Cereal husk sifting device

A technology for sifting husks and grains, which is applied to the field of grain sifting and husk devices, can solve the problems of poor dust and rice husk treatment effect, affecting rice consumption, etc., and achieve the effects of avoiding human health damage, good dust removal effect and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

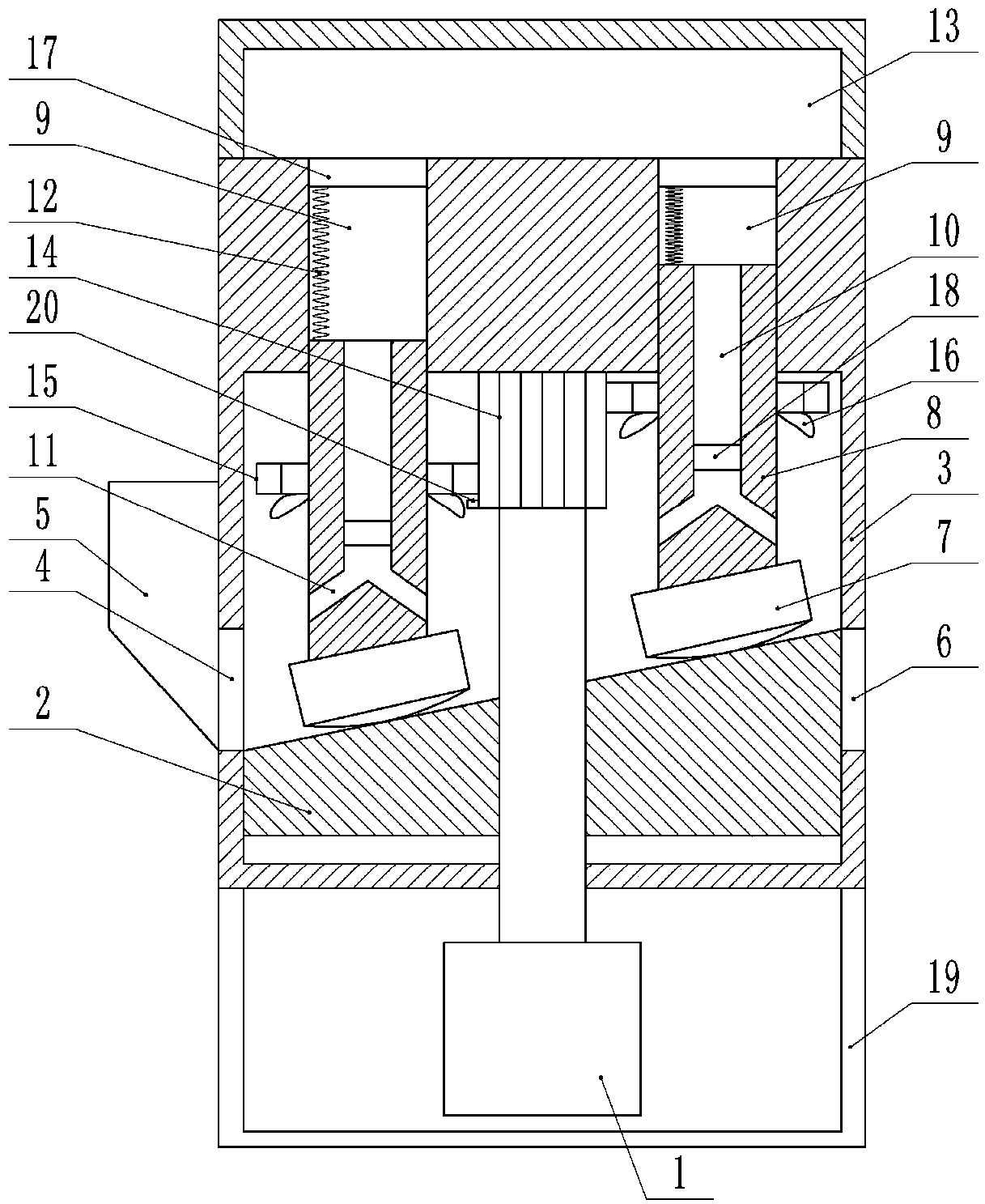

[0019] The reference signs in the accompanying drawings of the specification include: motor 1, abrasive disc 2, screen box 3, feed port 4, discharge box 5, discharge port 6, briquetting block 7, push rod 8, standpipe 9, suction Air pipe 10, suction hole 11, spring 12, waste box 13, first gear 14, second gear 15, impeller 16, first one-way valve 17, second one-way valve 18, frame 19, limit block 20.

[0020] Such as figure 1 Shown, a kind of grain sieve skin device comprises frame 19, sieve skin box 3 and at least one set of dust-absorbing mechanism, preferably two cover dust-absorbing mechanisms in the present embodiment; The motor 1 and the frame 19 are located above the motor 1 and are equipped with a sieve box 3 through bolts. The bottom of the sieve box 3 is provided with a shaft hole, and a bearing is installed in the shaft hole. The output shaft of the motor 1 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com