Automatic onion root/stem cutting machine

A technology of onion and root cutting, which is applied in applications, food processing, metal processing, etc., can solve the problems of increased product sanitation, low processing and production efficiency, and high labor intensity of workers, so as to reduce labor intensity, improve production efficiency, and reduce waste. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

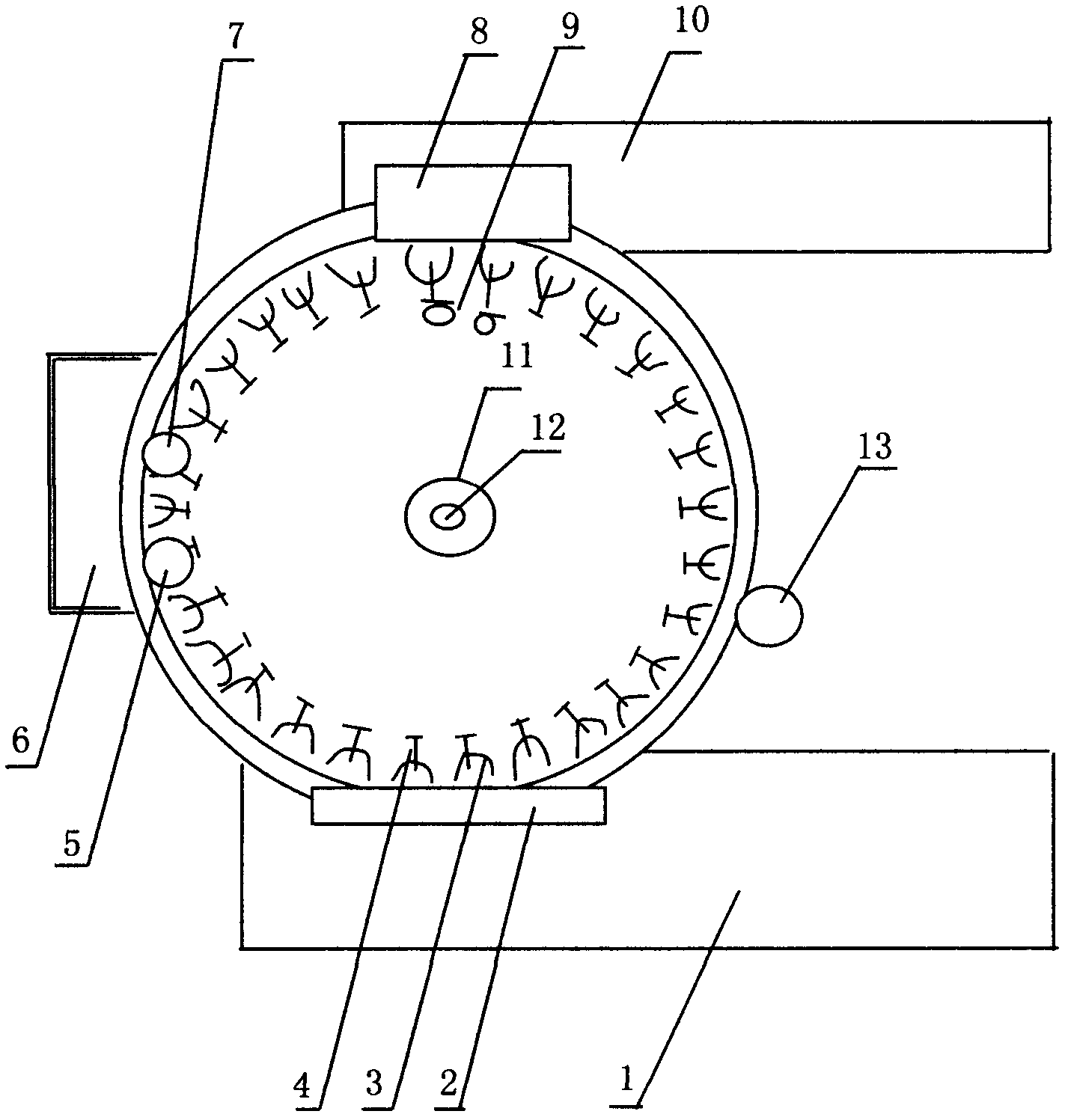

[0008] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0009] As can be seen from the accompanying drawings, the onion root-cutting and stem-cutting machine of the present program includes a feeding conveyor belt (1), a feeding port (2), and is located at the central machine shaft (12) and the power input slip ring (11). A number of onion clamping cards (3) are evenly distributed on the circumference of the disc, and there is a self-locking guide rod (4) at the tail of the onion clamping card (3) to control the clamping and releasing of the onion. The top of the box (6) is provided with multiple groups of rotary knives (7), and electromagnetic positioning (5), and there is a discharge port (8) above the discharge conveyor belt (10), and the corresponding There is a discharge retaining wheel (9) on the disk to complete the discharge, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com