Method for preparing TiNiCu shape memory alloy damping composite

A technology of damping composite materials and memory alloys, which is applied in the field of damping material manufacturing, can solve the problems of poor mechanical properties of polymer materials, limited mechanical properties, filling phase and matrix phase damage to practical materials, etc., to shorten infiltration time, Effect of low infiltration temperature and high damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step, the configuration of raw materials:

[0030] Weigh the required amount of titanium powder, nickel powder and copper powder, mix the ingredients according to the atomic percentages of Ni, Ti and Cu being 29%, 50% and 21% respectively, then place the mixed powder in a stainless steel ball mill tank, fill it with After sealing with water and ethanol, ball mill on a planetary ball mill for 5 hours, the ball-to-material ratio used in the ball mill is 10:1, and the rotating speed of the ball mill is 300 rpm. Let it stand for 3 minutes to complete the configuration of raw materials and set aside;

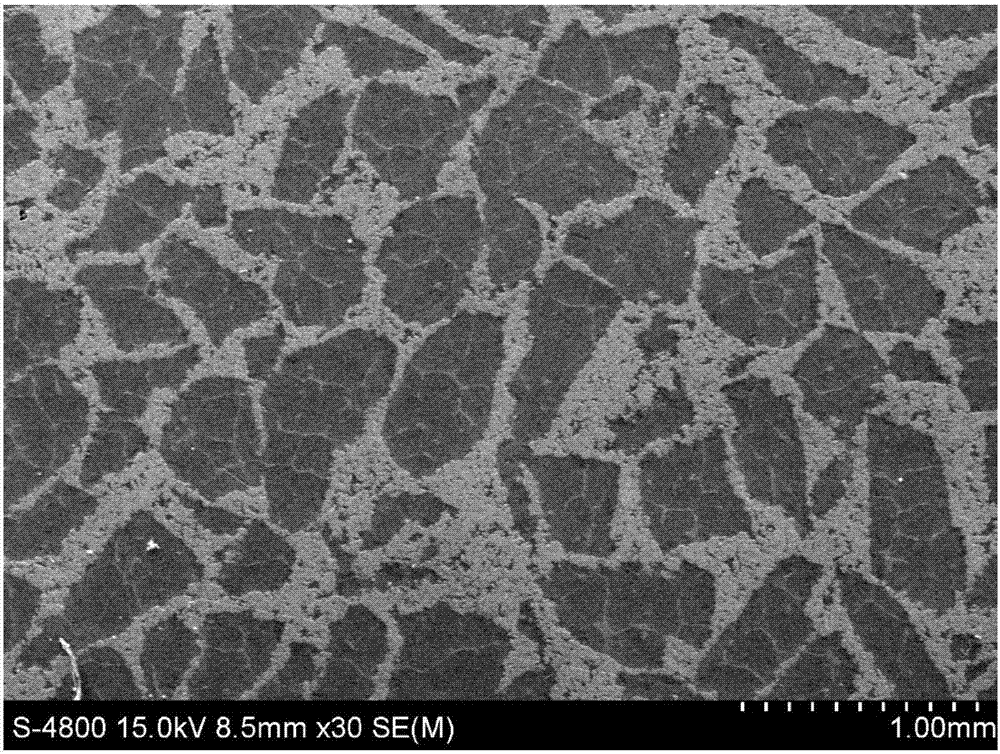

[0031] The second step, the preparation of porous TiNiCu shape memory alloy:

[0032] The mixed powder prepared in the first step is uniformly mixed with decrystallized water NaCl particles with an average particle diameter of 0.4mm, and the consumption of decrystallized water NaCl particles accounts for 60% of the volume percentage of the mixture of mixed powder an...

Embodiment 2

[0036] This example is a comparative example of Example 3.

[0037] The first step, the configuration of raw materials

[0038] Weigh the required amount of titanium powder, nickel powder and copper powder, and carry out batching according to the atomic percentages of Ni, Ti, and Cu being 30%, 50%, and 20% respectively, and then put the mixed powder in a stainless steel ball mill tank and fill it with anhydrous Seal after ethanol, ball mill on planetary ball mill for 6 hours, the ball-to-material ratio that adopts in ball mill is 10: 1, the rotating speed of ball mill is 300 rev / mins, afterwards, mixed powder is taken out and placed on filter paper and left standstill for 4 minutes, stand-by;

[0039] The second step, the preparation of porous TiNiCu shape memory alloy:

[0040] The mixed powder prepared in the first step is uniformly mixed with decrystallized water NaCl particles with an average particle diameter of 0.8mm, and the consumption of decrystallized water NaCl pa...

Embodiment 3

[0042] The first step, second step are with embodiment 2;

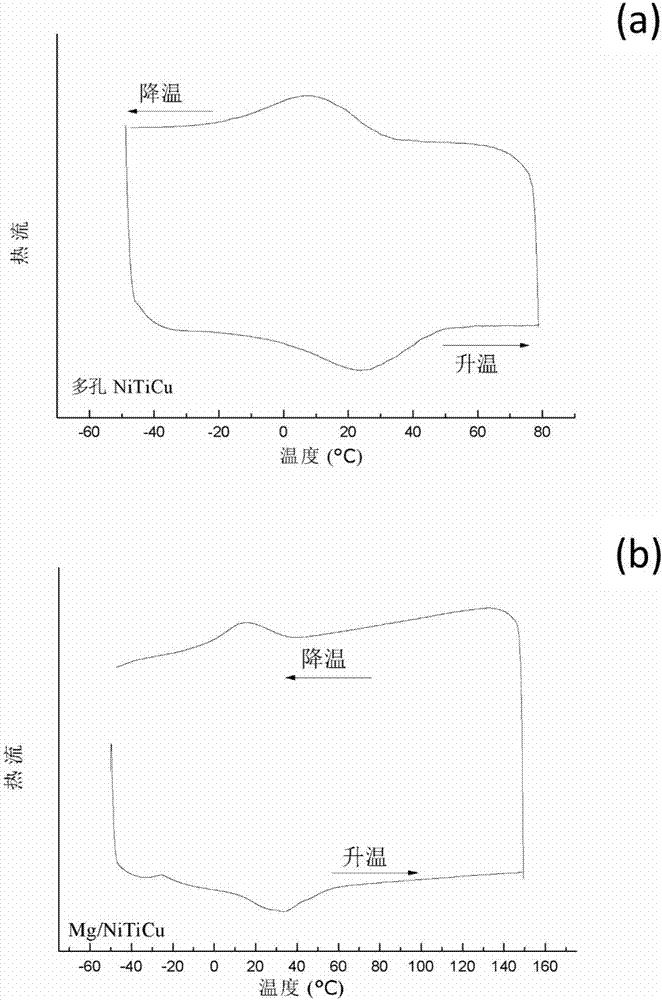

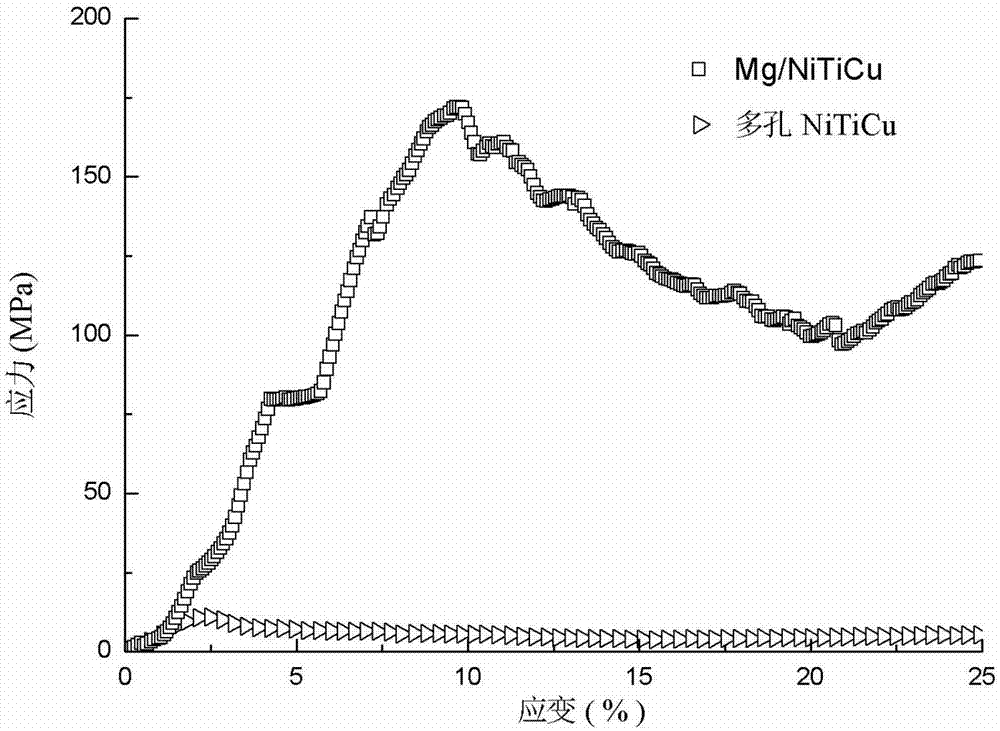

[0043] The third step is the preparation of the finished TiNiCu shape memory alloy-based damping composite material:

[0044] Cut off the upper and lower surface layers of the finished porous TiNiCu shape memory alloy prepared in the second step, place it in acetone, ultrasonically clean it for 50 minutes, and dry it. Clamp the upper and lower sides respectively and then bind them as a whole with moss wire, then put the whole bundled system into an alumina crucible, and place the crucible in the furnace tube of a tube-type vacuum sintering furnace, and wait for the vacuum in the furnace to reach 5Pa Then fill it with high-purity argon and then evacuate it to 5Pa again. Repeat this operation 3 times and then heat up to 700°C at a rate of 5°C / min and keep it for 20 minutes to melt the pure Mg and penetrate into the pores of the porous TiNiCu shape memory alloy. Among them, the furnace tube is then moved out of the hear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com