Patents

Literature

185results about How to "Substantive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

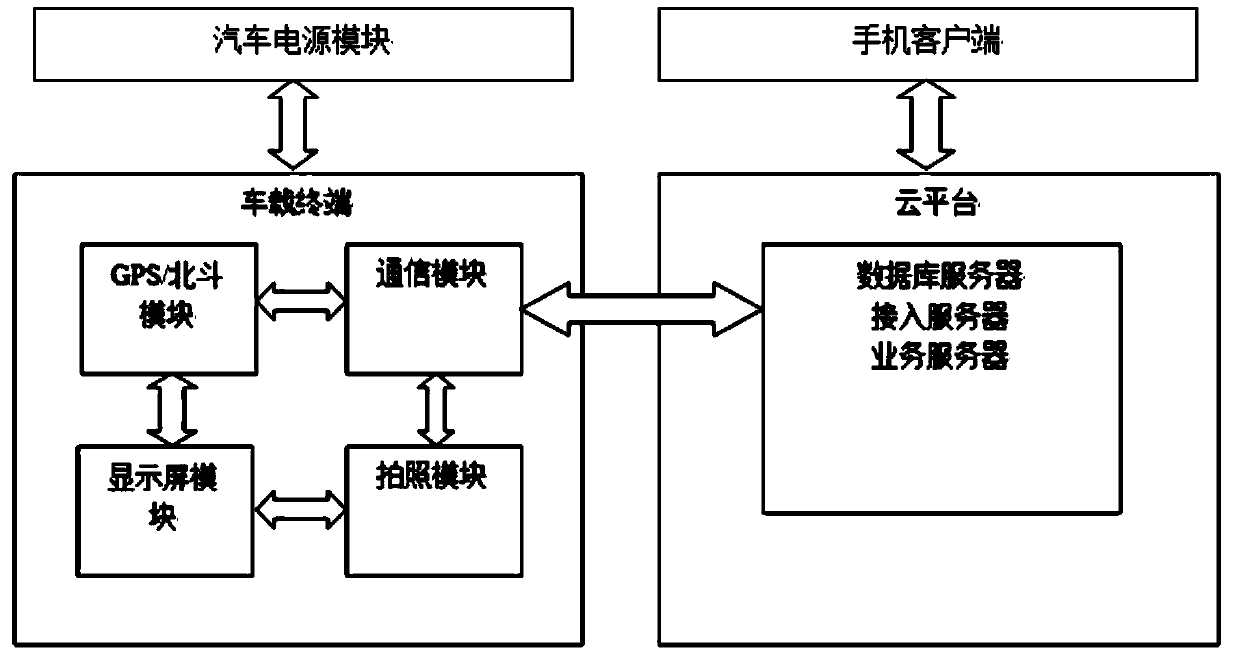

Real-time road condition sharing and video-on-demand method based on road condition pictures

ActiveCN104183120AReal-timeSubstantiveRoad vehicles traffic controlTraffic congestionVideo on demand

Provided is a real-time road condition sharing and video-on-demand method based on road condition pictures. A vehicle-mounted terminal is automatically triggered to photograph and uploads time, position, driving speed and a picture at the moment of photographing to a cloud platform, the cloud platform adds a time label, a position label, a driving speed label, a weather label and other labels to the picture, and then the picture is placed in a picture pool and is shared by all users; besides, the users can send road condition video-on-demand requests to users on the road section, when the requested user receives the video-on-demand requests, the user can agree or refuse the requests, if the user agrees the requests, the vehicle-mounted terminal is triggered immediately to photograph road condition pictures and upload the pictures to the cloud platform for sharing, and the cloud platform immediately pushes the road condition to the users sending out the requests. The method helps the users to avoid congested road sections in real time, and urban traffic congestion is relieved.

Owner:JIANGSU DACHENG PHARMA TECH CO LTD

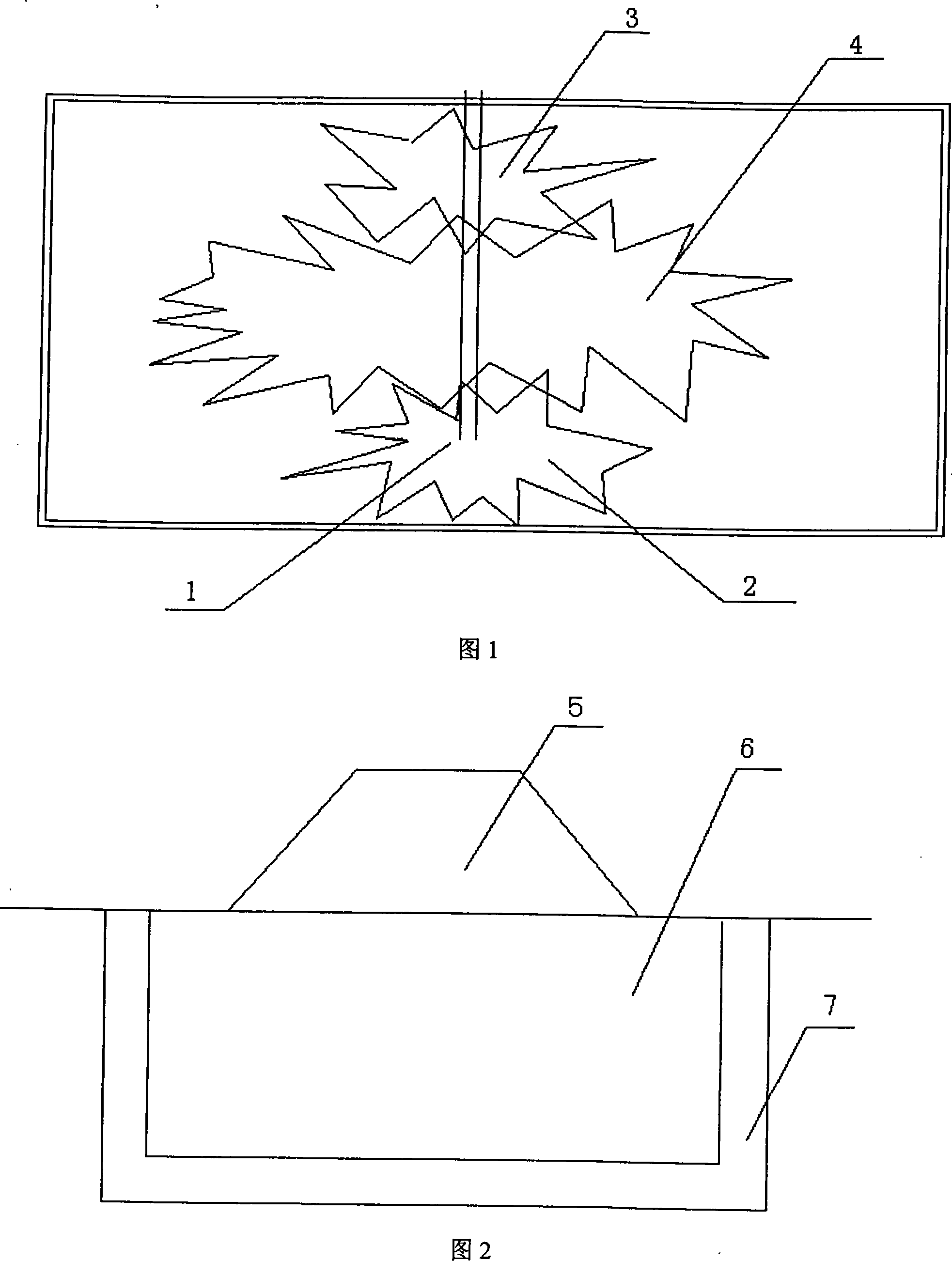

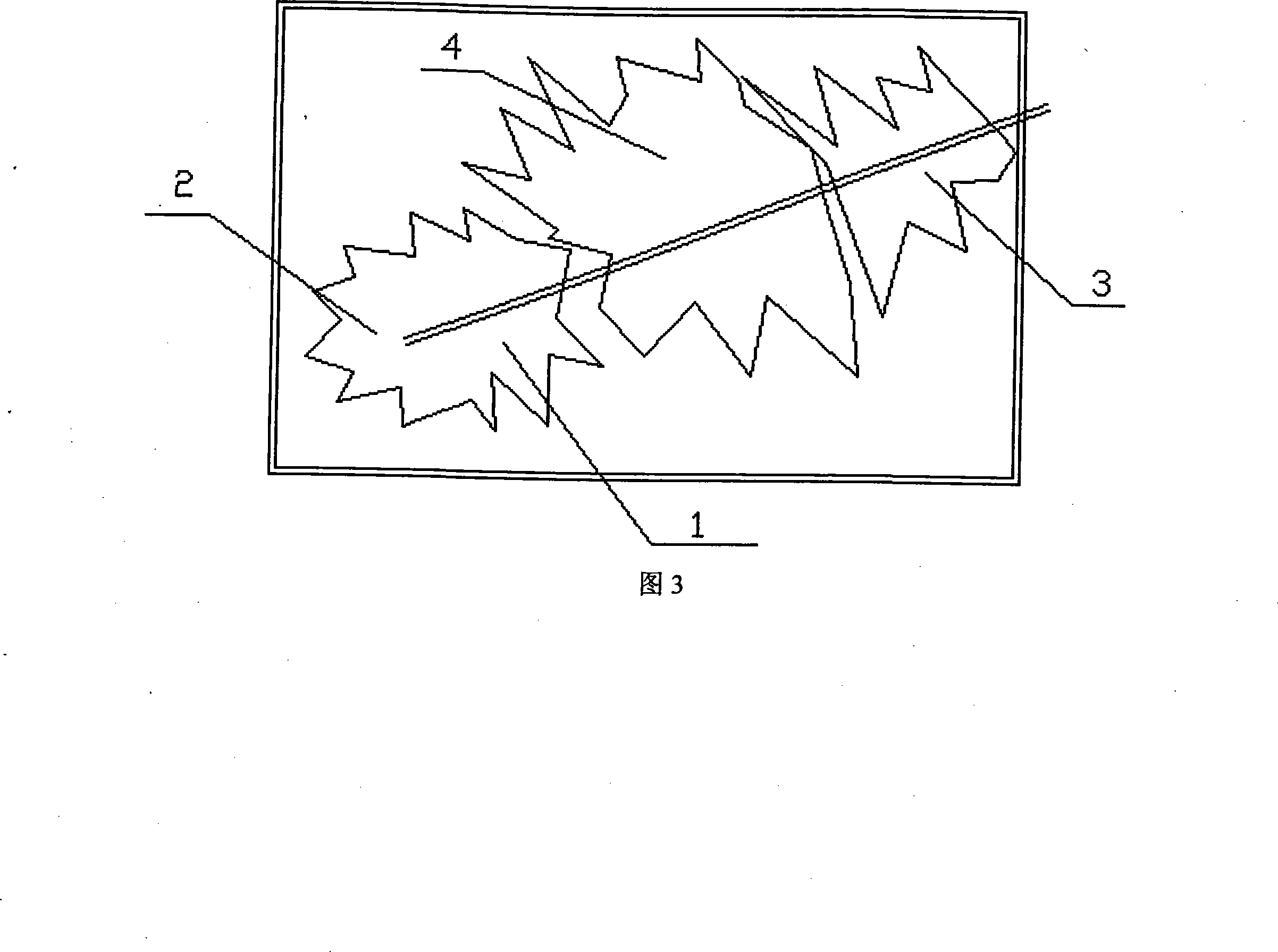

Layered multitime pressure regulating pulp conditioning casting method

The invention relates to a layered multiple pressure regulating grouting method which comprises the processing sequence: (1) a reinforced area is set up; the location and the depth of a grout stopping belt are determined; (2) the grouting soil distribution is determined according to different geological conditions, engineering features in the axial direction of a grouting hole; (3) a vary number of grouting pipes with different length are buried in the axial direction of a grouting hole according to different artesian conditions to cause grout to be spread in the designed different location; (4) a signal pole or soil sequencing holes of the reinforced area are repeatedly grouted. The invention has the characteristics of tangibility and strong pertinence, especially provides an efficient base process method for running grout, leaping grout caused by using a traditional grouting method in the geological conditions such as karst areas, large poriness when the fixing area is grouted and reinforced, and solves the deficiencies and shortcomings of the original construction technique through improving the techniques such as the grouting techniques, grouting materials, etc.

Owner:山东省交通厅公路局 +1

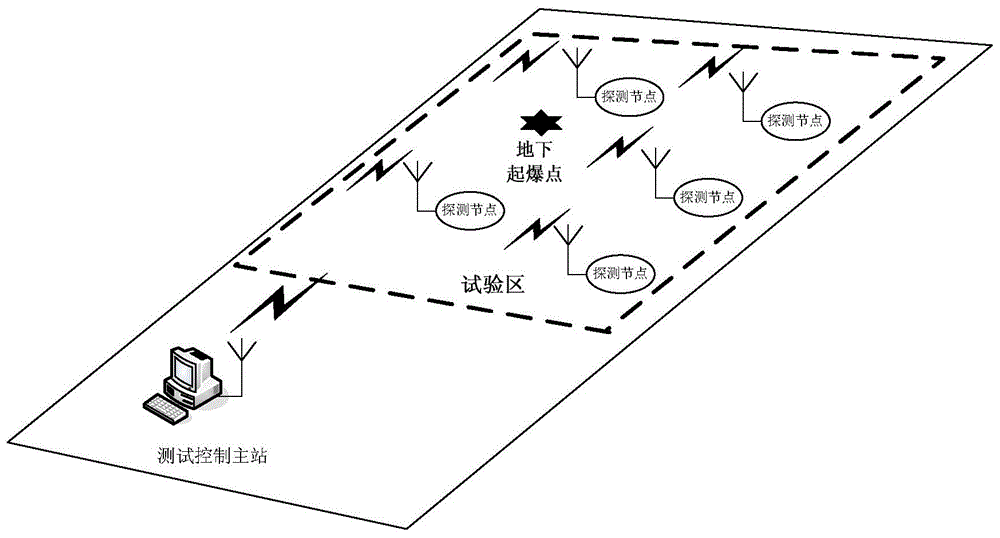

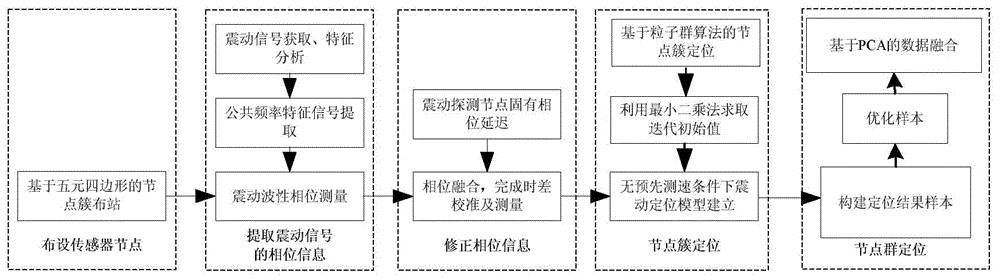

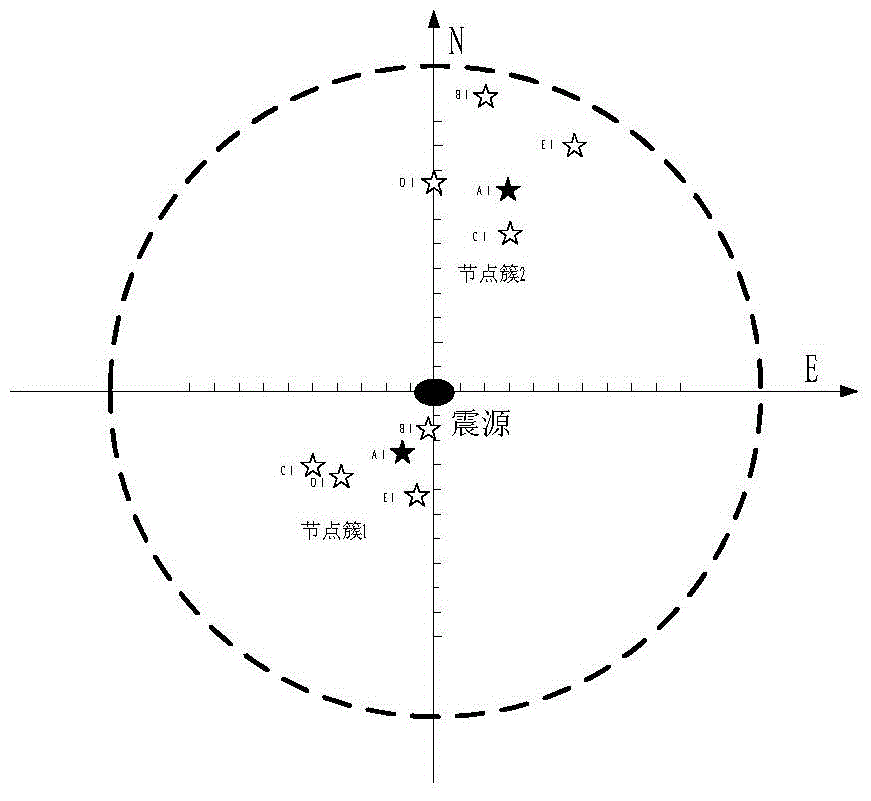

Distributed group wave shallow-layer slight shock positioning method based on phase measuring

ActiveCN103605151ASubstantiveSolve the problem that time difference positioning cannot be adoptedSeismic signal receiversSeismic signal processingNode clusteringSelf adaptive

The invention discloses a distributed group wave shallow-layer slight shock positioning method based on phase measuring. A distributed epicenter test system is employed, and the positioning of a distributed group wave shallow-layer slight shock epicenter is finally realized through five steps, i.e., shock sensor laying, shock signal phase information extraction, phase information calibration, node cluster positioning and node group positioning. According to the invention, sub-region node cluster laying and large-range node group random laying modes are adopted, a particle swarm algorithm is utilized for performing self-adaptive positioning on phase information corresponding to various advantaged frequency components, and a major constituent analytical method is utilized for data fusion of a positioning result so that the method provided by the invention has the advantages of low sensor laying difficulty, wide application scope, high positioning precision and reliability and the like.

Owner:ZHONGBEI UNIV

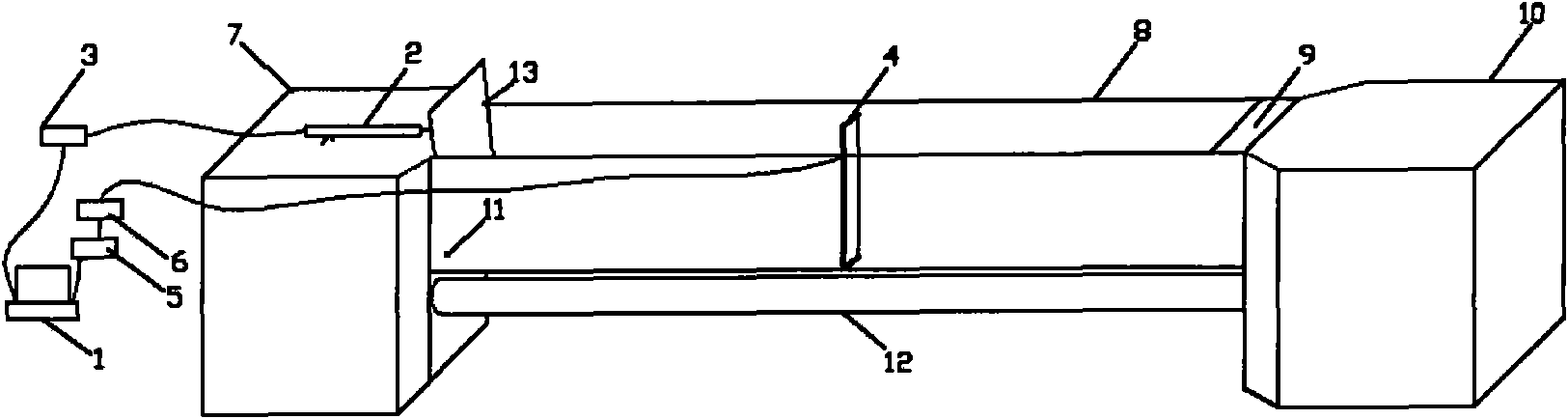

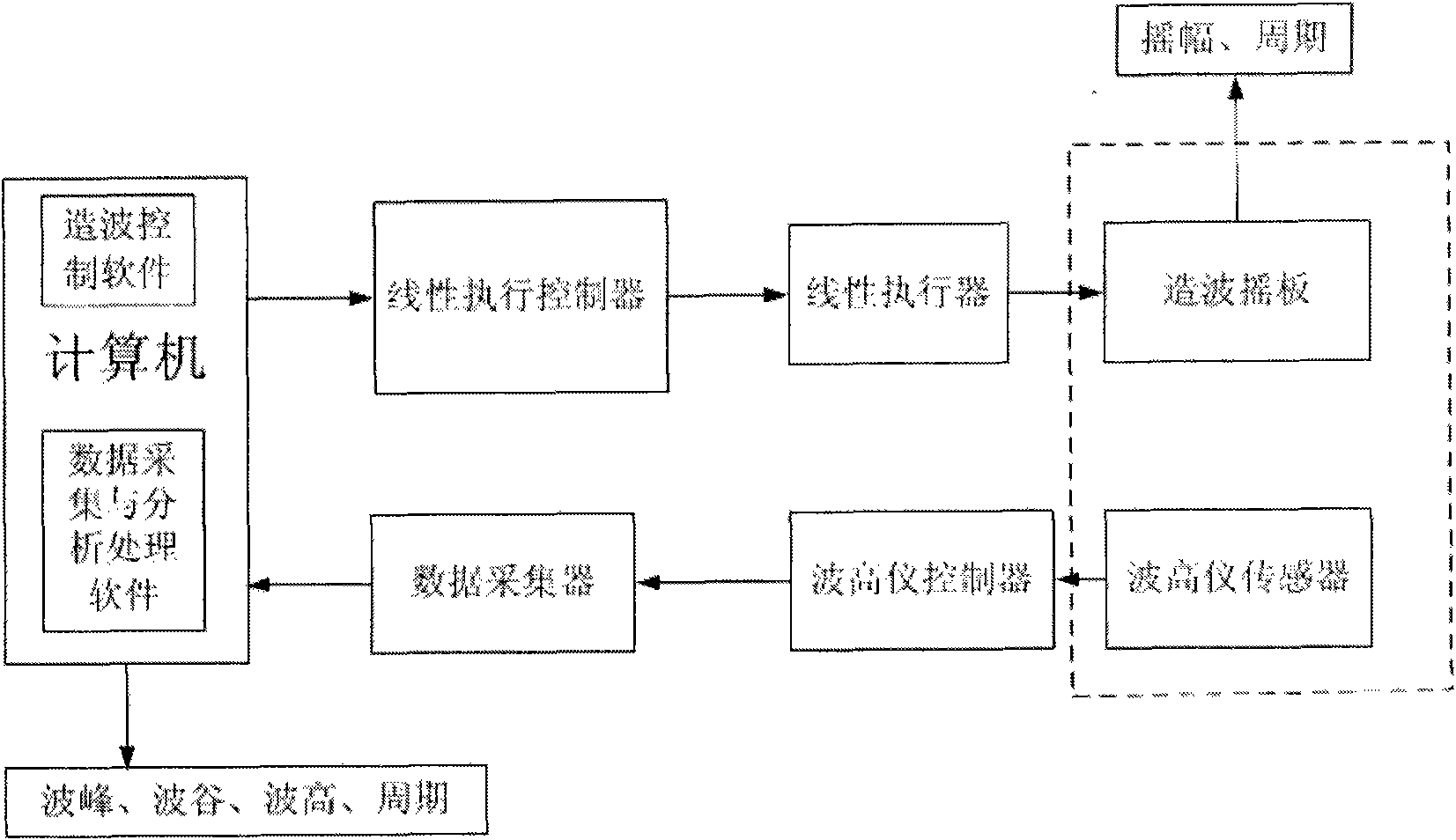

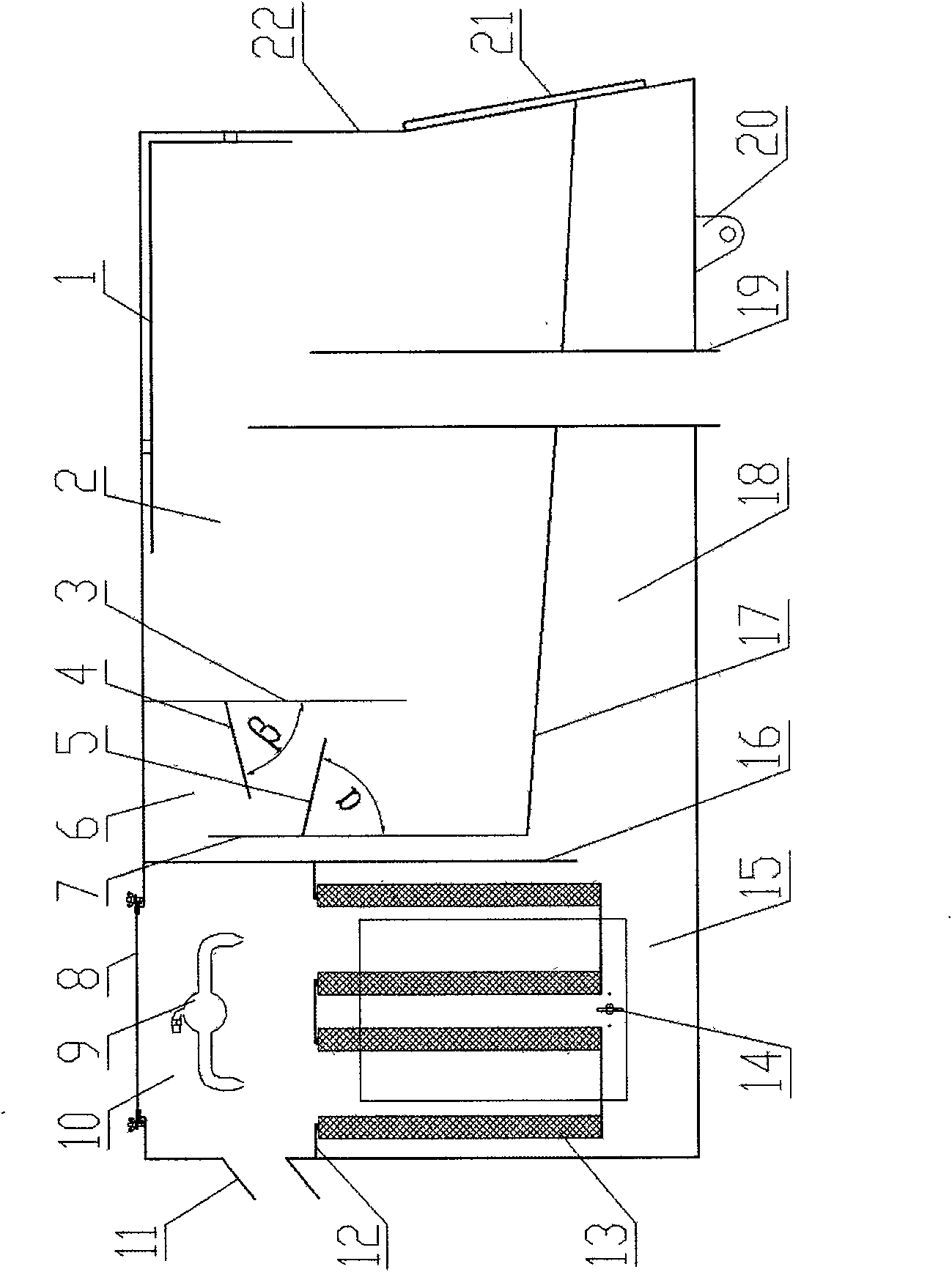

Water tank for regular wave generation research and teaching

The invention provides a water tank for regular wave generation research and teaching, which comprises a wave generation control part, a wave parameter acquisition and analysis processing part and a water tank main body structure, wherein the wave generation control part and the wave parameter acquisition and analysis processing part are connected with a computer; the inside of the computer is provided with a wave generation control software and a data acquisition and analysis processing software; the wave generation control part comprises a linear actuator and a linear actuator controller; the wave parameter acquisition and analysis processing part comprises a wave-height meter sensor, a wave-height meter controller and a data acquisition unit; and the water tank main body structure comprises a head tank body, a visual wave generation section, a tank end wave absorber, a wave generation rocking plate and a tail tank body. The water tank can conveniently and rapidly generate the high-quality regular wave, can accurately complete measurement work of the parameters of the regular wave, has the advantages of simple wave generation mechanism, low energy consumption and high efficiency, and meets the requirements for the regular wave generation experiment research and teaching.

Owner:HARBIN ENG UNIV

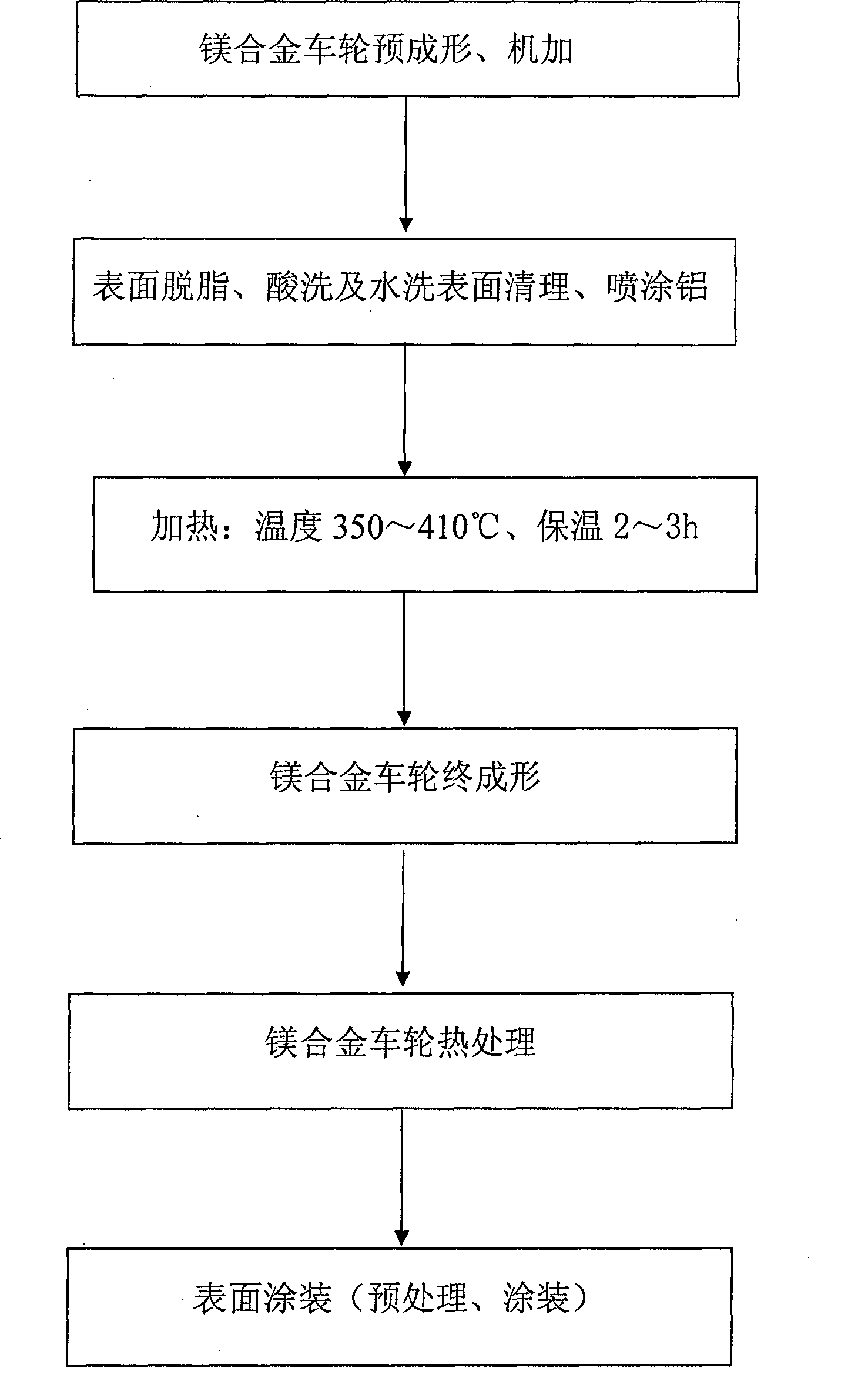

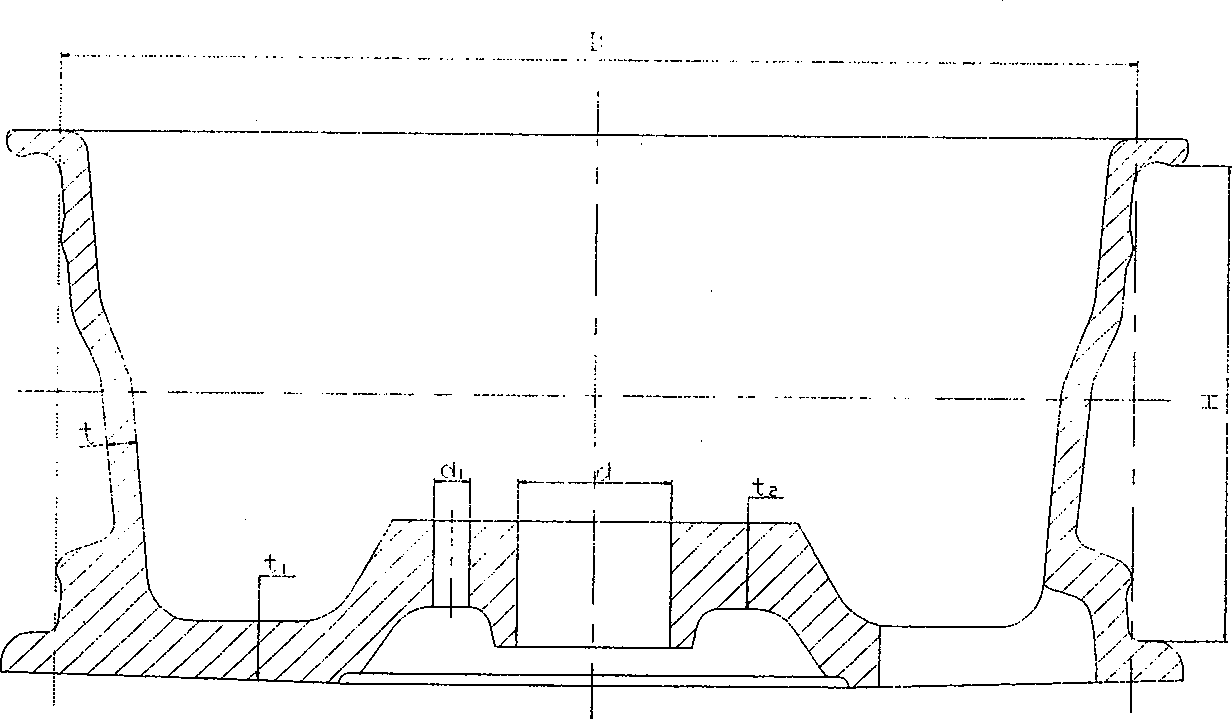

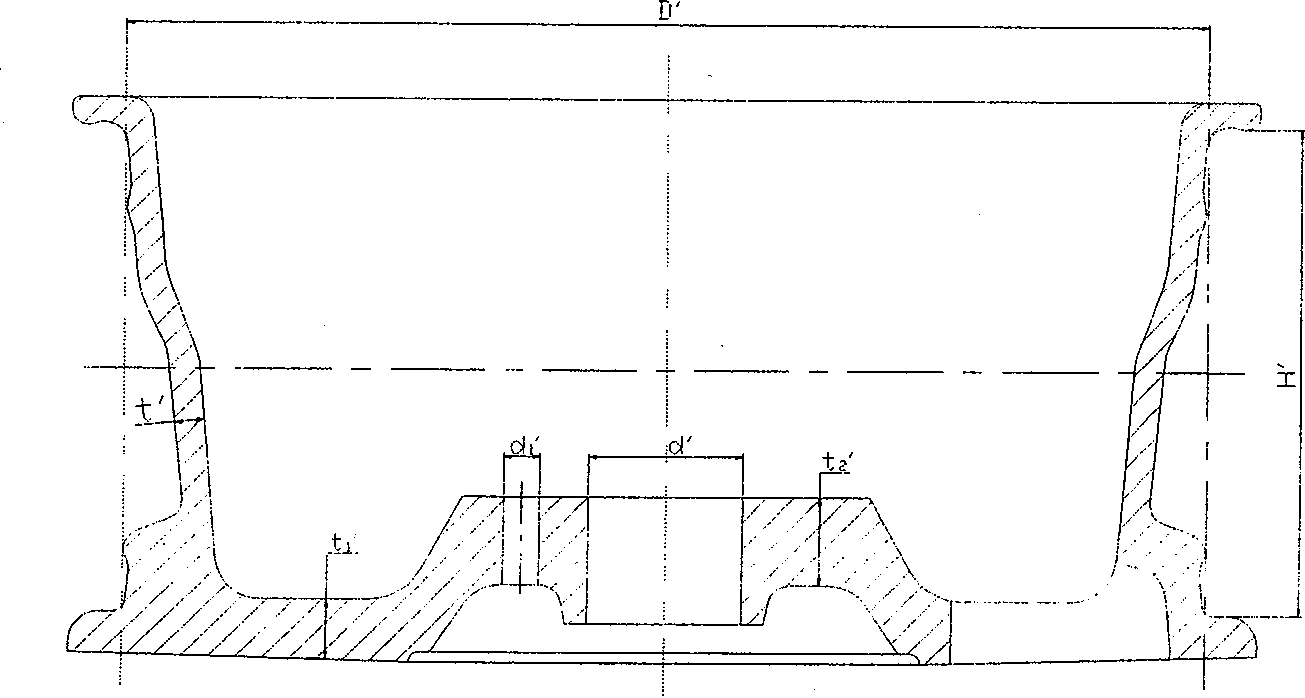

Magnesium alloy vehicle wheel surface treatment method and magnesium alloy vehicle wheel

InactiveCN101392380AImprove corrosion resistanceSolving Galvanic Corrosion ProblemsMolten spray coatingSurface finishingWork in process

The invention pertains to a surface treatment method of magnesium alloy wheels. The surface treatment method is characterized by the inclusion of preliminary shaping, machining, aluminium coating on the surface, heating and diffusion, final shaping, heat treatment and surface coating treatment, wherein, the preliminary shaping and the machining can provide a semi-product of a magnesium alloy wheel with a deflection left for the final shaping; after the aluminium coating on the surface and the heating and diffusion, a finished product of the magnesium alloy wheel can be obtained through the final shaping. Heating action during the procedure of the heating and diffusion and mechanical action during the procedure of deformation improve the bonding force of an aluminium coating and a magnesium alloy substrate as well as corrosion resistance of the magnesium alloy wheel, solve the problem of electrochemical corrosion of a bonding part and the problem that a coating with a common treatment method is liable to fall off, and do not reduce mechanical performance of materials of the magnesium alloy substrate with low production cost and no environmental pollution.

Owner:ZHONGBEI UNIV

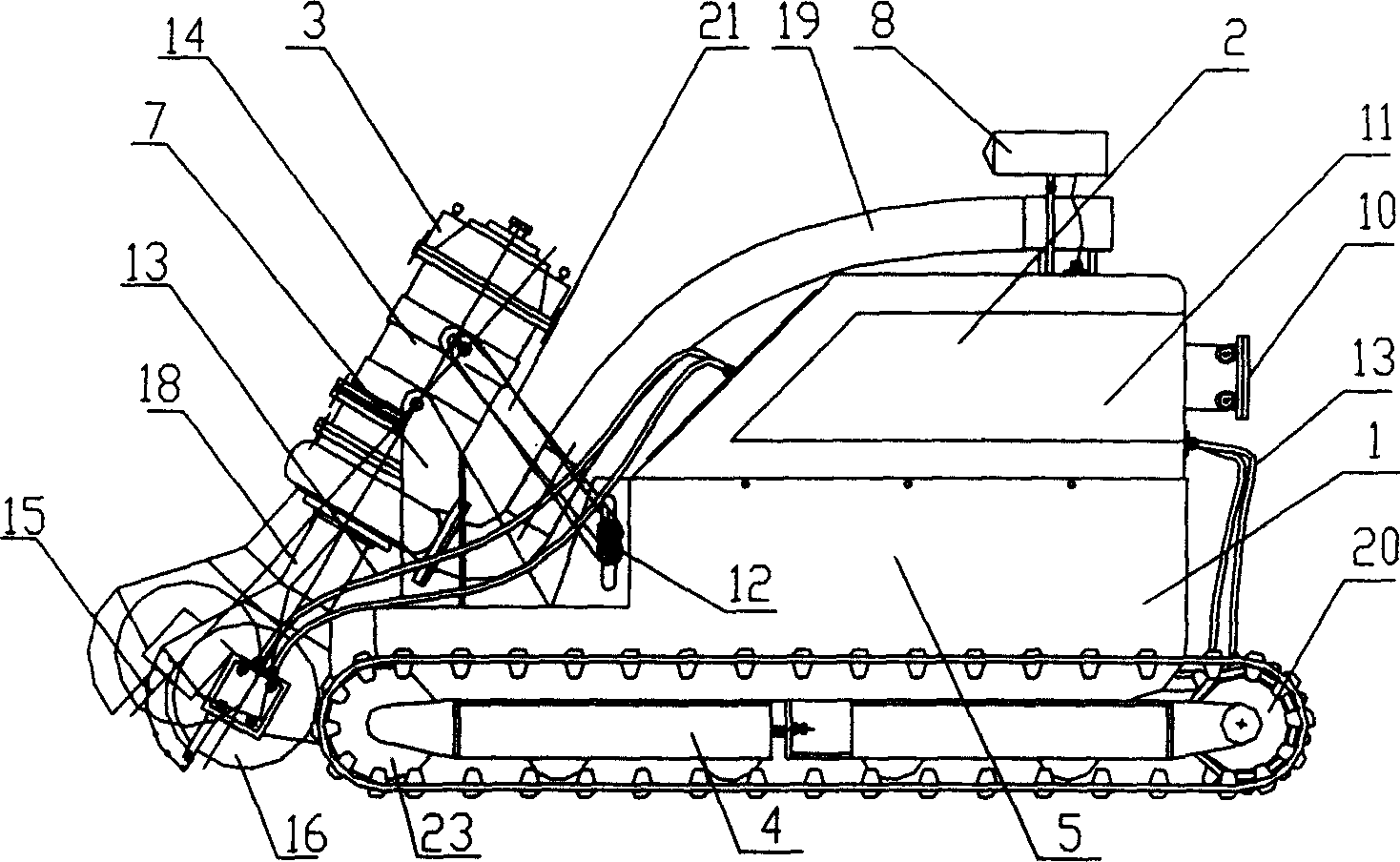

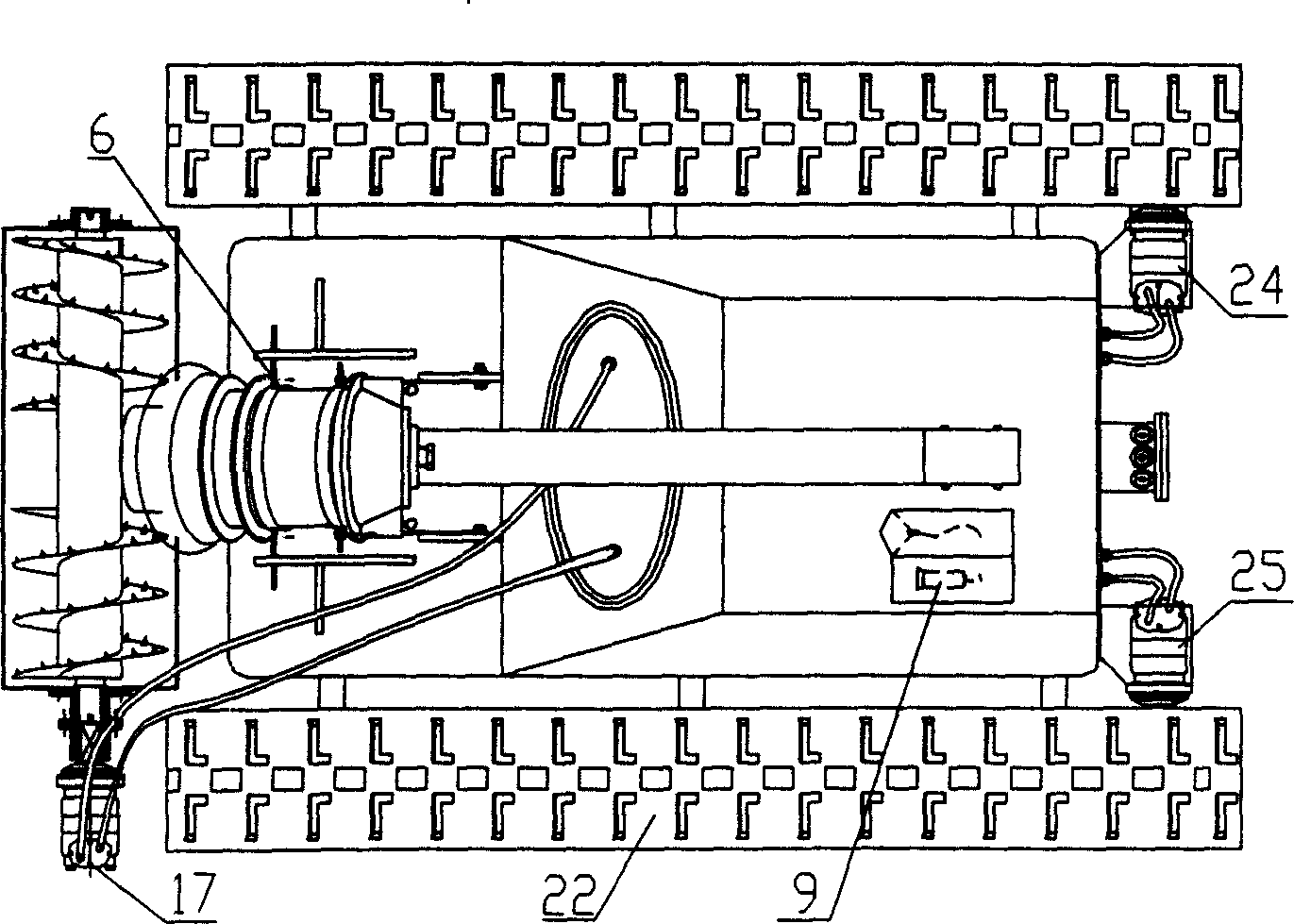

Crawler-type under water ecological precision thin layer slurry dredger

InactiveCN1554833A"Endogenous" Pollution ControlLarge footprintMechanical machines/dredgersSludgeControl system

The present invention belongs to the field of environment protecting technology. The crawler-type underwater ecological precise thin-layer sludge dredger consists of main system, hydraulic control system, sludge sucking system in front of the main system, and walking system below the main system. The main system includes box, support rods, frame, lighting unit and video monitor. The present invention has small size, light weight, simple structure and easy operation, and is suitable for dredging sludge in river, lake, reservoir, etc.

Owner:章永泰

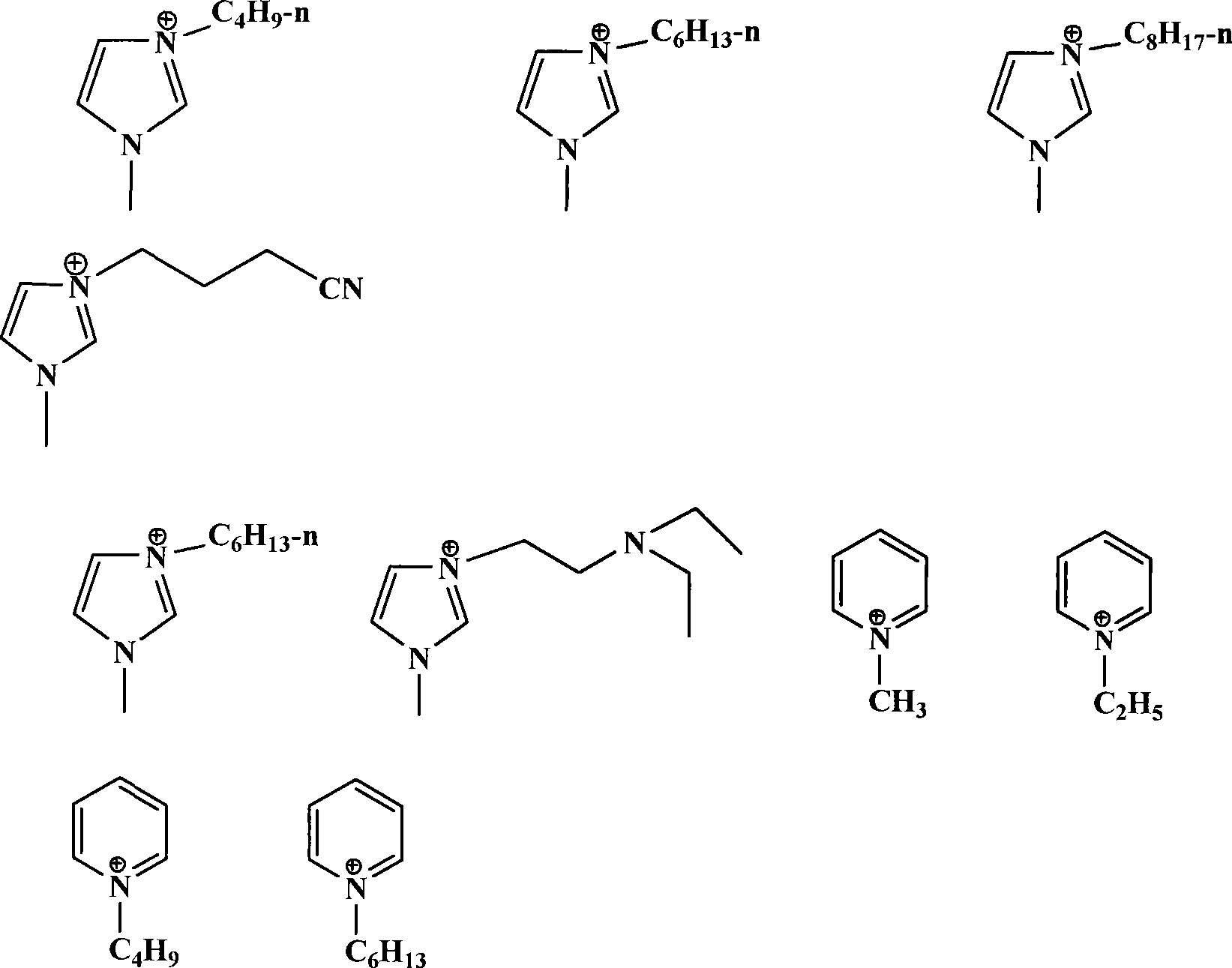

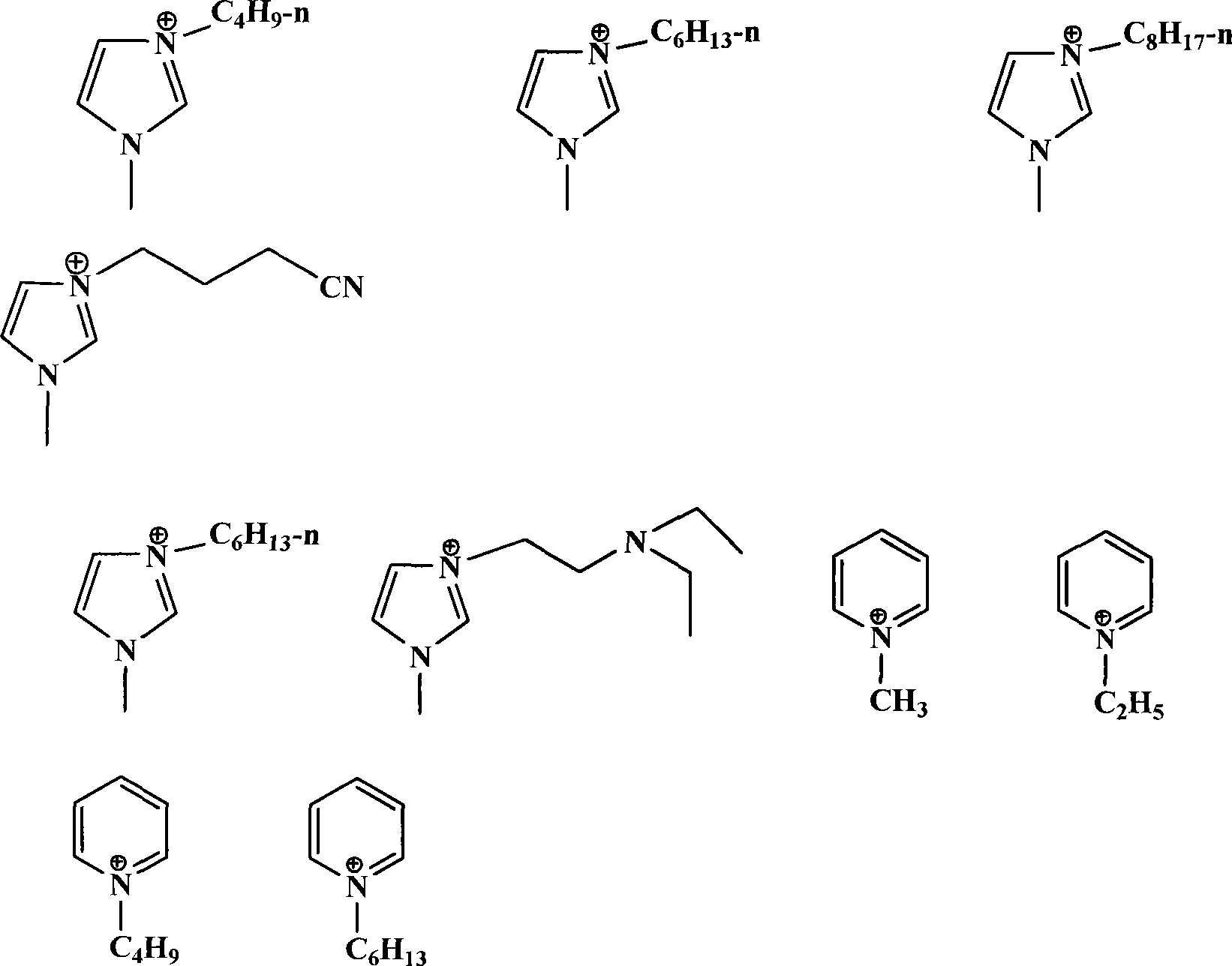

Supported ionic liquid material for reversibly and selectively absorbing carbon dioxide and preparation method thereof

InactiveCN101468308AEasy to operateHigh surface areaOther chemical processesDispersed particle separationSubmarineSelective adsorption

The invention discloses a reversible selective adsorption carbon dioxide material as supported ionic liquid, and a preparation method thereof. The material is supported ionic liquid on honeycomb ceramics; the mass percentage content of the supported ionic liquid is 5 to 45 percent; and the material is prepared by an impregnation method. The material has broad application prospects in the fields of adsorbing and recovering CO2 in fuel gas, flue gas and industrial exhaust gas, adsorbing CO2 in aerospace, spacecrafts, space capsules, submarines, bomb shelters, high-precision technical closed rooms and other closed systems, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

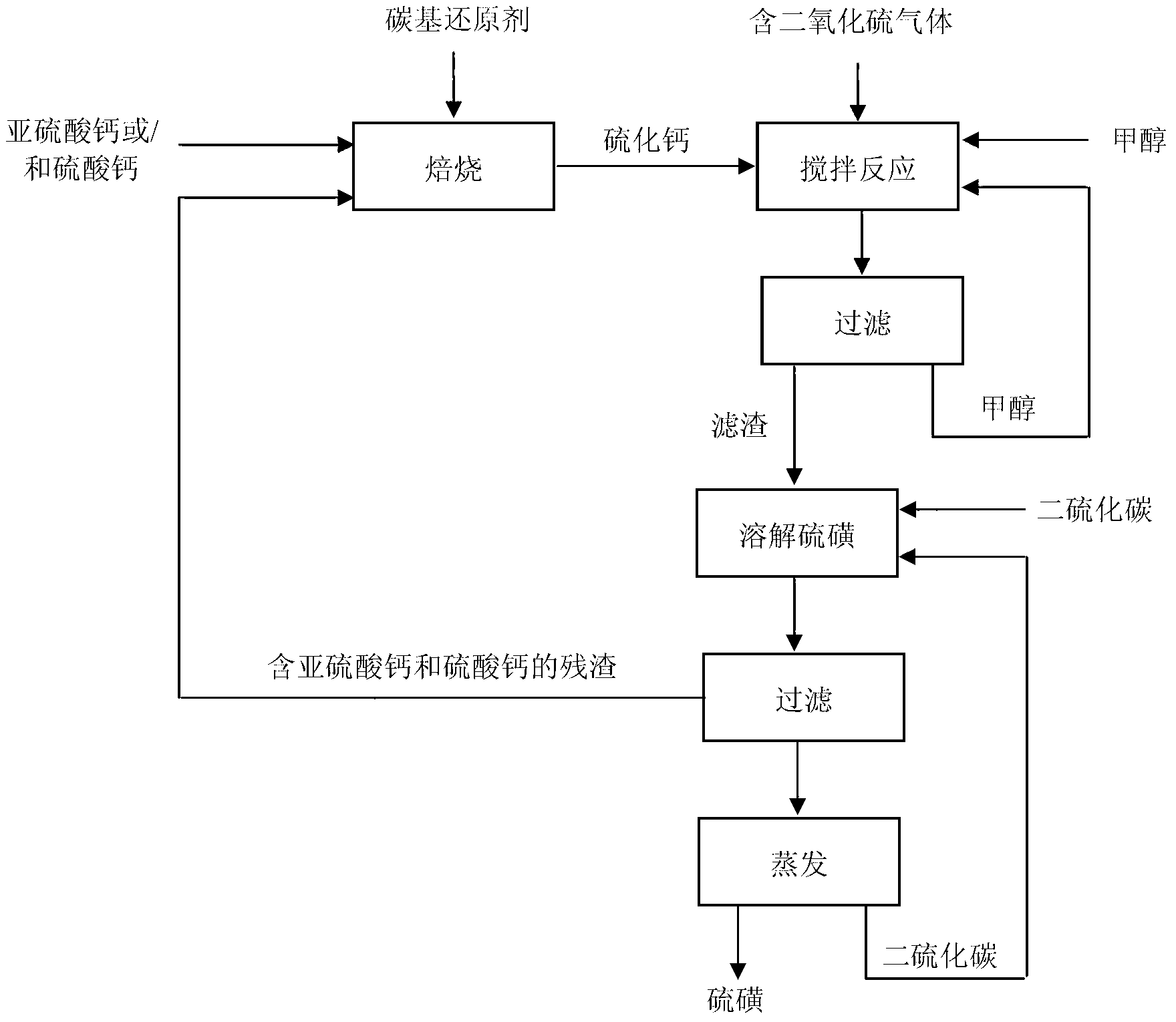

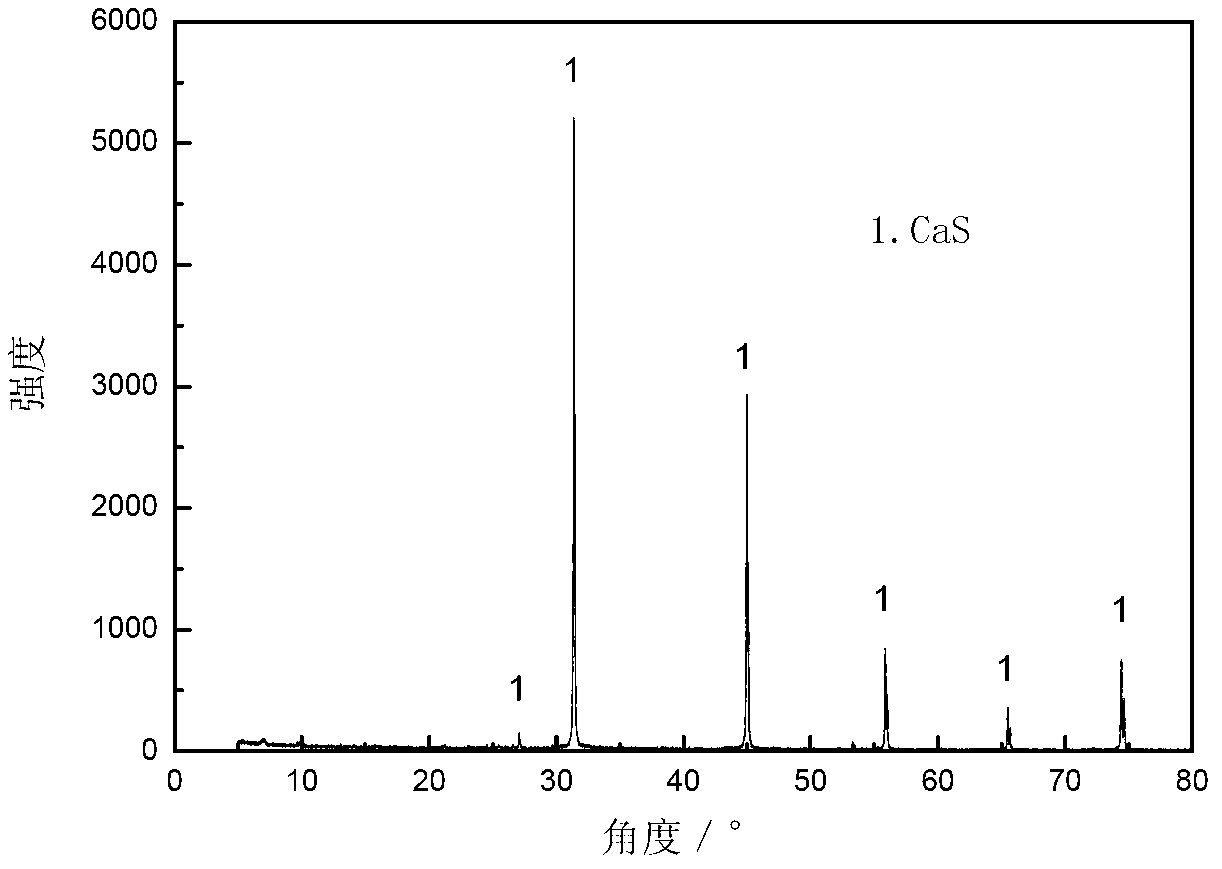

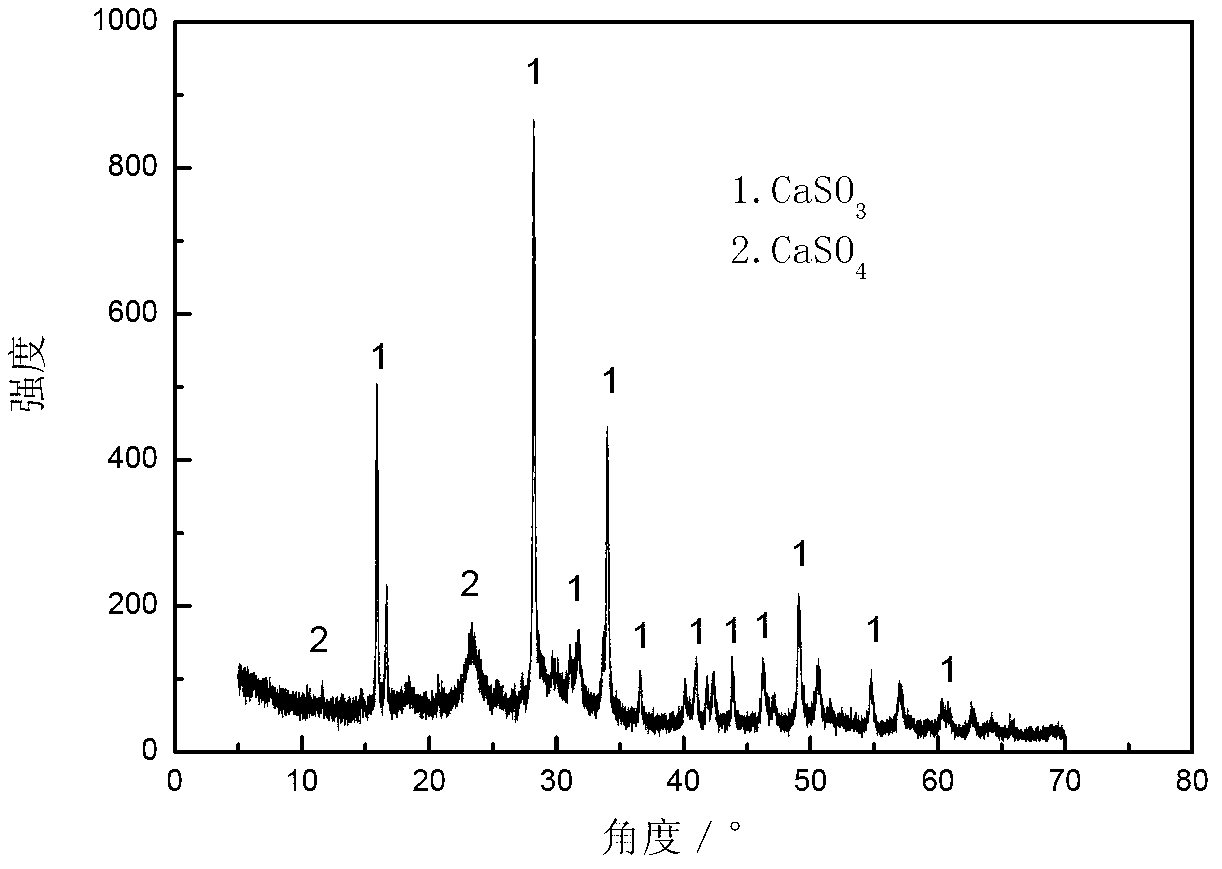

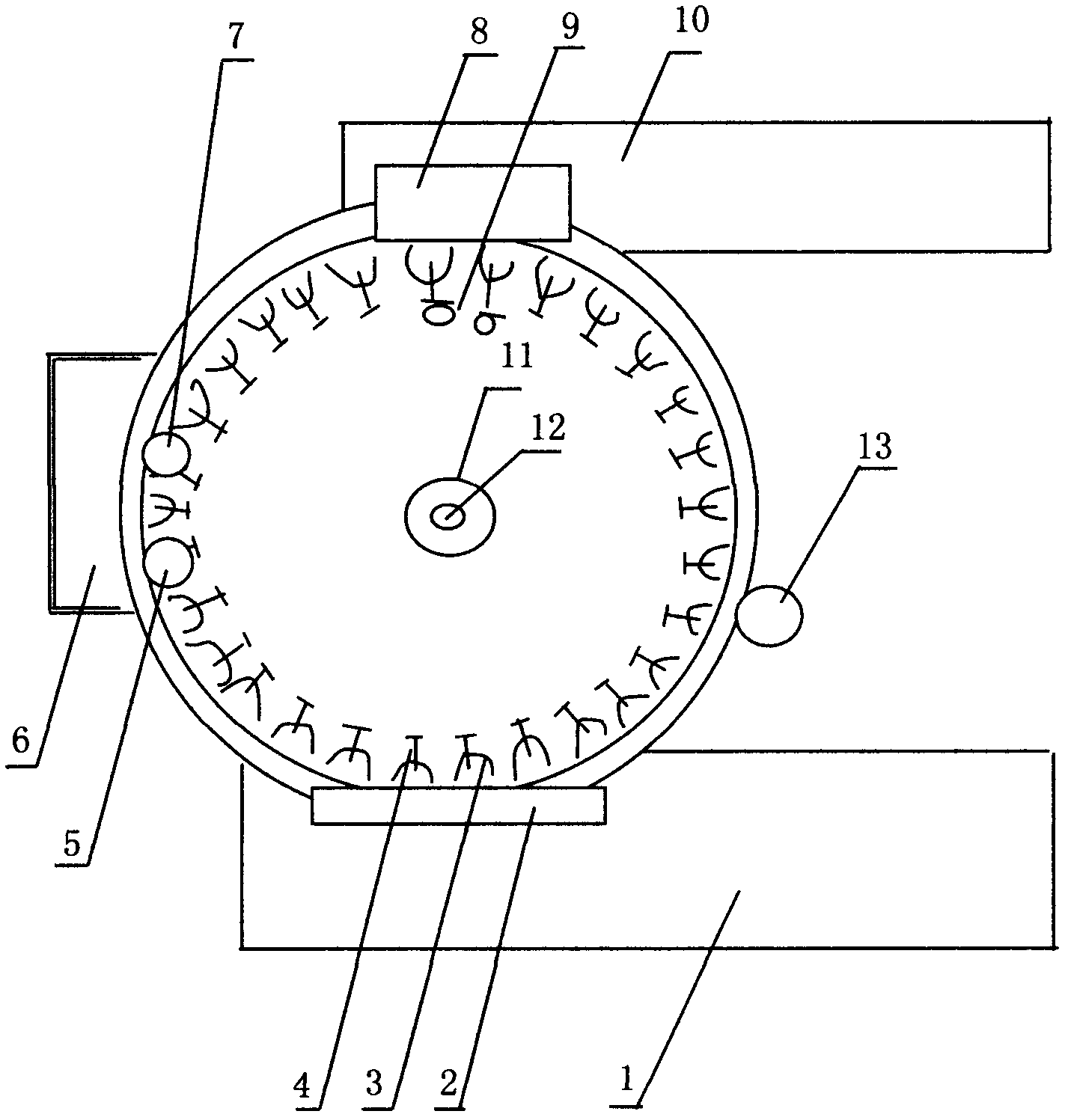

Method for absorbing sulfur dioxide and co-producing sulphur

ActiveCN103316578ASubstantiveEffective absorptionDispersed particle separationSulfur preparation/purificationCalcium sulfideSulfate

The invention provides a method for absorbing sulfur dioxide and co-producing sulphur. The method comprises the following basic steps of: mixing calcium sulfite or / and calcium sulfate with a carbon-based reducing agent; roasting for 1.5 to 2 hours at 800 to 1,000 DEG C to obtain calcium sulphide; adding calcium sulphide, methanol or / and ethanol to a reactor; adjusting the liquid-solid mass ratio to 3 to 10:1; charging sulfur dioxide containing gas along with stirring; stirring for reacting sulfur dioxide with calcium sulphide under room temperature of 0 to 40 DEG C; separating after the reaction is done to obtain sulphur and a mixture containing calcium sulfite and calcium sulfate. By adopting the method, the sulfur dioxide in the gas can be absorbed, and the sulfur can be recovered; the method has the advantages of being economic, efficient and free of waste residues.

Owner:CENT SOUTH UNIV

Automatic onion root/stem cutting machine

InactiveCN102349693AIncrease productivityReduce labor intensityMetal working apparatusFood treatmentEngineeringMechanical engineering

The invention provides an automatic onion root / stem cutting machine. The machine comprises a round rotary table which is in a stepping type, wherein a plurality of U-shaped onion head clamps are arranged on the circumference of the round rotary table and are used for clamping onion heads. The machine is characterized in that the roots and stems are automatically cut off by upper and lower rotary cutting blades; the round rotary table and a shell are provided with electromagnetic positioners; the rotary table rotates in a stepping manner during work; and when the raw materials are fed into the clamps manually, push rods automatically lock the clamps due to displacement and the clamps clamp the onion heads under the action of springs, the rotary table steps at a certain angle, the clamped onions are moved to the rotary cutting blades and are locked by the electromagnetic positioners, as the electromagnetic positioners and a rotary blade driving motor are interlocked, the rotary cutting motor is started at the moment to drive the upper and lower cutting blades to simultaneously cut the roots and stems of the onions, the blades return after completing cutting and the round rotary table continues rotating forward in a stepping manner and comes to a discharge opening for discharge.

Owner:张本照

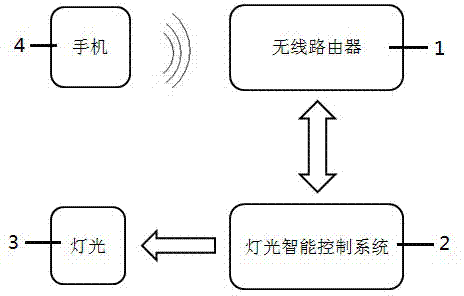

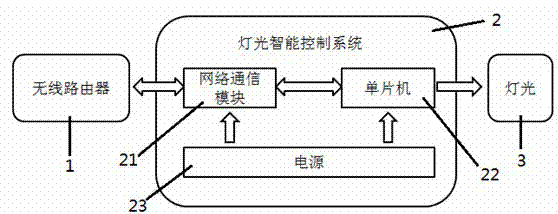

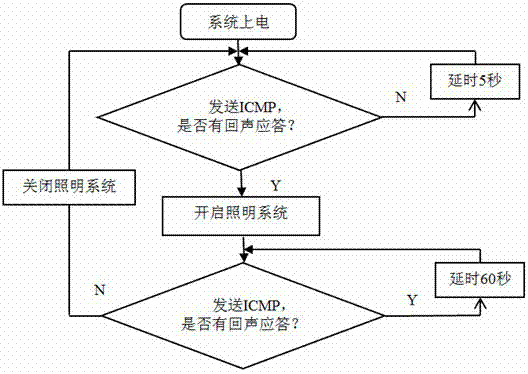

Intelligent lamplight control system adopting mobile phone for identification purpose

InactiveCN103249223ASubstantiveReduce volumeElectric light circuit arrangementEnergy saving control techniquesIntelligent control systemIp address

The invention discloses an intelligent lamplight control system adopting a mobile phone for identification purpose. The intelligent lamplight control system comprises a wireless router, an intelligent lamplight control system body, lamplight and the mobile phone. When the mobile phone is connected with the wireless router, a user sets the IP (Internet Protocol) address of the mobile phone and an IP address required to be detected by singlechip internal programs; and by utilizing the characteristic that the mobile phone can be automatically connected with a hot point saved before through WiFi (Wireless Fidelity), the singlechip programs can automatically detect the access of a specified IP in the wireless network. When the specified IP is detected to be accessed, a user is about to be indoor or is already indoor can be judged and an illuminating system is turned on, and when the specified IP can not be detected, the leaving of the user is known and the illuminating system is turned off.

Owner:SHANGHAI UNIV

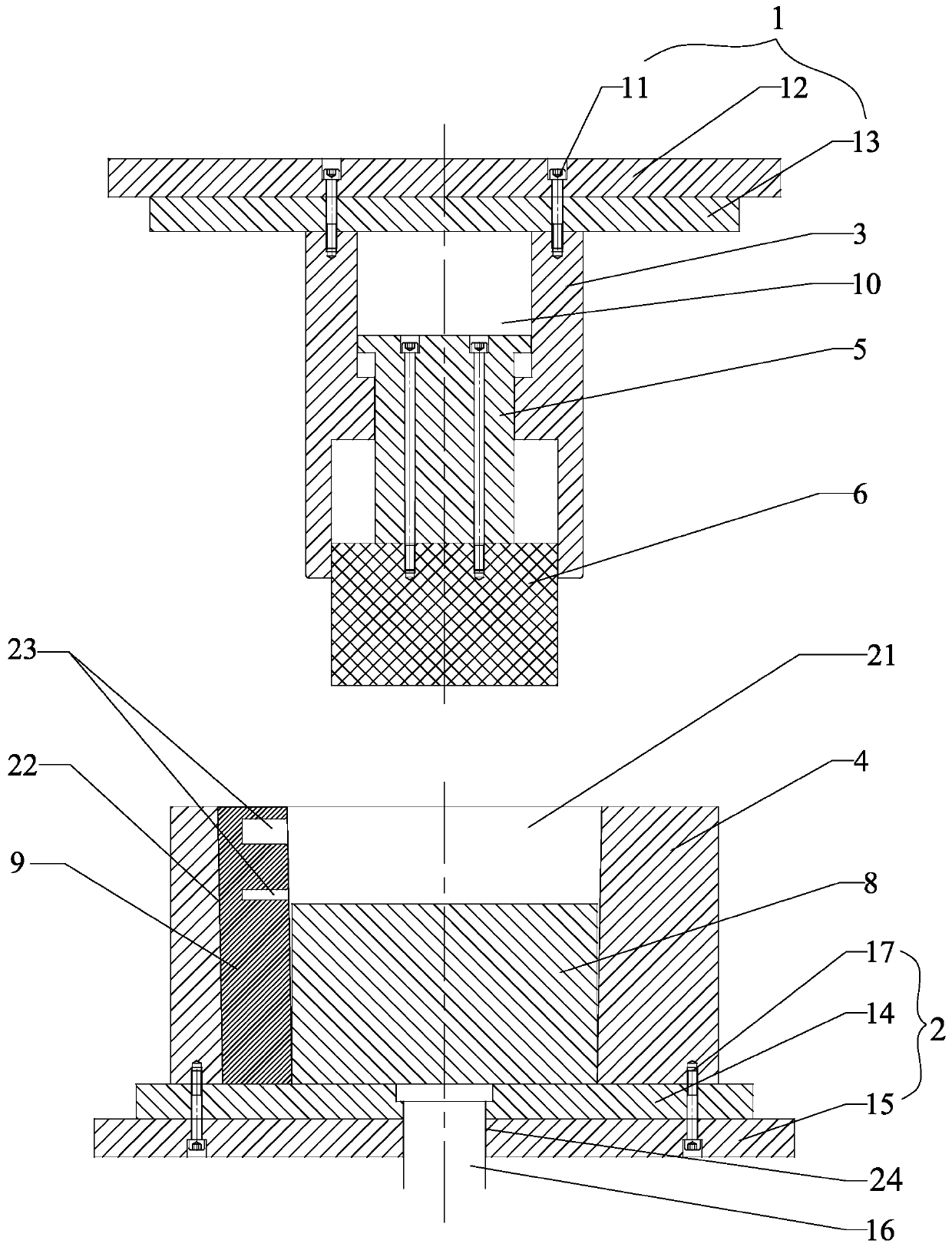

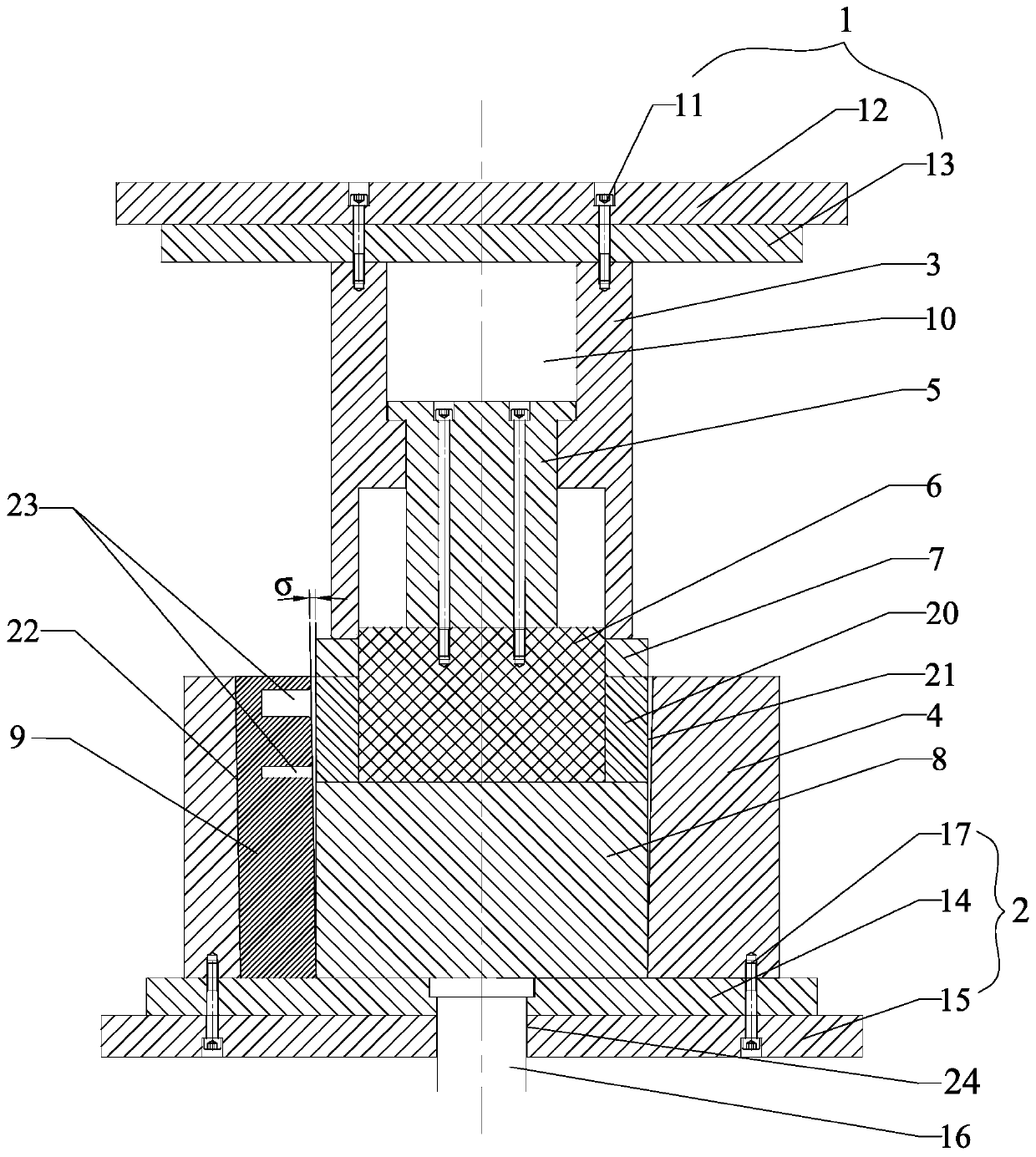

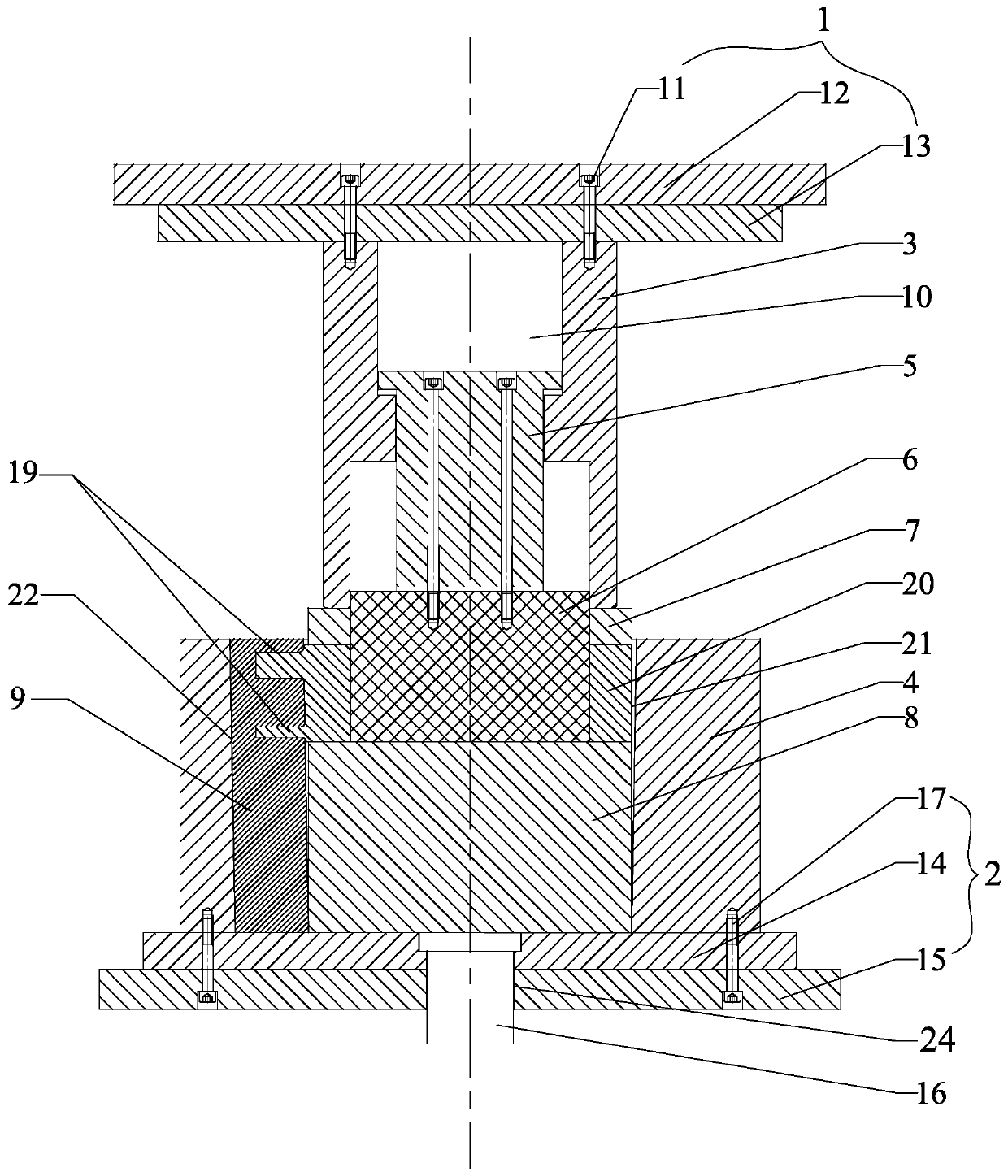

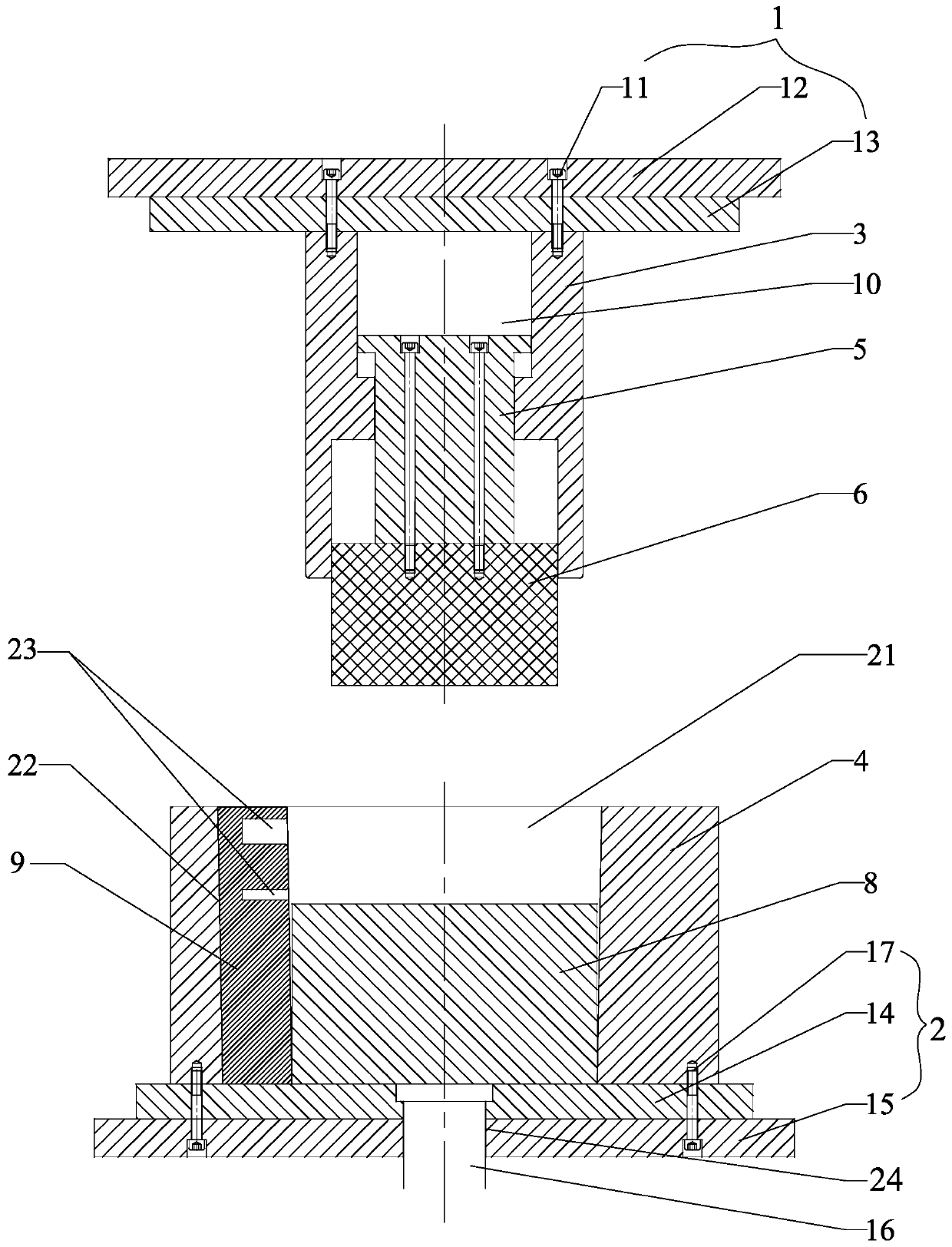

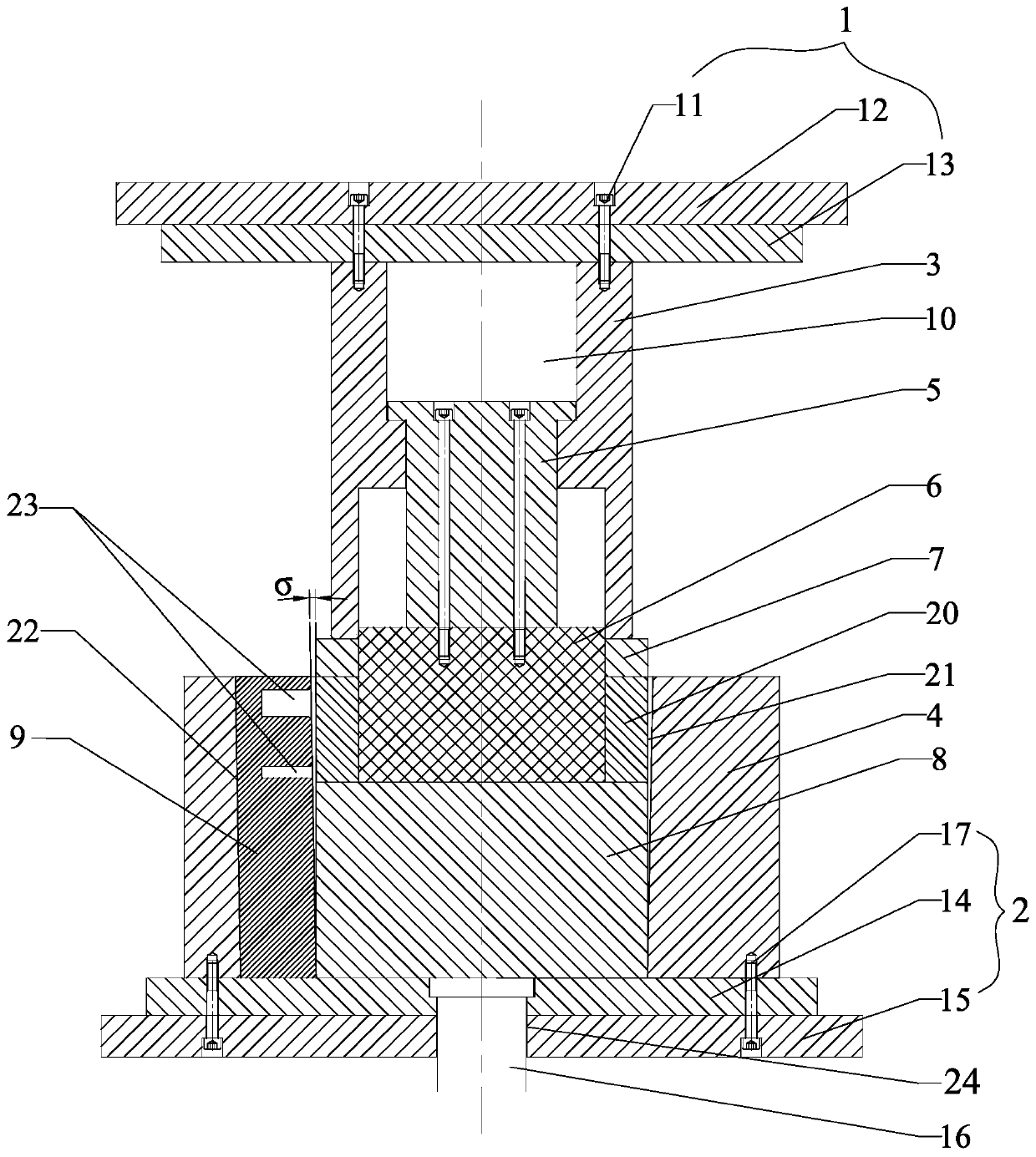

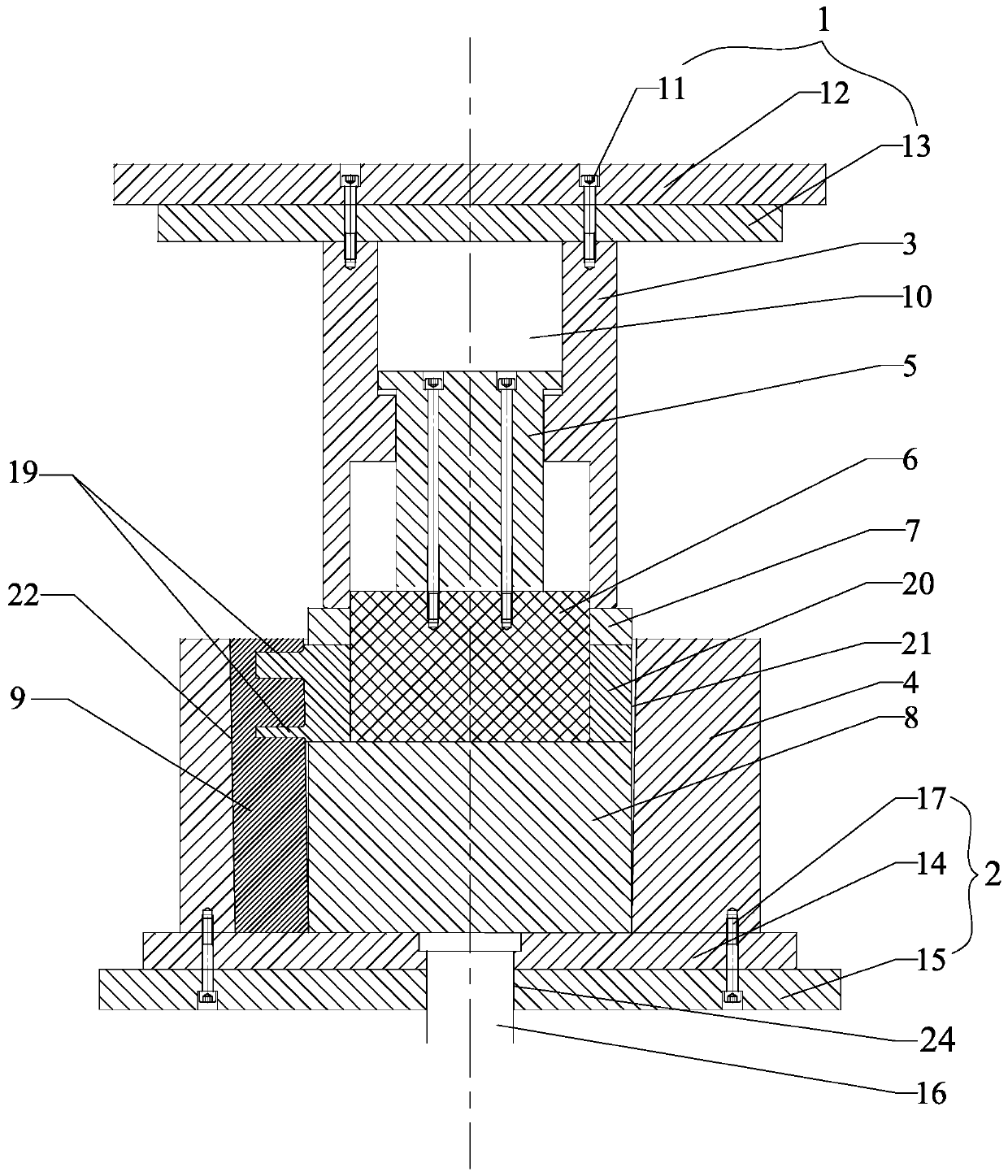

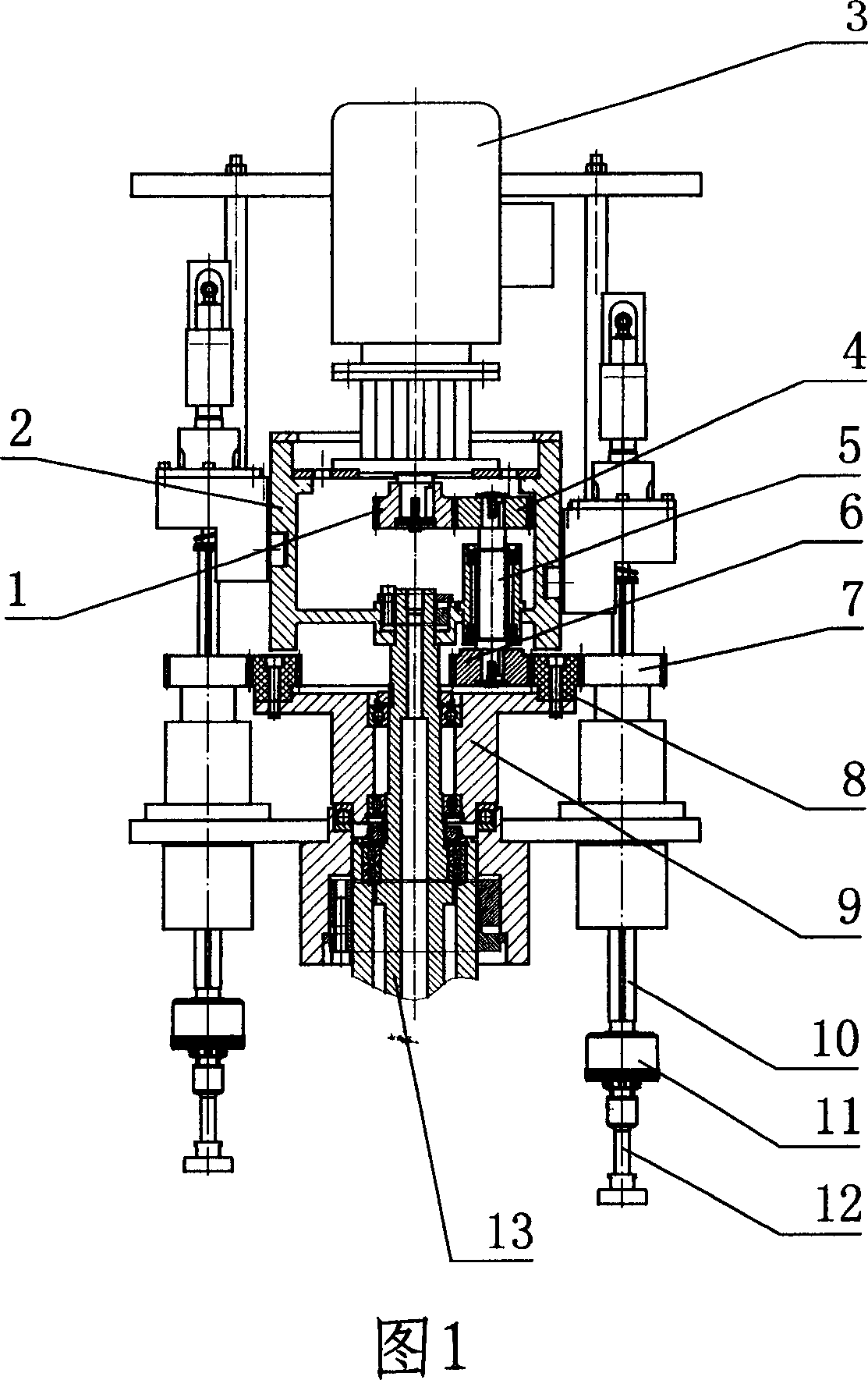

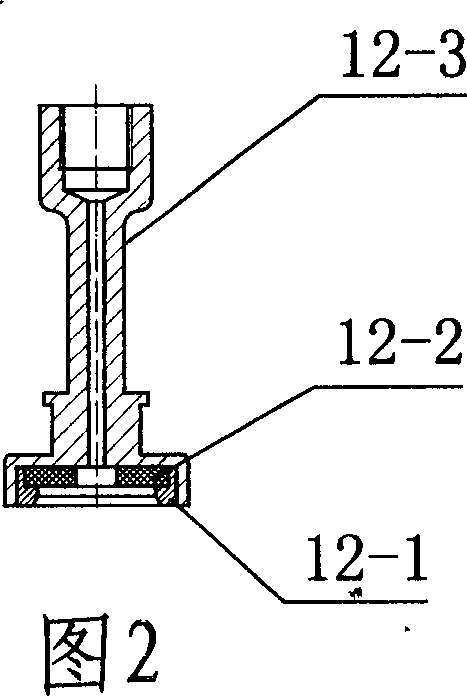

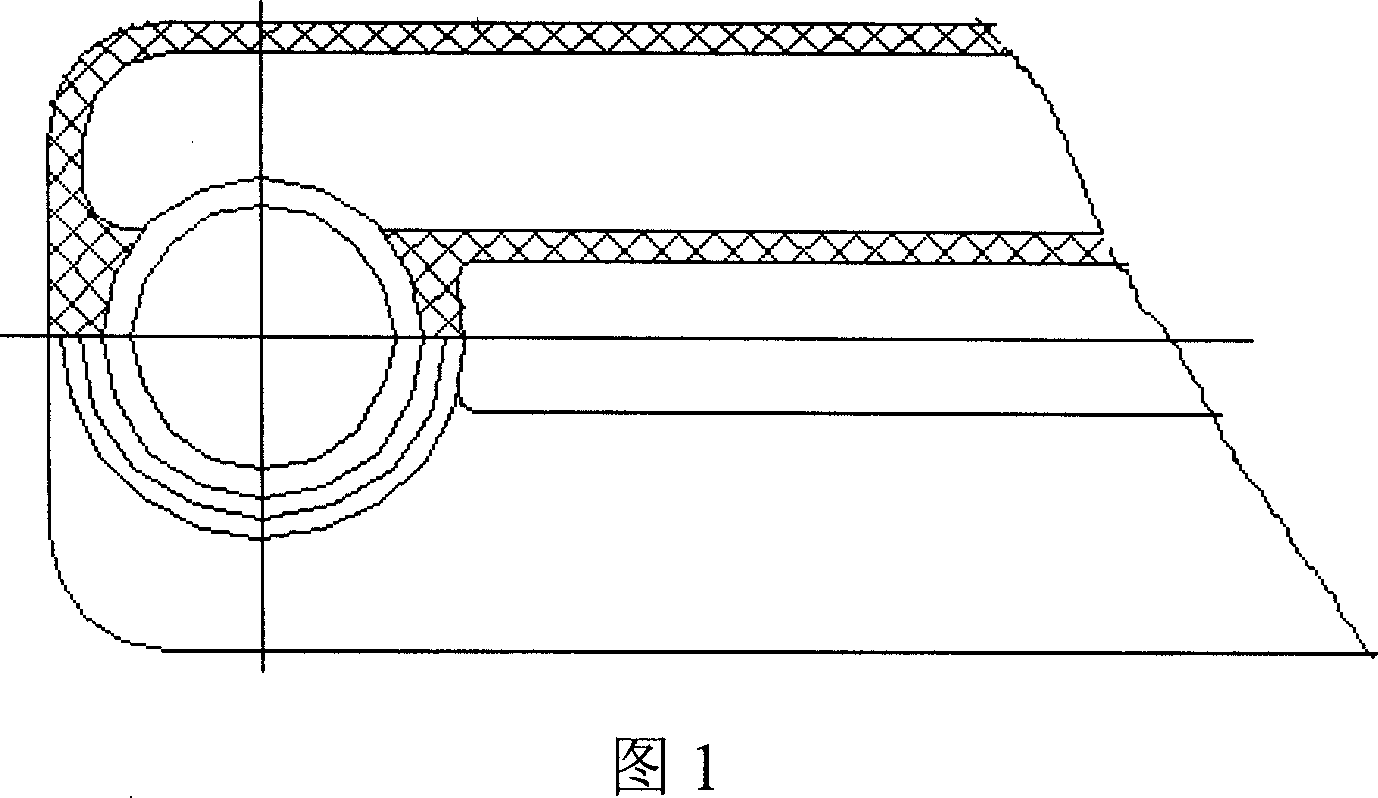

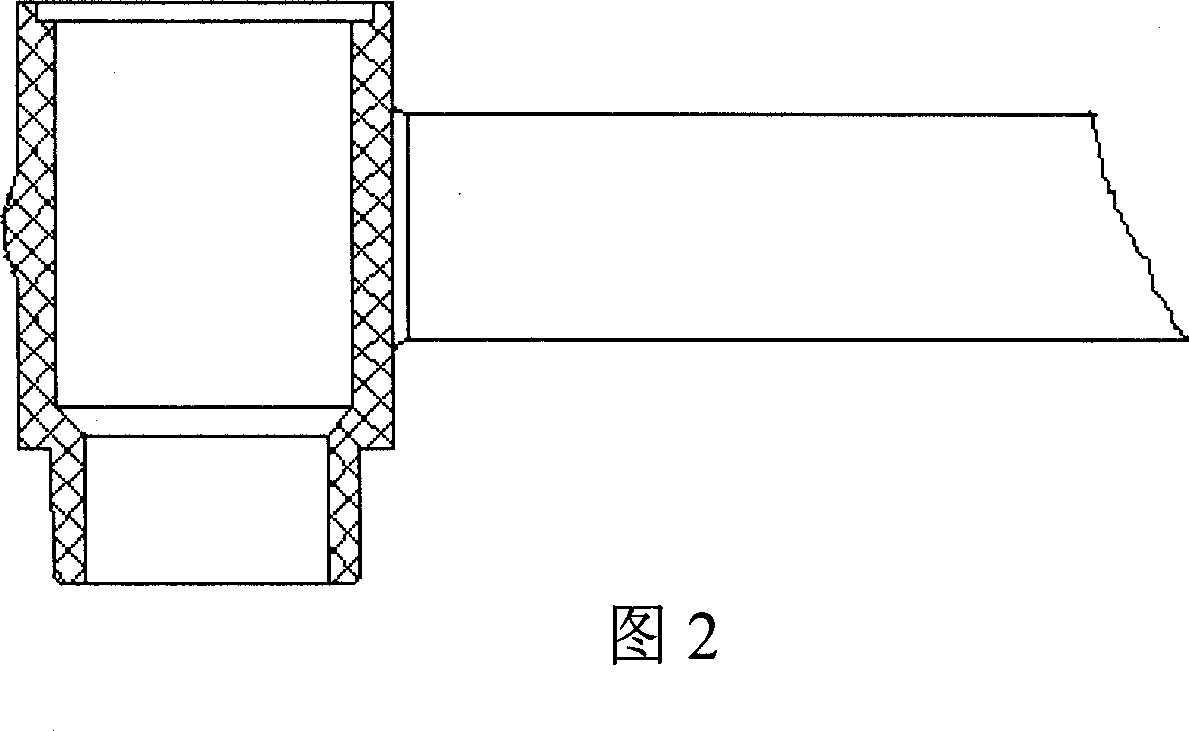

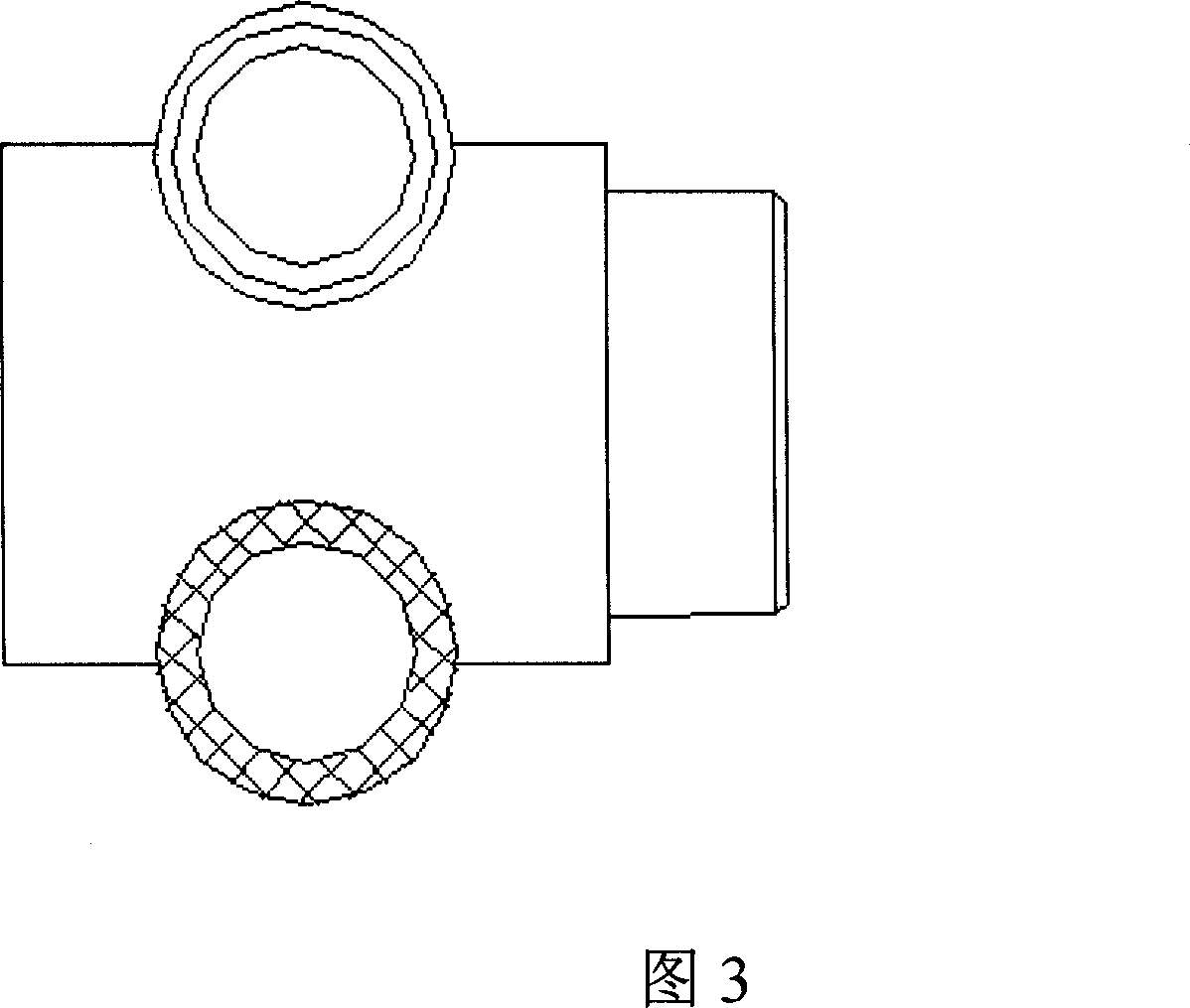

Radial-reverse combination extrusion forming mold of thin-wall cylindrical piece with outer boss

ActiveCN110695111ASubstantiveAvoid cumbersome proceduresExtrusion diesMechanical engineeringThin wall

The invention discloses a radial-reverse combination extrusion forming mold of a thin-wall cylindrical piece with an outer boss. The mold comprises an upper mold assembly, a lower mold assembly, a male mold, a female mold, a mandrel, a core support, an extrusion ring, an ejection block and a movable block, wherein the male mold is mounted on the upper mold assembly, the core support is mounted atthe bottom of the mandrel, the mandrel drives the core support to slide and stretch out and draw back of the male mold, and the extrusion ring sleeves the part stretching out of the core support; thefemale mold is mounted on the lower mold assembly, a cavity and a movable block groove are arranged in the female mold, the core support and the cavity are located on the same central shaft, after themovable block groove allows the movable block to be placed and is filled with the movable block, the shape of the cavity is a full cylinder shape, the ejection block is arranged in the cavity, the height of the ejection block is smaller than the height of the cavity, the upper part of the movable block protrudes out of the ejection block, the side surface forms an inwards-concaved boss cavity, and the outer diameter of the extrusion ring is the same as the diameter of the female mold cavity. The radial-reverse combination extrusion forming mold of the thin-wall cylindrical piece with the outer boss can directly form the thin-wall cylindrical piece with any position, size and number of bosses at one step, and the mechanical performance of the thin-wall cylindrical piece is greatly improved.

Owner:ZHONGBEI UNIV

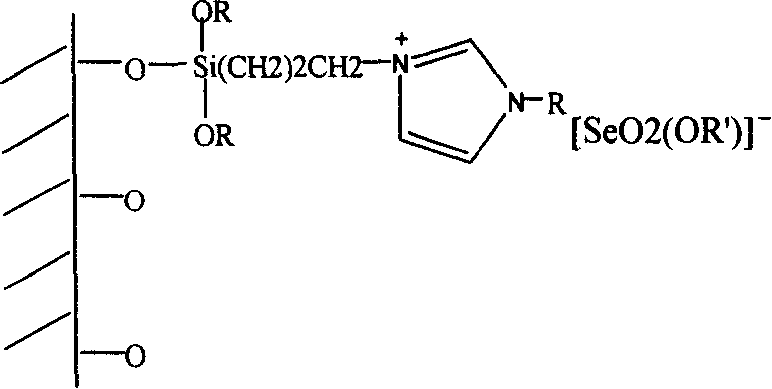

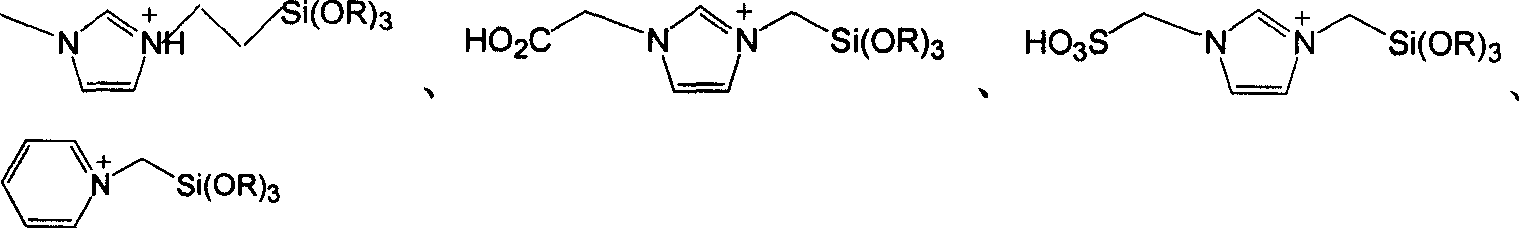

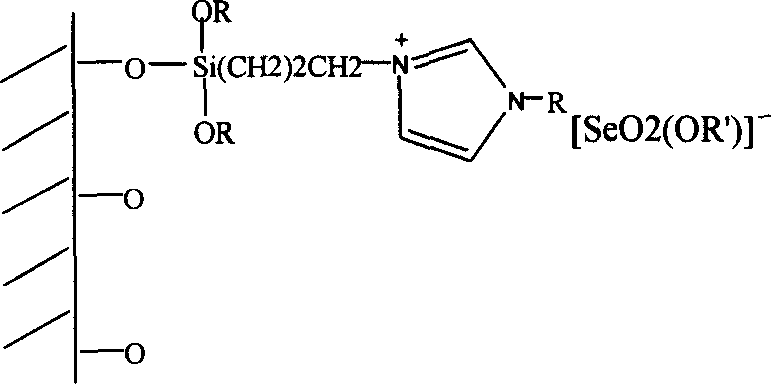

Ionic liquid catalyst of selenium anion loaded by silica gel, process for preparing same and use thereof

InactiveCN1990106ASubstantiveLow costCarbamic acid derivatives preparationOrganic compound preparationCarbamateSilica gel

The invention relates to a silicone impregnated Se anion and the ionic liquid catalyst preparation methods and application. Bonding the containing selenium ionic liquid on the porous silica gel prepared with ionic liquid as mold agent to preparing accelerating agent. The catalyst can under the condition of 100-120 degreeC, 3MPa-6MPa pressure catalyze Aromatic amine to make corresponding carbamate. The catalyst was characterized by high activity, supported by the carrier of silica can be adjusted, reducing the amount of ionic liquid, effectively lowering the cost of the catalyst.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Filter material, filter element, filter module and machining method thereof

InactiveCN104128044ASufficient air intakeFulfil requirementsFiltration separationFiberCellulose acetate

The invention provides a filter material, a filter element, a filter module and a machining method thereof. The filter material comprises rattan cores, rattan peels and poplar. At the first stage, the rattan cores are crushed into fibers and the rattan peels are softened and crushed into fibers; the poplar is crushed into fibers; at the second stage, all the materials are mutually dissolved; at the third stage, solid-liquid separation is carried out to obtain solid-state substances; the solid-state substances are dried to obtain the filter material; then the filter material is paved and rolled to obtain fiber cloth; the fiber cloth is subjected to die cutting and molding to obtain the filter module; cellulose acetate fibers which account for at least 30% of a ratio of the mixture is added to obtain a micro-filtration filter material; flower or Chinese herbal medicine fiber-shaped grains are added to obtain the filter material with fresh air attaching effect, and sterilization, deodorization and refreshing effects. According to the invention, the filtering effect is greatly increased and the service life of the filter element is prolonged; meanwhile, the air inlet quality is optimized and the air inflow is guaranteed; compared with other filter materials in the same grade, the filter material has small resistance, light weight, high capacity, environmental friendliness (combustible property) and low cost.

Owner:沃卡瑞(天津)贸易有限公司

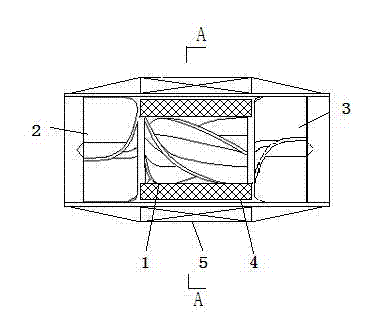

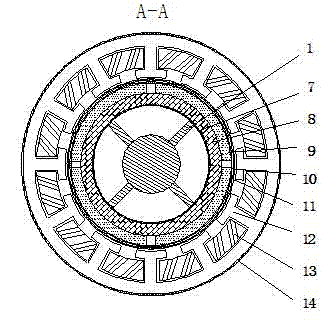

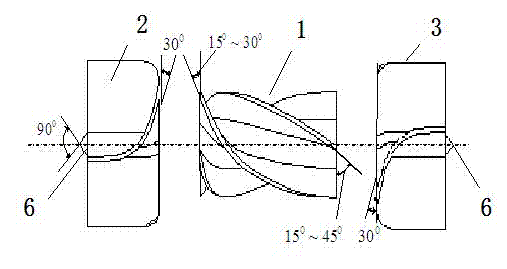

Low-blood-loss micro axial-flow type artificial heart

The invention discloses a low-blood-loss micro axial-flow type artificial heart which comprises a vane wheel, a motor rotor, and a motor stator, wherein the vane wheel is arranged inside the motor rotor in an interference fit and coaxial mode, the vane wheel is placed between an entry guide vane and an exit guide vane, two flow-guiding cones with large ends of 3mm are respectively arranged on an inlet end of the entry guide vane and an outlet end of the exit guide vane, the conical degree of the flow-guide cone is 90 degrees, and the two flow-guiding cones are in symmetrical arrangement. The helical angle of each flow-guiding vane on the entry guide vane gradually reduces from 90 degrees to 30 degrees along the axial direction from the inlet end to the outlet end, and the helical angle of each flow-guiding vane on the exit guide vane 3 gradually increases from 30 degrees to 90 degrees along the axial direction from the inlet end to the outlet end. The vanes on the vane wheel and all the flow-guiding vanes are in the shape of a logarithm helical line. Shaftless drive of the vane wheel reduces thrombus risk, and the micro structure improves the ability to implant. The low-blood-loss micro axial-flow type artificial heart has the advantages of being low in hemolysis, strong in implanting ability, simple in structure, high in reliability and the like.

Owner:JIANGSU UNIV

Surface sizing agent and its production method

InactiveCN101457499ASubstantiveGood water solubilityWater-repelling agents additionFunctional monomerMechanical stability

The invention relates to a method for preparing a surface sizing agent for papers. The raw materials used for preparing the surface sizing agent for papers consist of main agents and assistant agents. The main agents are rigid monomers, soft monomers and functional monomers; and the assistant agents are compound emulsifying agents, protective colloids and evocating agents. The proportions of the main agents by weight are as follows: 100 portions of rigid monomers, 40 to 100 portions of soft monomers and 5-40 portions of functional monomers; and the proportions of the assistant agents by weight are as follows: 1 to 10 portions of compound emulsifying agents, 1 to 10 portions of protective colloids and 1 to 8 portions of evocating agents. Compared with the styrene-maleic anhydride surface sizing agent prepared by common emulsifying agents, the surface sizing agent for papers prepared by the method has good mechanical stability, the latex contains no residual emulsifying agents, the particle surface is clean, and no side influence resulted from the emulsifying agents is existed during the sizing and drying process; the surface sizing agent has good membrane forming performance on the paper surface so as to provide excellent water-proof performance and surface flatness for the paper; and the surface sizing agent can increase the stiffness and the smoothness of the paper surface greatly.

Owner:上海埃格环保科技有限公司

Radial-reverse combined extrusion molding method for thin-walled cylindrical piece with outer bosses

ActiveCN110695112ASubstantiveAvoid cumbersome proceduresExtrusion diesEngineeringMechanical engineering

The invention discloses a radial-reverse combined extrusion molding method for a thin-walled cylindrical piece with outer bosses. A radial-reverse combined extrusion mold for the thin-walled cylindrical piece with the outer bosses is related in the method. The mold comprises a male mold, a female mold, a mandrel, a core support, an extrusion ring, a top block and a movable block. The core supportis installed at the bottom of the mandrel. The extrusion ring is connected to the extending outer portion of the core support in a sleeving mode. A cavity and a movable block groove are formed in thefemale mold. The upper portion of the movable block protrudes out of the top block. An inwards-concave boss type cavity is formed in the side face of the top block. The method includes the steps thatthe male mold downwards presses the extrusion ring and a hollow blank, the blank flows in the radial direction to fill in the boss type cavity, then the extrusion ring is omitted, the hollow blank moves down along with the male mold to be extruded into the thin-walled cylindrical piece, the thin-walled cylindrical piece is reversely extruded to rise, the movable block is driven to move up together, and the height of the thin-walled cylindrical piece is increased. By means of the scheme, the thin-walled cylindrical piece with an arbitrary number of bosses with arbitrary sizes at arbitrary positions can be directly formed at a time, and the mechanical performance of the thin-walled cylindrical piece is greatly improved.

Owner:ZHONGBEI UNIV

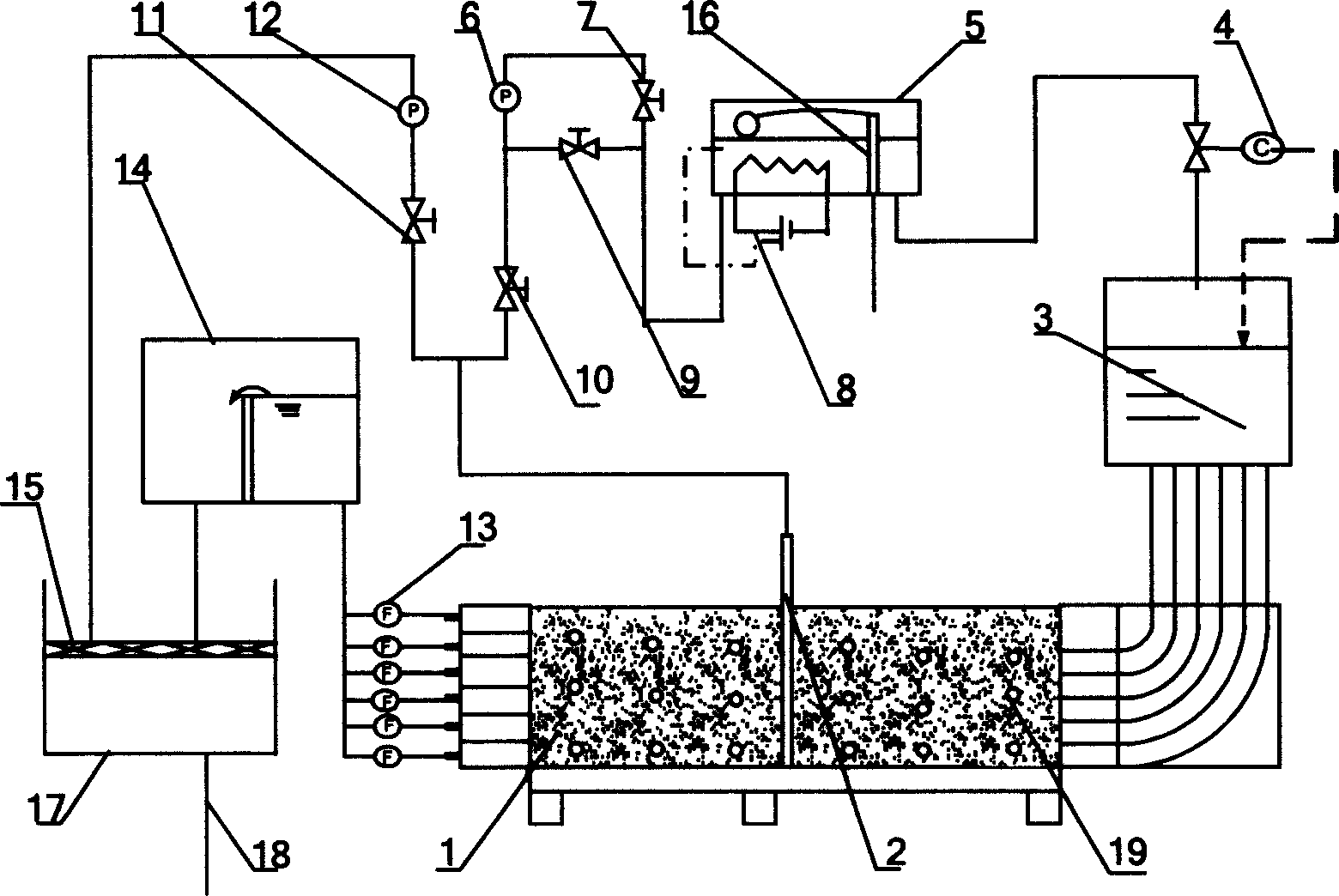

Tester for heat transferring and pore flowing character of aqueuos porous media materials

InactiveCN1584571ASimple structureSubstantiveMaterial thermal conductivityWater resource assessmentSolenoid valvePorous medium

A test device consists of test box, water injection pipe, water supply box, solenoid valve, water heating box, water pump, gate valve, flow meter, water collecting box, water filtering box and thermocouple. It is featured as placing thermocouple and water injection pipe in test box packing full of multihole media, measuring water temperature in media and flow rate flowing through media pore for obtaining real time picture of heat transfer and flowing property of the media.

Owner:SHANGHAI JIAO TONG UNIV

Catalyst for removing carbon monoxide and its preparation method

InactiveCN1579621ASubstantiveActive specificityHydrogen separation using liquid contactDispersed particle separationZincMetallic Nickel

The invention relates to an approach of producing a catalyst which can remove carbon monoxide in air or hydrogen. Catalyst in the invention is gold catalyst carried by hydroxid of iron, nickel, zinc and manganese. The catalyst can work to remove the carbon monoxide under room temperature. Characters of the catalyst are: working in a low temperature, low consumption and realizing to remove carbon monoxide under room temperature because carbon monoxide's activation is higher than hydrogen's.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

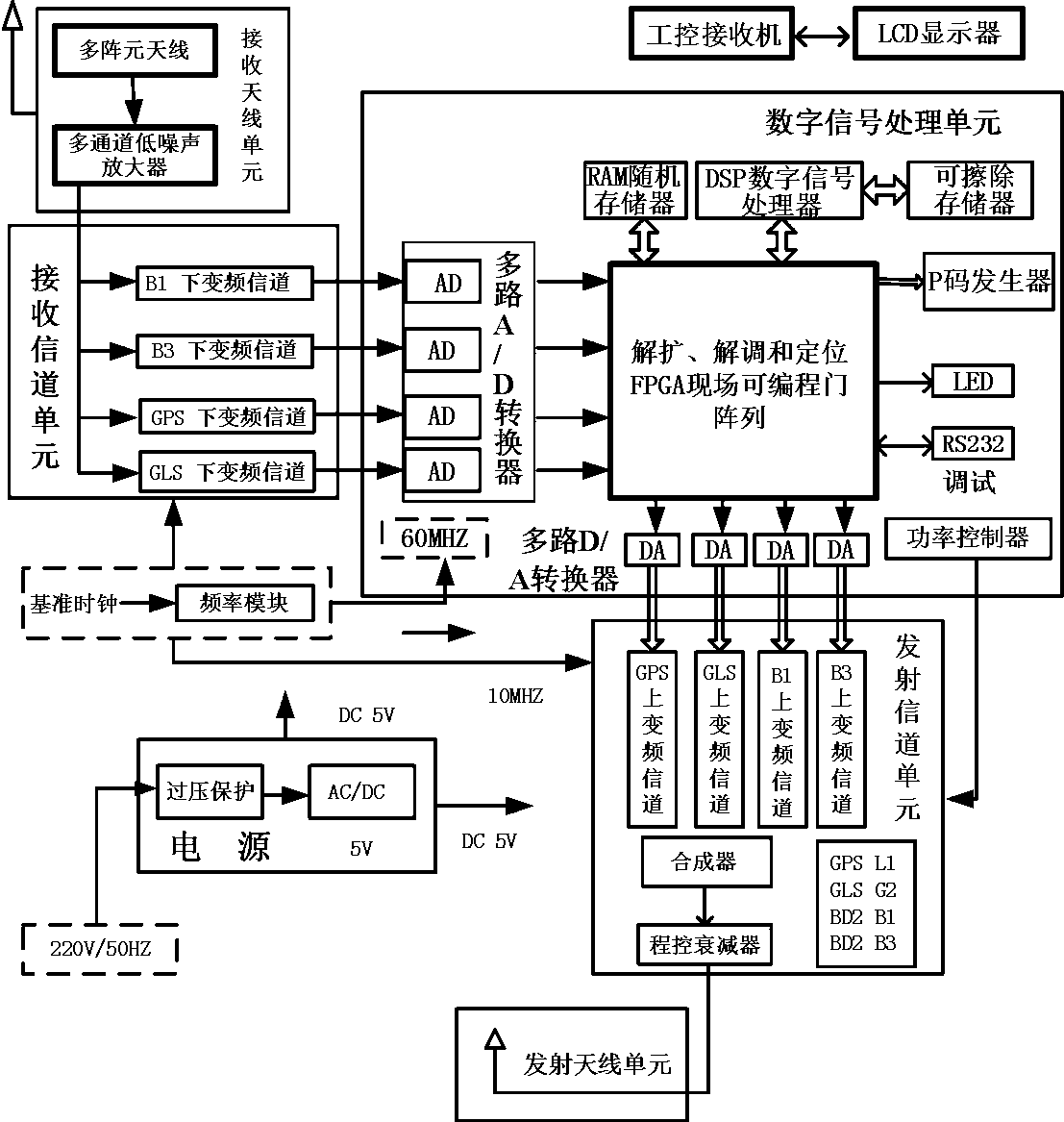

Monitoring simulator for transponding satellite signals

InactiveCN103684633ASolve the problem of noise interferenceSubstantiveRadio transmissionTransmission monitoringDigital signal processingPersonal computer

The invention discloses a monitoring simulator for transponding satellite signals. The monitoring simulator comprises a receiving antenna unit, a receiving channel unit, a transmitting channel unit, a transmitting antenna unit, a power source, an industrial personal computer and a digital signal processing unit. The receiving antenna unit is connected with the receiving channel unit. The receiving channel unit is connected with the digital signal processing unit. The digital signal processing unit is connected with the transmitting channel unit. The transmitting channel unit is connected with the transmitting antenna unit. The transmitting channel unit, the digital signal processing unit and the receiving channel unit are connected with the power source respectively. The digital signal processing unit is connected with the industrial personal computer. By the monitoring simulator, the problem of noise interference of the transponding satellite signals is effectively solved, and trackability of the transponding satellite signals is guaranteed.

Owner:CHENGDUSCEON TECH

Cap rotating mechanism for continuous round disc type cap rotating machine

The unscrewing mechanism of a consecutive disk type unscrewing device driven by electric motor speed reducer for free rotation, flexible and convenient of operation and applicable of bottles of alls kinds of specifications, comprises of electric motor speed reducer, speed reducer gear, cam of the middle cylinder, upper gear, gear shaft, lower gear, gear, middle gear, middle gear base, drive shaft, friction clutch, central fixing shaft, and unscrewing head, with speed reducer gears equipped on the shaft end of the electric motor speed reducer, and upper gears, gear shaft and lower gears equipped on the middle cylinder cam. The gear shaft fastens on the middle cylinder cam through a bearing base; the middle gear tooths with gears that connect sequentially with the drive shaft, the friction clutch and an unscrewing head.

Owner:SHANGHAI LONGTENG TECH

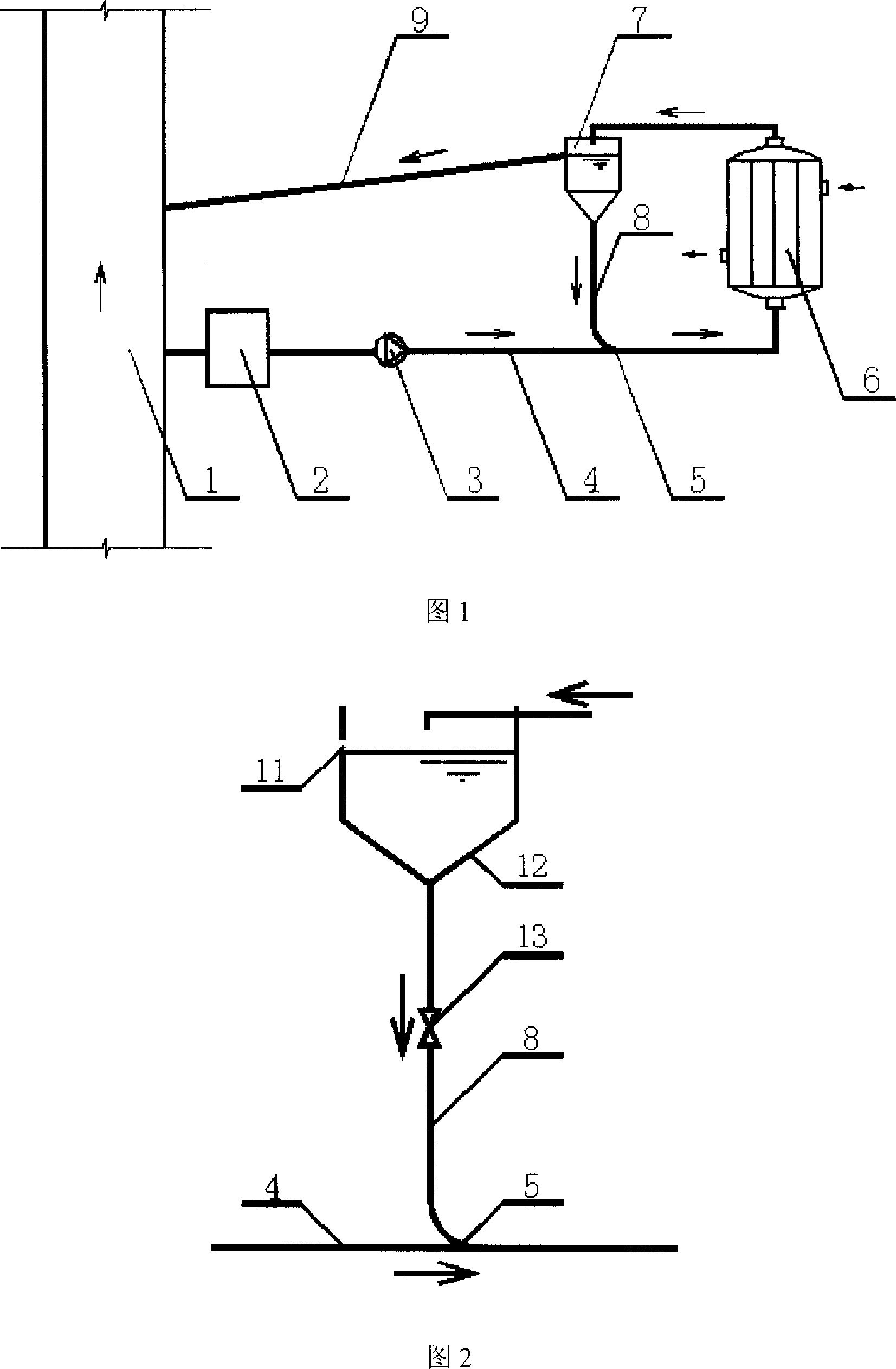

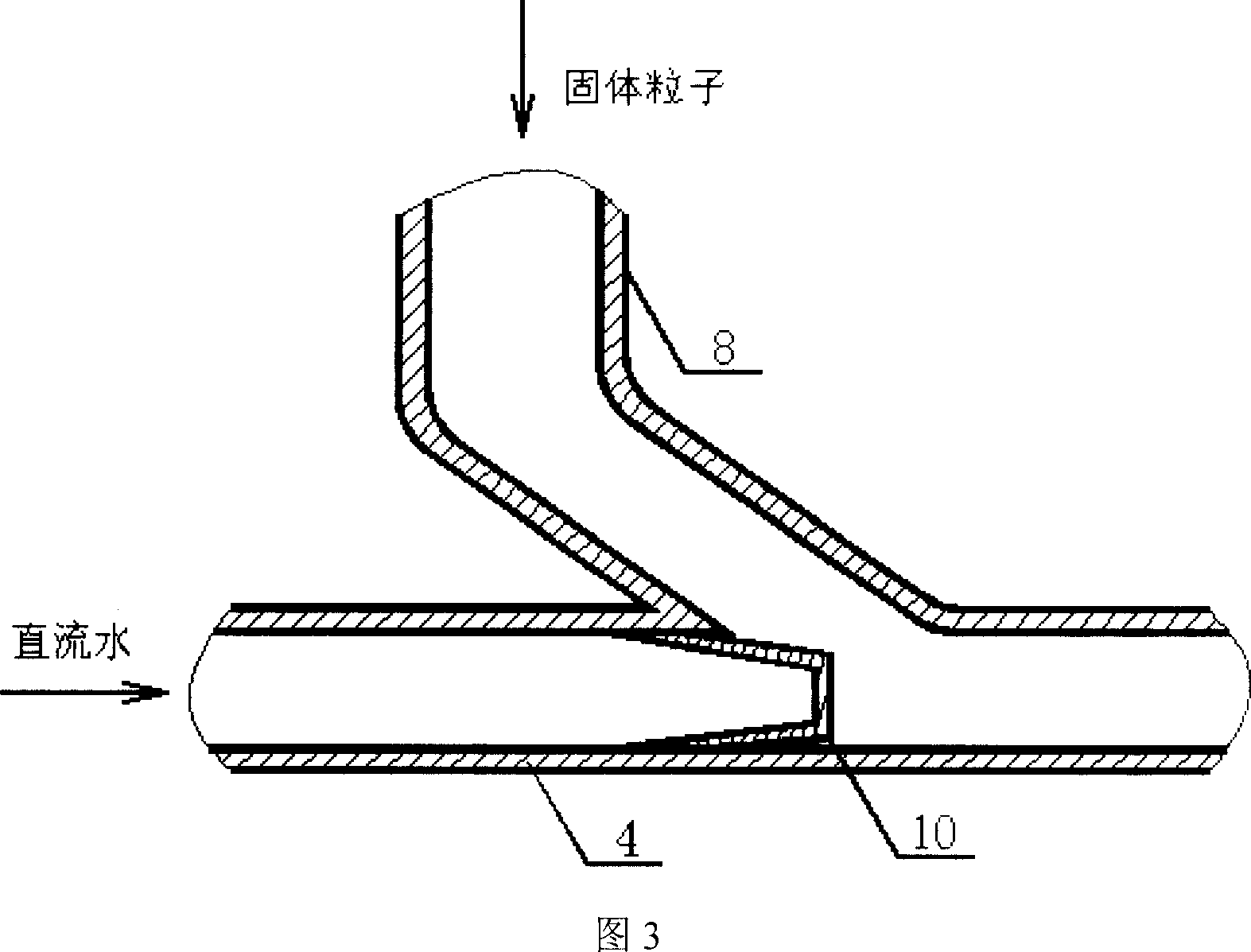

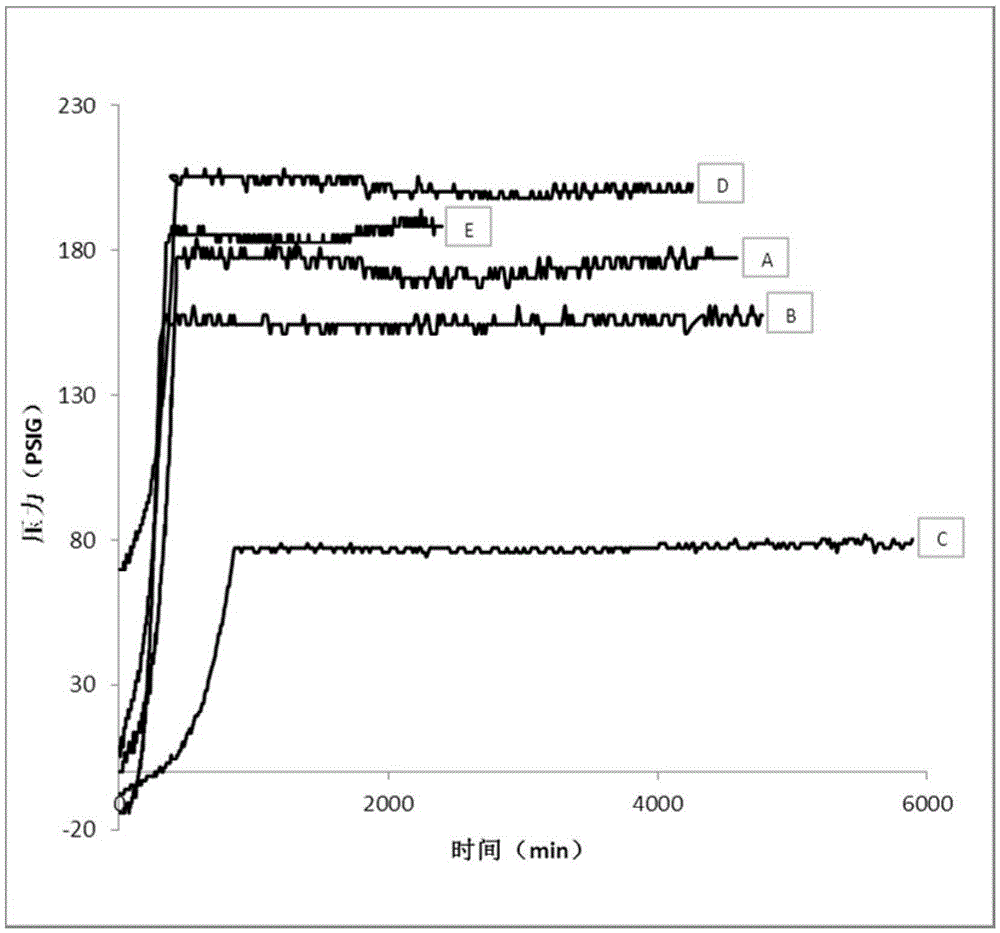

Solid-liquid separating method for fluidized bed heat exchanger

InactiveCN1995890ASignificant environmental benefitsSubstantiveHeat pumpsSedimentation separationSeawaterSewage

The invention relates to a solid-liquid separation method for fluidized-bed heat exchanging technology, when straight flowing water source is distilled as low-level heat source (river, municipal wastewater, lake water, underground water, sea water and so on) or cooling water. The invention belongs to synthesis utilization technology area for natural energy source. It is characterized in that gravity subside solid-liquid separator with no power, down-comer tube, overflow tube, bottom component of down-comer tuber and vertical cycling fluidized-bed heat changer and so on are adopted to separate solid particle form straight flow water source entirely so that added consumption is not increased and it is achieved that the low-level energy source in the straight water source is used by adopting fluidized-bed heat exchanger technology. Benefit effects comprises that not increasing added consumption, solving plugging of heat exchanger by sewage and bad performance for heat exchanging thoroughly. It can be applied in industrial equipment with cool and heat supply or cooling by the straight water source. It is provided with obvious environmental protection benefit, social benefit and economical benefit.

Owner:DALIAN UNIV OF TECH

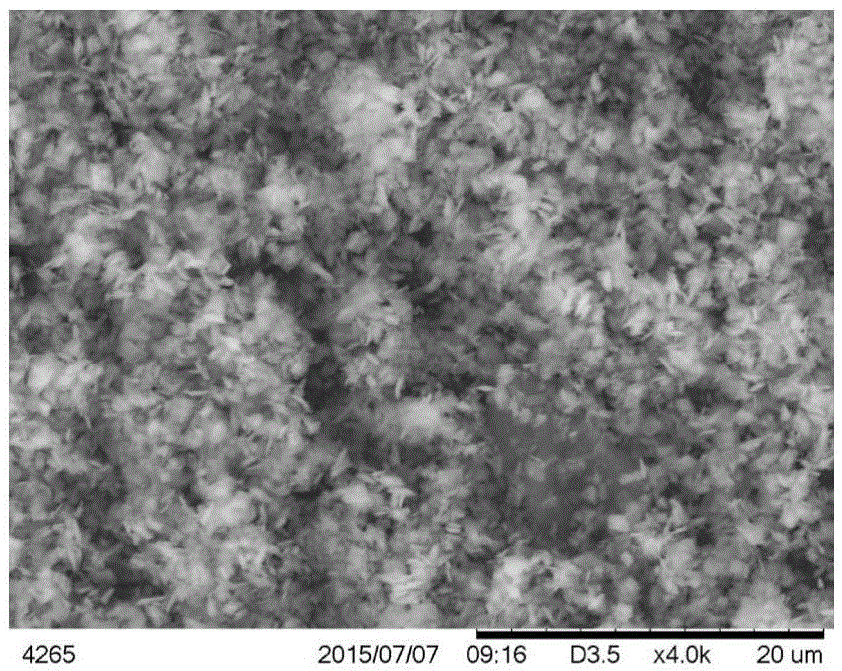

Method for preparing regular cubic particle SAPO-34 (Silicoaluminophosphate-34) molecular sieve and application thereof

ActiveCN105460956ASubstantiveAvoid generatingMolecular sieve catalystsMolecular sieve catalystMolecular sieveDistilled water

The invention discloses a method for preparing a regular cubic particle SAPO-34 (Silicoaluminophosphate-34) molecular sieve, wherein the method comprises the following steps of mixing a template agent with distilled water, sequentially adding a phosphorus source, a silicon source and an aluminum source, stirring the sources to form gel, preparing homogeneous gel by means of cutting the gel through a homogenizer, vacuumizing the homogenized gel, and ageing, crystallizing and activating the vacuumized homogeneous gel so as to obtain a white active molecular sieve. The regular cubic particle SAPO-34 molecular sieve prepared according to the method disclosed by the invention has the advantages of regular shape, easiness in recycling, low cost, high specific surface area, and better MTO (Methanol to Olefins) catalytic performance.

Owner:天津众智科技有限公司

Iron compound supported platinum catalyst and preparation thereof

InactiveCN101209419ASubstantiveHigh activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationPt element

The invention discloses an iron compound loaded platinum catalyst and a preparation method thereof. A catalyst carrier is iron oxide or iron hydroxide, and an active component is platinum; percentage composition of platinum mass is 0.1 to 20 percent of the carrier and the catalyst is prepared by adopting a coprecipitation method. The catalyst of the invention is expected to be widely applied in reforming reaction, hydrogenation dehydrogenation reaction and catalyzing combustion pollutants, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Carbon monoxide and selective oxidizing catalyst and preparation thereof

InactiveCN1745879ASubstantiveActive specificityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDeposition precipitationHydrogen

A catalyst for oxidizing the CO in waste gas and selectively oxidizing the CO under the existence of oxygen and the CO in the mixture of CO and hydrogen gas is prepared from the carrier which is the alumina particle carried oxide of transition metal chosen from Fe, Co and Mn, and the Au as the active component through the combination of dipping method and deposition-precipitation method.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ferric oxide carried palladium catalyst and its preparation method and application

InactiveCN1966143AImprove oxidation activityLow ignition temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceWater vapor

The invention relates to a ferric oxide palladium catalyst, wherein said catalyst is palladium catalyst loaded on ferric oxide, while the palladium mass percentage is 0.1-20% of carrier; and it is prepared by deposit method; said catalyst is multifunctional one, which has better low-temperature oxidize activity on CO, H2, CO+H2 and methane, and eliminates CO+H2 at room temperature, while it has high catalysis activity on steam.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

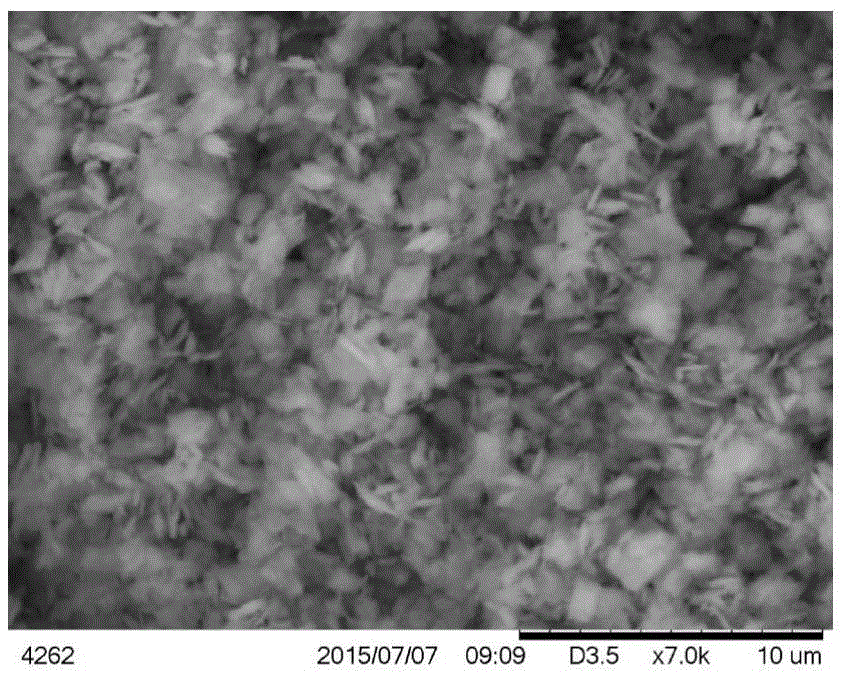

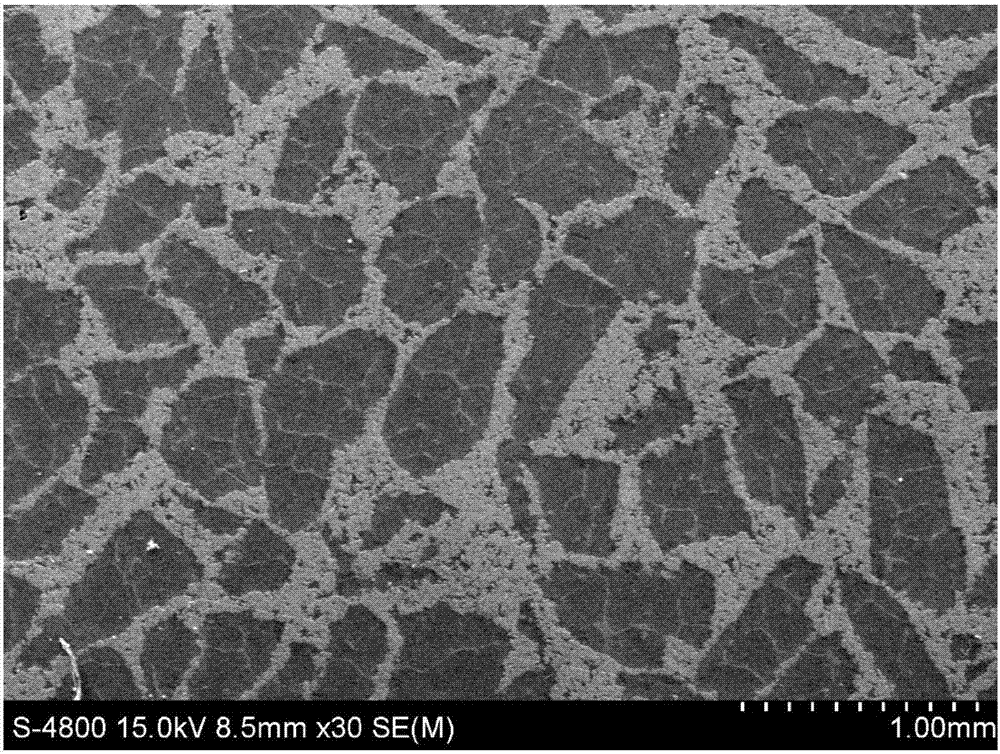

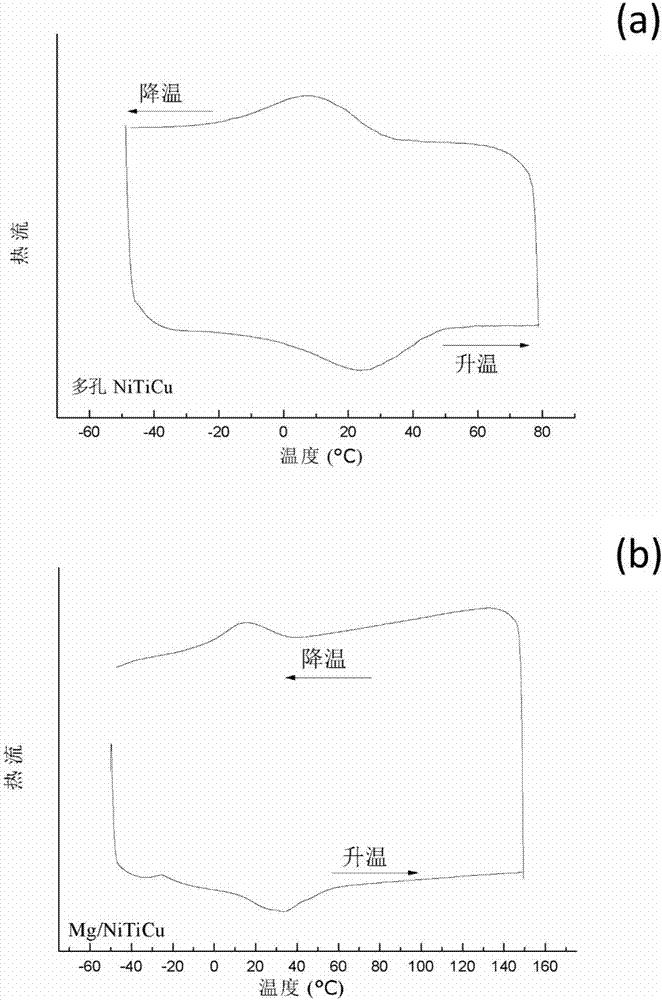

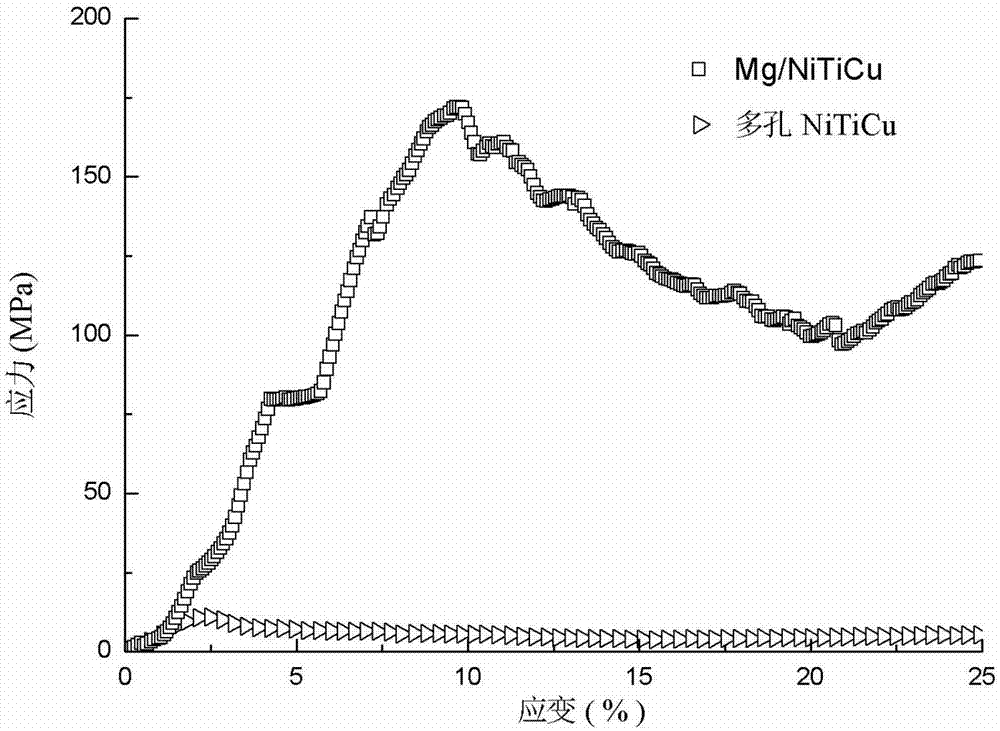

Method for preparing TiNiCu shape memory alloy damping composite

The invention relates to manufacturing of a damping material, in particular to a method for preparing a TiNiCu shape memory alloy damping composite. A porous TiNiCu shape memory alloy is prepared, holes of the TiNiCu shape memory alloy are filled with metal Mg, and the TiNiCu shape memory alloy damping composite, namely, Mg / TiNiCu is prepared. The defects that in an existing porous TiNiCu shape memory alloy preparation method, the porosity, the aperture and the hole type are all hard to control; and an existing technology of introducing Mg into the porous alloy cannot be used for filling porous TiNiCu alloy with Mg, and the damping performance and other mechanical performance of an alloy product need to be improved are overcome.

Owner:HEBEI UNIV OF TECH

Mineral-base composite material and the heat sink therewith

InactiveCN101067034AImprove pressure resistanceAbility to withstand pressureDomestic articlesCross-linkFiber

The present invention relates to is mineral-base composite material and the heat sink therewith. The mineral-base composite material is prepared with 1500-3000 mesh graphite powder, polypropylene, carbon fiber, cross-linking agent and antioxidant, and through high speed stirring and pelletizing. The heat sink with the mineral-base composite material is made through injection molding in an injection molding machine and welding with one sweating welder.

Owner:周士钦 +1

Pure absorption type dust absorption vehicle body

ActiveCN101638886AImprove cleaning efficiencyIncrease volumeRoad cleaningFiltrationHigh pressure pulse

The invention relates to a pure absorption type dust absorption vehicle body for ground cleaning, and belongs to the technical field of cleaning equipment vehicles. The vehicle body is characterized in that dusty gas flow absorbed in the dust absorption vehicle body is sent to a gravity settling chamber of the vehicle body, the dust is subject to sedimentation and collection, then the dust is sentto a labyrinth type settling chamber, the dust is further subject to sedimentation under the action of a baffle in the labyrinth type settling chamber, then the dusty gas flow enters a filtration dust collecting chamber for high-effective filtration, the filtered dustless air flow is discharged from the vehicle body through an air gathering chamber and a fan joint, a high-pressure pulse dust collector is arranged in the air gathering chamber, and separated dust can be discharged from the vehicle body when the discharging sealed gate is open. The dust absorption vehicle body has the advantagesof high cleaning efficiency, large volume of a dust collection chamber and the like.

Owner:SHANGHAI SHENZHOU AUTOMOBILE ENERGY SAVING ENVIRONMENTAL PROTECTION HAIAN +1

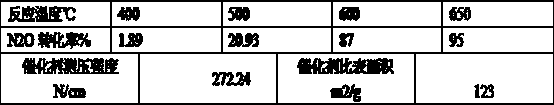

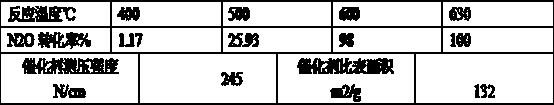

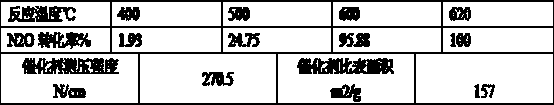

Preparation method of direct N2O catalytic decomposition catalyst

InactiveCN103506129ASimple preparation processGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsActivated carbonCatalytic decomposition

The invention relates to a preparation method of a direct N2O catalytic decomposition catalyst, and belongs to the technical field of environment-friendly catalytic materials and atmospheric pollution control. The catalyst uses a composite as a carrier and loads two layers of metal oxide by twice or multiple times of impregnation. The composite is the molded product of two or more of clay, activated carbon, bakelite powder, sesbania powder, special pseudo-boehmite powder, SiO2, TiO2, ZrO2, sandy soil or high alumina cement; the first layer of metal oxide is the composite oxide of Cu, Zn and Ni, and the second layer of metal oxide is an oxide of Ba, Ca, Mg, Y, Cr, Mo, Co, La, Pr or Nd; the catalyst takes the shape of a column, a clover or a five-leaf grass, and the outer diameter is 1-20 nm. The catalyst can be widely used in decomposition of N2O in a nitric plant, an adipic acid plant or other N2O-producing industrial processes.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

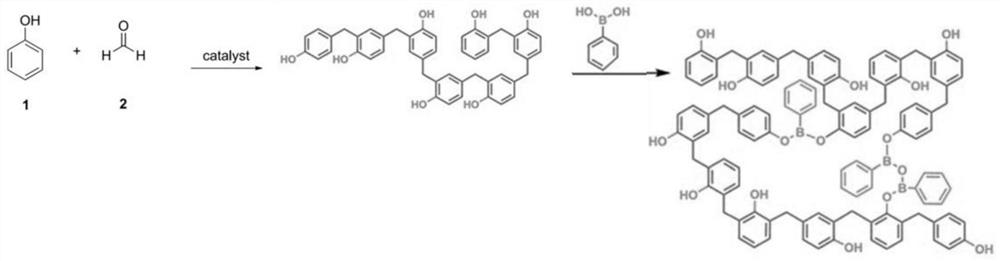

Preparation and degradation methods of hot-melt phenolic resin and composite material thereof

ActiveCN113429533AEasy to operateReduce energy consumptionPlastic recyclingPtru catalystChemical recovery

The invention provides preparation and degradation methods of hot-melt phenolic resin and a composite material thereof, and relates to the technical field of high polymer materials and chemical recovery thereof. The preparation method of the hot-melt phenolic resin comprises the following specific steps of: carrying out heating reaction on a phenolic compound and an aldehyde compound under the action of a catalyst, cooling, adding arylboronic acid and a derivative thereof, heating, boiling and refluxing again, carrying out decompression dehydration after the reaction is finished, adding a modifier and a flexibilizer, and vacuumizing to obtain the hot-melt phenolic resin. The preparation method of the hot-melt phenolic resin-based composite material comprises the following steps of: preparing a resin adhesive film from the hot-melt phenolic resin by adopting a hot-melt preimpregnation method, compounding the resin adhesive film with a fiber reinforcement body, and carrying out hot-pressing treatment to obtain the hot-melt phenolic resin-based composite material. The hot-melt phenolic resin and the hot-melt phenolic resin-based composite material are heated and decomposed in an ethanol or acetone solvent, and can be degraded and recycled. The preparation process is simple to operate and low in energy consumption, the production process is easy to control, and large-batch continuous production can be realized. The degradation process is safe, environment-friendly, green and pollution-free.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com