A safe sugar dissolving machine

A sugar-dissolving machine and safe technology, applied in the directions of dissolving, dissolving, and mixing machines, can solve the problems of crisis medication safety, influence of sugar liquid quality, etc., and achieve the effect of good inhalation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

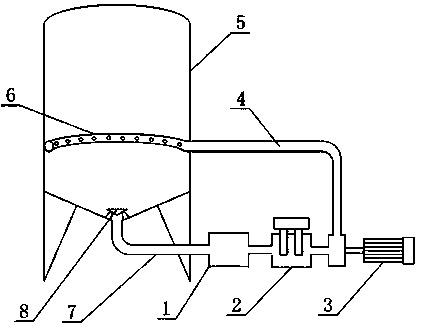

[0019] Such as figure 1 , a safe sugar dissolving machine, comprising a sugar dissolving tank 5, a pump unit 3, an inlet fluid pipe 7 and an outlet fluid pipe 4, one end of the inlet fluid pipe 7 is fixedly connected to the bottom of the sugar dissolving tank 5, and the other end is fixedly connected to On the inlet flange of the pump group 3, one end of the inlet fluid pipe 7 is connected to the outlet flange of the pump group 3, and the other end is fixedly connected to the sugar dissolving tank 5. It is characterized in that it also includes an annular The annular pipe 6 is fixedly connected to the inner wall of the sugar dissolving tank 5 and communicated with the outlet fluid pipe 4 . The annular pipe 6 is also provided with a plurality of outlet holes.

[0020] The sugar and water mixture is sucked into the inlet fluid pipe 4 from the bottom of the sugar dissolving tank 5 by the set pump group 3, and the inhaled medium is introduced into the annular pipe 6 through the ou...

Embodiment 2

[0022] This embodiment is further improved on the basis of embodiment 1, as figure 1 , also includes a filter 1, the filter 1 is arranged on the inlet fluid pipe 7.

[0023] The set filter 1 is beneficial to filter out relatively large impurities in the suction medium, and is beneficial to improving the quality of the sugar solution.

[0024] It also includes an iron removal device 2 which is arranged on the inlet fluid pipe 7 of the filter 1 and the inlet flange of the pump unit 3 .

[0025] The set iron removal device 2 is used to absorb the iron element dissolved in the sugar, so as to obtain the sugar liquid with low iron content.

[0026] The filter 1 is a filter screen type filter, the filter screen is a stainless steel filter screen, and the number of meshes is between 200 mesh and 250 mesh.

[0027] The screen type filter is clear and convenient, and the mesh size is selected between 200 mesh and 250 to allow the sugar particles to just pass through, while the insolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com