. In step 1, the organic pigment ultrafine powder can be added as required, and the color depth of the ink can be adjusted according to the addition amount of the organic pigment ultrafine powder, which can be carried out within 3-7%.

[0025] Step 2: Take a 500ml four-necked flask, install a tetrafluoro stirring paddle in the middle hole, a condenser tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com