Hard high-damping coating preparation process used for surface of high-temperature damping part

A preparation process and damping coating technology, which is applied in the field of damping coating preparation, can solve problems such as inability to give full play to damping performance, uncertain coating thickness, and aggravated workpiece surface wear, so as to increase the applicable range of temperature and improve the inherent Vibration frequency, effect of high damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: NiCrAlY coating is selected in the NiCr superalloy coating, and the NiCrAlY coating is sprayed on the surface of the workpiece using GP-80 plasma spraying equipment. The alloy composition accounts for the mass percentage (wt%) of the NiCrAlY coating: Cr: 16 ; Al: 6; Y: 0.5; Ni: balance. Voltage 55-60V, current 550-580A, argon gas 60L / min, hydrogen gas 20L / min, powder feeding rate 20g / min.

Embodiment 2

[0028] Embodiment 2: FeCrMo coating is selected among FeCrMo ferromagnetic coatings, and GP-80 plasma spraying equipment is used to spray FeCrMo coating on the surface of the workpiece. The alloy composition accounts for the mass percentage (wt%) of FeCrMo coating: Cr: 16 ; Mo: 3; Fe: balance. Voltage 58-60V, current 550-570A, argon gas 60L / min, hydrogen gas 20L / min, powder feeding rate 30g / min.

Embodiment 3

[0029] Embodiment three: choose ZrO in YSZ ceramic coating 2 Ceramic coating, using GP-80 plasma spraying equipment to spray ZrO on the surface of the workpiece 2 Ceramic coating, the ceramic composition occupies ZrO 2 The mass percentage (wt%) of the ceramic coating is: Y 2 o 3 : 8, ZrO 2 :margin. Voltage 55-60V, current 550-580A, argon gas 60L / min, hydrogen gas 20L / min, powder feeding rate 20g / min.

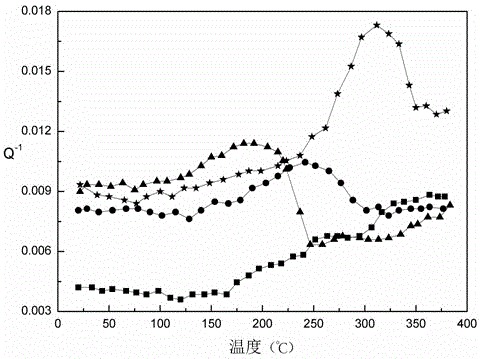

[0030] The devices used in the above embodiments are all known devices in the industry. The microstructure of the coating prepared by the above method shows that there is an obvious interface between the substrate and the coating, and there are many voids inside the coating. High porosity is one of the important structural features of plasma coatings, and its value is about 4.8-33%. These pores will become one of the higher sources of internal friction under vibration loads. As the spray particles overlap each other during the deposition process, some interlayer interface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com