Patents

Literature

62results about How to "Improve inhalation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

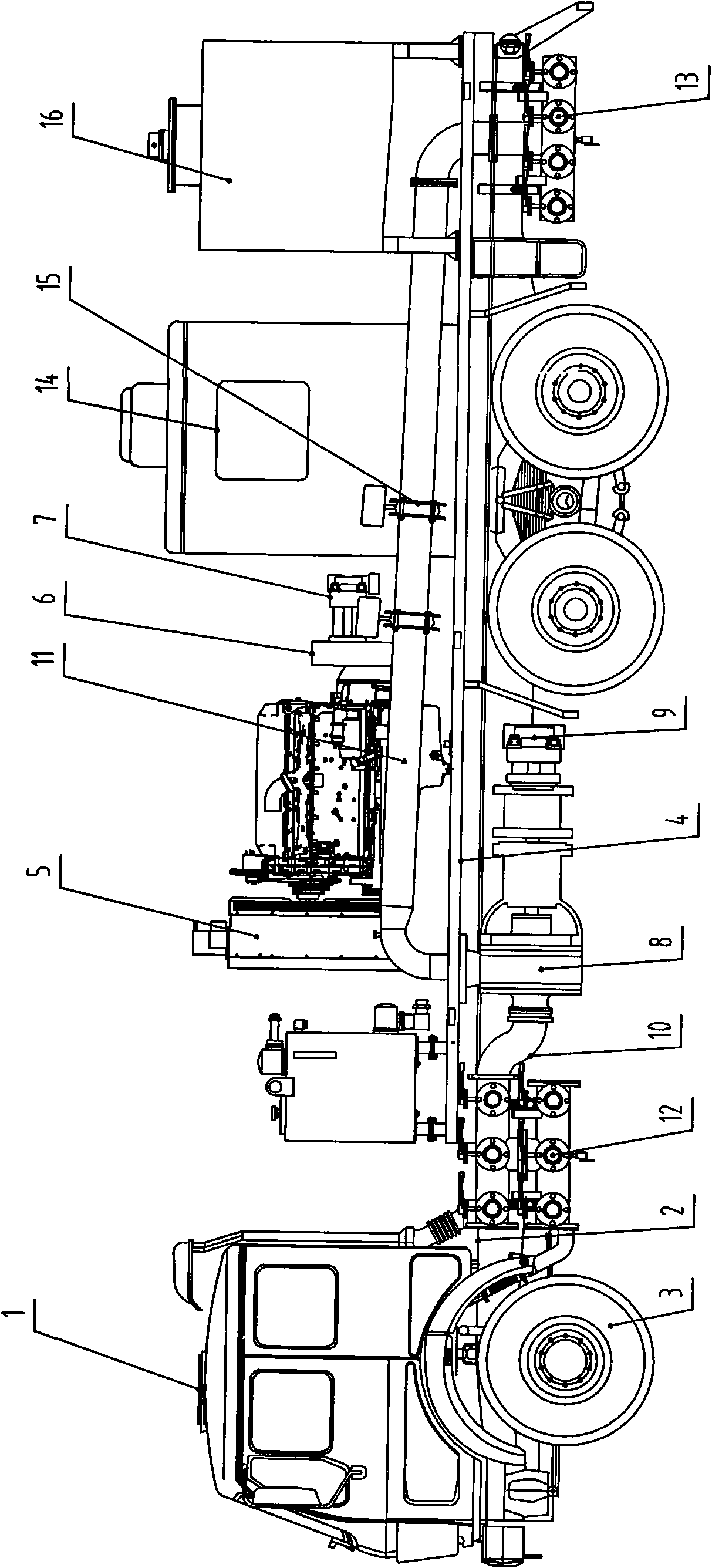

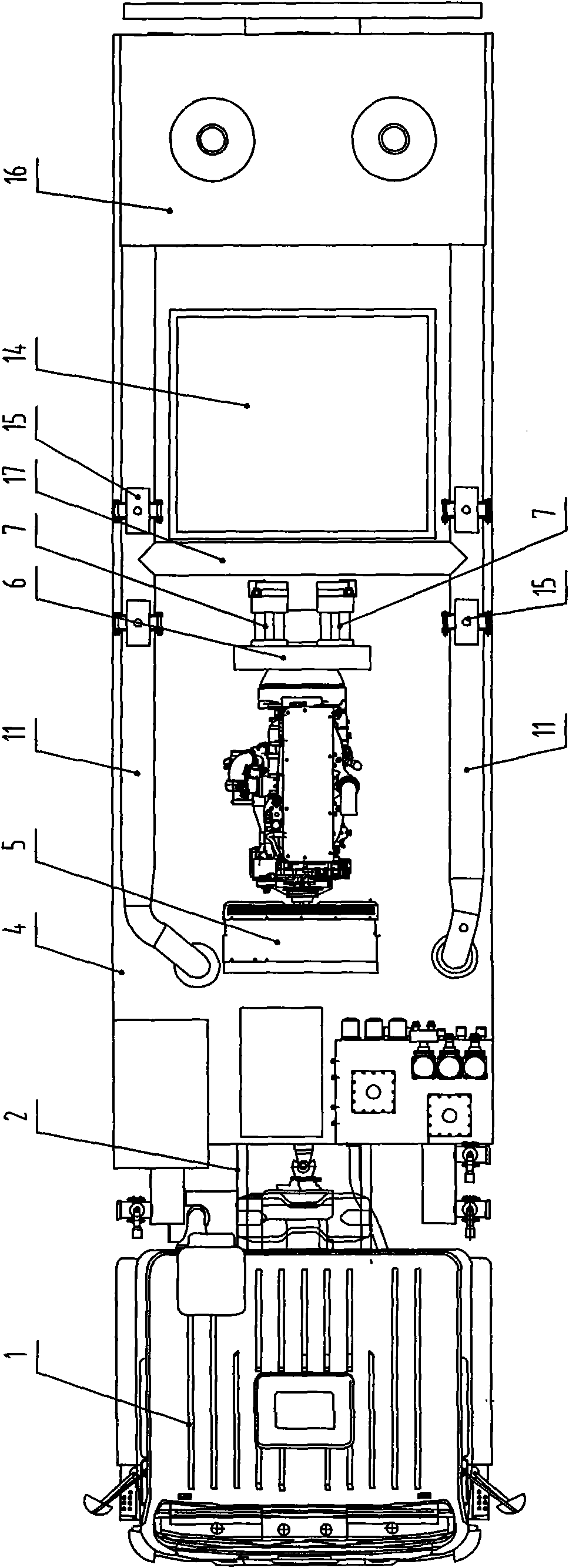

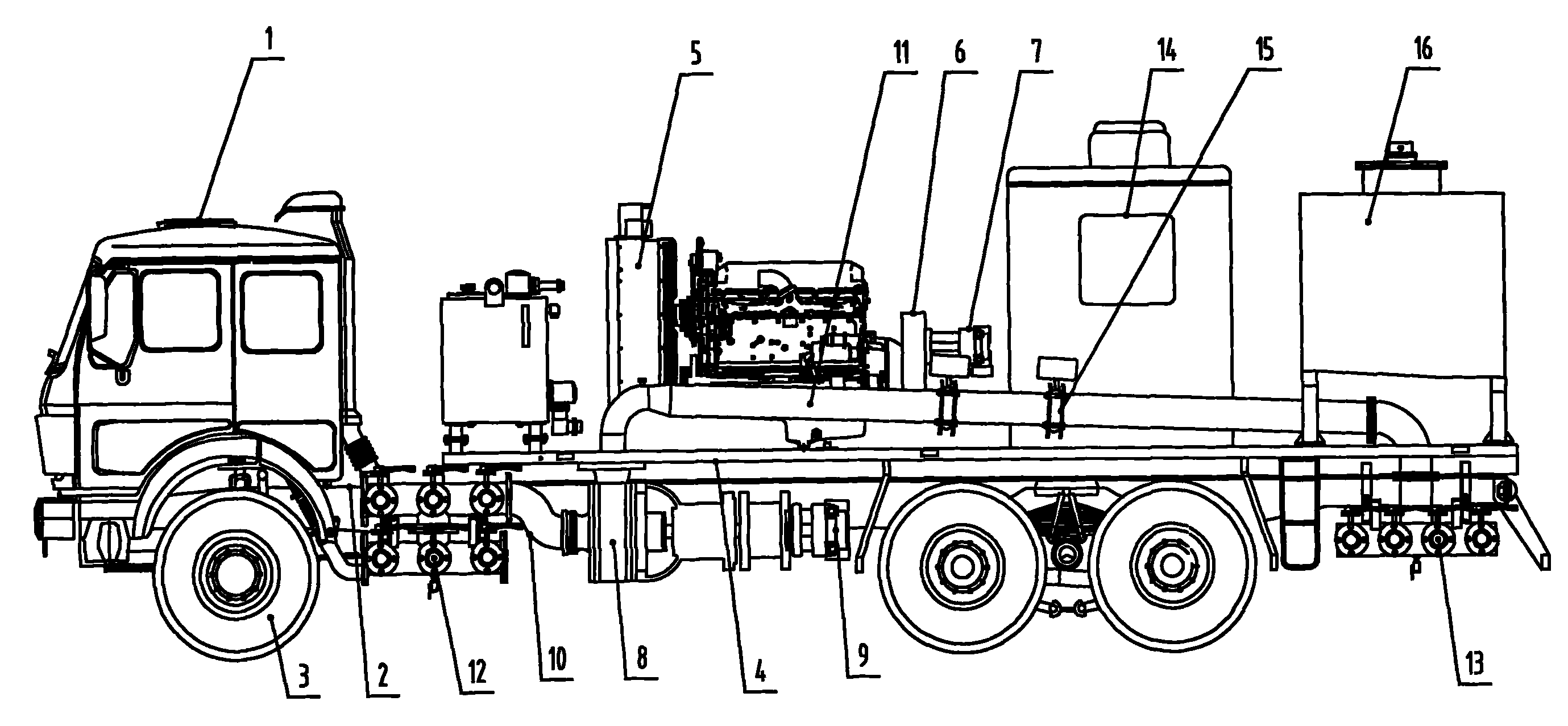

Liquid supply vehicle

ActiveCN101885307ALower suction heightImprove inhalation performanceFluid removalItem transportation vehiclesVehicle frameSewage

The invention discloses a liquid supply vehicle, which comprises a frame with a cab. The lower part of the frame is provided with wheels, the rear upper part of the frame is provided with a bedplate, a power driving device is arranged on the bedplate, a centrifugal pump is arranged below the bedplate, the power driving device is in transmission connection with the centrifugal pump, and an inlet and an outlet of the centrifugal pump are connected with a suction pipe and a discharge pipe respectively. The liquid supply vehicle has the advantages of improving the self-sucking effect of a fracturing truck, improving the operation efficiency of the fracturing truck and shortening the operation time, along with reasonable design, simple structure, easy assembly and manufacture, and also can be used for liquid delivery in other industries of flood drainage, sewage clearing and the like.

Owner:ZYT GASOLINEEUM EQUIP

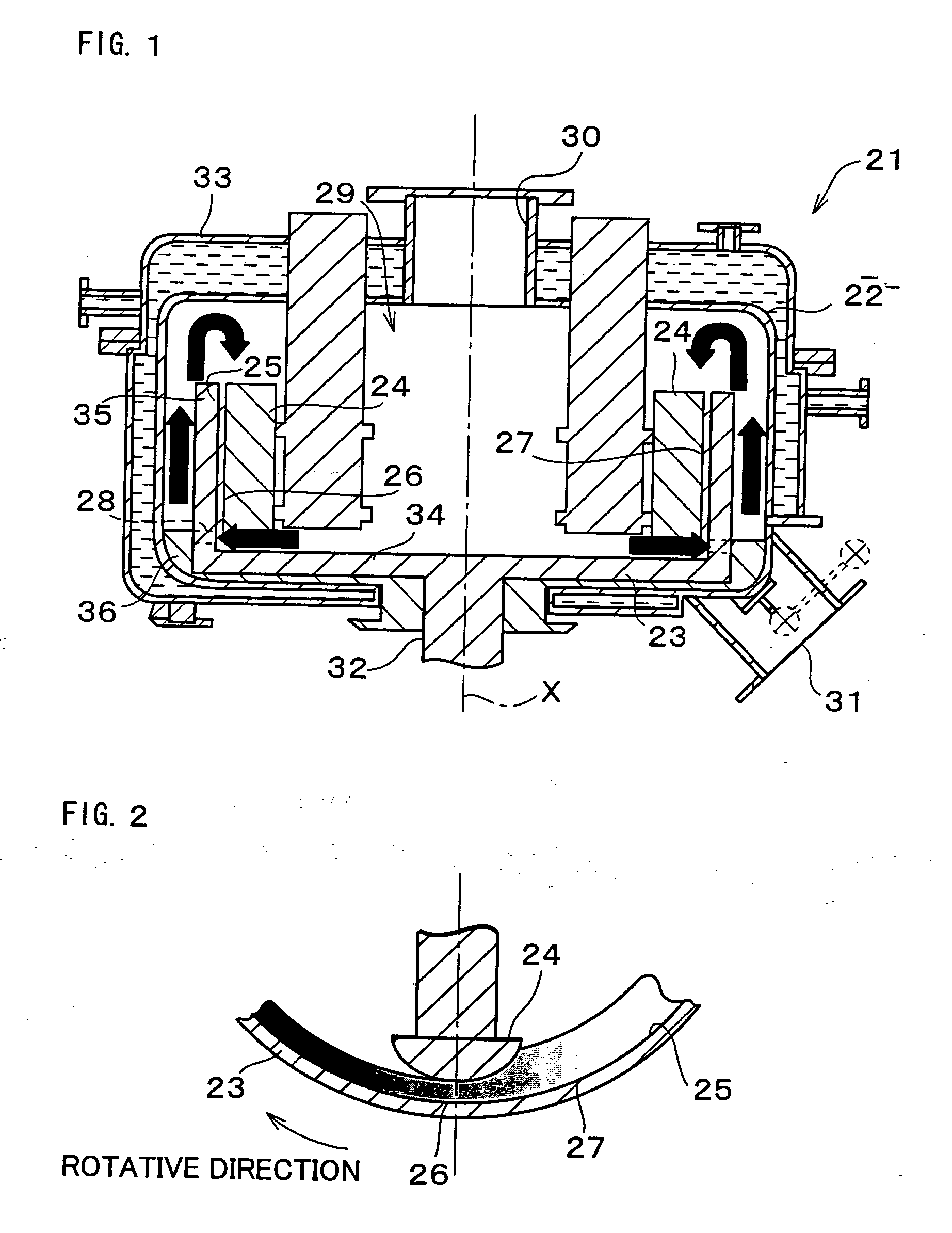

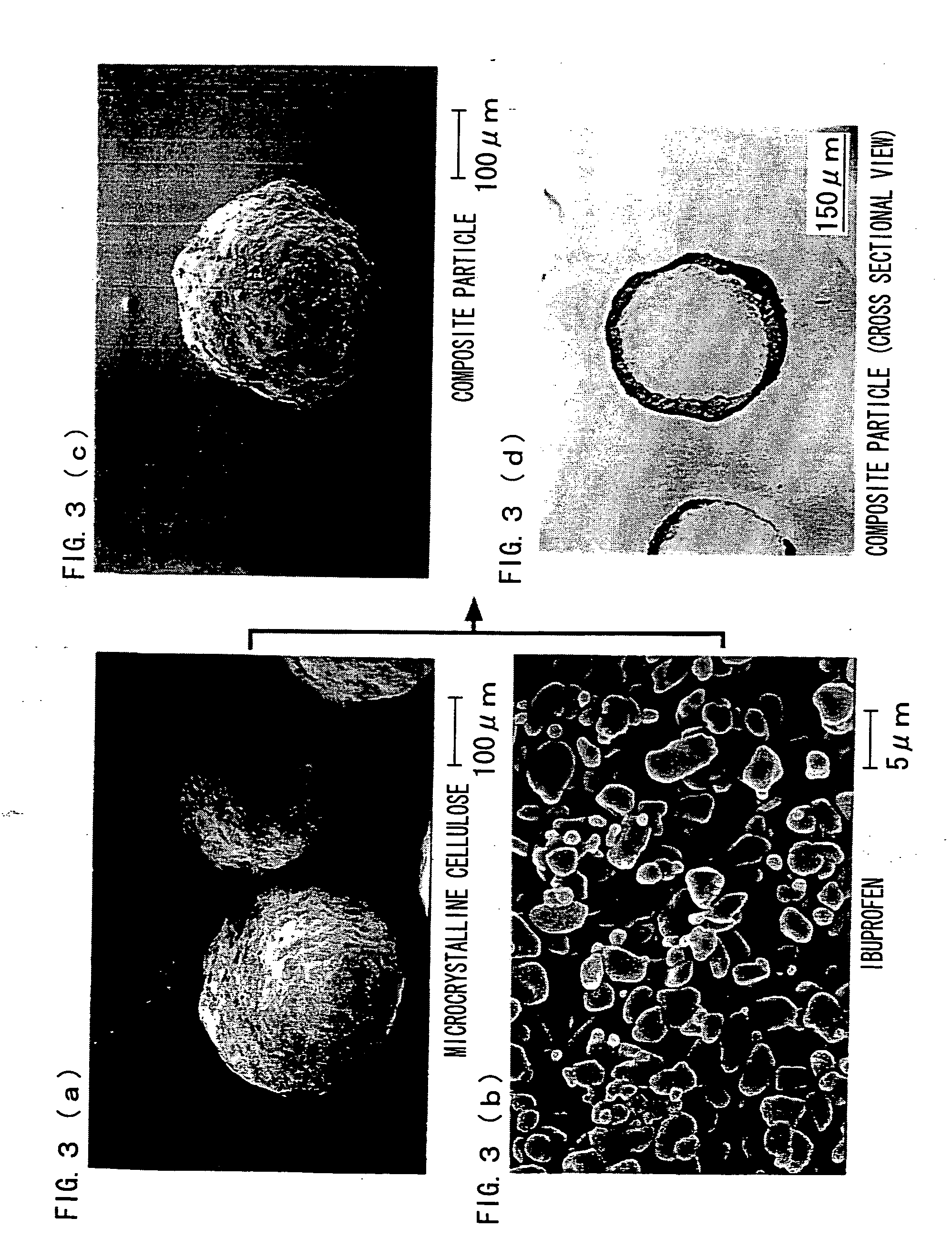

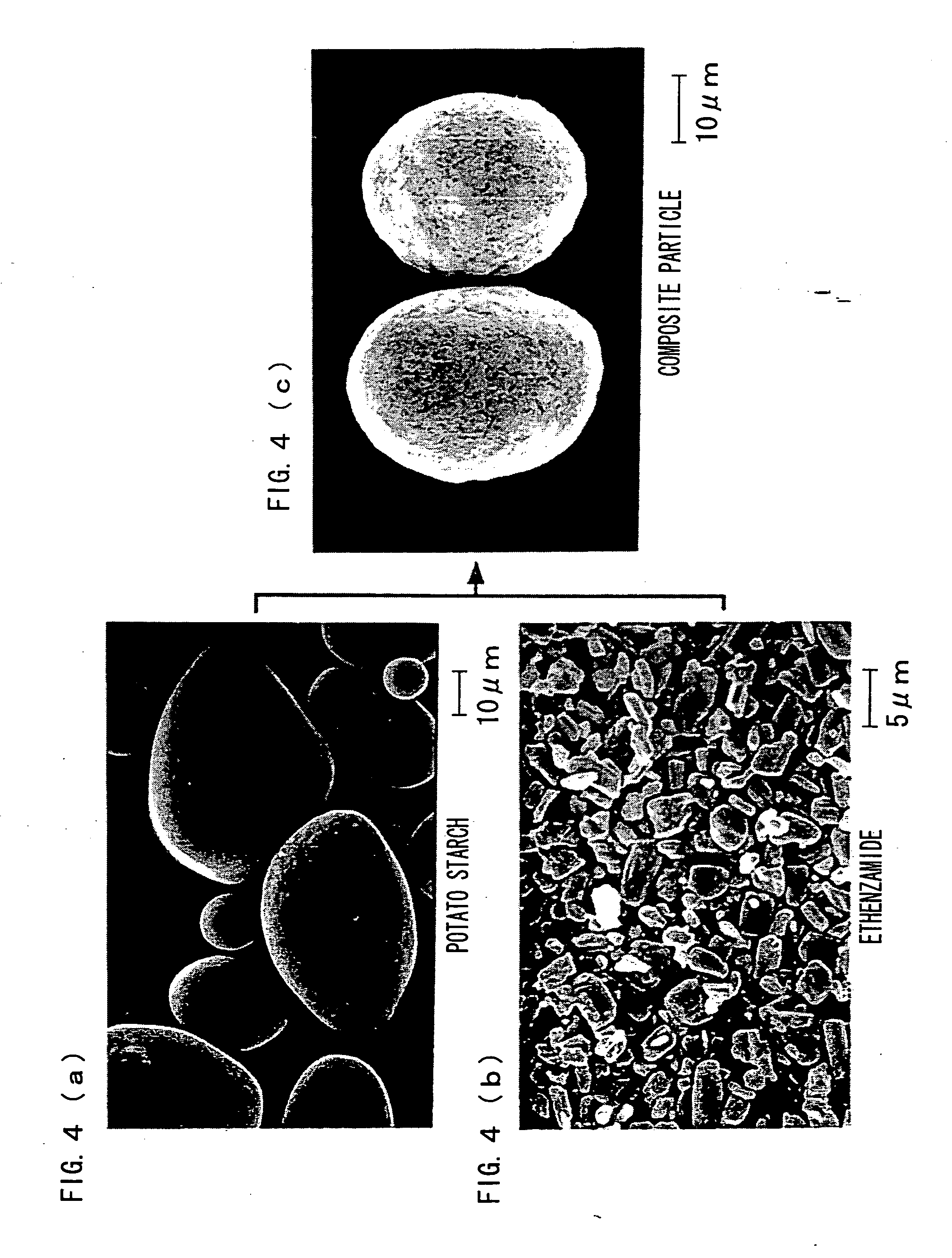

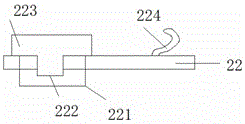

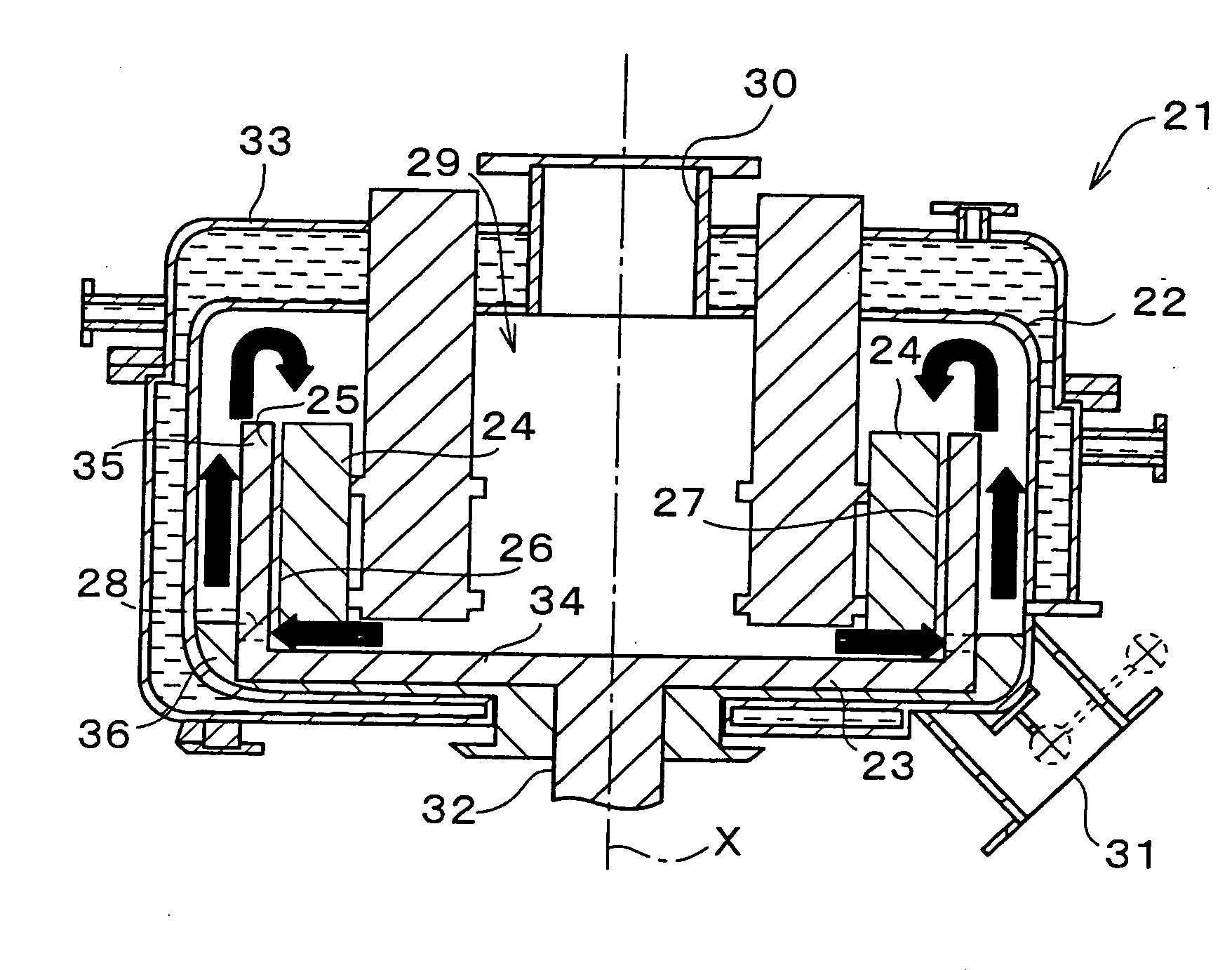

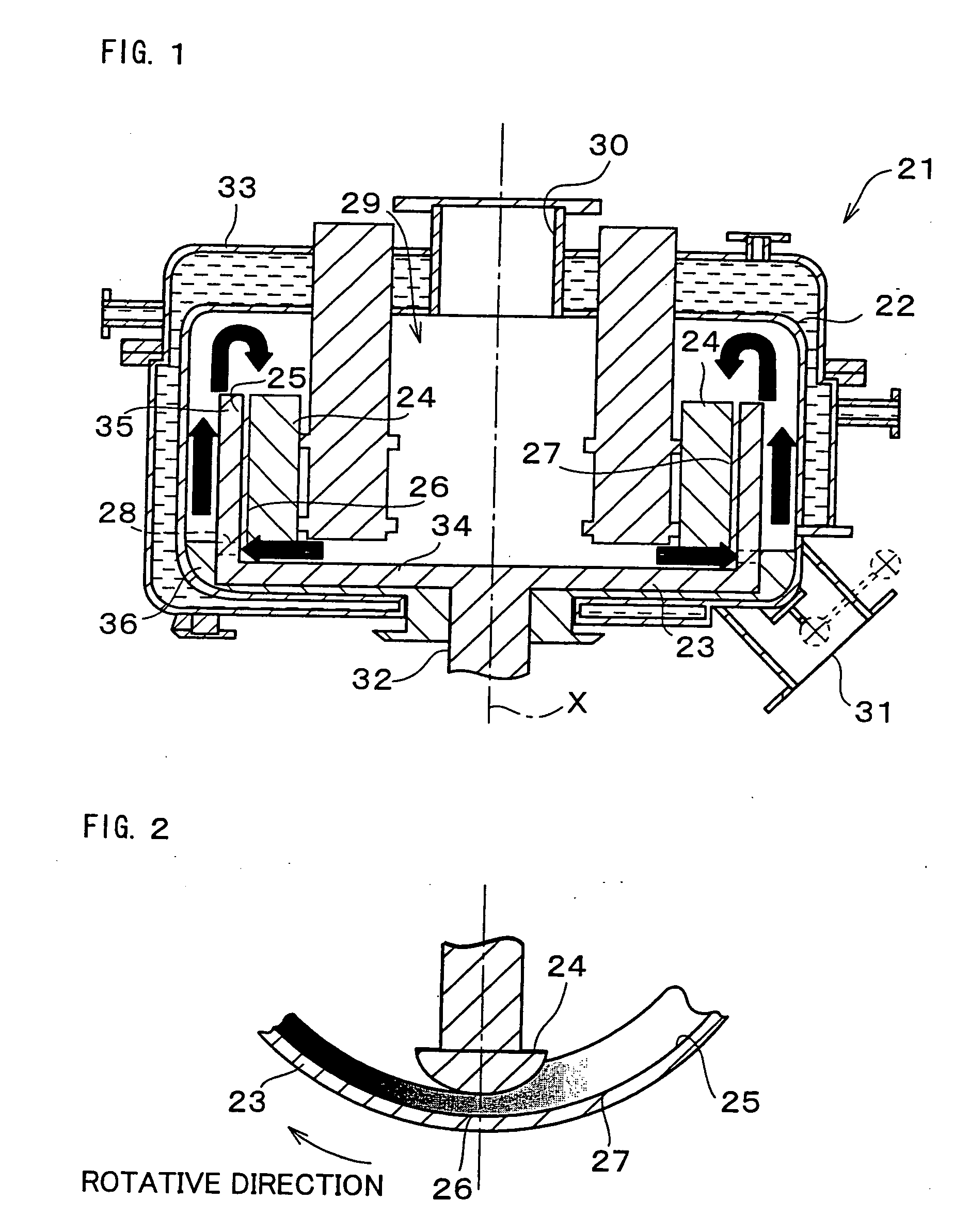

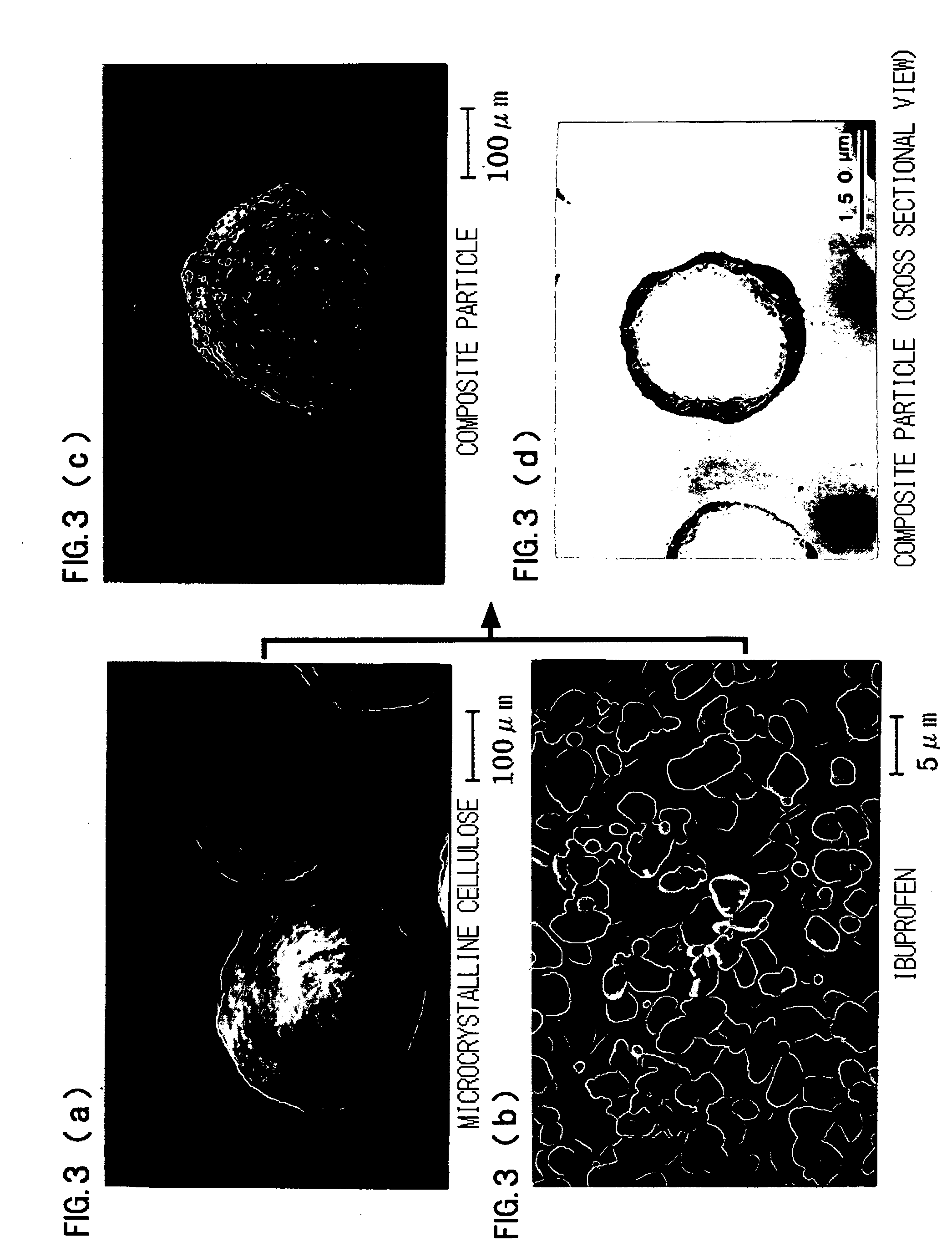

Method of manufacturing chemical-containing composite particles

InactiveUS20050191357A1Easy to useFine surfacePowder deliveryOrganic active ingredientsNanoparticleCompound (substance)

A strong pressure and a strong shearing force are exerted to a mixture, constituted of two kinds or more of powder materials including a drug powder, while causing the mixture to pass between a press section (26) of a press head (24) and a receiving surface (25) of a cylindrical rotator (23), thereby combining the drug powder with the other powder material. For example, at least one of a drug and a biocompatible polymer is made into a nano particle whose average particle diameter is less than 1000 nm, and the nano particle is made into a composite in accordance with a dry mechanical particle combining method, so as to form a polymer nano composite particle. Thus, it is possible to produce a composite particle, which contains a drug under a stable condition, in a short time, and it is possible to remarkably improve its handling property without losing advantages of the nano particle. As a result, it is possible to favorably apply the foregoing technique to DDS of a powdery drug taken into the body through the lung or a similar drug.

Owner:HOSOKAWA MICRON CORP

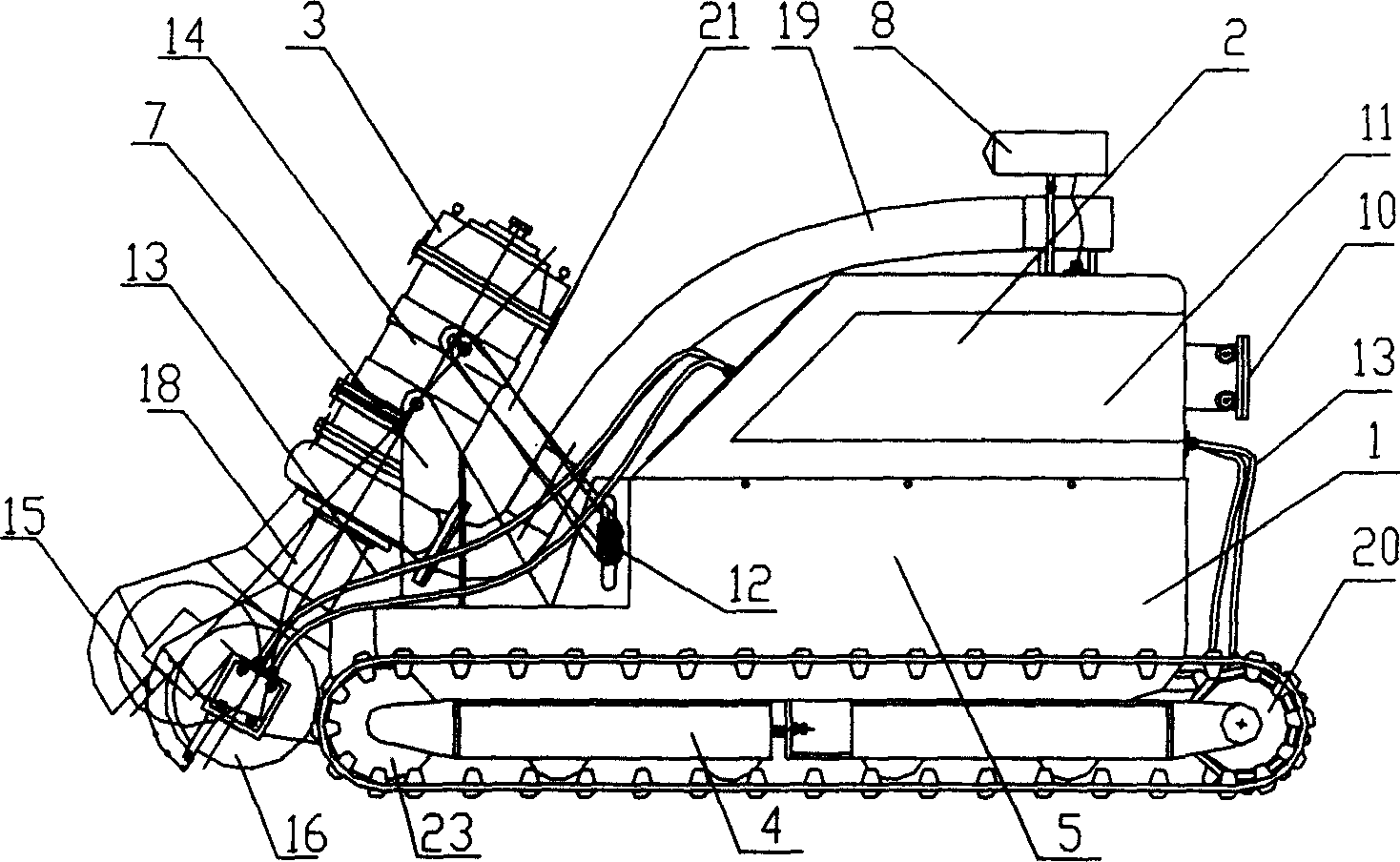

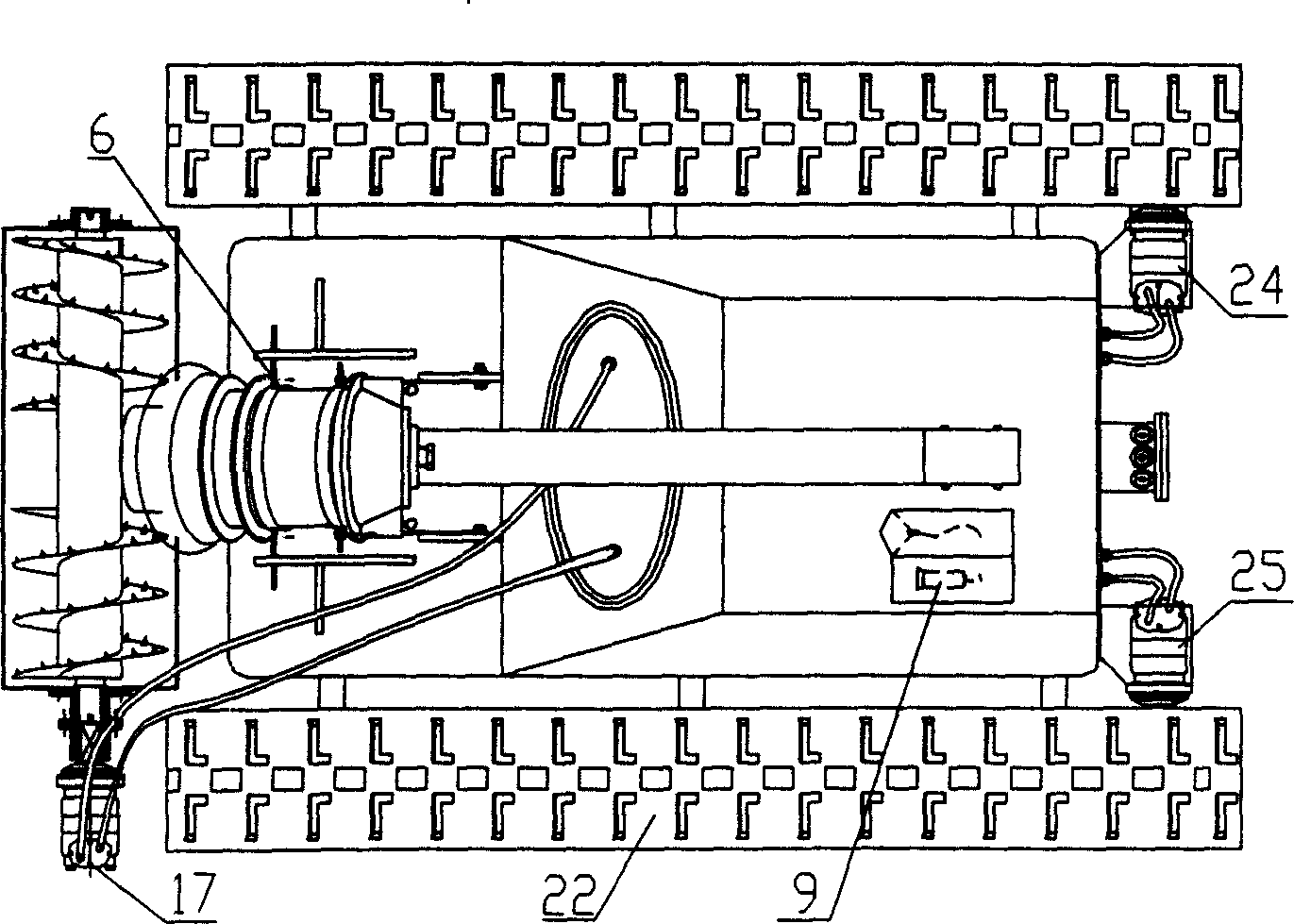

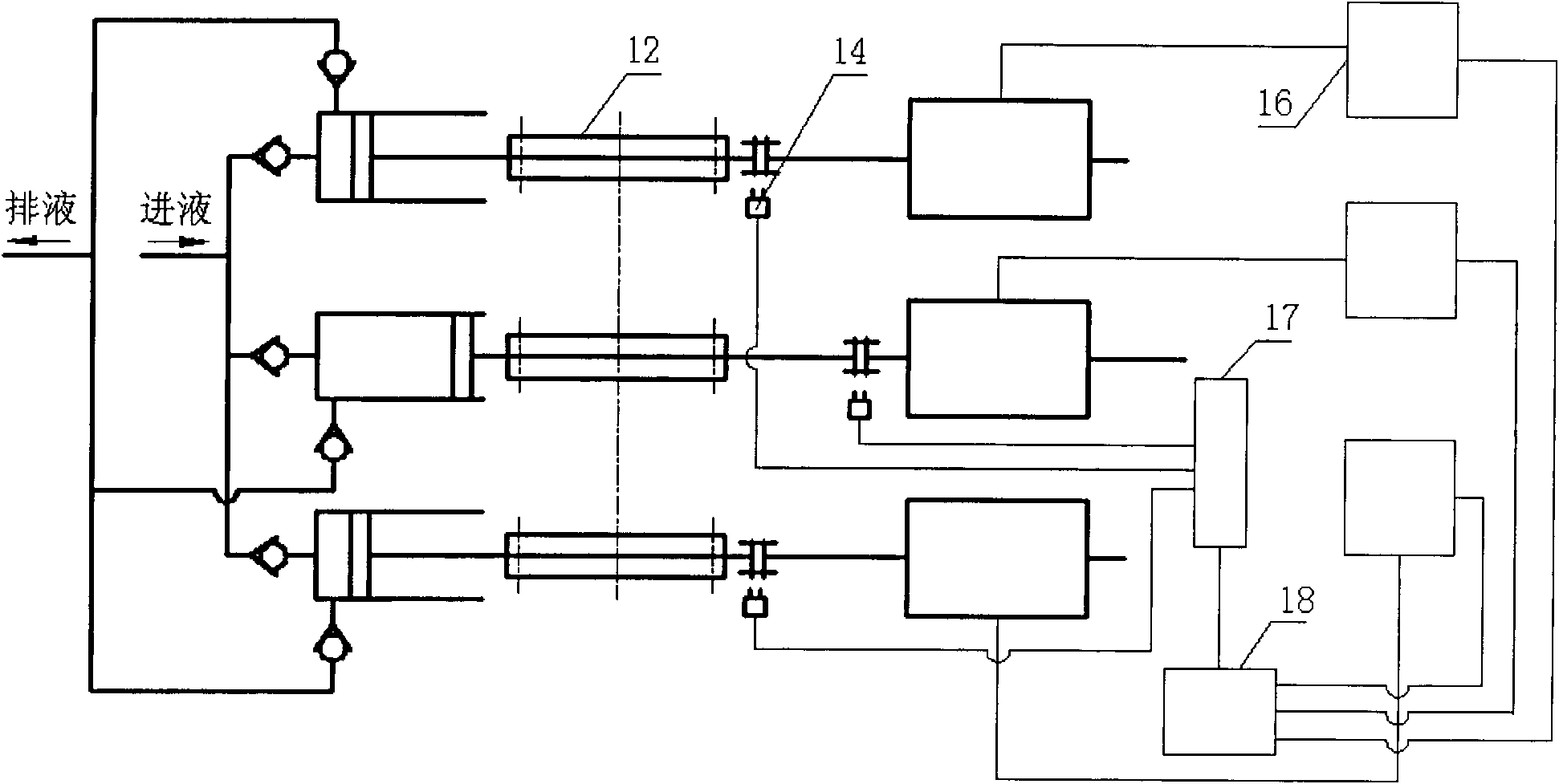

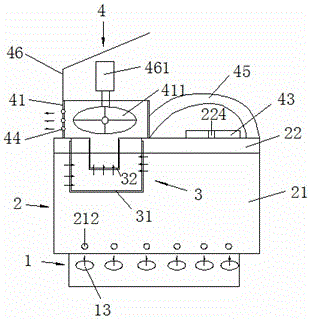

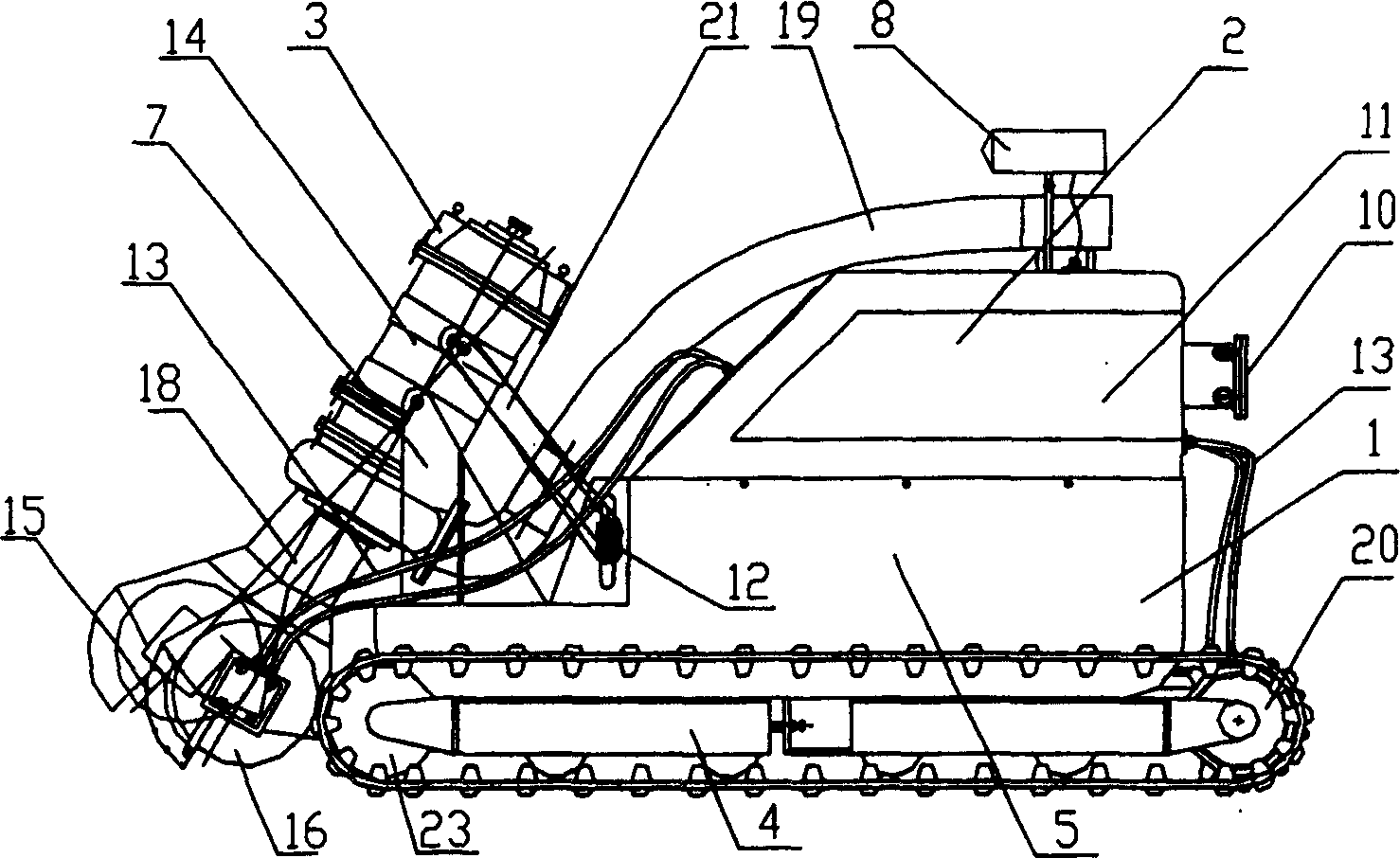

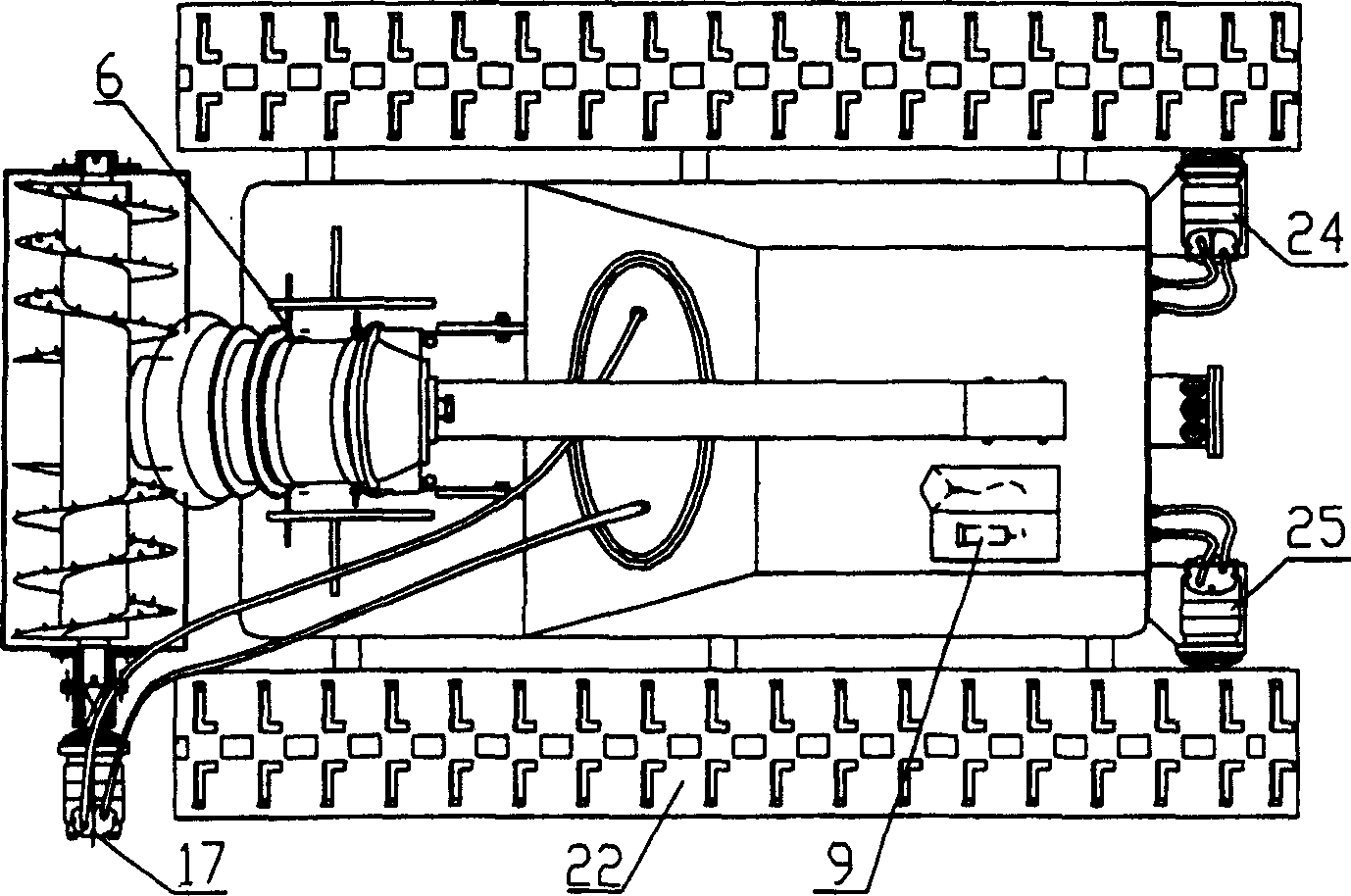

Crawler-type under water ecological precision thin layer slurry dredger

InactiveCN1554833A"Endogenous" Pollution ControlLarge footprintMechanical machines/dredgersSludgeControl system

The present invention belongs to the field of environment protecting technology. The crawler-type underwater ecological precise thin-layer sludge dredger consists of main system, hydraulic control system, sludge sucking system in front of the main system, and walking system below the main system. The main system includes box, support rods, frame, lighting unit and video monitor. The present invention has small size, light weight, simple structure and easy operation, and is suitable for dredging sludge in river, lake, reservoir, etc.

Owner:章永泰

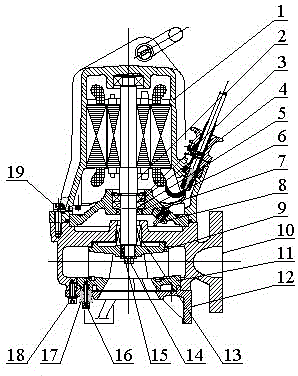

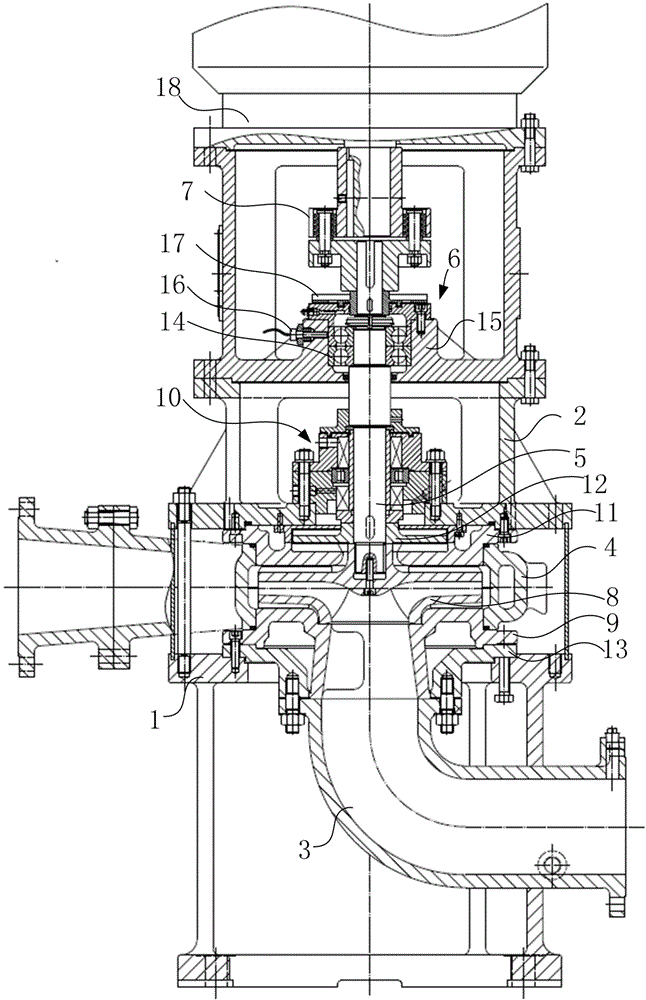

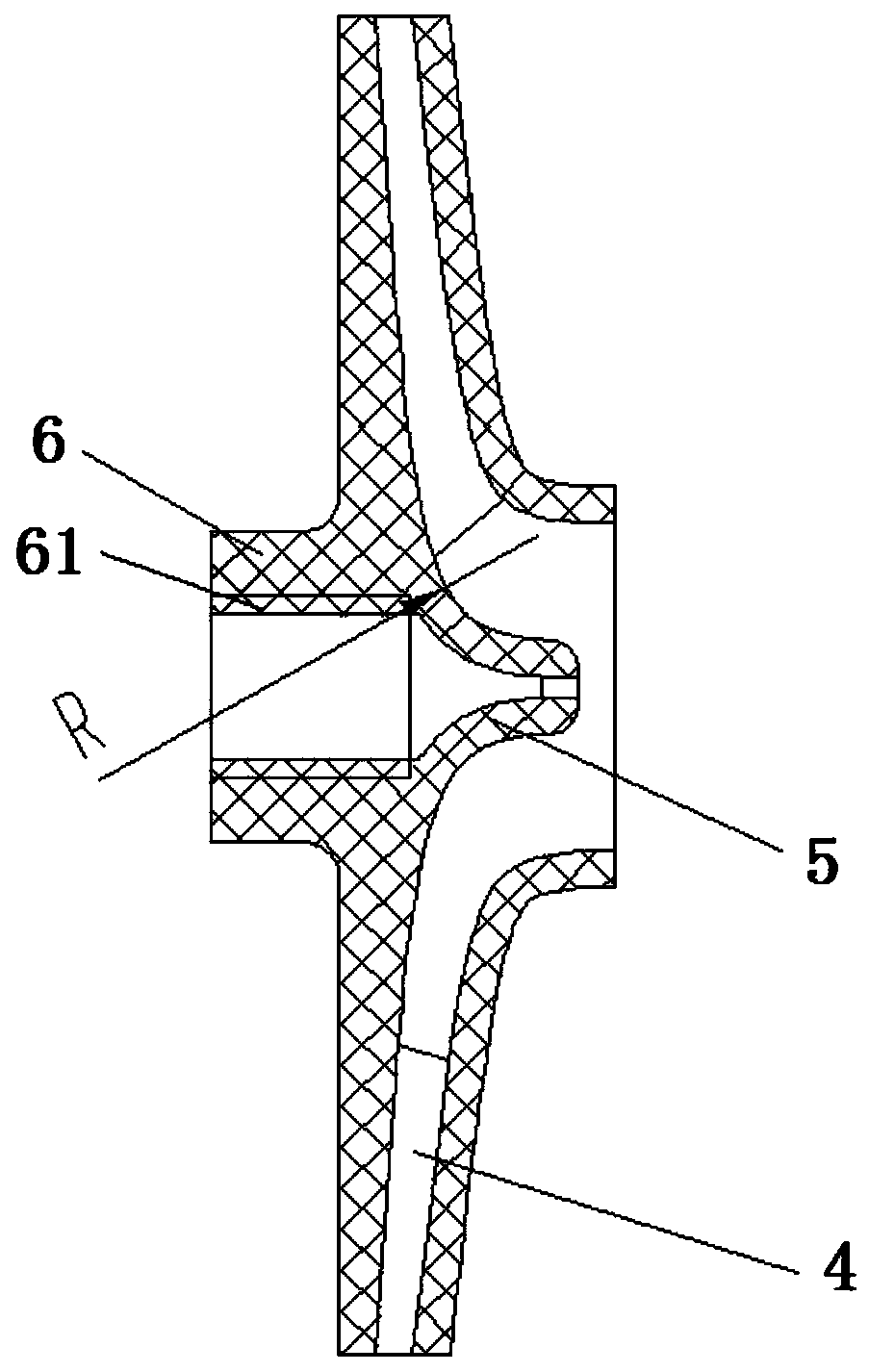

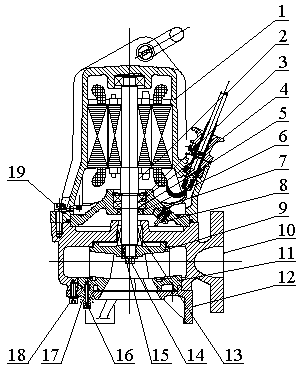

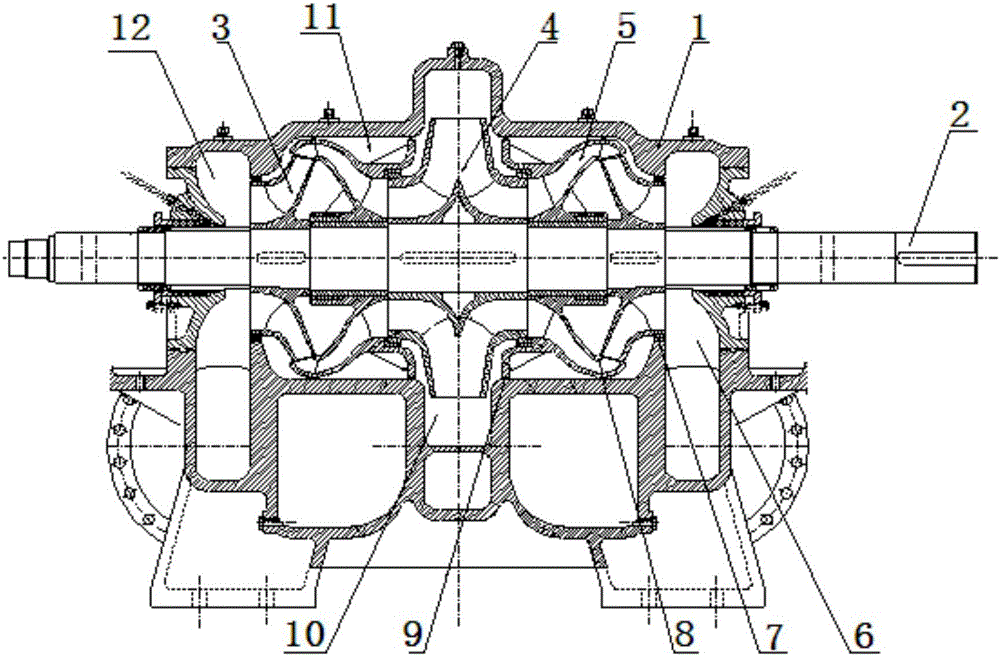

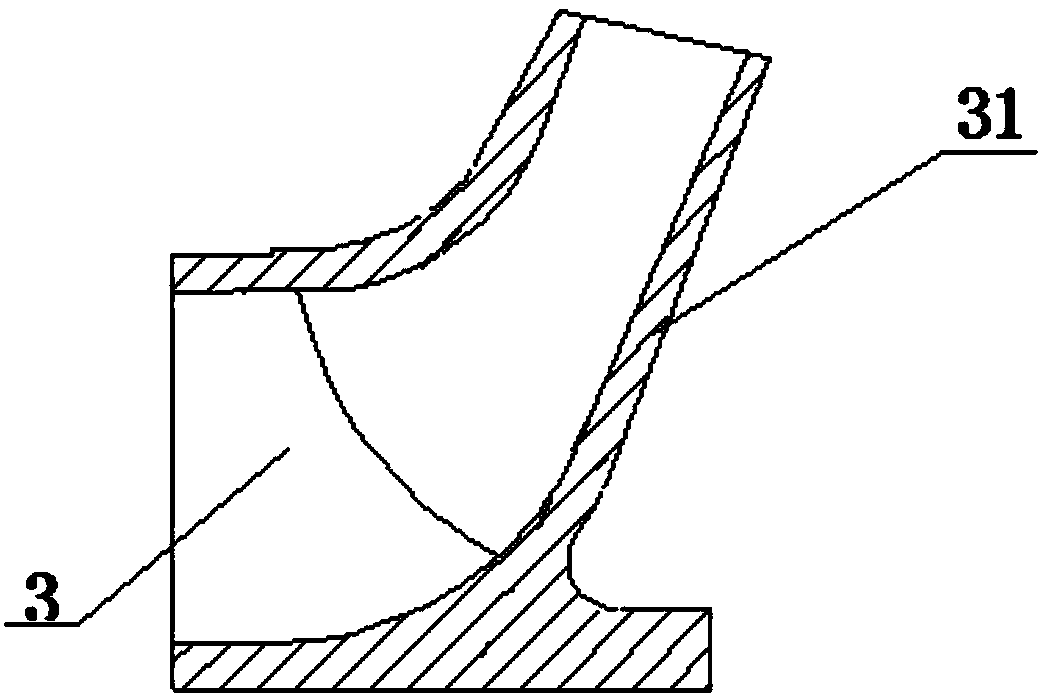

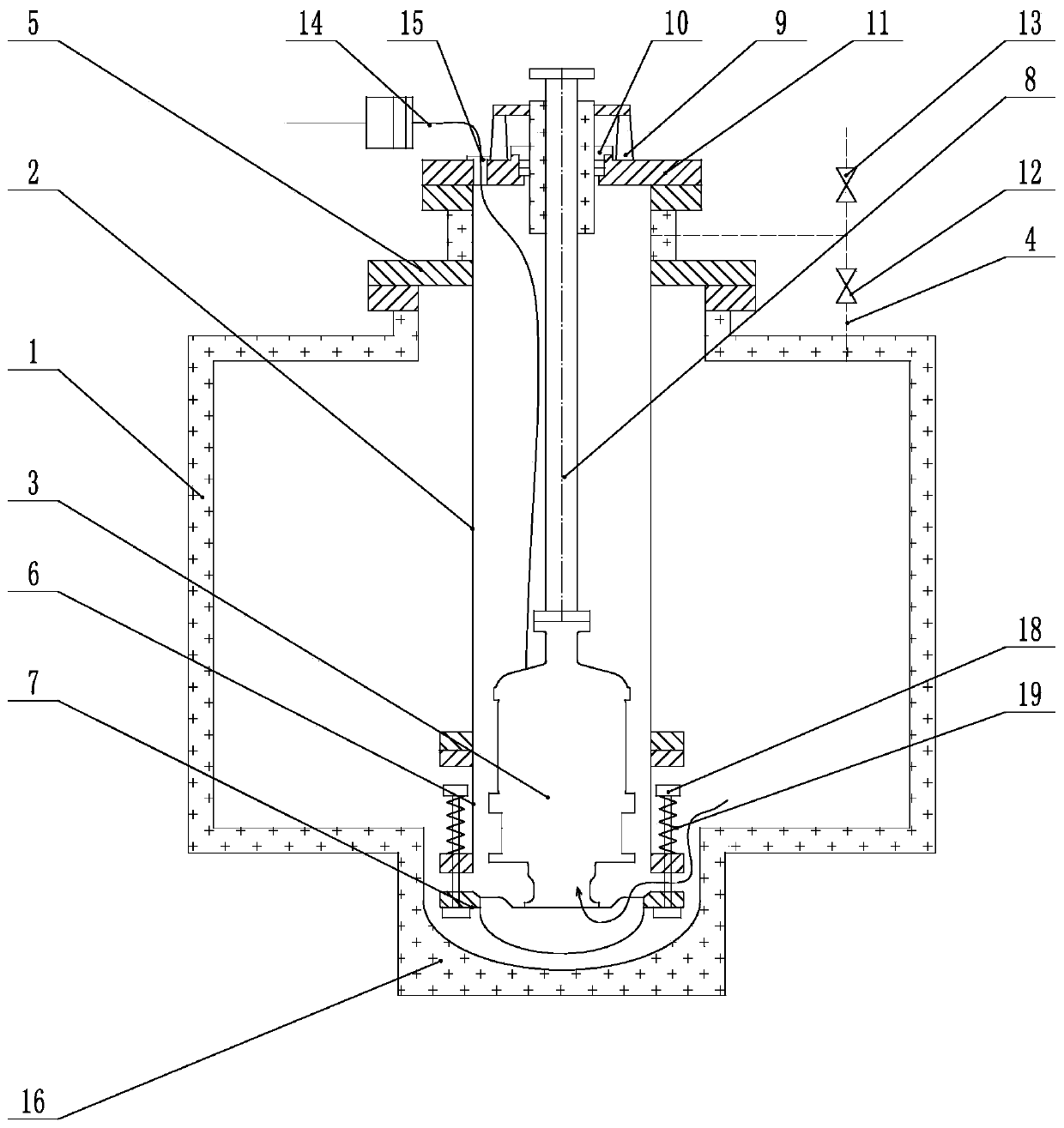

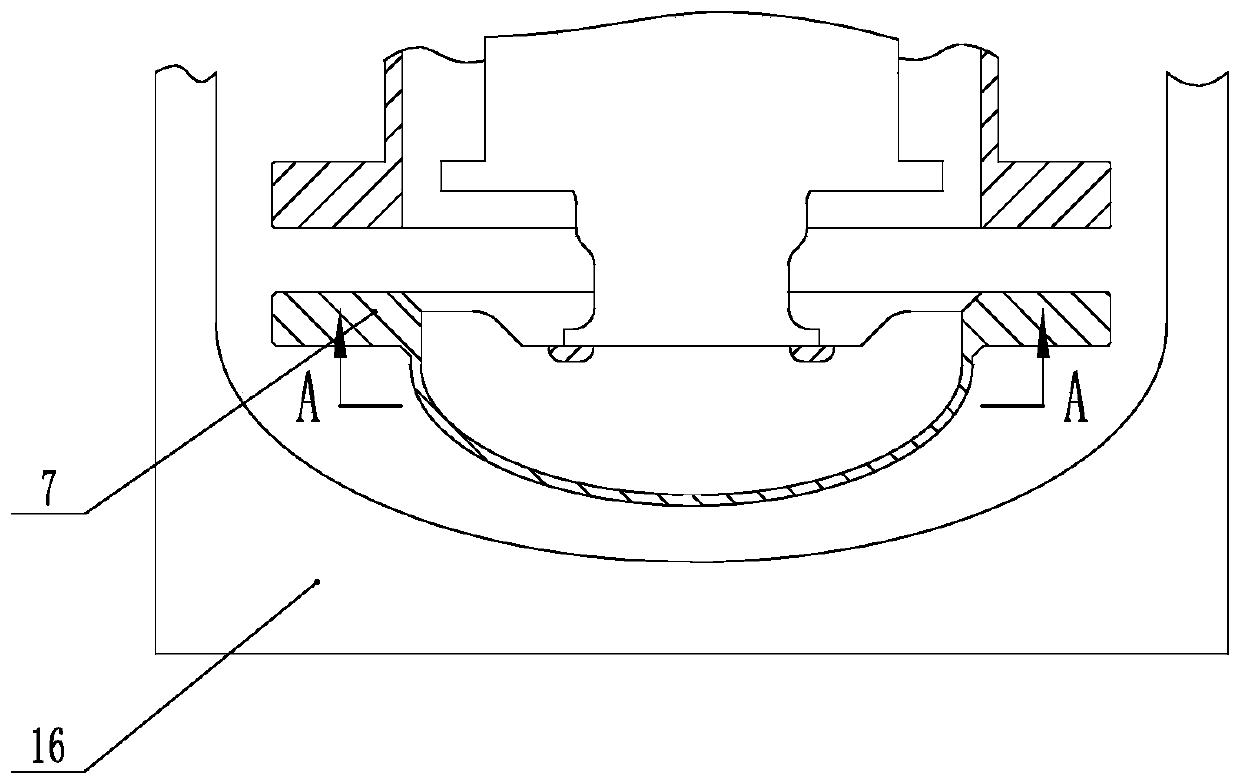

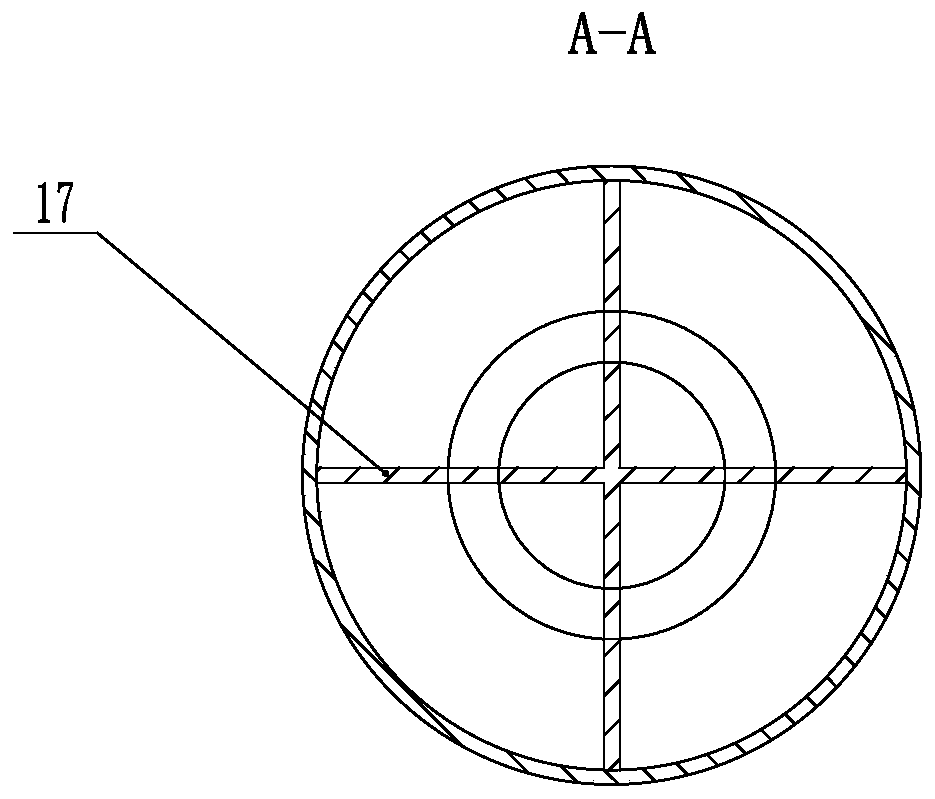

Submersible cutting sewage pump with efficient hydraulic performance

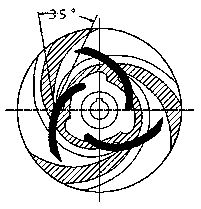

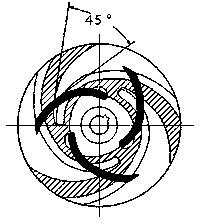

ActiveCN104100534AImprove inhalation performanceThe pump flow-head characteristic curve changes smoothlySpecific fluid pumpsPump componentsImpellerFront cover

The invention relates to a submersible cutting sewage pump with efficient hydraulic performance and belongs to the technical field of submersible pumps. The submersible cutting sewage pump comprising a submersible motor is characterized in that the submersible motor is connected with a pump body below through a connection segment to form a cooling and lubricating oil chamber; an efficient large-pass semi-open impeller having a rear cover plate is disposed in the center of the lower portion of the pump body; an inlet edge of each impeller blade is provided with a 30-45-degree large guiding tilt angle from the rear cover plate and a front cover plate, and a center line of an impeller blade outlet pass is flush with a center line of a radial outlet of the pump body; the lower end face of the pump body is connected with a pump base, a cutting disc which is axially adjustable is connected to the upper portion of the pump base, the cross section of the upper end of the cutting disc is completely the same as a flow surface of the front cover plate, projecting to the impeller blade axial surface, in shape, and a 0.2-0.3 mm required gap can be formed between the upper end of the cutting disc and the flow surface of the front cover plate, projecting to the impeller blade, by adjusting axial movement of the cutting disc. The submersible cutting sewage pump is high in hydraulic efficiency, has a wide efficient area, allows suctioning and passage of large particles, and has good effect of impurity cutting and tearing.

Owner:NANJING ZHONGDE ENVIRONMENTAL PROTECTION EQUIP MFG

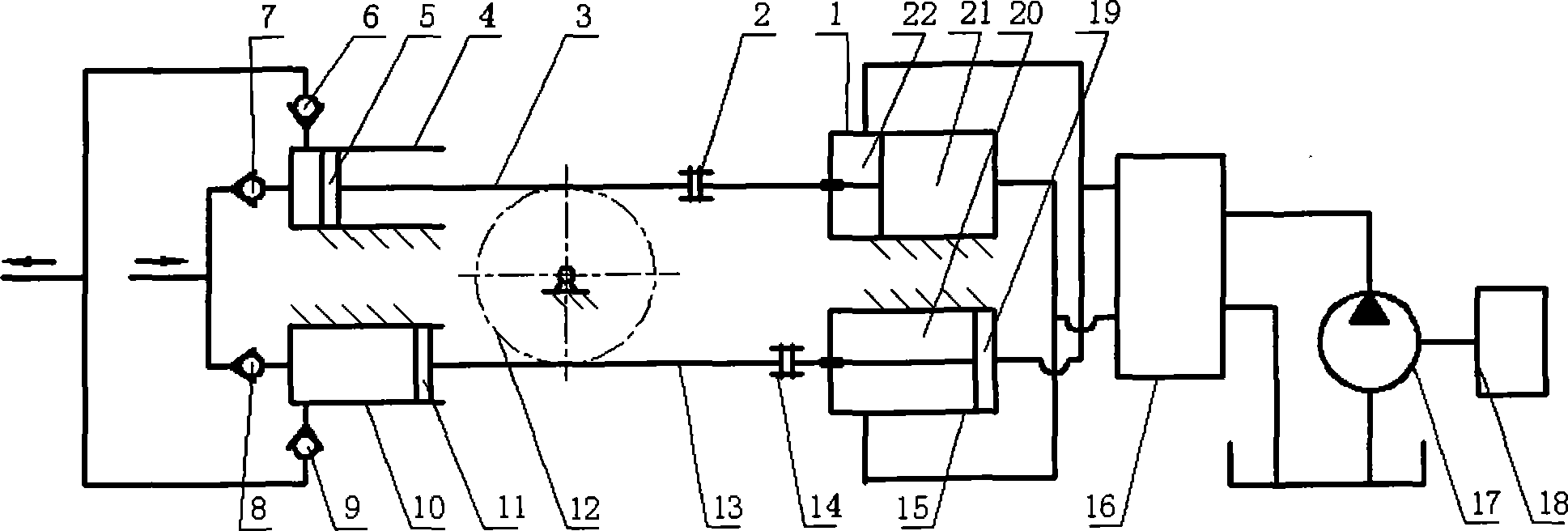

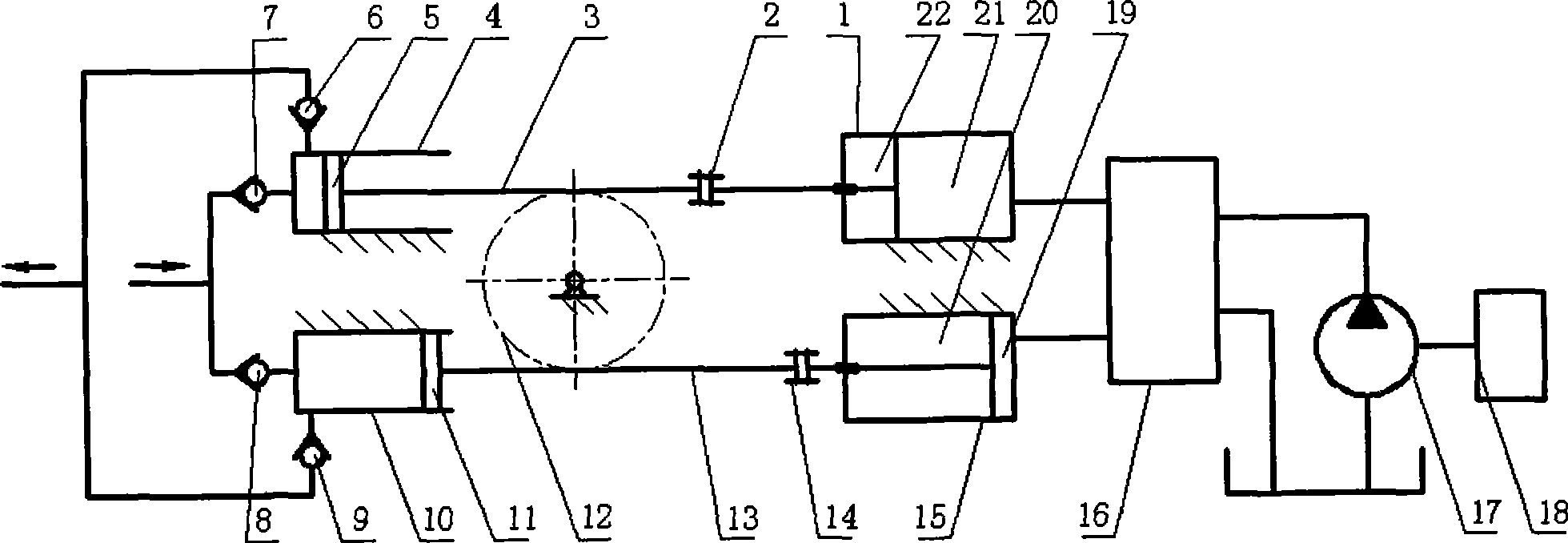

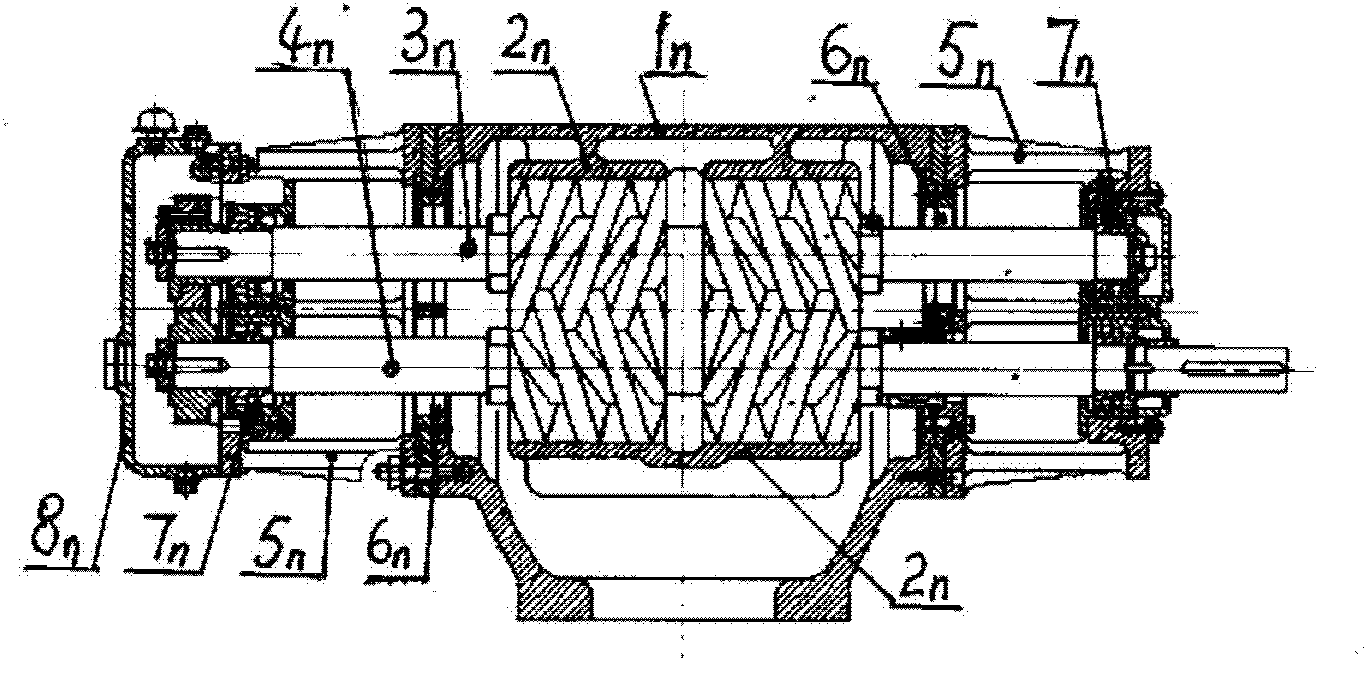

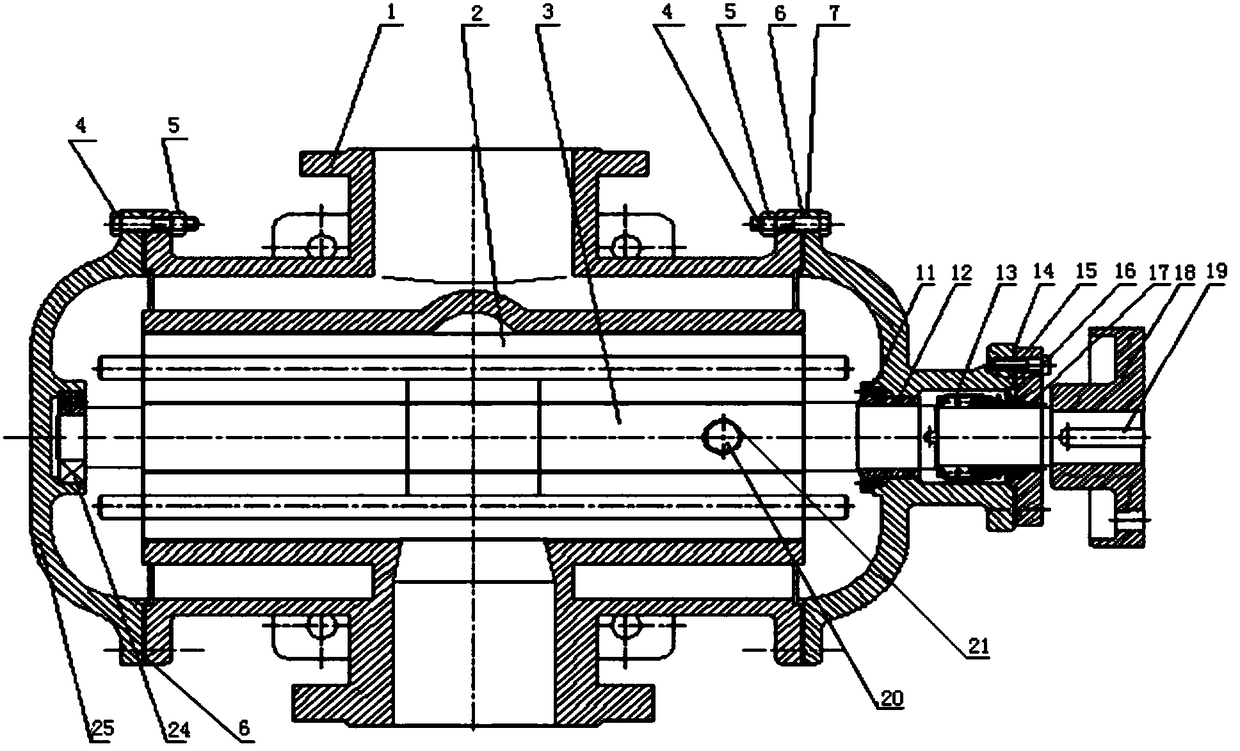

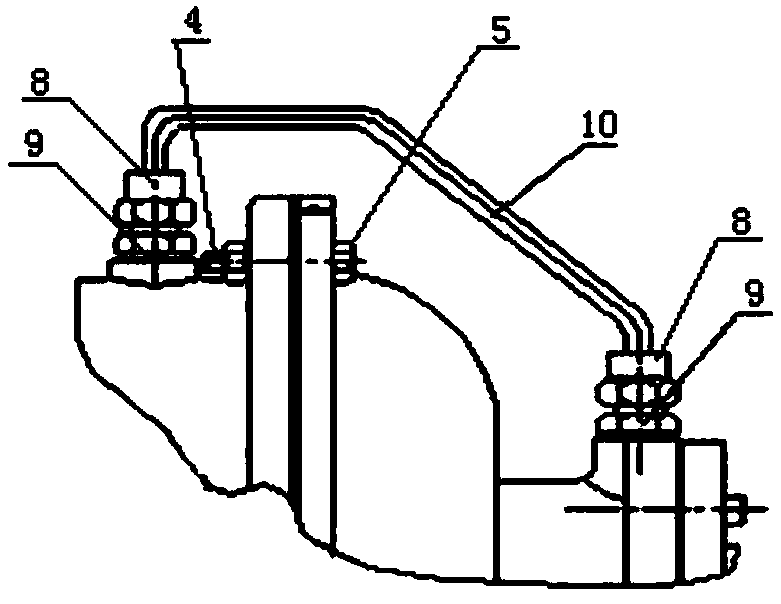

Rack-and-pinion coupled hydraulic multi-cylinder reciprocating pump

InactiveCN101476553AReduce degradationReduce shearPiston pumpsPositive-displacement liquid enginesPhase differenceGear wheel

The invention relates to a gear wheel and rack coupled hydraulic multi-cylinder reciprocating pump, which consists of a hydraulic oil cylinder, a coupling, a cylinder sleeve of a working hydraulic cylinder, a piston, a piston rod, a gear wheel, a suction valve, a discharge valve, a hydraulic directional control valve, a hydraulic oil pump, an electric motor, and the like which are assembled and connected. The piston rod is provided with a rack; the hydraulic oil cylinder and the piston rod are arranged parallelly; the gear wheel is engaged with racks on the two piston rods simultaneously; and the two piston rods are arranged according to the movement phase difference of 180 degrees. Two hydraulic oil cylinders and two working hydraulic cylinders form a basic unit, and for the two hydraulic oil cylinders in the basic unit, oil can be provided to both non-rod chambers and rod chambers, and can be only provided to the non-rod chambers of the oil cylinders. The invention can be combined into a multi-cylinder reciprocating pump with two cylinders, four cylinders, six cylinders, and more even cylinders. The hydraulic multi-cylinder reciprocating pump has the advantages of high systematic efficiency, long stroke, low stroke frequency, large displacement, high pump pressure, long service life of wearing parts, small fluctuation of the displacement and the pump pressure, good suction performance, and simple and convenient maintenance.

Owner:SOUTHWEST PETROLEUM UNIV

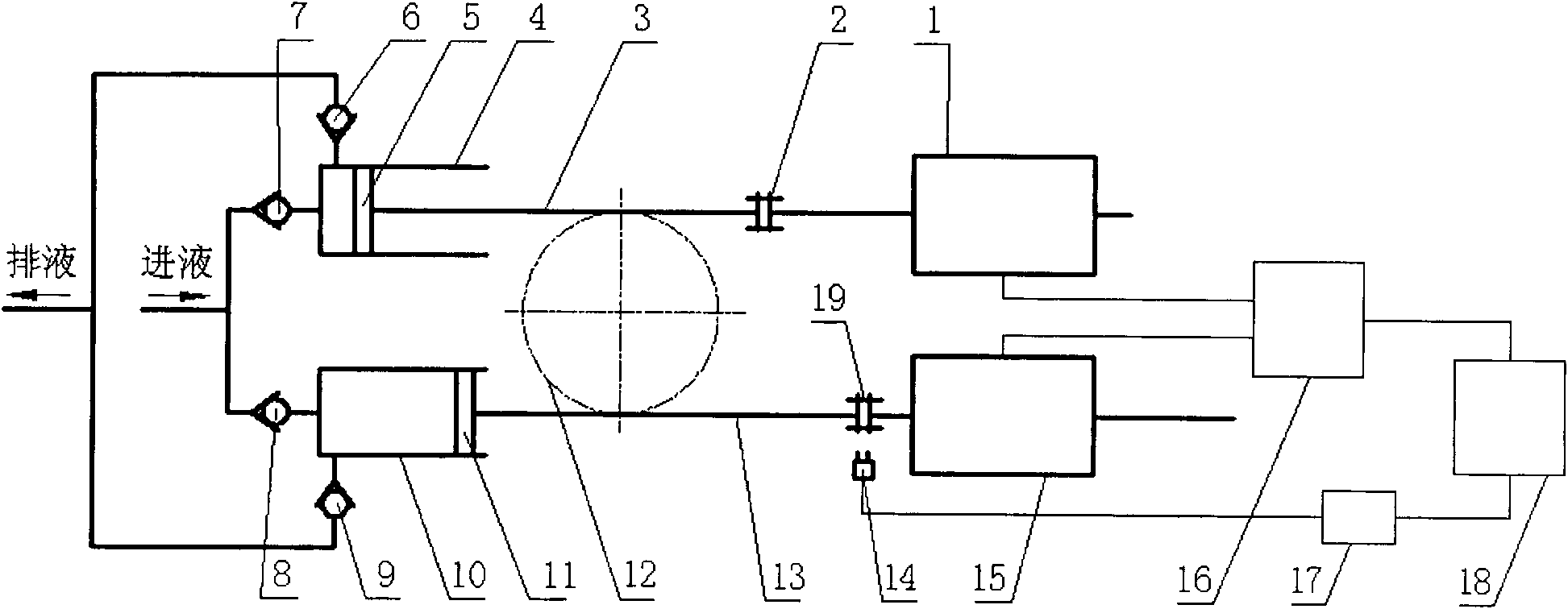

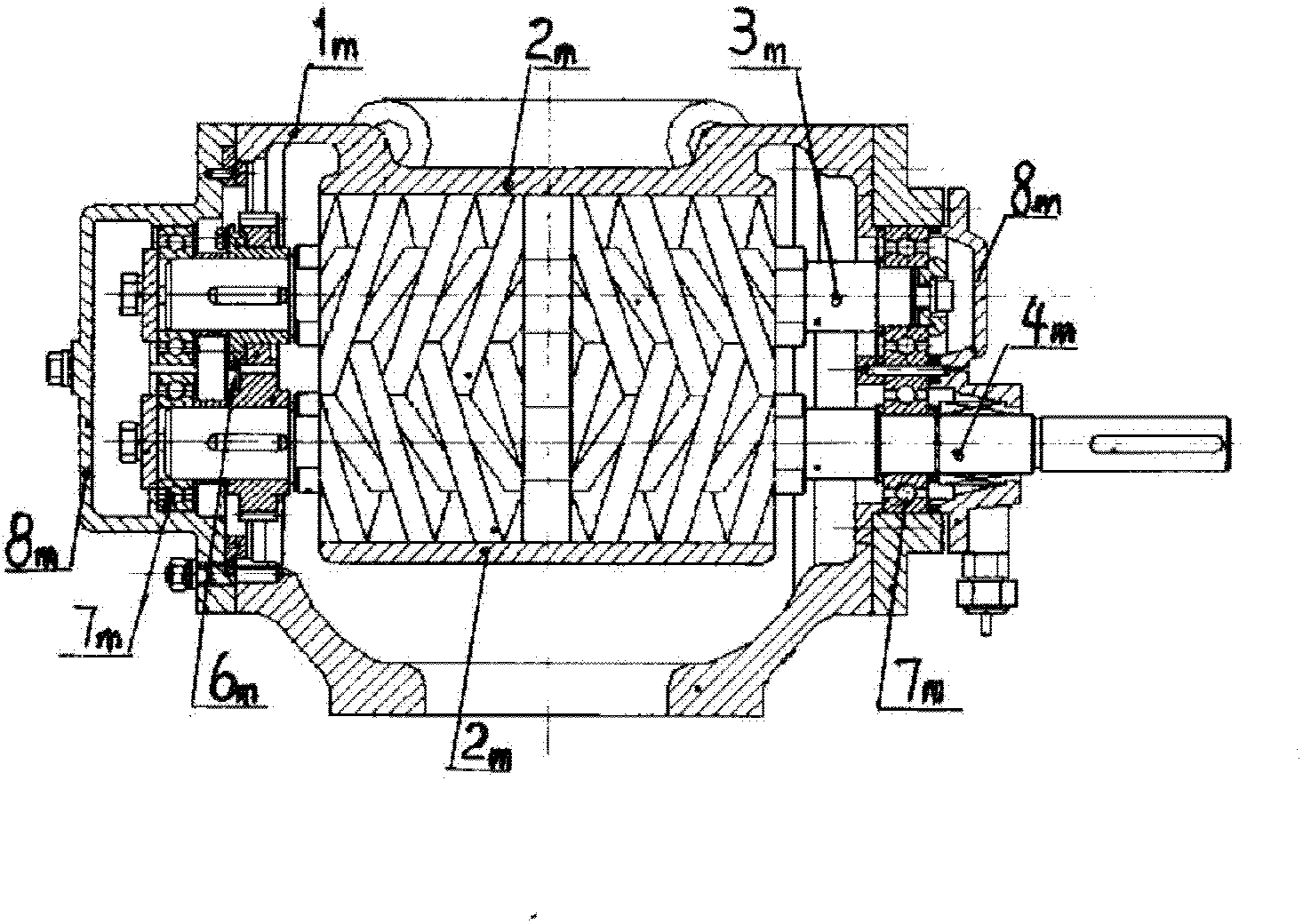

Linear motor multi-cylinder reciprocating pump with coupled gear and rack

InactiveCN101672260AReduce motor lossImprove efficiencyPiston pumpsPositive-displacement liquid enginesReciprocating pumpPetroleum

The invention relates to a linear motor reciprocating pump with coupled gear and rack, which mainly consists of a linear motor, a coupler, working hydraulic cylinders, a piston, a piston rod, a gear,a suction valve, a discharge valve, a data collection card, a control computer, a driver, etc. Two cylinders with one coupled gear and rack form an elementary unit; and a multi-cylinder reciprocatingpump with double cylinders, four cylinders and cylinders of even number of more than four can be formed. Two linear motors in one elementary unit can be electrified at respective positive strokes thereof, and can be interrupted at the reverse strokes, and also can be electrified synchronously both at the positive strokes and the reverse strokes. One elementary unit is provided with only one position detection sensor to detect the displacement signal of the motor, and the displacement signal is collected by the data collection card, transferred, and input into the control computer; after the displacement signal is analyzed, a control signal is sent to the driver to lead the motor to realize a desired motion rule. The linear motor reciprocating pump with coupled gear and rack has the advantages of good suction performance, high system efficiency, large discharge capacity, high pump pressure as well as small fluctuation of pump pressure and discharge volume; moreover, the linear motor reciprocating-pump with coupled gear and rack can better fulfill the productive requirements of petroleum, chemical engineering, etc.

Owner:SOUTHWEST PETROLEUM UNIV

Sandwich jelly and processing method thereof

InactiveCN104286617ARich tasteImprove inhalation performanceFood ingredient functionsFood preparationFruit juiceLiquid state

The invention relates to a sandwich jelly and a processing method thereof. The sandwich jelly comprises two layers, namely an outer jelly layer and an inner sandwich layer; the outer jelly layer is prepared by the following steps: adding sweet sugar, fruit and vegetable juice and / or fermented glutinous rice to jelly powder; adjusting the concentration by water; adjusting the pH by acid; and heating, concentrating, sterilizing and cooling to obtain a viscous jelly liquid; and the inner sandwich layer is frozen from fruit juice, fermented bean drink, or lactic acid bacteria fermentation liquor or liquid milk. The preparation method of the sandwich jelly comprises the following steps: spraying the viscous jelly liquid on the sandwich; further cooling; and solidifying the outer jelly layer. According to the sandwich jelly, a traditional jelly processing method is broken through; due to adoption of a traditional jelly sandwich method, the sandwich jelly is relatively abundant in taste in comparison with traditional jelly; and the sandwich is in a solid state in a frozen state, and is in a liquid state at room temperature while the outer jelly is in a solid state at room temperature, so that the sandwich jelly can be well sucked when being eaten.

Owner:ZHEJIANG OCEAN UNIV

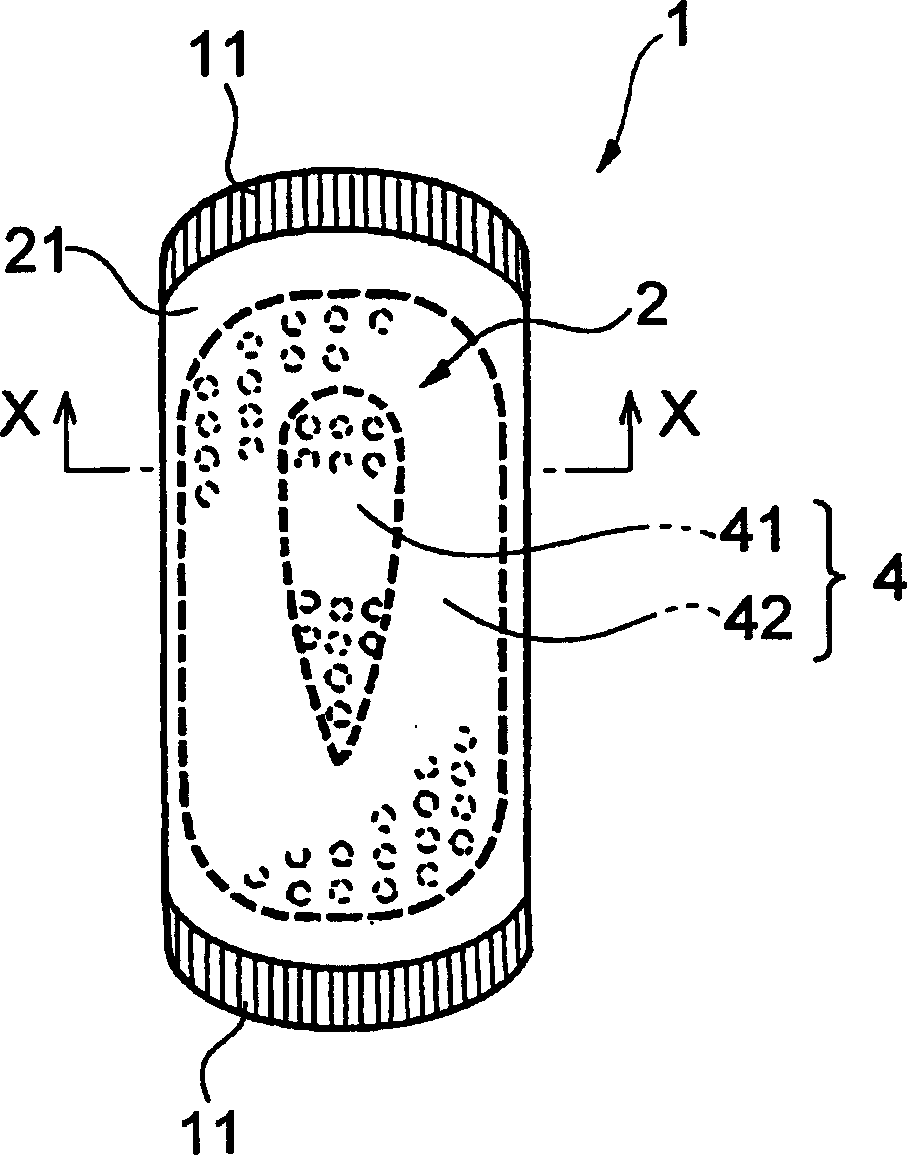

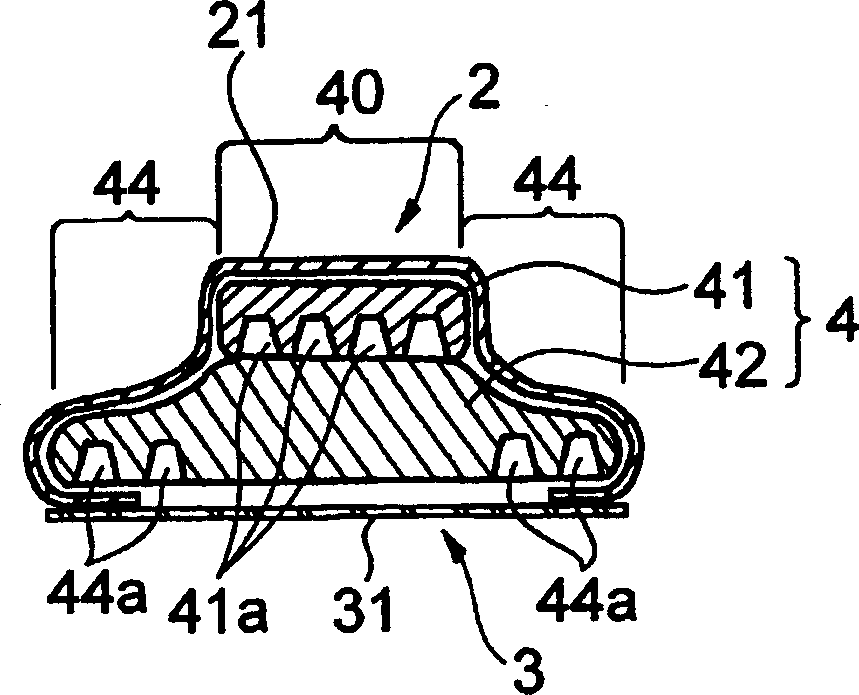

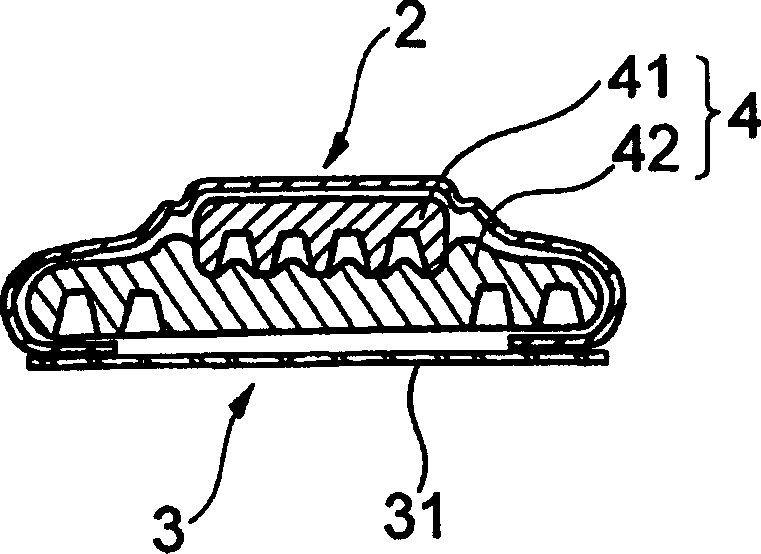

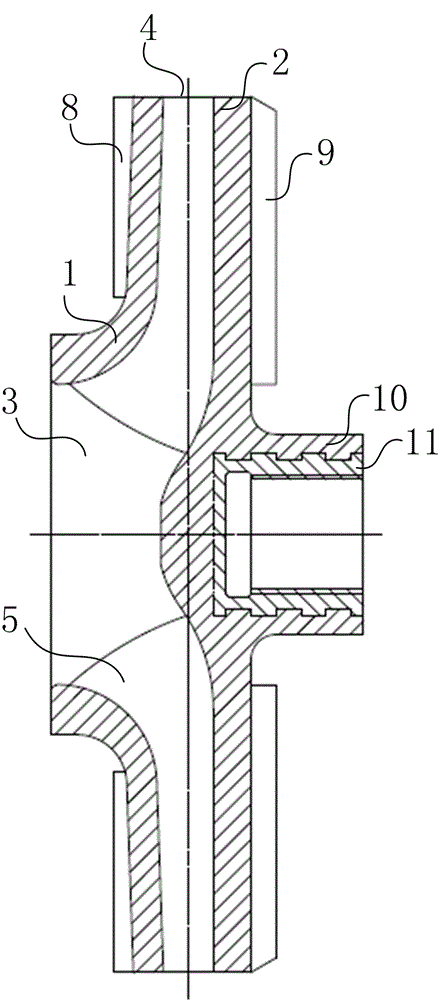

Absorbent article

InactiveCN1732874AImprove inhalation performanceImprove fitSanitary towelsBandagesApparent densityEngineering

The absorbent article 1 of the present invention includes a skin abutting surface 2, a non-skin abutting surface 3 and an absorber 4 interposed between both of the surfaces. The absorber 4 includes a layered part 40 where an upper absorption layer 41 and a lower absorption layer 42 are layered, and the upper absorption layer 41 is positioned on the side of the skin abutting surface. The layered part 40 of the absorber 4 is constituted in such a way that the apparent density of the lower absorption layer 42 is lower than that of the upper absorption layer 41 under loading of 0.5g / cm<2>, and the apparent density of the lower absorption layer 42 is not lower than that of the upper absorption layer 41 under loading of 20g / cm<2>.

Owner:KAO CORP

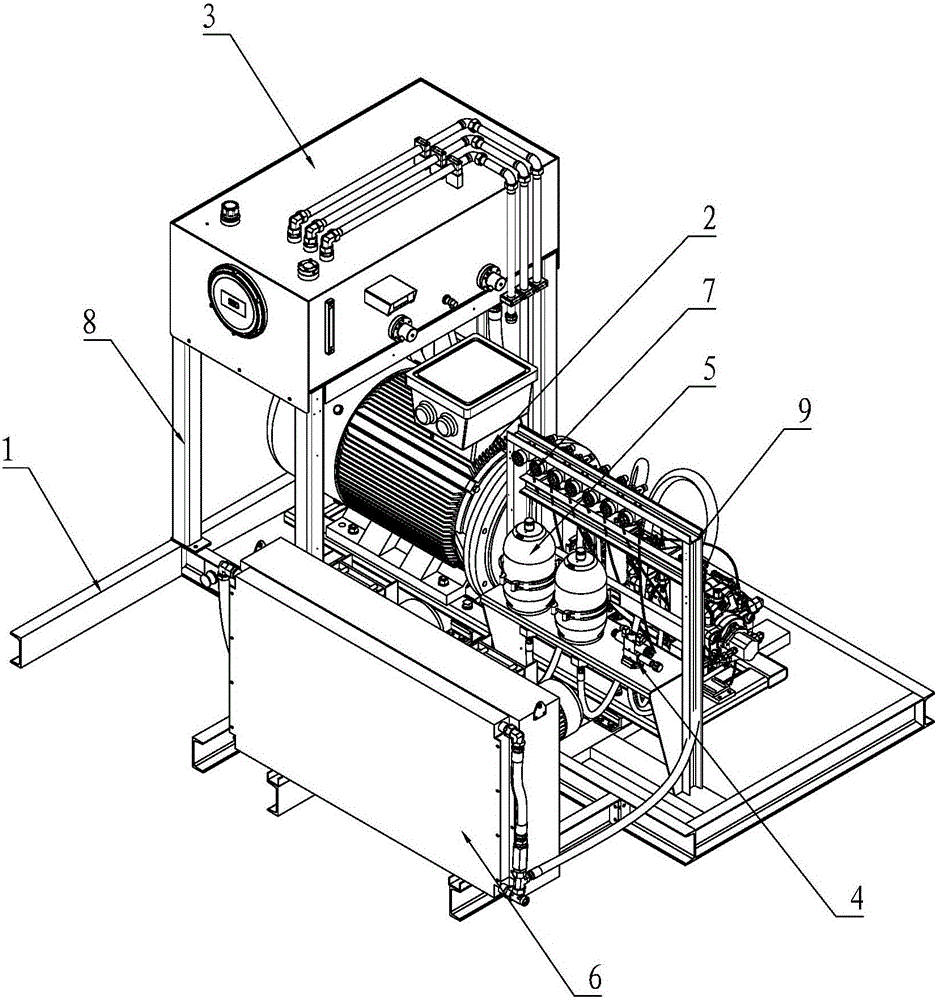

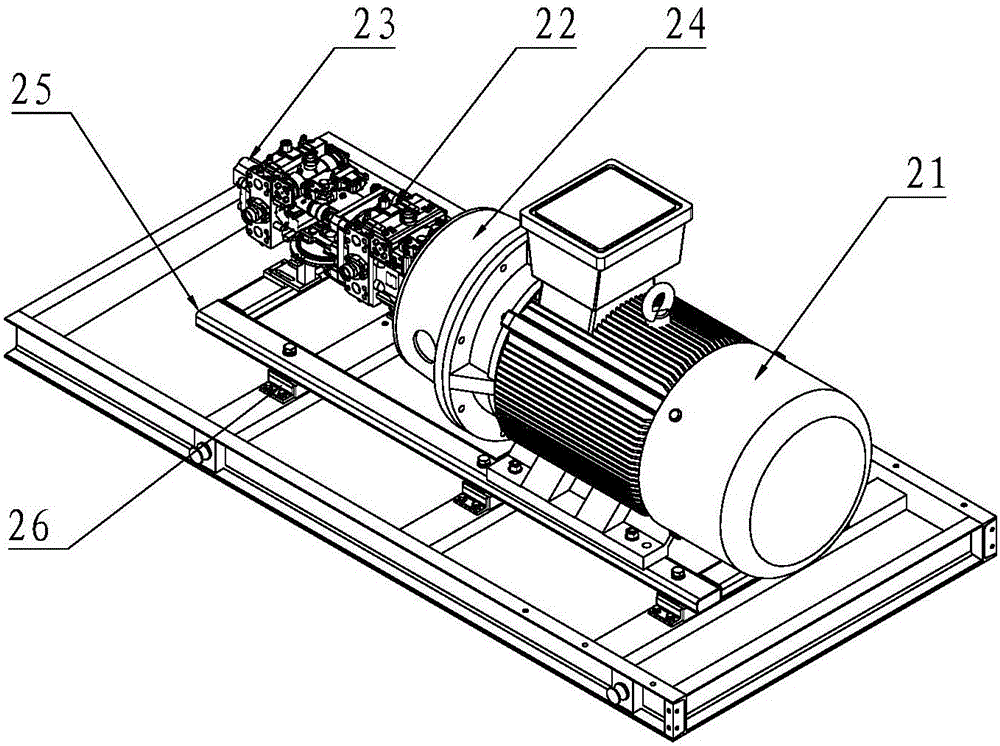

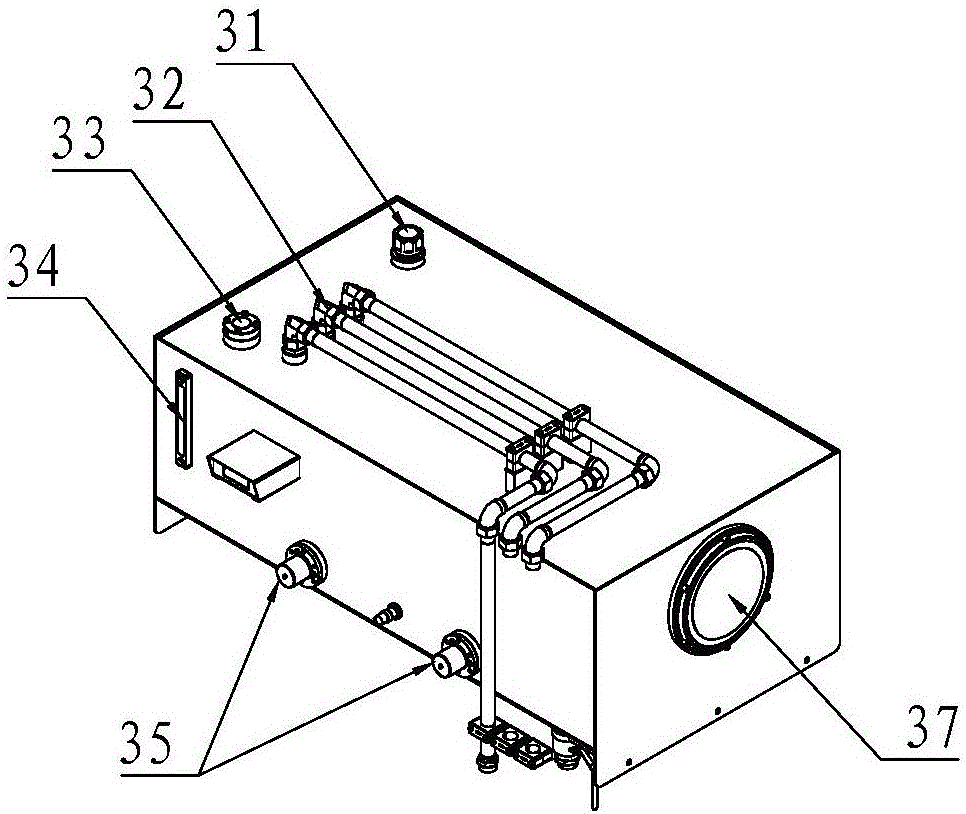

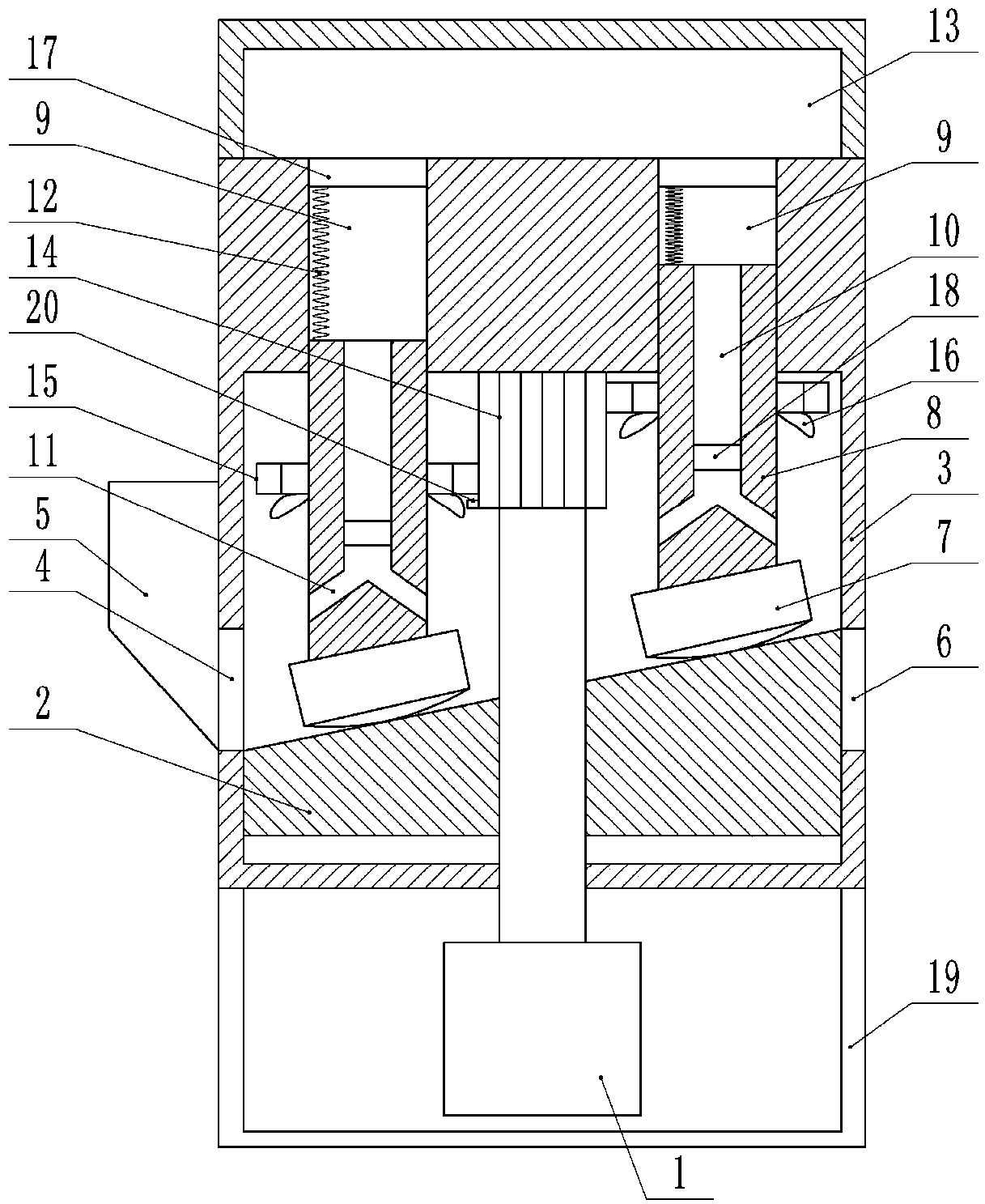

Shear type crusher hydraulic station

InactiveCN105864114ASimple structureCompact structureServometer circuitsGrain treatmentsGear pumpDisplay device

The invention relates to a shearing crusher hydraulic station, which relates to a hydraulic station. The purpose of the utility model is to provide a shearing crusher hydraulic station with compact structure, low noise and good heat dissipation. The shearing crusher hydraulic station of the present invention includes a base, and the base is equipped with a motor pump group, an oil tank, a valve group, an accumulator, a cooling device, and a display device, and the motor pump group includes a motor, an oil charge pump, a plunger pump and a gear pump. The motor is connected to the plunger pump, the gear pump is connected in series with the plunger pump, the charge pump is connected to the plunger pump; the fuel tank is set above the motor, and the accumulator is set on one side of the plunger pump; the plunger pump is connected to the valve group, The oil inlet of the oil pump is connected to the oil tank, the oil outlet is connected to the accumulator, the oil inlet of the gear pump is connected to the oil tank, and the oil outlet is connected to the valve group; The oil return line of the pump is connected; the display device includes the plunger pump oil outlet pressure gauge, the plunger pump oil return pressure gauge, the charge pump pressure gauge and the gear pump pressure gauge.

Owner:SID MACHINERY BEIJING

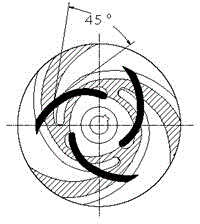

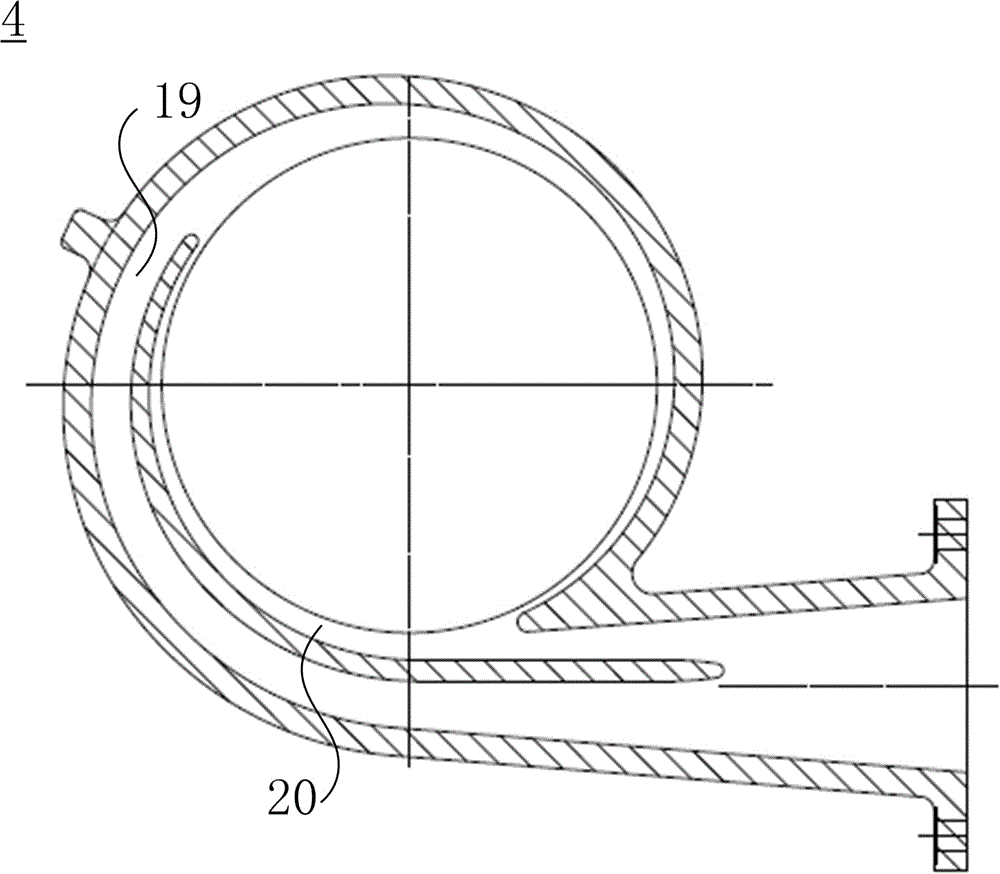

Centrifugal coal water slurry pump

InactiveCN103953549AEasy to adjust clearanceIncrease the import areaSpecific fluid pumpsPump componentsCoal waterSingle stage

The invention provides a centrifugal coal water slurry pump, which is a vertical single-stage cantilever type centrifugal pump. The centrifugal coal water slurry pump comprises a pump base, a pump frame, an inlet elbow, a water outlet section, a bearing support, a bearing assembly, a shaft, a driving assembly and an impeller, the inlet elbow is connected with the pump base, the water outlet section is respectively connected with the pump base and the pump frame, the bearing support is connected with the pump frame, the bearing assembly is arranged on the bearing support, the shaft is fixed on the bearing support and the bearing assembly, the driving assembly is used for driving the shaft to rotate, the impeller is arranged on the front end of the shaft, the impeller, which is of a closed structure, comprises a front cover plate, main blades and a back cover plate, the center of the front cover plate is an impeller inlet, the main blades are arranged between the front cover plate and the back cover plate and integrated with the front cover plate and the back cover plate, the main blades are a plurality of long blades and a plurality of short blades, the long blades and the short blades are alternately arranged at intervals, so that impeller flow passages are formed, and at one side of the impeller flow passages, which is close to the impeller inlet, the long blades are longer than the short blades.

Owner:SHANGHAI FIRST PUMP WORKS

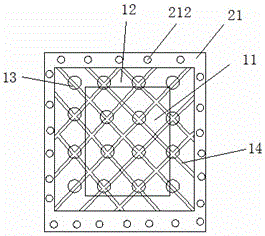

Dust-absorbing blackboard eraser

The invention relates to the field of teaching equipment, in particular to a dust-absorbing blackboard eraser. The dust-absorbing blackboard eraser comprises a dust storage box, dust wiping cotton attached to the bottom of the dust storage box, a filtering device arranged in the dust storage box and an air exhausting device connected with the dust storage box; honeycomb holes and grooves connected with the honeycomb holes are formed in the dust wiping cotton; and dust absorbing holes corresponding to the honeycomb holes are formed in the bottom of the dust storage box. The invention aims at providing the dust-absorbing blackboard eraser which is low in price and is capable of effectively reducing dust pollution of a classroom.

Owner:黄自武

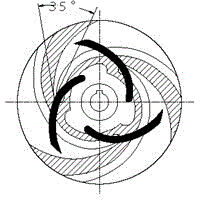

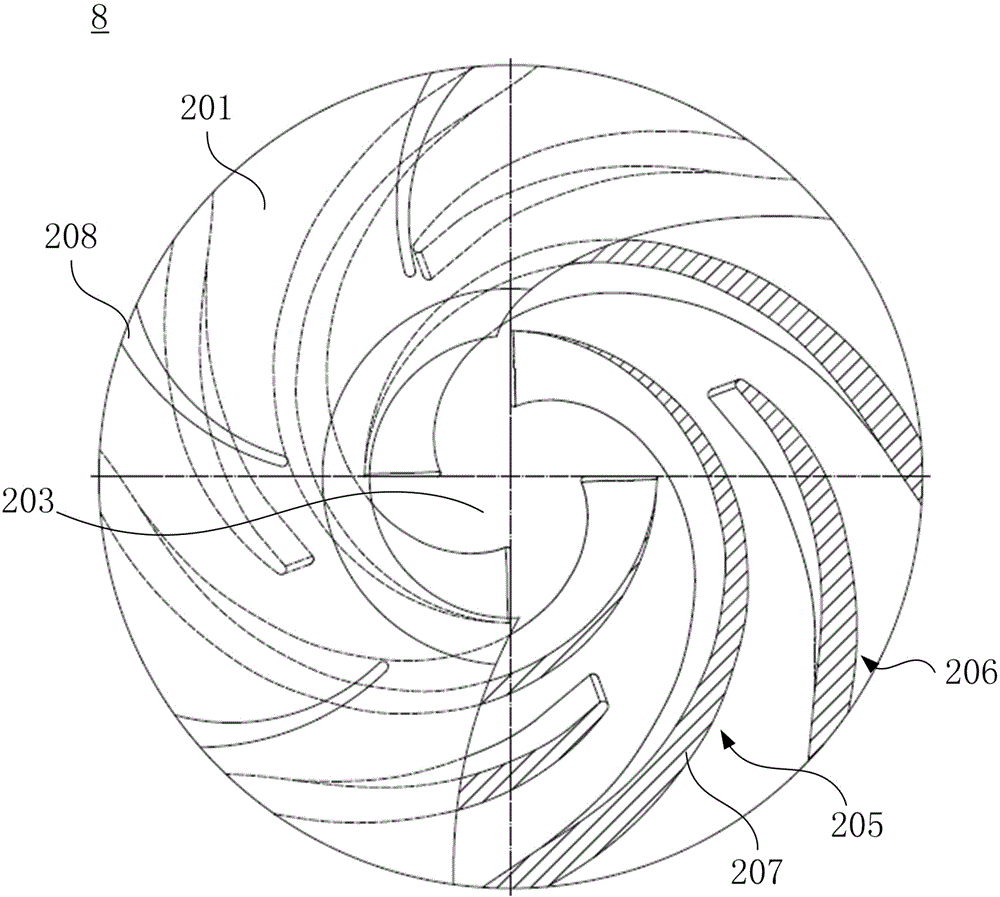

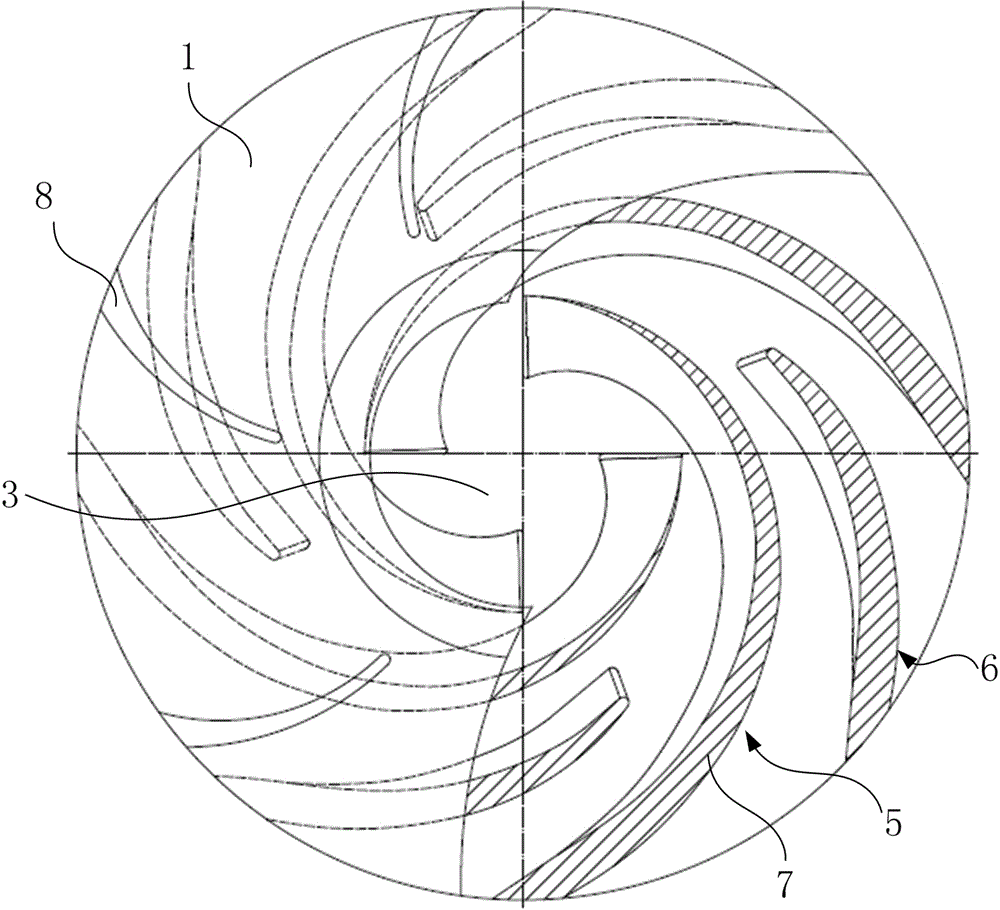

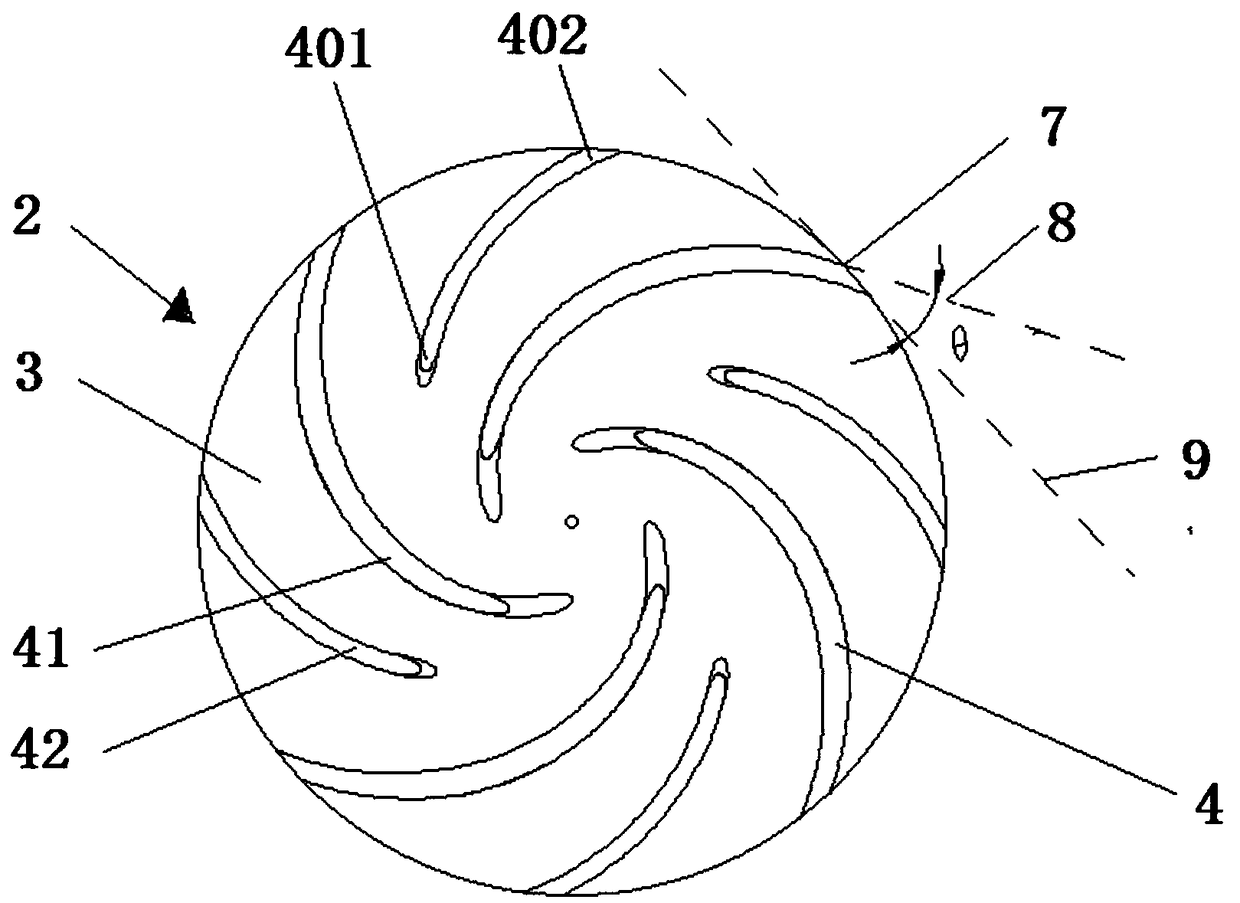

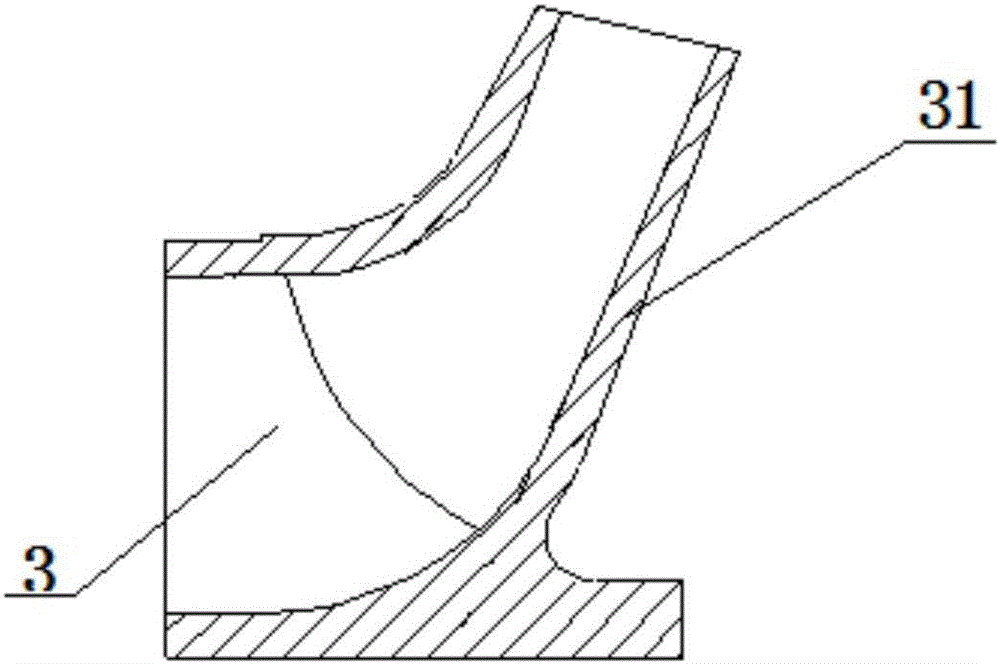

Impeller for coal water slurry pump

InactiveCN103953578AIncrease the import areaImprove inhalation performancePump componentsPumpsCoal waterImpeller

The invention provides an impeller for a coal water slurry pump. The impeller for the coal water slurry pump comprises a front cover plate, main blades and a rear cover plate; the center of the front cover plate is of an impeller inlet; the main blades are arranged between the front cover plate and the rear cover plate; the main blades, the front cover plate and the rear cover plate are integrated; the main blades comprise multiple long blades and short blades which are alternatively arranged at intervals, so an impeller runner is formed; at one side, close to the impeller inlet, of the impeller runner, the long blades are longer than the short blades. The impeller for the coal water slurry pump has the advantages that the sucking property of the impeller is improved, the hydraulic loss of the impeller inlet is reduced, and coal water slurry is prevented from being accumulated at the impeller inlet; the influence of flow separation and backflow phenomena at an outlet to the impeller performance is reduced or prevented, and the scouring abrasion of the impeller outlet is reduced; the disc loss is reduced, the efficiency is improved, and an energy saving aim is realized. The rotary speed of the pump is reduced under the same impeller outer diameter condition, and the abrasion of the impeller and other parts of the pump is reduced.

Owner:SHANGHAI FIRST PUMP WORKS

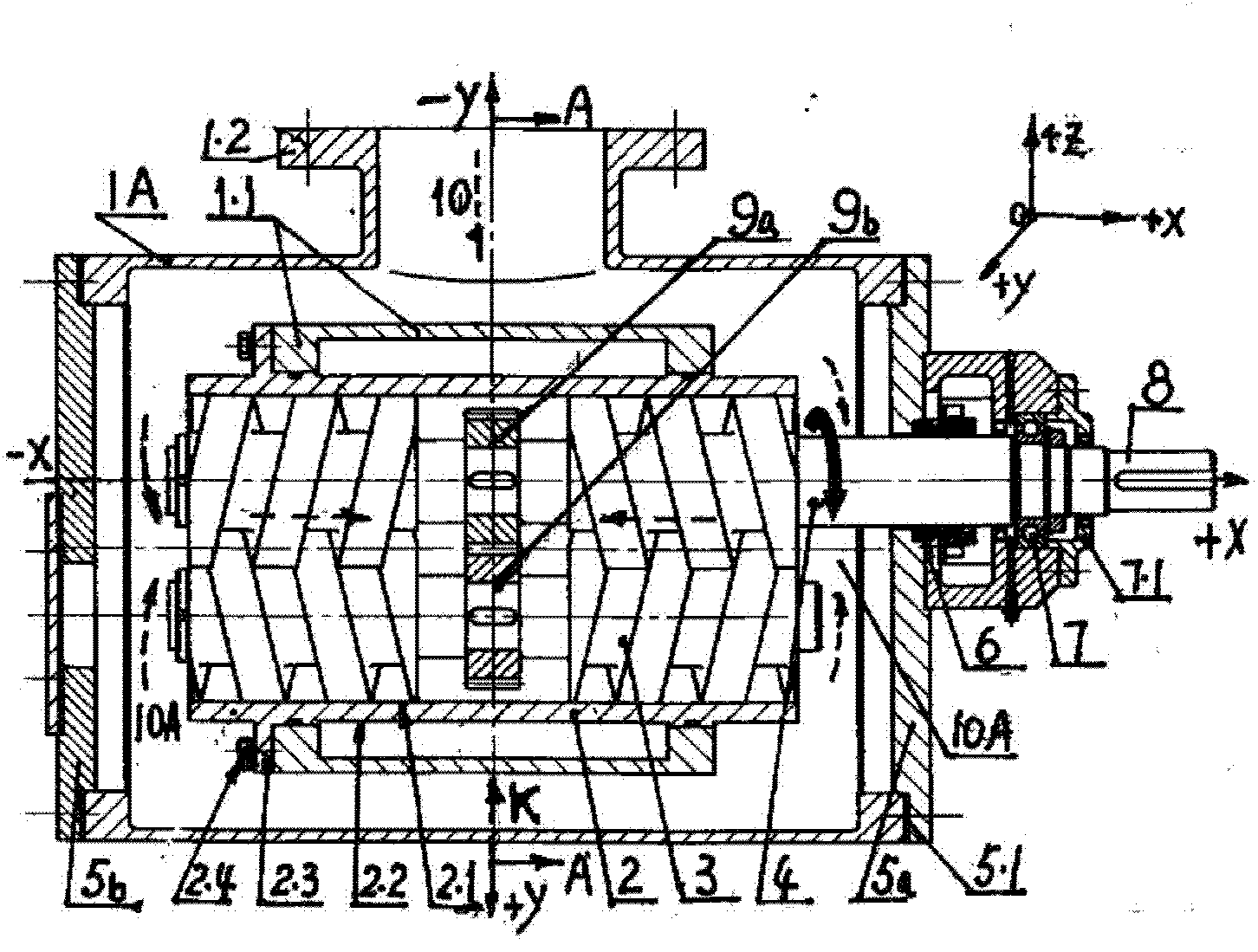

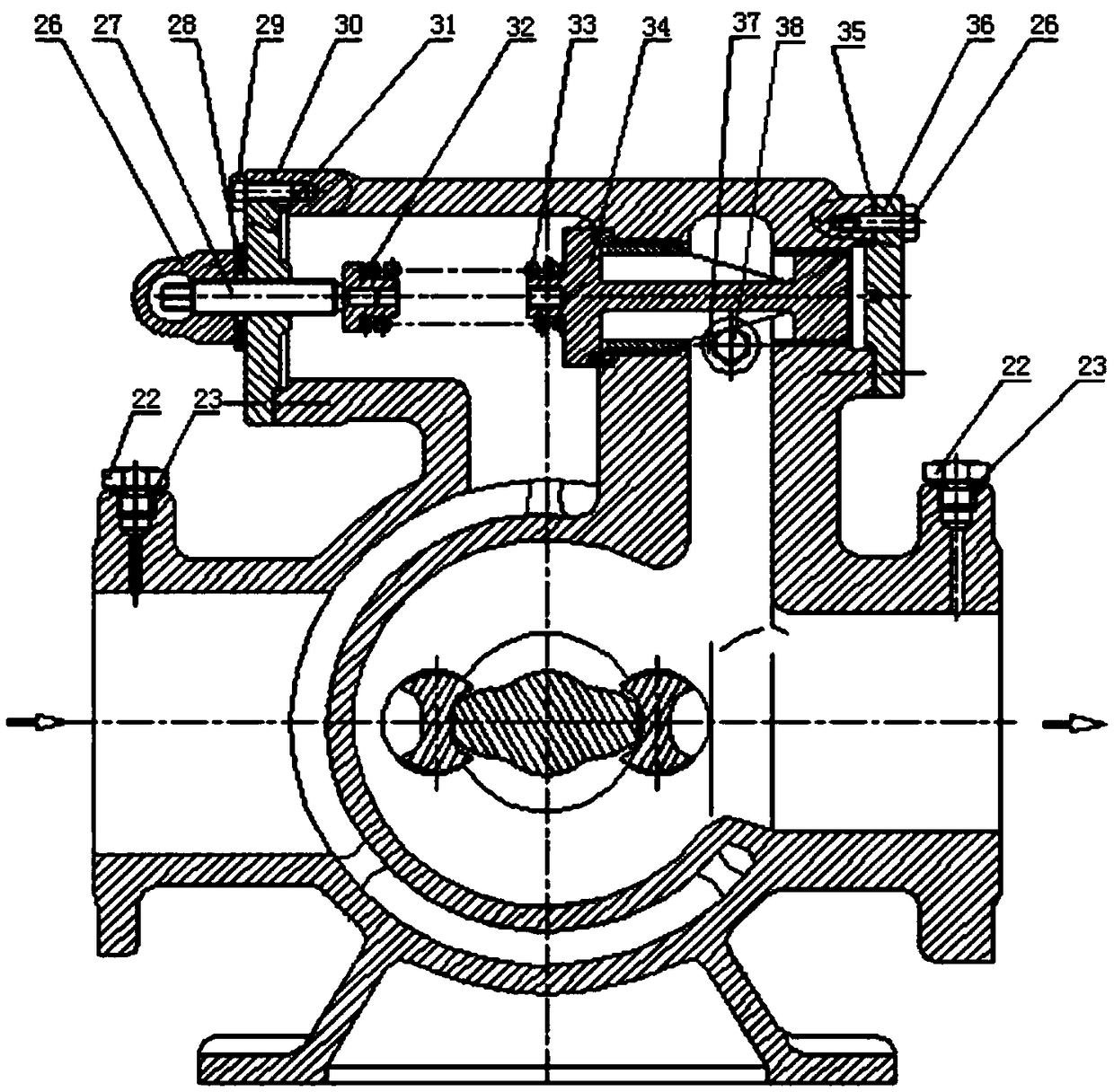

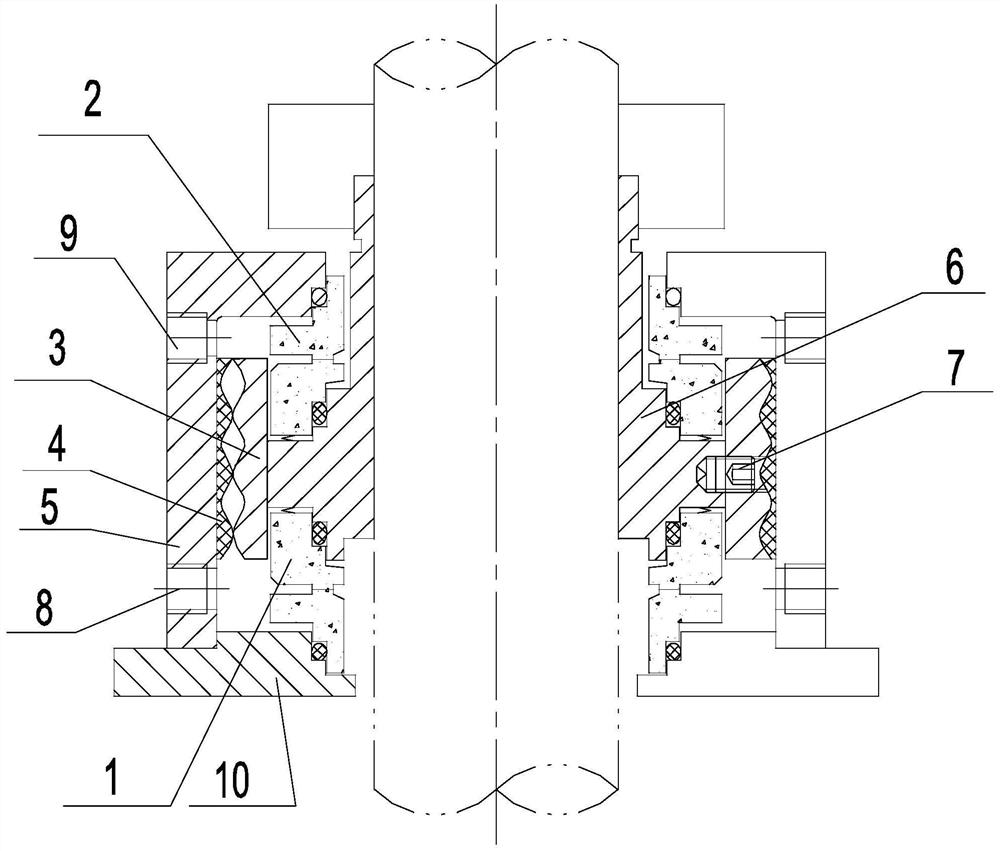

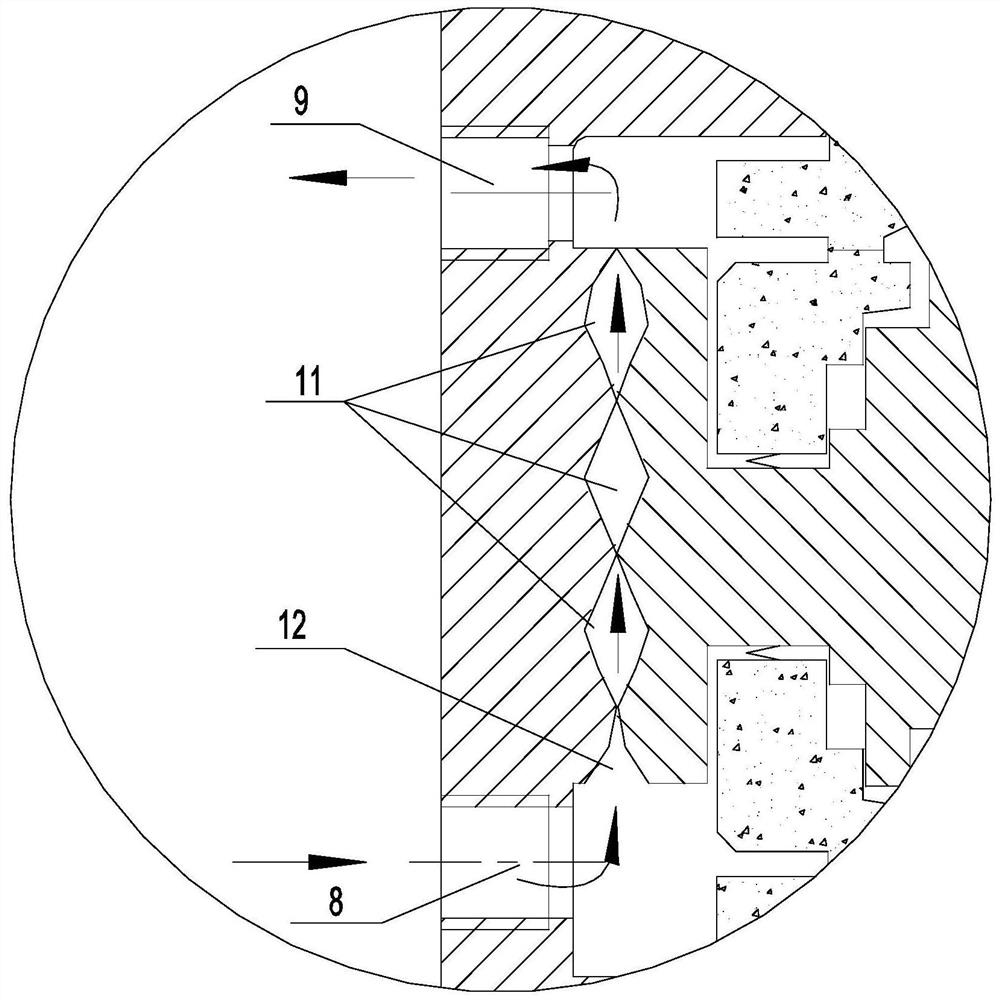

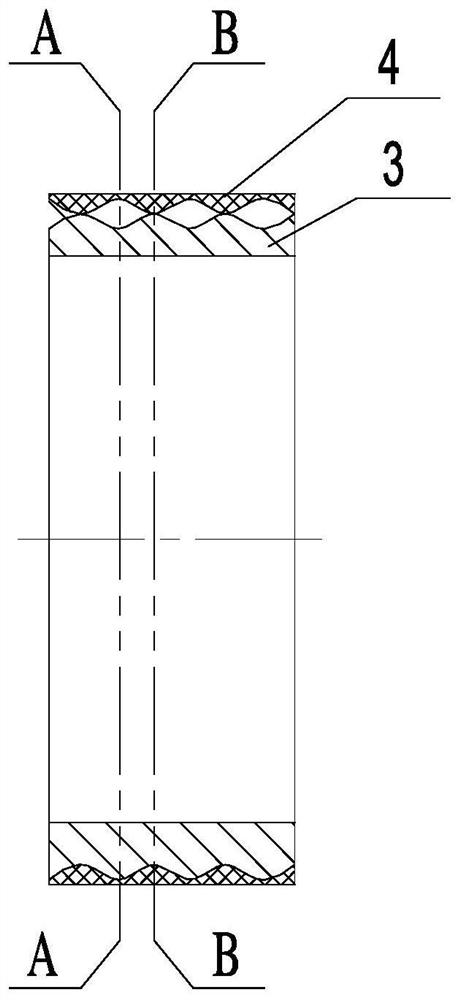

Double-screw pump without bearing

ActiveCN102220974AReduce runoutReduce axial sizeRotary piston pumpsRotary piston liquid enginesRolling-element bearingEngineering

The invention discloses a double-screw pump without a bearing. A tightly-fitting 8-shaped fitting surface which is arranged between the external surfaces of the main sub screw shaft and the sub screw shaft in a housing and the interior surface of a lining of the housing, is the main bearing-surface, so that there is no bearing in the working section. Helical grooves on the two screw shafts form a natural lubricating channel. In the process of pumping material, a lubricating liquid film with a certain thickness and a supporting liquid film are formed on the fitting surface by using the principal of dynamic and static pressure, and the heat generated from the fitting surface is taken away, so that a virtuous cycle forms. Two synchronous gears are arranged in the central sections of the main and the sub screw shaft, so as to improve the performance of suction greatly. The lining of the housing and the housing can be arranged as an integral structure or a detachable structure. A mechanical seal is arranged between the main screw shaft and a front end shield. The outer end of the mechanical seal can be provided with a small rolling bearing as an auxiliary bearing of seal. The double-screw pump without the bearing provided by the invention solves the problems of complicate structure, long dimension, bad rigidity, poor performance of suction and the like existing in the prior art, and can be used in places with high temperature, high pressure and the like that traditional double-screw pumps can not handle, especially is suitable for used in conveying clean material with high viscosity.

Owner:MECHANICS RES & DESIGN ACAD SICHUAN PROV

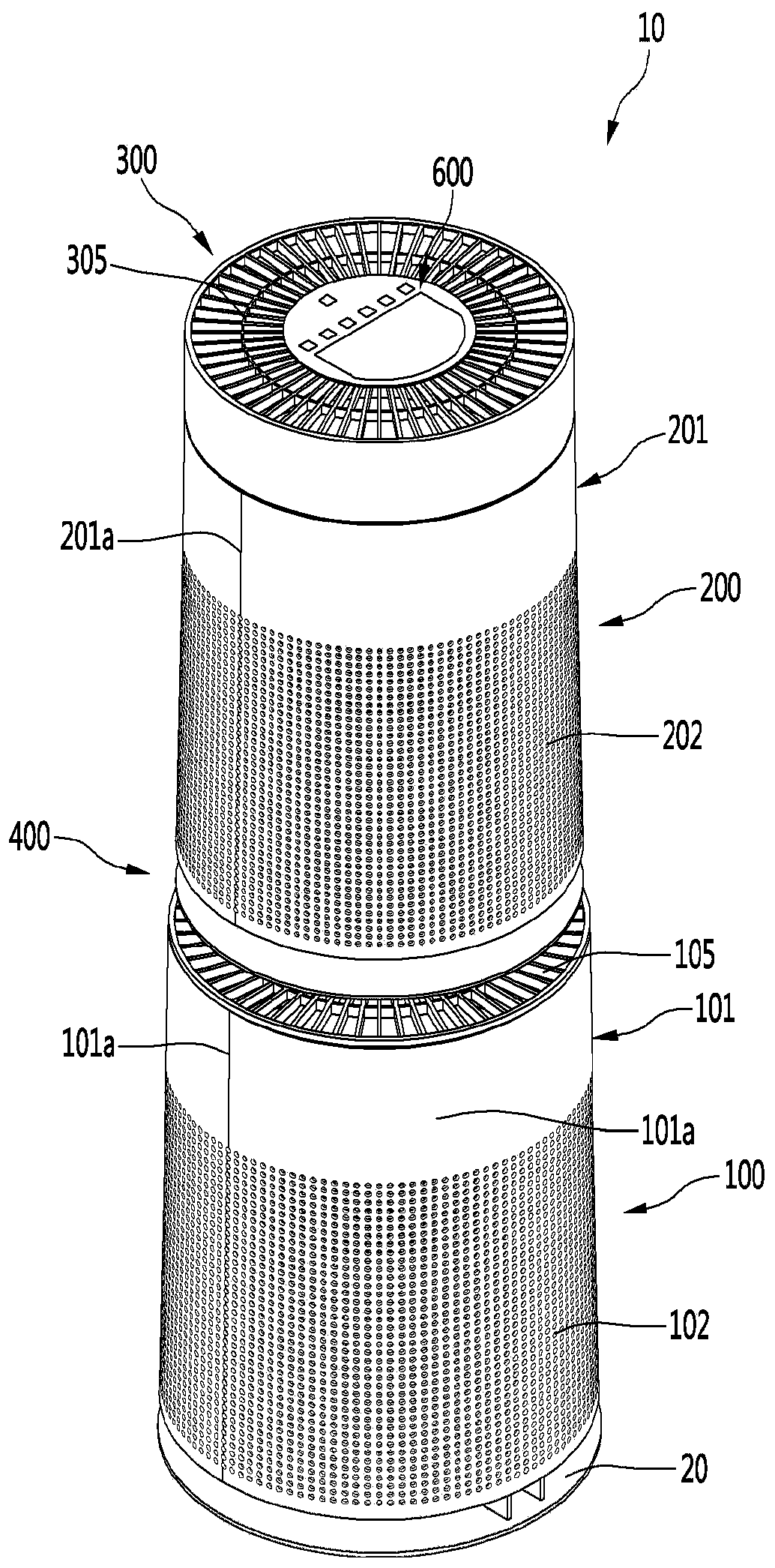

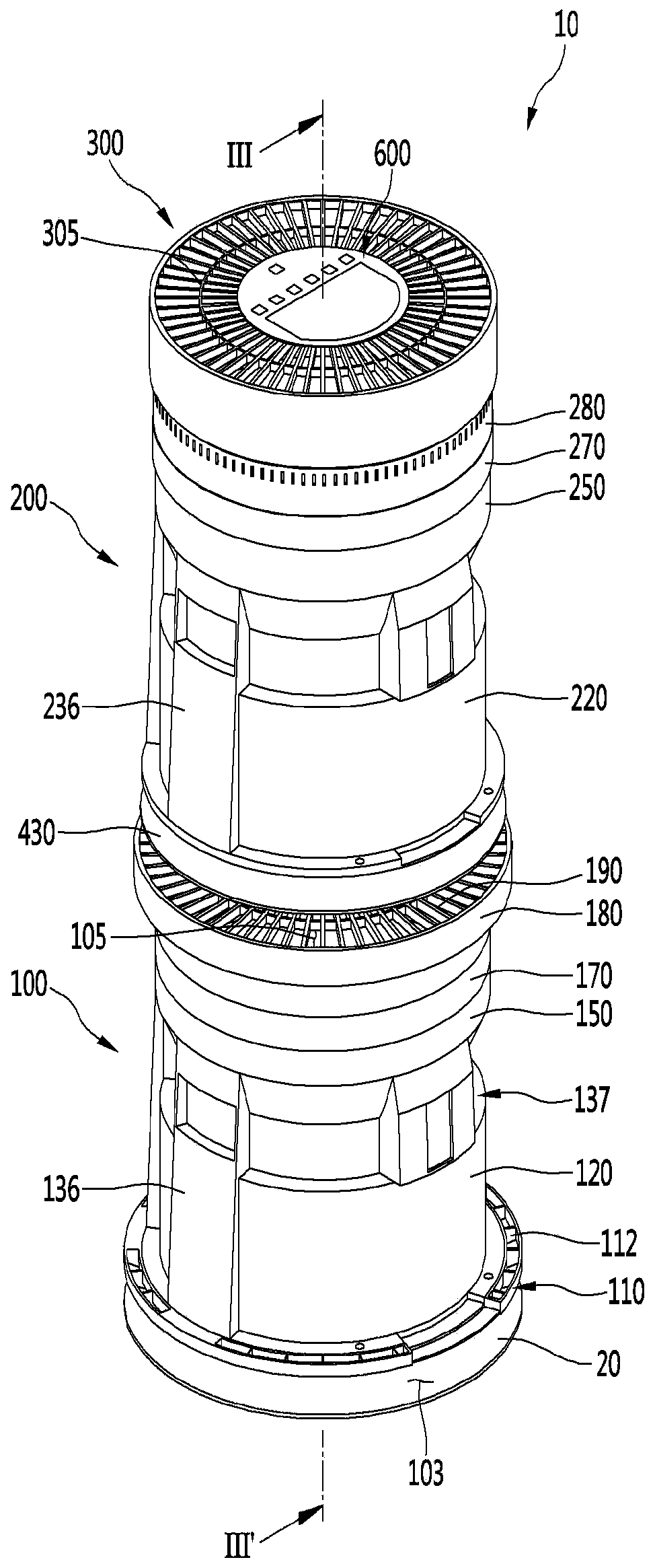

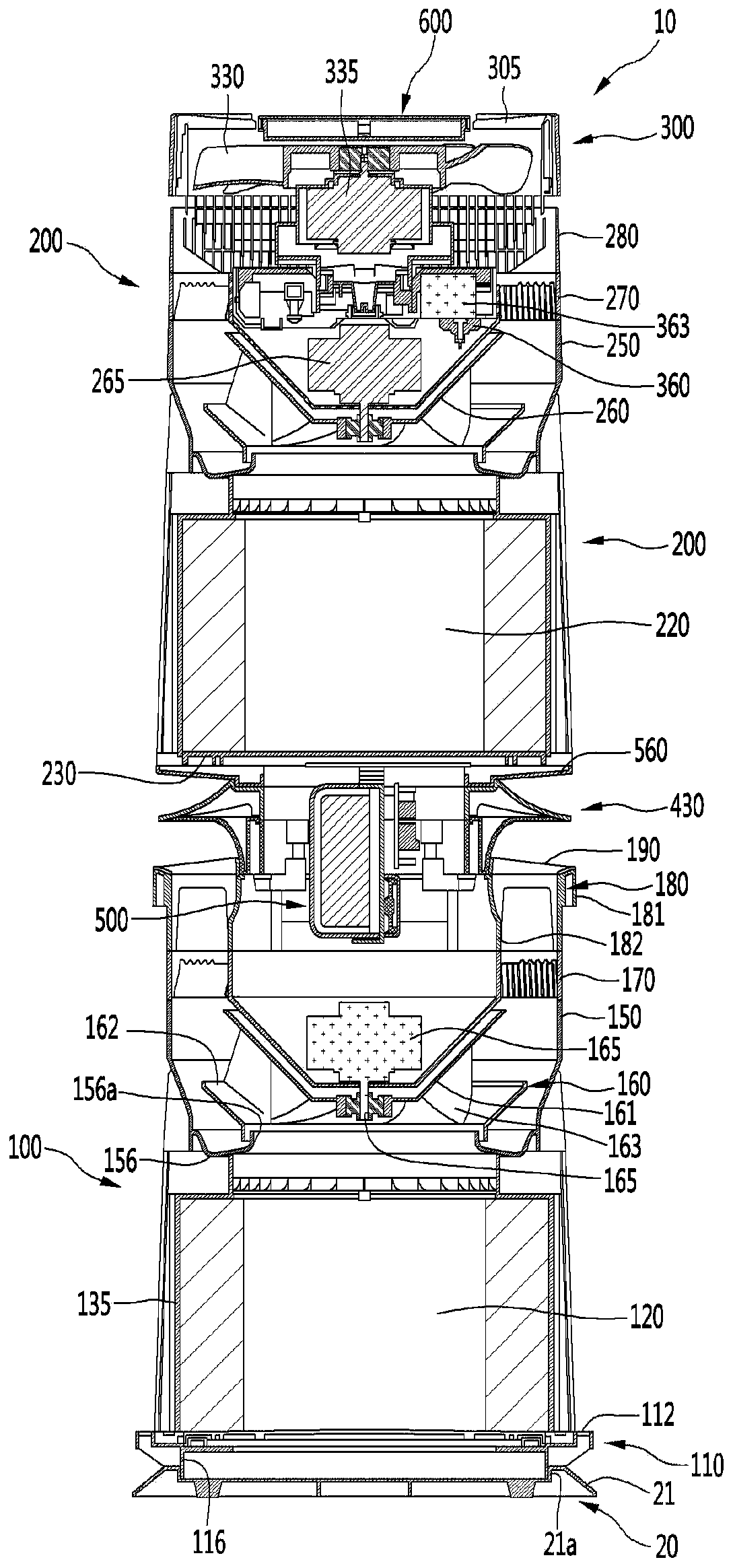

AIR Cleaner

ActiveCN111156623AIncrease the suction areaNo structural resistanceMechanical apparatusDispersed particle filtrationAir cleaningEngineering

The present disclosure provides an air cleaner including: an air cleaning module including a fan housing, a cylindrical filter, and a filter frame; a shell provided with a suction inlet and comprisingtwo parts; the filter frame includes: a lower frame, an upper frame and a plurality of support frames, wherein the fan housing is arranged above the filter frame and is supported by the filter frameand the plurality of through holes are uniformly spaced in the circumferential direction along the outer peripheral surface of the shell; the suction inlet includes a lower suction portion and an upper suction portion; when the two parts are separated from the air cleaning module, the outer peripheral surface of the cylindrical filter, the filter frame, and the outer surface of the fan housing areall opened, and the cylindrical filter can be drawn out in a radial direction through a space between the plurality of support frames. According to the invention, the suction capacity is improved, the structural resistance of the shell cannot be generated in the air suction process, and the suction area of air can be increased.

Owner:LG ELECTRONICS INC

Production method of drug containing composite particle

InactiveUS20080248119A1FunctionalEasy to handlePowder deliveryOrganic active ingredientsNanoparticleDrug powder

A strong pressure and a strong shearing force are exerted to a mixture, constituted of two kinds or more of powder materials including a drug powder, while causing the mixture to pass between a press section (26) of a press head (24) and a receiving surface (25) of a cylindrical rotator (23), thereby combining the drug powder with the other powder material. For example, at least one of a drug and a biocompatible polymer is made into a nano particle whose average particle diameter is less than 1000 nm, and the nano particle is made into a composite in accordance with a dry mechanical particle combining method, so as to form a polymer nano composite particle. Thus, it is possible to produce a composite particle, which contains a drug under a stable condition, in a short time, and it is possible to remarkably improve its handling property without losing advantages of the nano particle. As a result, it is possible to favorably apply the foregoing technique to DDS of a powdery drug taken into the body through the lung or a similar drug.

Owner:HOSOKAWA MICRON CORP

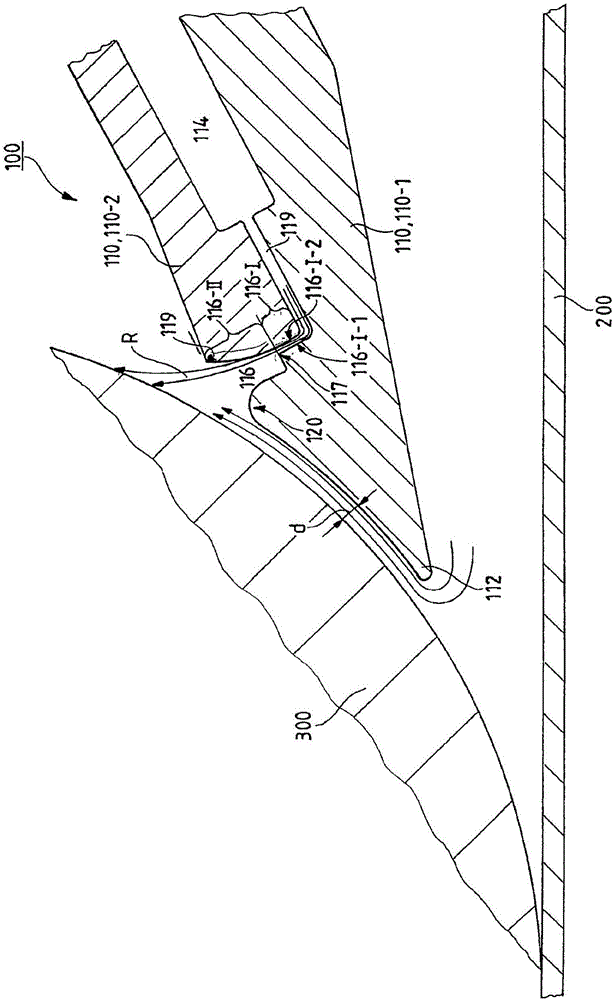

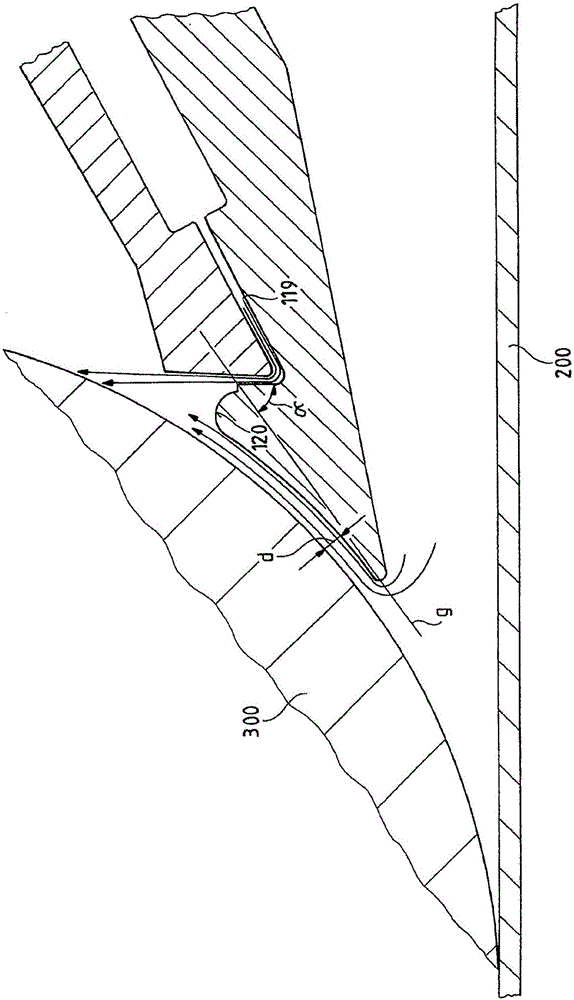

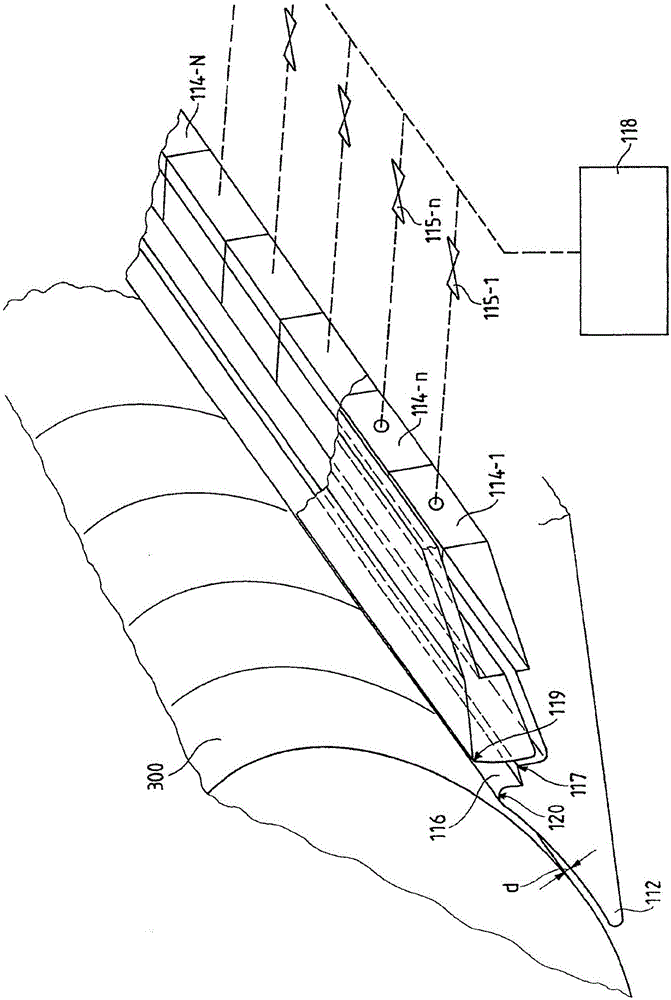

Strip deflector and roll assembly

ActiveCN106660089AAvoid vortexImprove sealingGuiding/positioning/aligning arrangementsRollsMetal stripsStructural engineering

The invention relates to a strip deflector for deflecting a rolling medium from the surface of a metal strip. The invention further relates to a roll assembly, comprising a roll, adjacent to which the strip deflector is placed at a distance, and comprising the strip deflector according to the invention. The strip deflector consists substantially of a main body, in which a compressed-air chamber and a nozzle (116) connected to the compressed-air chamber in a flow-conducting manner are formed. The nozzle (116) comprises a first nozzle channel segment (116-I) connected to the compressed-air chamber (114) and a second nozzle channel segment (116-II) connected downstream. According to the invention, in order to improve the sealing action of the strip deflector with respect to the roll in a roll stand, the side wall (116-I-2) facing away from the tip (112) of the main body (110) is bent away from the tip (112) of the strip deflector, a second separation edge (119) thus being formed at the end of the second nozzle channel segment (116-II).

Owner:SMS GRP GMBH

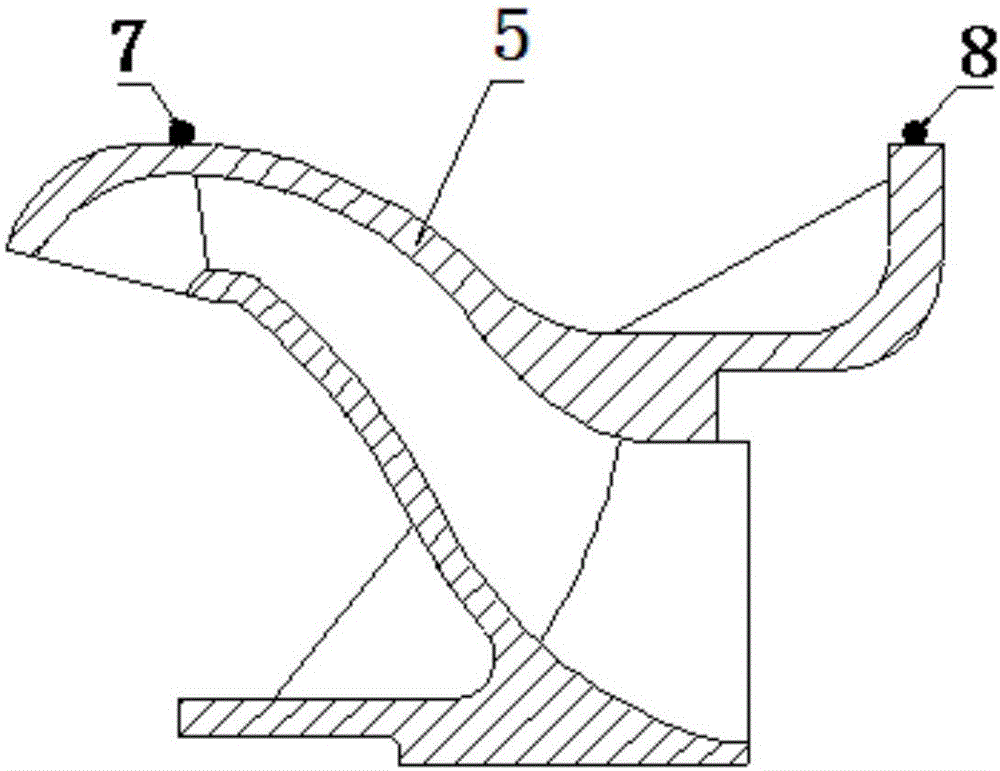

High-lift pump impeller for electric automobile

The invention relates to the field of impellers and discloses a high-lift pump impeller for an electric automobile. The high-lift pump impeller for the electric automobile comprises an impeller body (2) installed in a pump body, the impeller body (2) comprises a panel (3) and blades (4) installed on the panel (3), the blades (4) comprise main blade bodies (41) and auxiliary blade bodies (42), themain blade bodies (41) and the auxiliary blade bodies (42) are circumferentially arranged round the central axis of the panel (3), and the length of the main blade bodies (41) is larger than that of the auxiliary blade bodies (42). According to the high-lift pump impeller for the electric automobile, the two kinds of blade bodies are arranged, so that the flow area between the blades is increased;since bending of the blades is reduced and jamming of the blades is also reduced, the circulation area of the blades is increased; and the inlet flow speed is reduced, so that the anti-cavitation performance of the impeller is improved.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

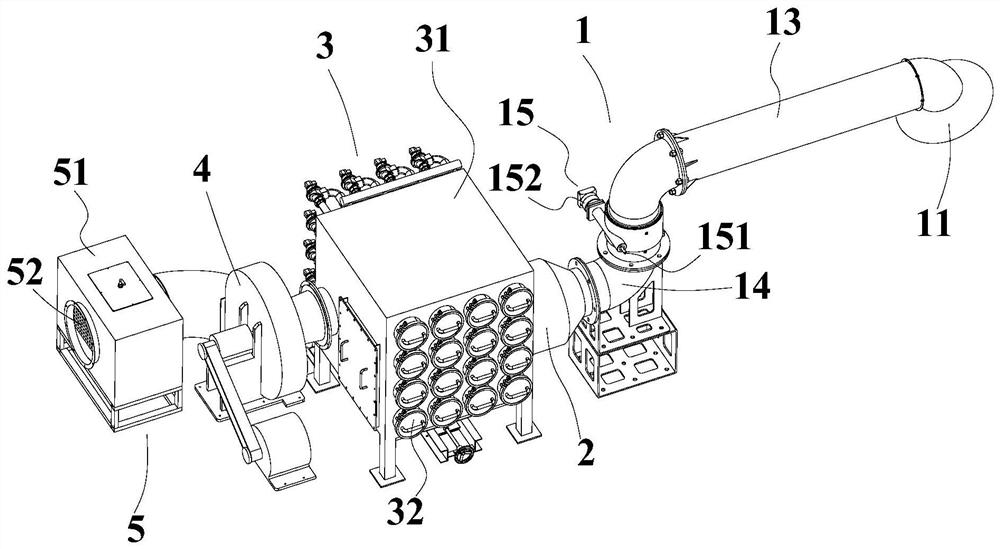

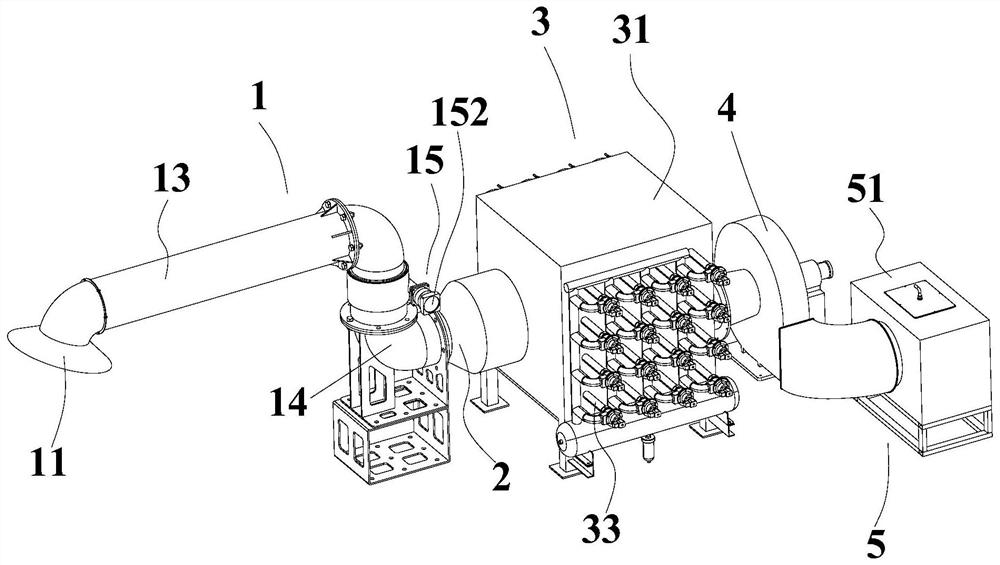

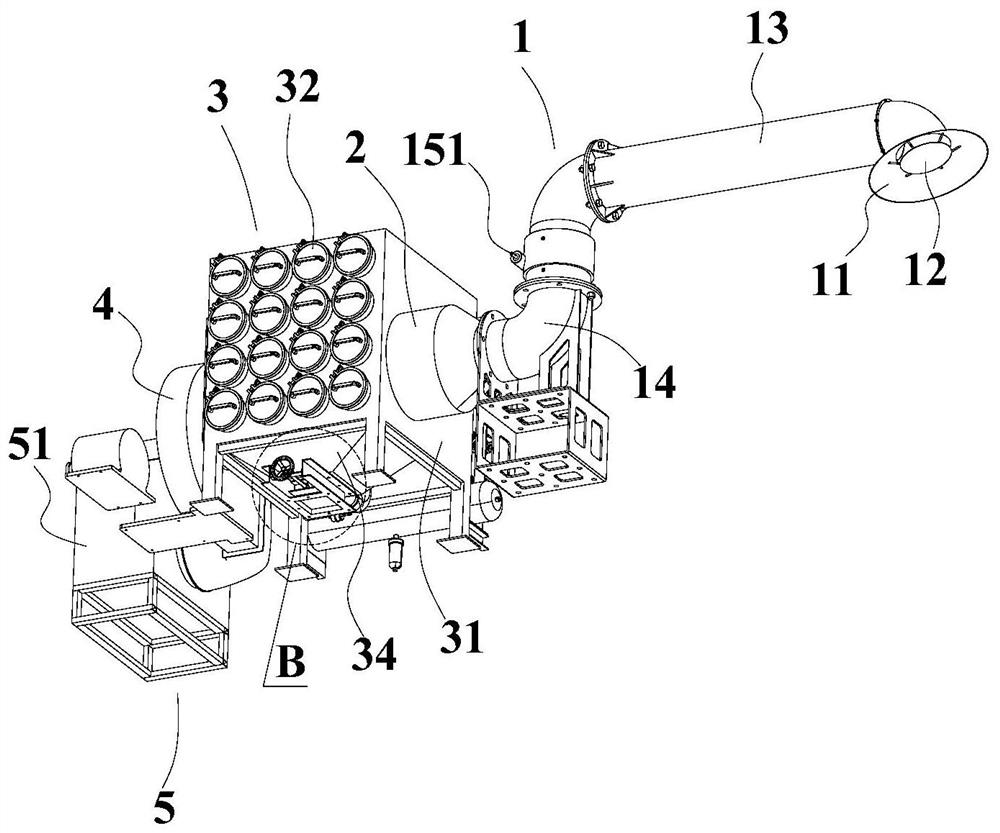

Built-in fire smoke decontamination device

PendingCN112197612ARapid smoke removal and coolingQuick evacuationGas treatmentDispersed particle filtrationToxic gasParticulates

The invention relates to the field of fire fighting, and particularly relates to a built-in fire smoke decontamination device. The built-in fire smoke decontamination device comprises a gas inlet pipe, a CO eliminating device, a smoke filtering device, an air draft device and a gas-water mixed smoke cooling device which are sequentially connected. The built-in fire smoke decontamination device hasthe advantages that compared with the prior art, insoluble toxic gas such as carbon monoxide in smoke can be eliminated, meanwhile, water and mist are not sprayed in a long and narrow space, so thatsurrounding electrical circuits cannot be damaged, secondary fire cannot be caused, and the safety is good. The built-in fire smoke decontamination device can actively suck fire smoke to filter smokeparticles, and smoke cooling, carbon monoxide elimination and soluble toxic gas elimination are carried out in a machine body. Rapid smoke elimination and cooling of a fire scene are realized, the visibility is improved, and rapid evacuation and rescue of people can be organized.

Owner:HEFEI KDLIAN SAFETY TECHNOLOGY CO LTD

A submersible cutting sewage pump with high-efficiency hydraulic characteristics

ActiveCN104100534BImprove inhalation performanceImprove operating conditionsSpecific fluid pumpsPump componentsAxial displacementImpeller

The invention relates to a submersible cutting sewage pump with efficient hydraulic performance and belongs to the technical field of submersible pumps. The submersible cutting sewage pump comprising a submersible motor is characterized in that the submersible motor is connected with a pump body below through a connection segment to form a cooling and lubricating oil chamber; an efficient large-pass semi-open impeller having a rear cover plate is disposed in the center of the lower portion of the pump body; an inlet edge of each impeller blade is provided with a 30-45-degree large guiding tilt angle from the rear cover plate and a front cover plate, and a center line of an impeller blade outlet pass is flush with a center line of a radial outlet of the pump body; the lower end face of the pump body is connected with a pump base, a cutting disc which is axially adjustable is connected to the upper portion of the pump base, the cross section of the upper end of the cutting disc is completely the same as a flow surface of the front cover plate, projecting to the impeller blade axial surface, in shape, and a 0.2-0.3 mm required gap can be formed between the upper end of the cutting disc and the flow surface of the front cover plate, projecting to the impeller blade, by adjusting axial movement of the cutting disc. The submersible cutting sewage pump is high in hydraulic efficiency, has a wide efficient area, allows suctioning and passage of large particles, and has good effect of impurity cutting and tearing.

Owner:NANJING ZHONGDE ENVIRONMENTAL PROTECTION EQUIP MFG

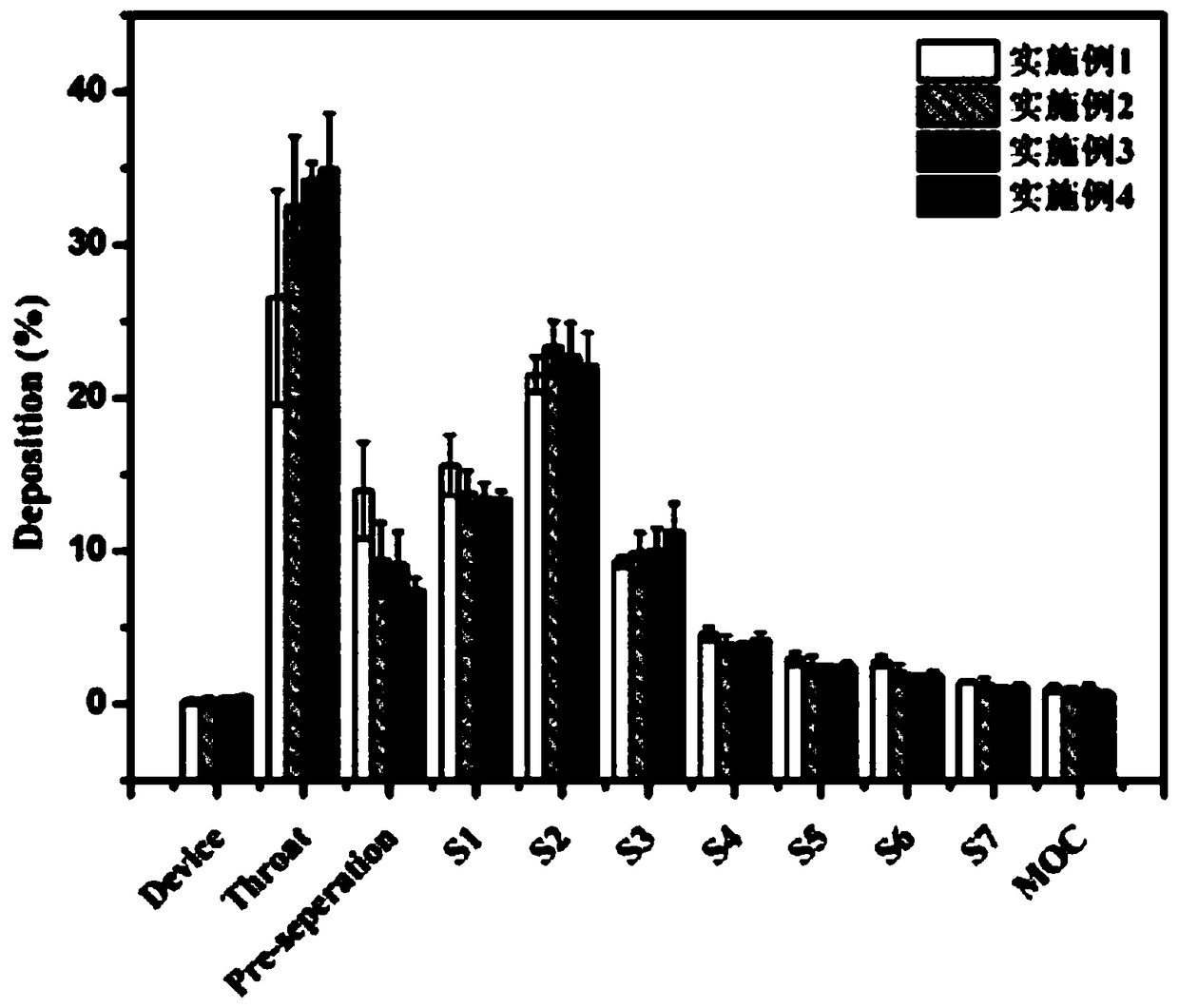

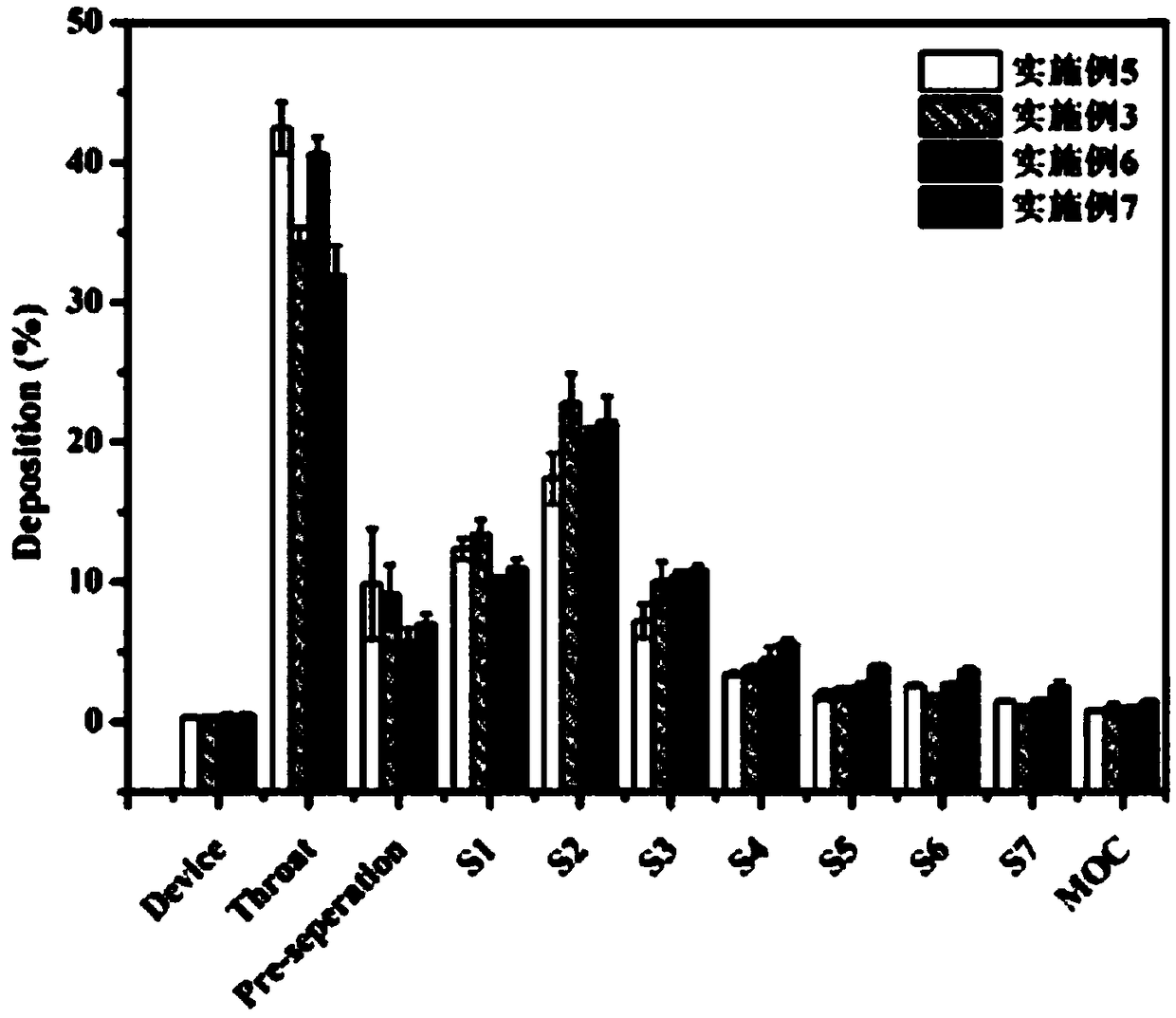

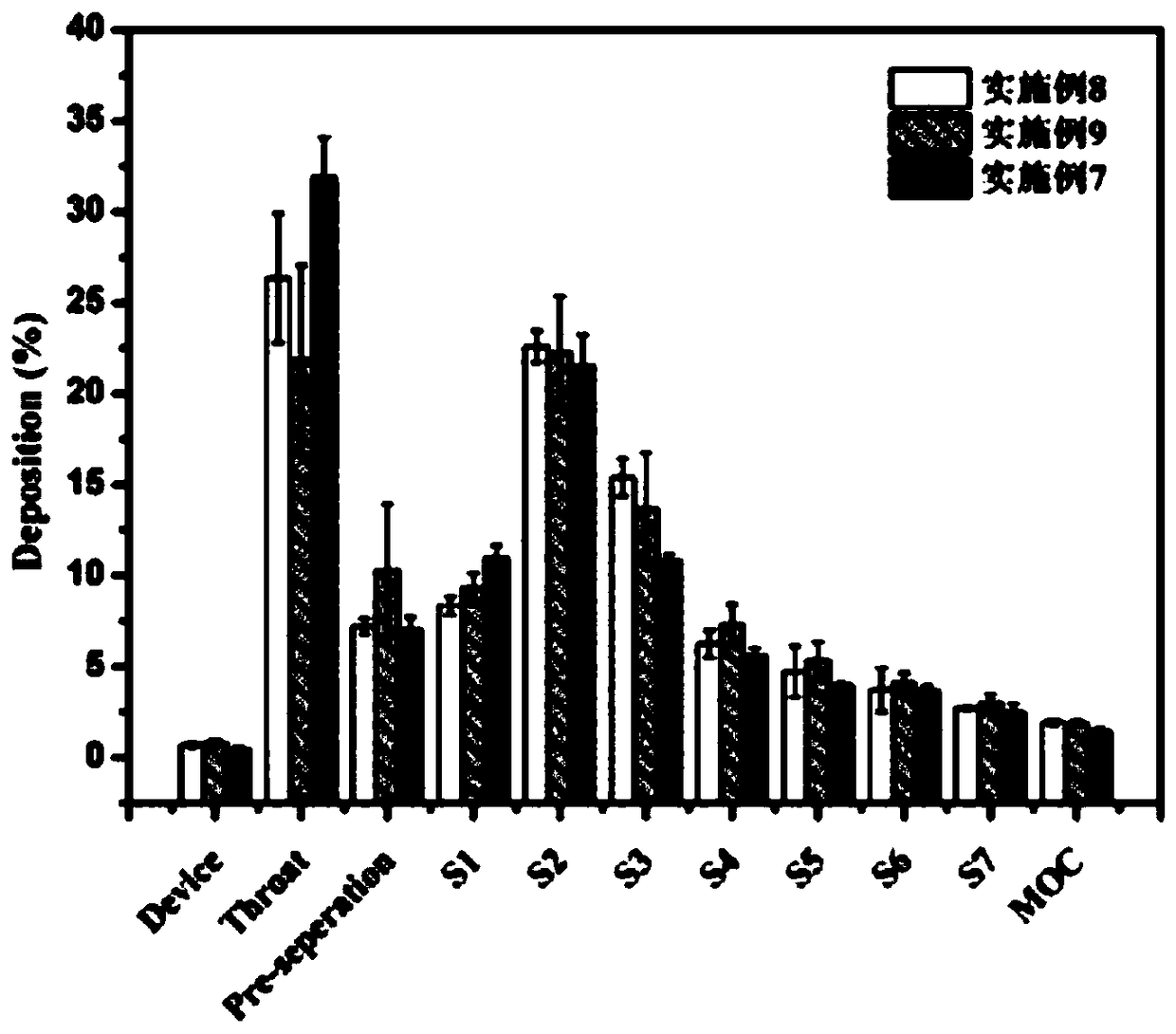

Ciprofloxacin dry powder inhaler and preparation method thereof

ActiveCN108771660AFluffy cotton-like structureHigh emptying rateAntibacterial agentsOrganic active ingredientsSpidroinMannitol

The invention discloses a ciprofloxacin dry powder inhaler and a preparation method thereof. The dry powder inhaler is prepared from a drug and a binary auxiliary material, wherein the drug accounts for 80 to 20 percent by mass of the dry powder inhaler, the binary auxiliary material accounts for 20 to 80 percent by mass of the dry powder inhaler, and the binary auxiliary material comprises a mucus diluting agent and biological adhesive protein; the mucus diluting agent is at least one of mannitol, ambroxol hydrochloride, aminothiopropionic acid, and bromhexine hydrochloride; and the biological adhesive protein is at least one of silk fibroin, albumin or spidroin. The dry powder inhaler prepared by the invention is good in mobility, good in aerodynamic performance, capable of targeting thedrug to lung and capable of effectively increasing the local concentration of the drug, has mucus diluting and biological mucosa adsorption characteristics, and is particularly suitable for a patientwith bronchiectasia caused by the chronic infection of the lung.

Owner:SUN YAT SEN MEMORIAL HOSPITAL SUN YAT SEN UNIV

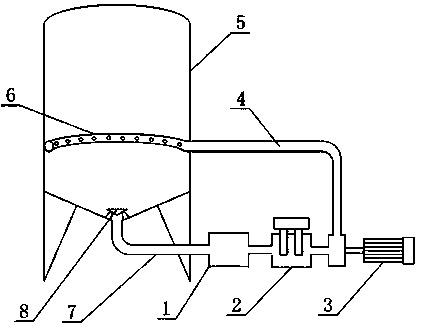

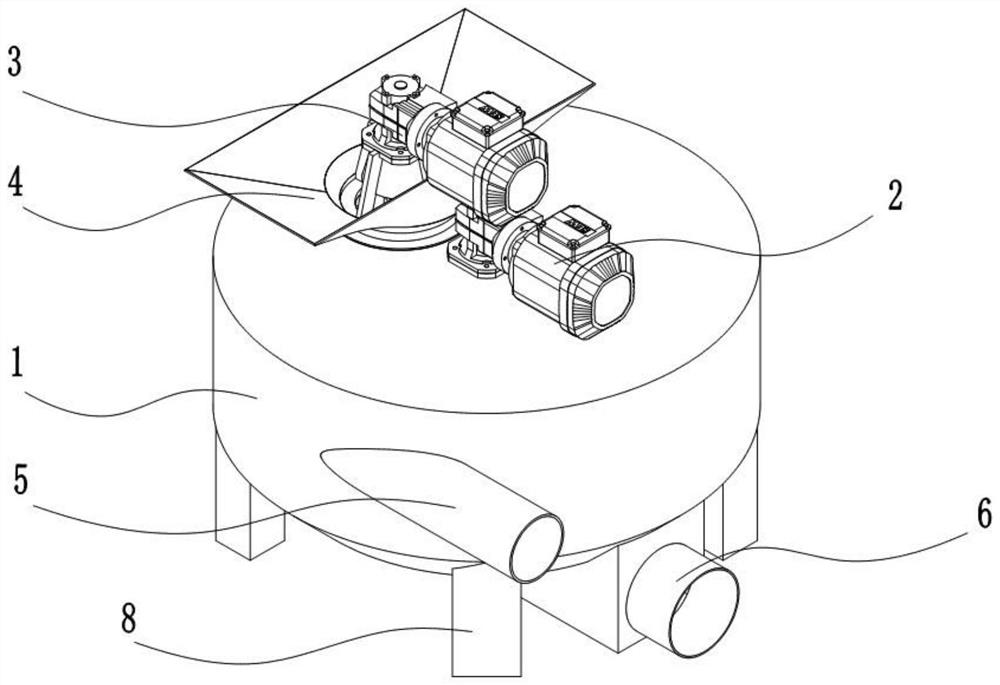

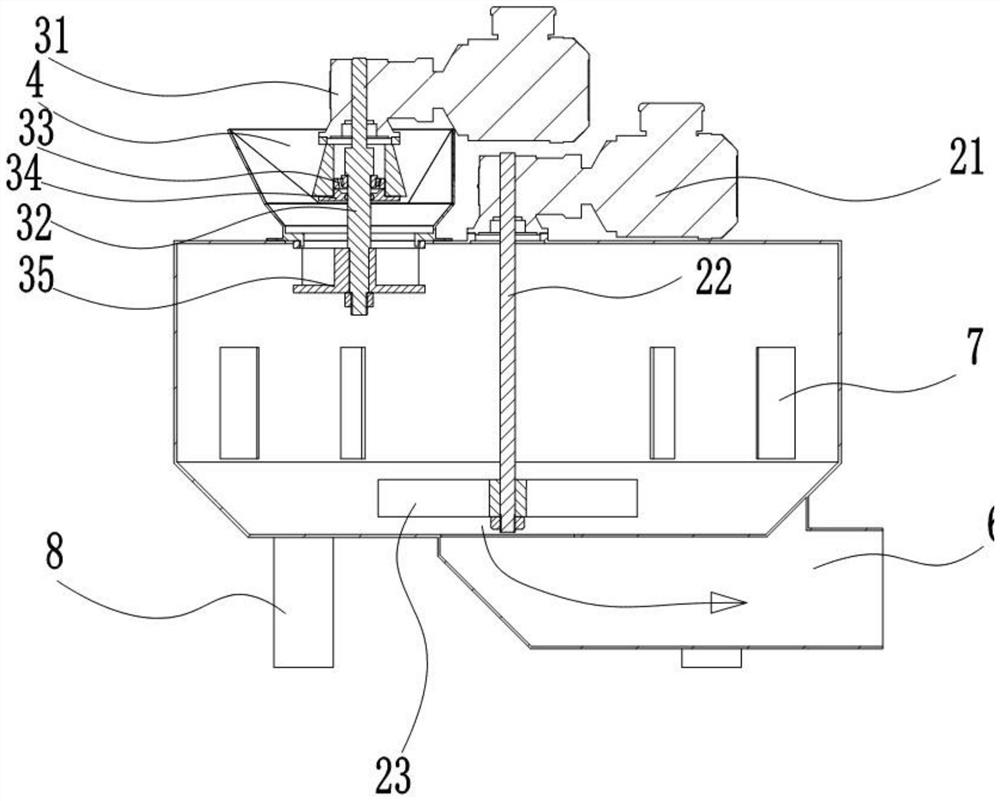

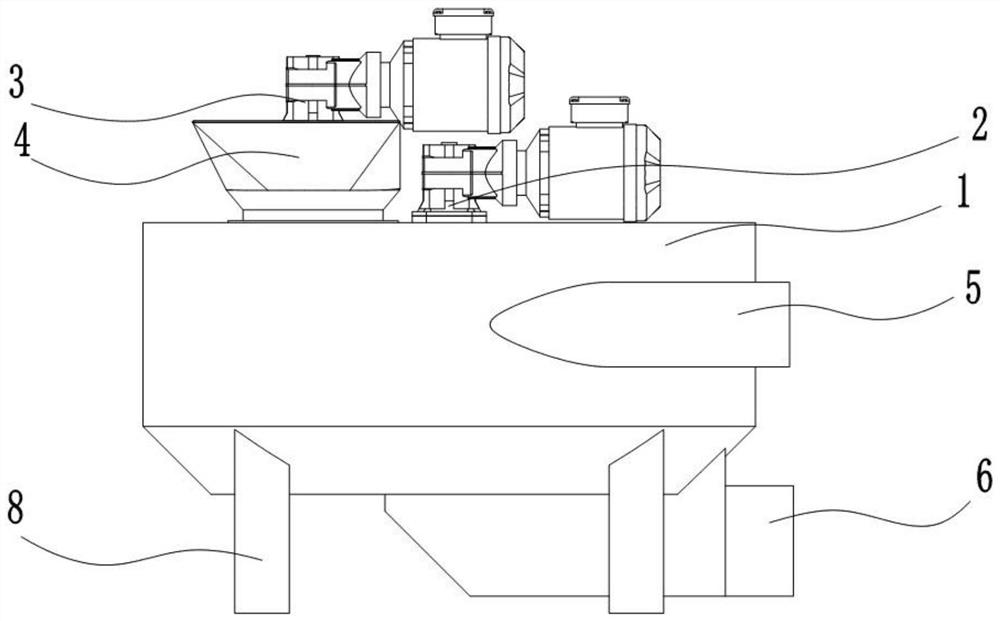

A safe sugar dissolving machine

InactiveCN104338442AImprove inhalation performanceAvoid harmFlow mixersTransportation and packagingEngineeringSugar

A safe sugar dissolving machine is disclosed. The sugar dissolving machine comprises a sugar dissolving tank (5), a pump package (3), a fluid feeding pipe (7) and a fluid discharging pipe (4). One end of the fluid feeding pipe (7) is fixedly connected to the bottom of the sugar dissolving tank (5), and the other end is fixedly connected to an inlet flange of the pump package (3). One end of the fluid feeding pipe (7) is connected to the inlet flange of the pump package (3), and the other end is fixedly connected to the sugar dissolving tank (5). The sugar dissolving machine also comprises a ring pipe (6) that is circular. The ring pipe (6) is fixedly connected to the inner wall of the sugar dissolving tank (5), is communicated with the fluid discharging pipe (4), and is provided with a plurality of outlet holes. The sugar dissolving machine can avoid influences of lubricating oil on sugar liquid quality, and is simple in structure and good in sugar dissolving effects.

Owner:王正述

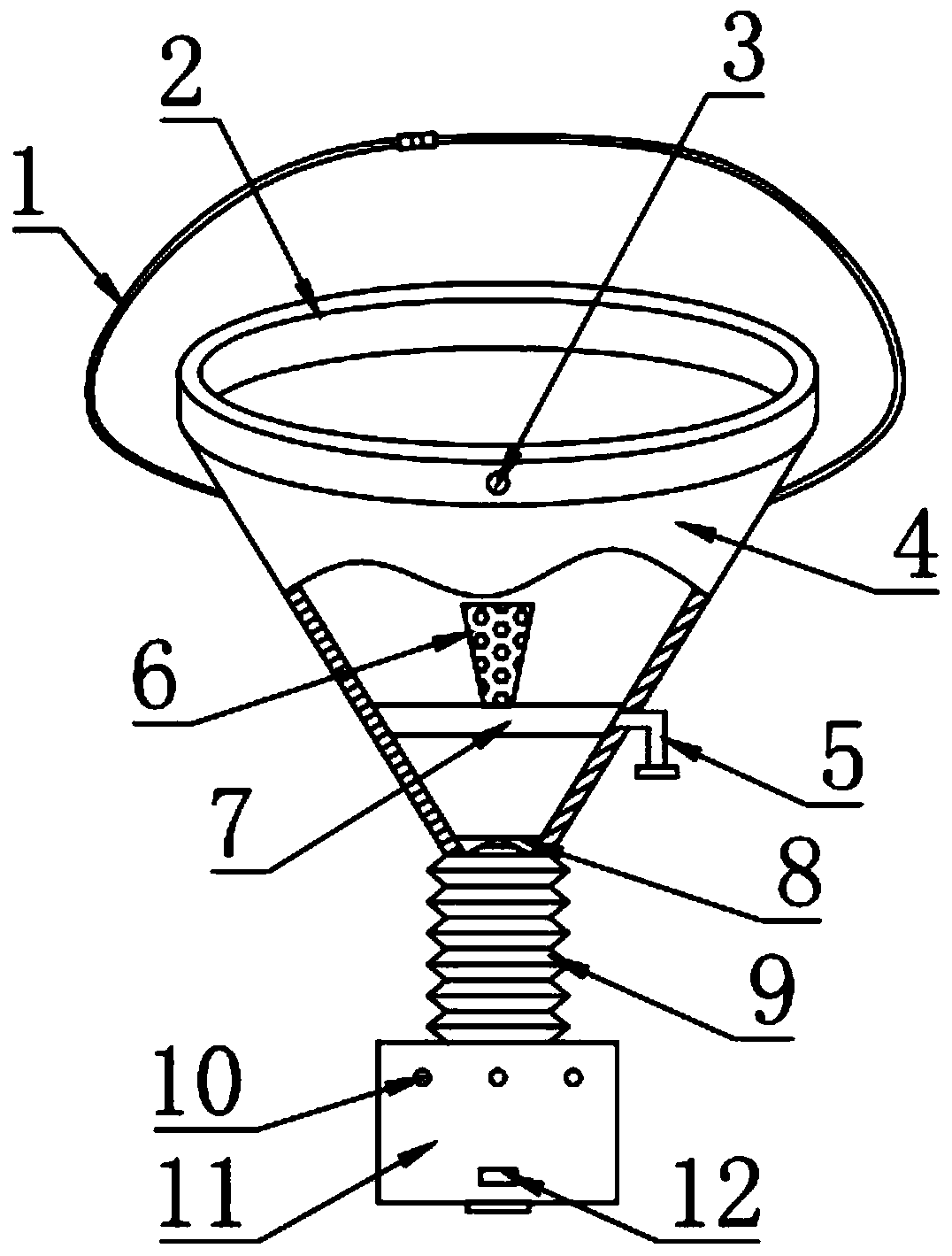

Atomizing inhalation device for pediatric internal medicine department

ActiveCN110354352AImprove inhalation performanceSufficient inhalationMedical atomisersInhalatorsInhalationFiltration

The invention relates to the technical field of medical instruments, in particular to an atomizing inhalation device for the pediatric internal medicine department. The device comprises a fixing belt,an air bag, an air tube, a breathing mask and an atomizing inhalation tube, wherein the air bag is arranged at the upper end of the breathing mask, the air tube is arranged on the air bag, the fixingbelt is also arranged at the upper part of the breathing mask, and the atomizing inhalation tube is arranged on the side face of the lower part of the breathing mask; the atomizing inhalation tube isconnected with an air distribution device arranged in the breathing mask, the upper side of the air distribution device is provided with an exhaust head, the lower end of the breathing mask is connected with a corrugated pipe, and the other end of the corrugated pipe is connected with an inhalation filtering device. The atomizing inhalation device is simple in structure, reasonable in design andgood in atomizing inhalation effect and can guide filtration and discharge of exhaled air of sick children and prevent cross infection.

Owner:车媛媛

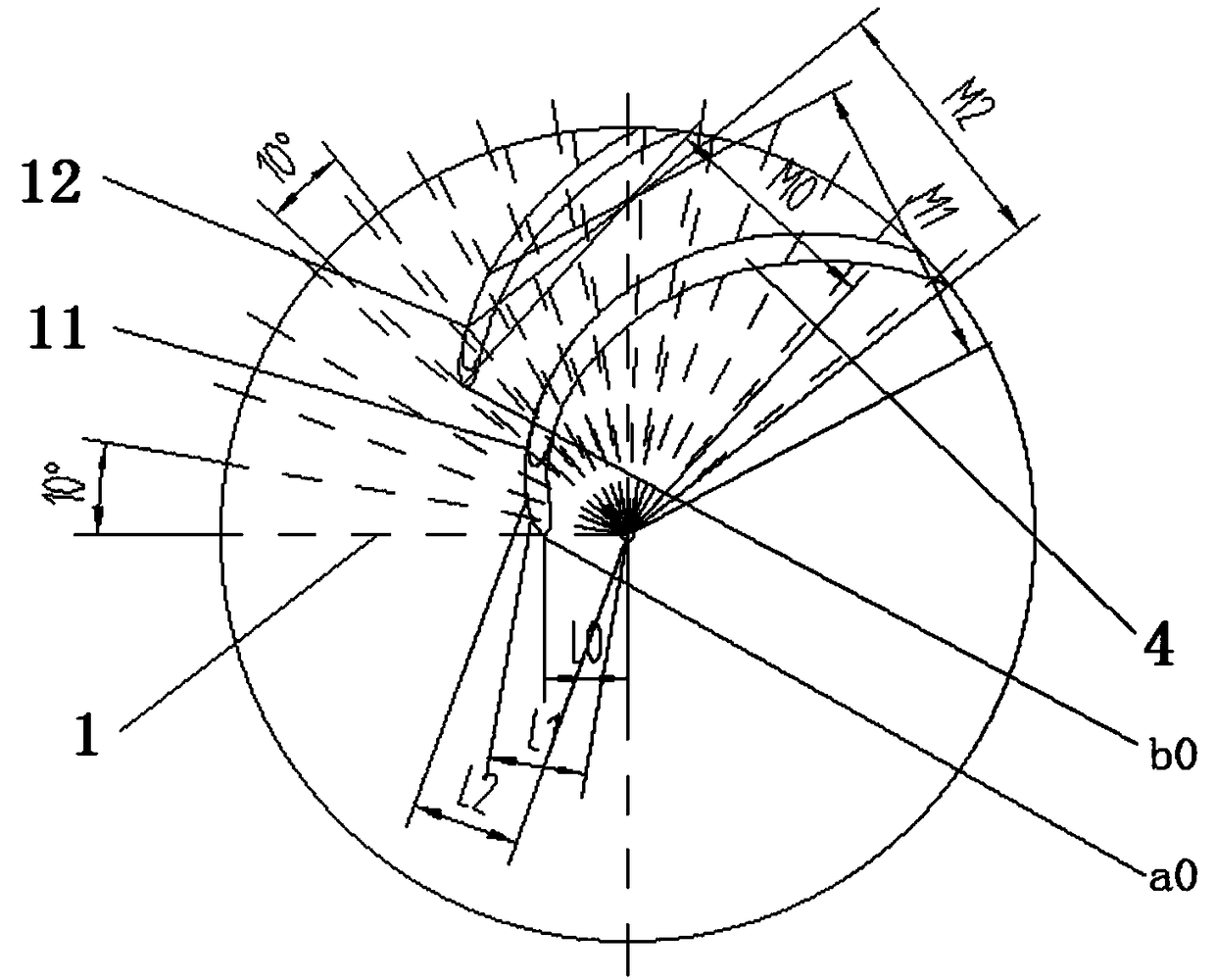

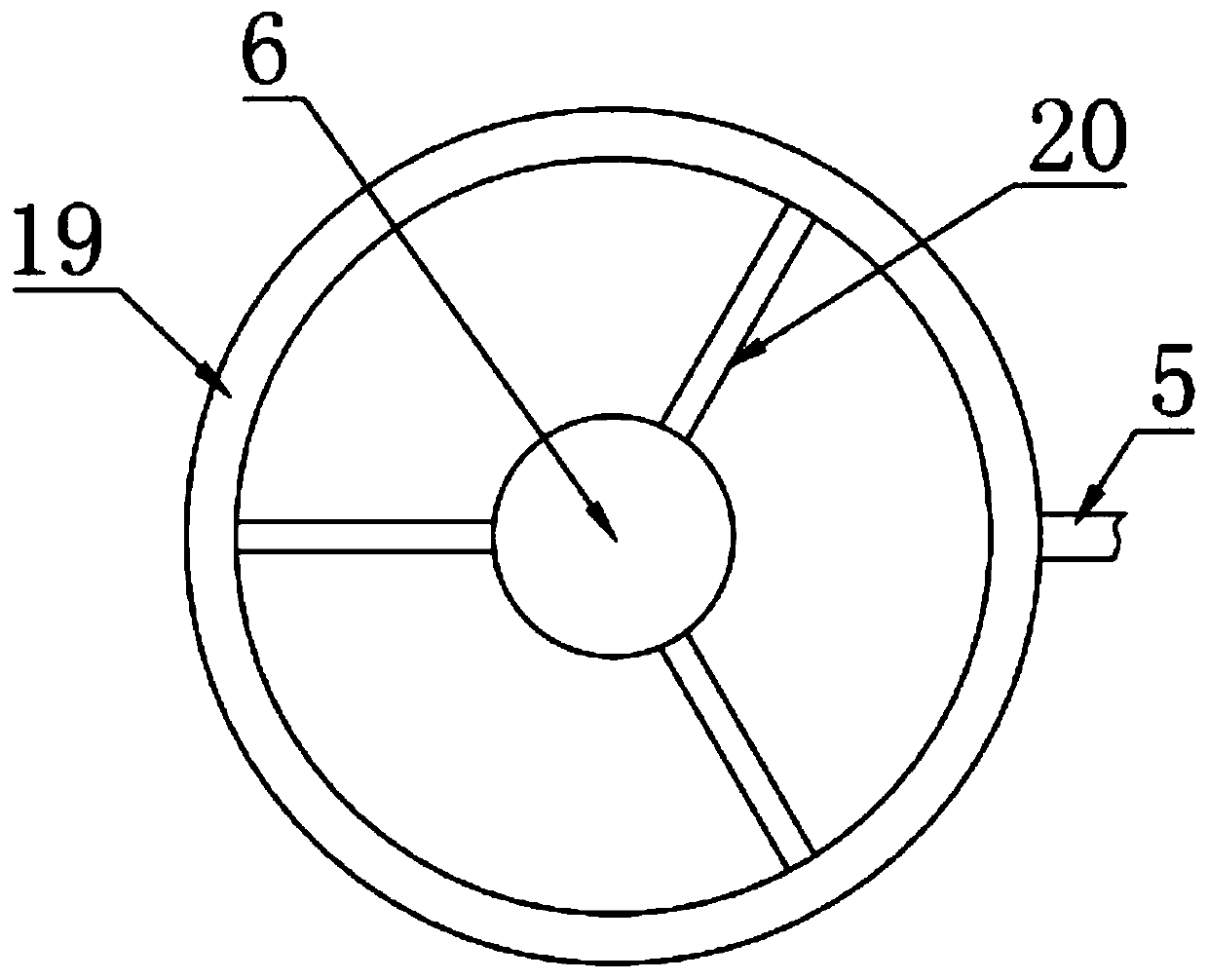

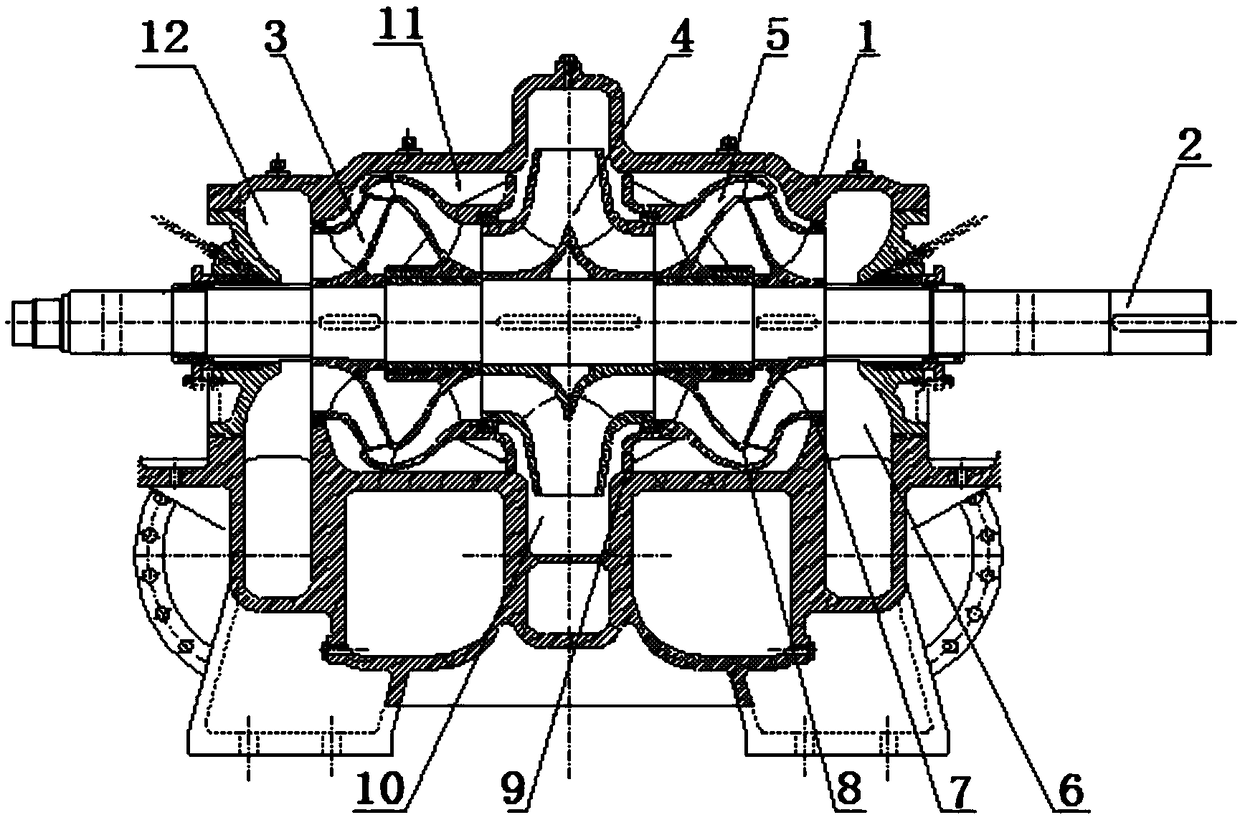

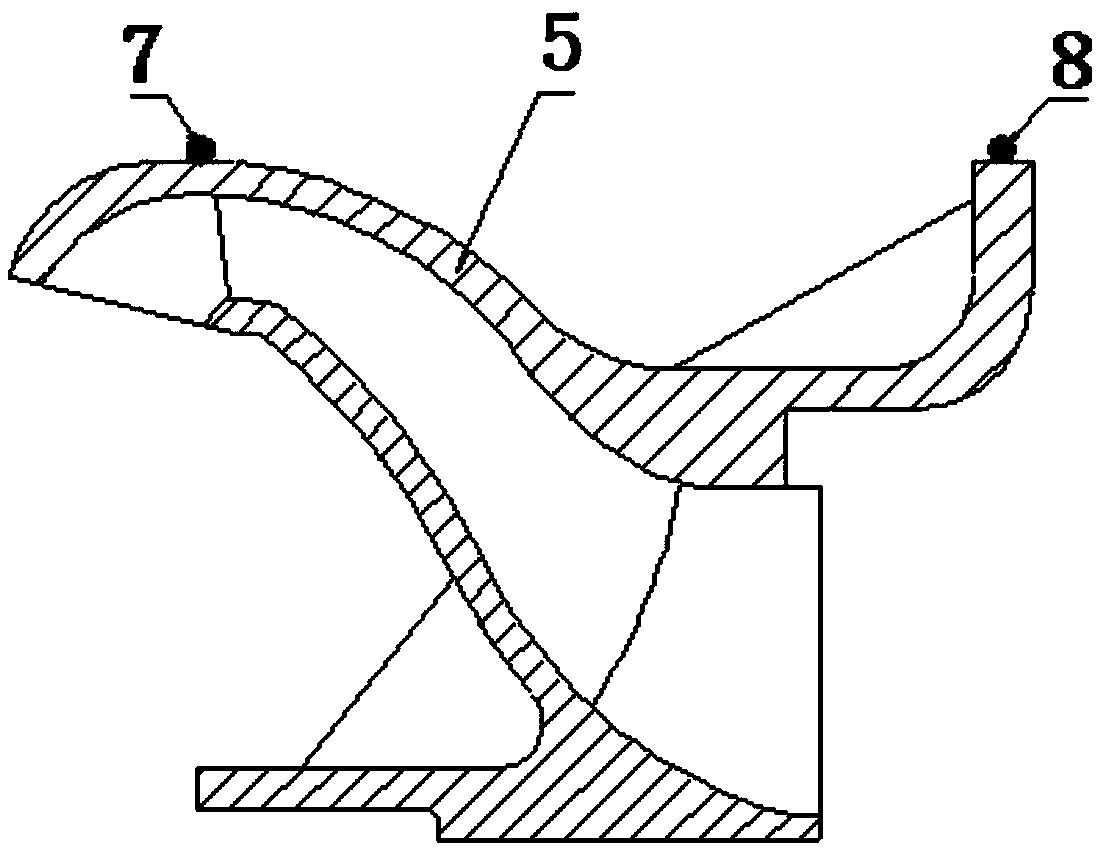

Flow diversion shell type double-stage double-suction centrifugal pump

The invention relates to a flow diversion shell type double-stage double-suction centrifugal pump. The flow diversion shell type double-stage double-suction centrifugal pump comprises a pump body and a transmission shaft penetrating through the pump body and rotationally connected with the pump body. Two first-stage impellers are arranged on the part, located in the pump body, of the transmission shaft front and back in a spaced mode. A second-stage impeller is arranged on the part, located between the two first-stage impellers, of the transmission shaft. An interstage flow diversion shell is fixedly arranged in the pump body and is an impeller. A runner of the interstage flow diversion shell is in an S shape. The interstage flow diversion shell is located among the first-stage impellers and the second-stage impeller. The inlet end of the interstage flow diversion shell is connected with the outlet ends of the first-stage impellers. The outlet end of the interstage flow diversion shell is connected with the inlet end of the second-stage impeller.

Owner:CHINA AGRI UNIV

Carbon dioxide gas compressor screw rod oil pump capable of removing excess gas automatically

InactiveCN108286516AFast deliveryGuaranteed uptimeRotary piston pumpsRotary piston liquid enginesGas compressorProduct gas

The invention discloses a carbon dioxide gas compressor screw rod oil pump capable of removing excess gas automatically. The carbon dioxide gas compressor screw rod oil pump comprises a pump shell, two ends of the pump shell are provided with an end cover and a pump body rear cover correspondingly, the end cover and the pump body rear cover are connected with the pump shell through bolts and nutswhich are matched with each other, the middle position of the inner portion of the pump shell is provided with one driving screw rod and two driven screw rods, the driven screw rods are arranged on two sides of the driving screw rod, the driving screw rod and the driven screw rods are all double-direction screw rods with threads being distributed symmetrically, the three screw rods are arranged horizontally and are symmetrically engaged with one another, the top of the pump shell is provided with a safety valve, the safety valve comprises a pressure adjusting screw rod, a spring seat and a valve core which are connected in sequence, one end of the pressure adjusting screw rod is fixed to a valve cover through a locking nut, the valve cover is connected with the pump shell through a third bolt, the other end of the pressure adjusting screw rod is connected with the spring seat, the other end of the spring seat is connected with the valve core, the tail end of the valve core is providedwith a valve rear cover, the valve rear cover is connected with the pump shell through the third bolt, and the pump shell is provided with a first screw plug and second screw plugs.

Owner:SHAANXI UNIV OF SCI & TECH

Cereal husk sifting device

InactiveCN108620156AAvoid enteringFully peeled and dustedGrain huskingGrain polishingHuskEngineering

The invention belongs to the technical field of food processing equipment, and in particular discloses a cereal husk sifting device. The cereal husk sifting device comprises a husk sifting box and atleast one set of dust sucking mechanism; a motor is arranged at the bottom of the husk sifting box; an abrasive disc is arranged at the upper part of an output shaft; the dust sucking mechanisms comprise vertical pipes, first one-way valves, second one-way valves, push rods and pressing blocks; the vertical pipes are vertically and fixedly connected with one side of the husk sifting box; springs are connected between the upper end surfaces of the push rods and the upper parts of the vertical pipes; air sucking pipelines are arranged in the push rods; the first one-way valves are arranged at the upper parts of the vertical pipes; air sucking holes are formed in the lower parts of the push rods; the second one-way valves are arranged at the lower parts of the air sucking pipelines; the husksifting box is provided with a feed port and a discharge port; and the lowest part of the feed port and the lowest part of the discharge port are flush with the lowest part of an inclined surface of the abrasive disc. The cereal husk sifting device is mainly used for sifting husks of unhusked rice, and solves the problem of influence on the rice eating by bad dust and unhusked rice husk treatmenteffect in the husk sifting operation of unhusked rice after primary milling.

Owner:凤冈县万福食品有限责任公司

Crawler-type under water ecological precision thin layer slurry dredger

InactiveCN1279249C"Endogenous" Pollution ControlSubstantiveMechanical machines/dredgersSupporting systemControl system

The utility model relates to a crawler-type underwater ecological precision thin-layer desilting machine, which belongs to the technical field of environmental protection. It is composed of main system, hydraulic control system, mud suction system and walking system. The main system is the overall support. The mud suction system is set in front of the main system, and the walking system is set under the main system. The main system includes: box body, support Rod, bracket, lighting device, camera monitoring device, connection mode: the middle part of the box body is connected with the bracket, the bracket is connected with the support rod, the upper part of the box body, the lighting device and the camera monitoring device are respectively connected with the upper part of the box body, and the lighting device is connected with the upper part of the box body. The camera and monitoring devices are all rotated 360°, the hydraulic control system is installed in the box, the mud suction system is set in the middle of the box, the support rods and brackets are connected with the mud suction system, and the lower part of the box is symmetrically connected with the walking system. The invention has the characteristics of small size, light weight, simple structure and convenient operation, and is especially suitable for water purification projects of natural water bodies such as vast rivers, lakes and reservoirs in my country.

Owner:章永泰

A diversion shell type two-stage double-suction centrifugal pump

The invention relates to a flow diversion shell type double-stage double-suction centrifugal pump. The flow diversion shell type double-stage double-suction centrifugal pump comprises a pump body and a transmission shaft penetrating through the pump body and rotationally connected with the pump body. Two first-stage impellers are arranged on the part, located in the pump body, of the transmission shaft front and back in a spaced mode. A second-stage impeller is arranged on the part, located between the two first-stage impellers, of the transmission shaft. An interstage flow diversion shell is fixedly arranged in the pump body and is an impeller. A runner of the interstage flow diversion shell is in an S shape. The interstage flow diversion shell is located among the first-stage impellers and the second-stage impeller. The inlet end of the interstage flow diversion shell is connected with the outlet ends of the first-stage impellers. The outlet end of the interstage flow diversion shell is connected with the inlet end of the second-stage impeller.

Owner:CHINA AGRI UNIV

Immersed pump system in low-temperature tank

InactiveCN111412148AReduce cold lossEasy to maintainSpecific fluid pumpsPump componentsPhysicsEngineering

The invention relates to an immersed pump system in a low-temperature tank and belongs to the technical field of low-temperature liquid conveying. The problems that an existing immersed pump is not convenient to install and poor in use effect are solved. The immersed pump system comprises the low-temperature tank and an immersed pump and further comprises a pump well which is arranged in the low-temperature tank and is used for isolating the low-temperature tank and the immersed pump, a pump well upper installation seat which is arranged at the upper portion of the pump well and used for installing the pump well, and a top plate arranged on the pump well upper installation seat. A valve body is arranged at the lower portion of the pump well, and the lower portion of the valve body is connected with a valve plate through an elastic assembly. A gas phase pipeline is arranged at the upper portion of the low-temperature tank. A gas phase valve is arranged on the gas phase pipeline. The gasphase pipeline passes through the gas phase valve, then penetrates the pump well upper installation seat and then communicates with the pump well. An air inlet pipeline at the upper portion of the gas phase pipeline is provided with a nitrogen valve.

Owner:ZIBO BOSHAN LVYUAN GAS EQUIP CO LTD

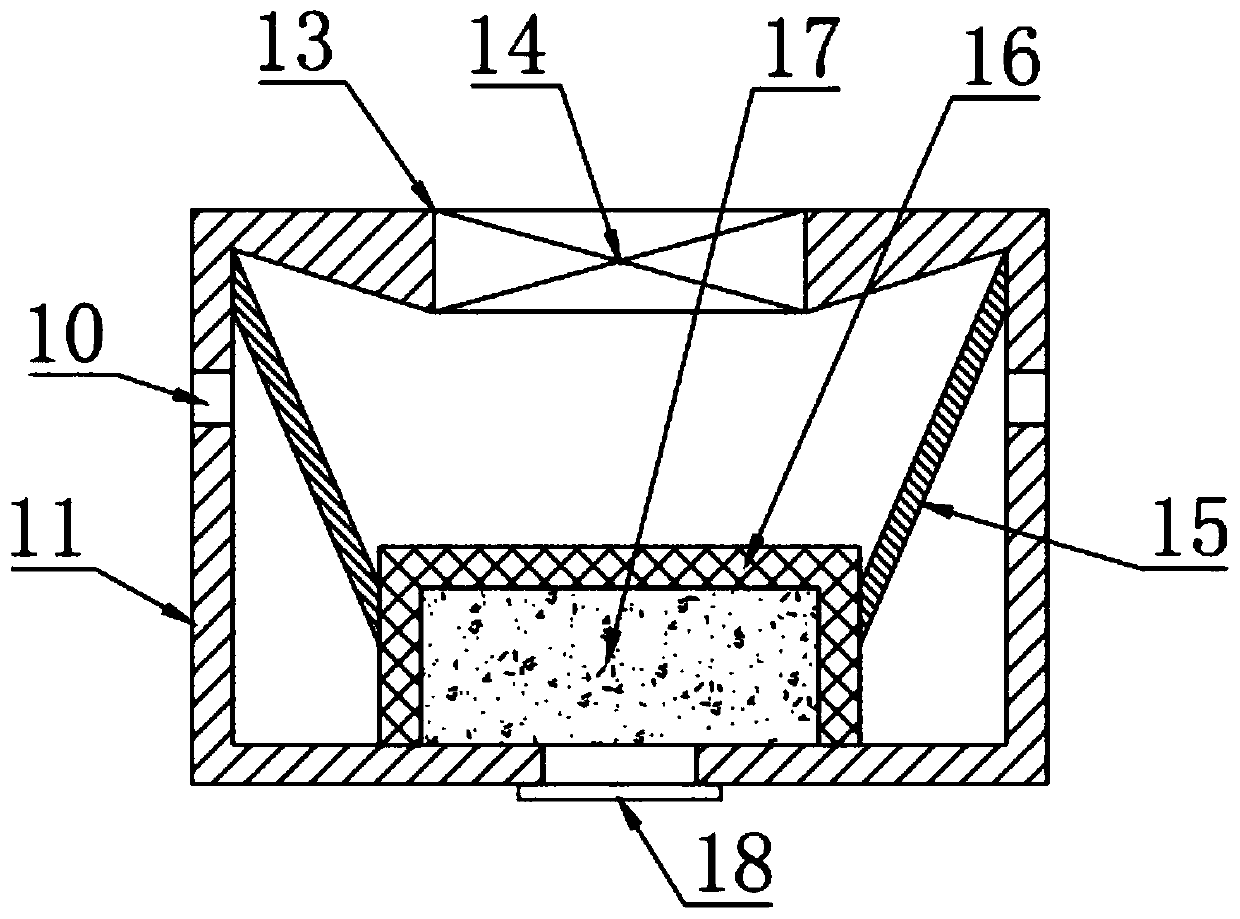

Stirrer mechanical seal pumping circulation device

ActiveCN110762214BImprove inhalation performanceLow agitationEngine sealsTransportation and packagingEngineeringAgitator

The invention provides a mechanical seal pumping circulation device for an agitator. The top of the sealing cavity is connected to the shaft sleeve through the air-side sealing core, the bottom of the sealing cavity is fixedly connected to the base, and the base and the shaft sleeve are connected through the medium-side sealing core. A liquid sealing cavity is formed, a stator is fixed on the sealing cavity, a rotor is fixed on the shaft sleeve, and the rotor is at a position opposite to the stator. The invention has good self-circulation ability, the sealing liquid is sucked in the axial direction, the influence of centrifugal force is ignored, the structure of the stator and the rotor has little agitation for the sealing liquid, the generated stirring heat is small, and the energy loss is low. The sealing liquid has good suction performance, uniform flow and pressure, stable operation, and no extra impact on the mechanical seal.

Owner:DALIAN SONGLONE PUMP MFG

Sand mixing device

PendingCN113546557AFix stability issuesAddress riskRotary stirring mixersMixing methodsThermodynamicsOil field

The invention discloses a sand mixing device, and belongs to the field of oil field corollary equipment. The device comprises a stirring tank body, the stirring tank body is provided with a stirring device used for stirring, a sand inlet is formed in the upper portion of the stirring tank body, a sand adding device is arranged at the position, where the sand inlet is located, of the stirring tank body, sand adding / sand adding stopping is controlled through the sand adding device, and a closed space in the tank body is formed. According to the sand mixing device, the problems of unstable liquid level, even tank overflow risk and short service life of quick-wear parts of a traditional open type sand mixing device when more foam exists are solved, and the risk of tank overflow is effectively avoided by combining the open type sand mixing device and the centrifugal pump principle.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com