Mineral-base composite material and the heat sink therewith

A technology of composite materials and radiators, applied in other home appliances, household components, home appliances, etc., can solve the problems of short service life, waste of resources, high maintenance costs, etc., and achieve excellent anti-aging performance, improved pressure bearing capacity, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

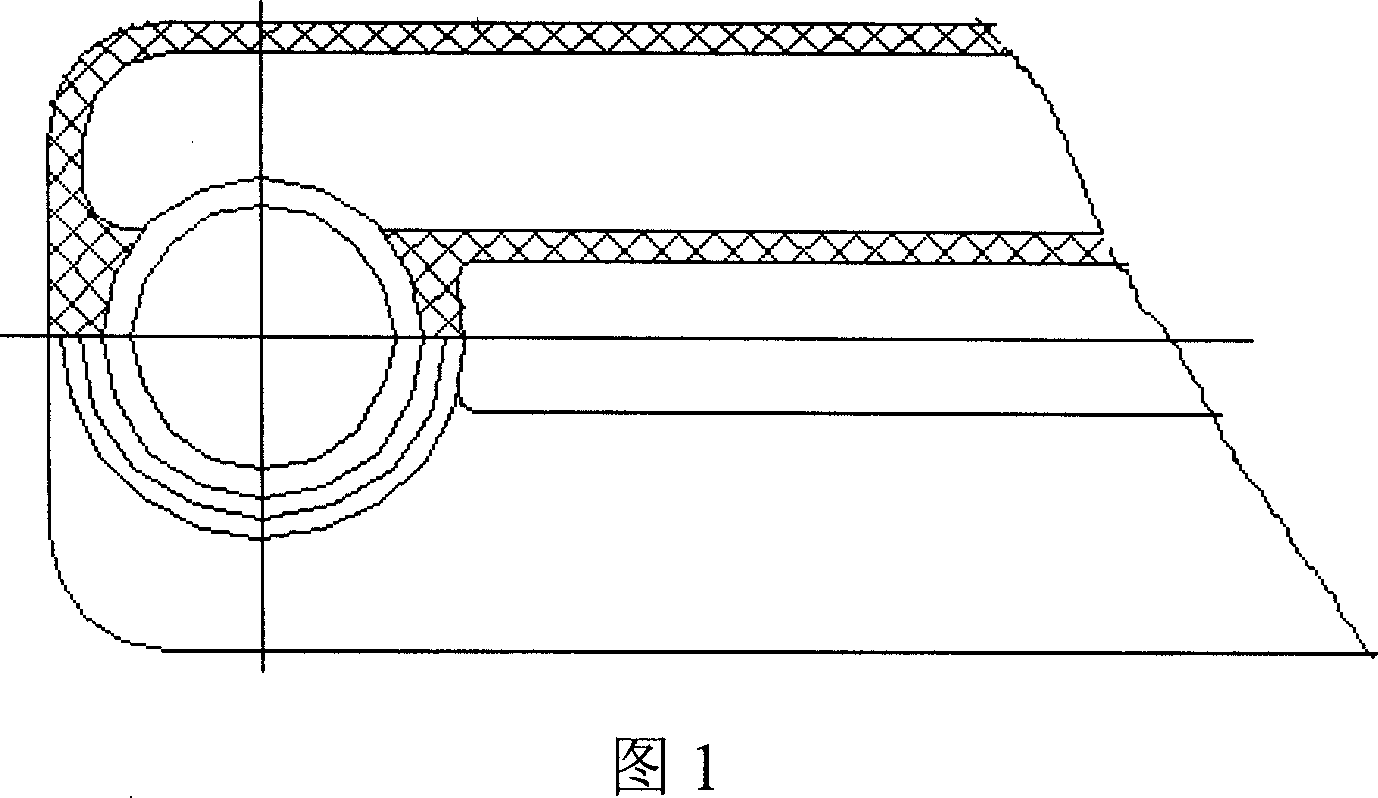

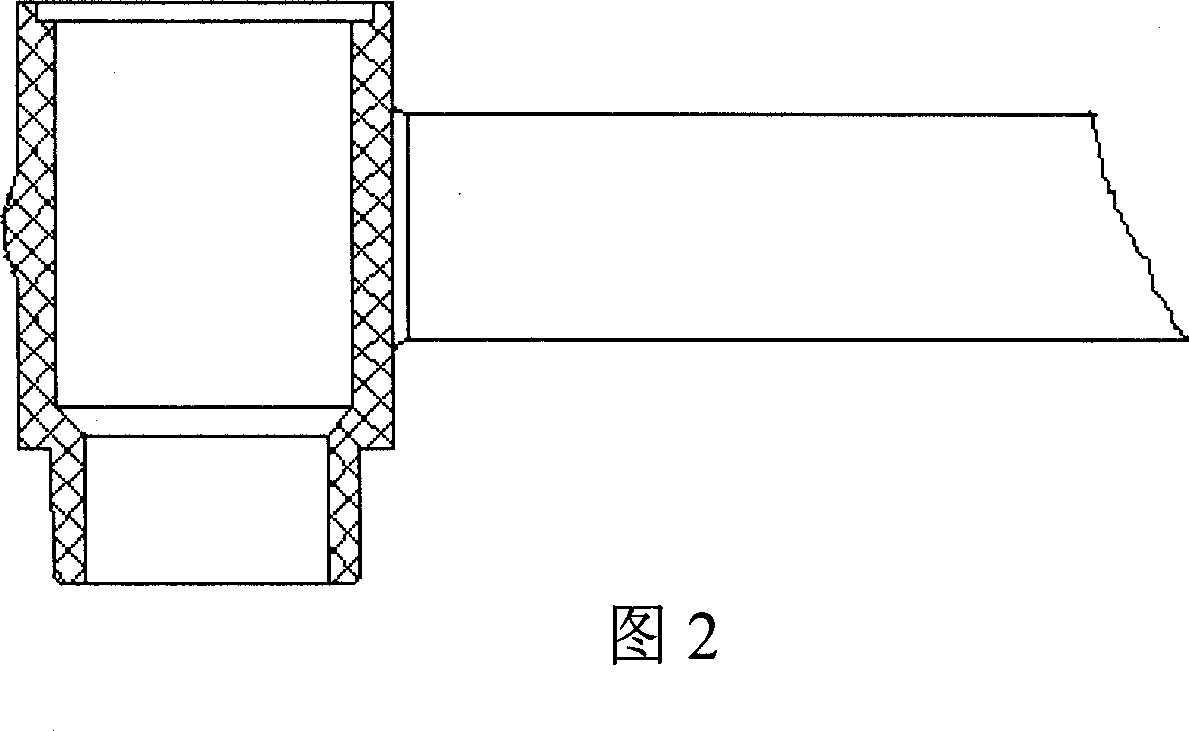

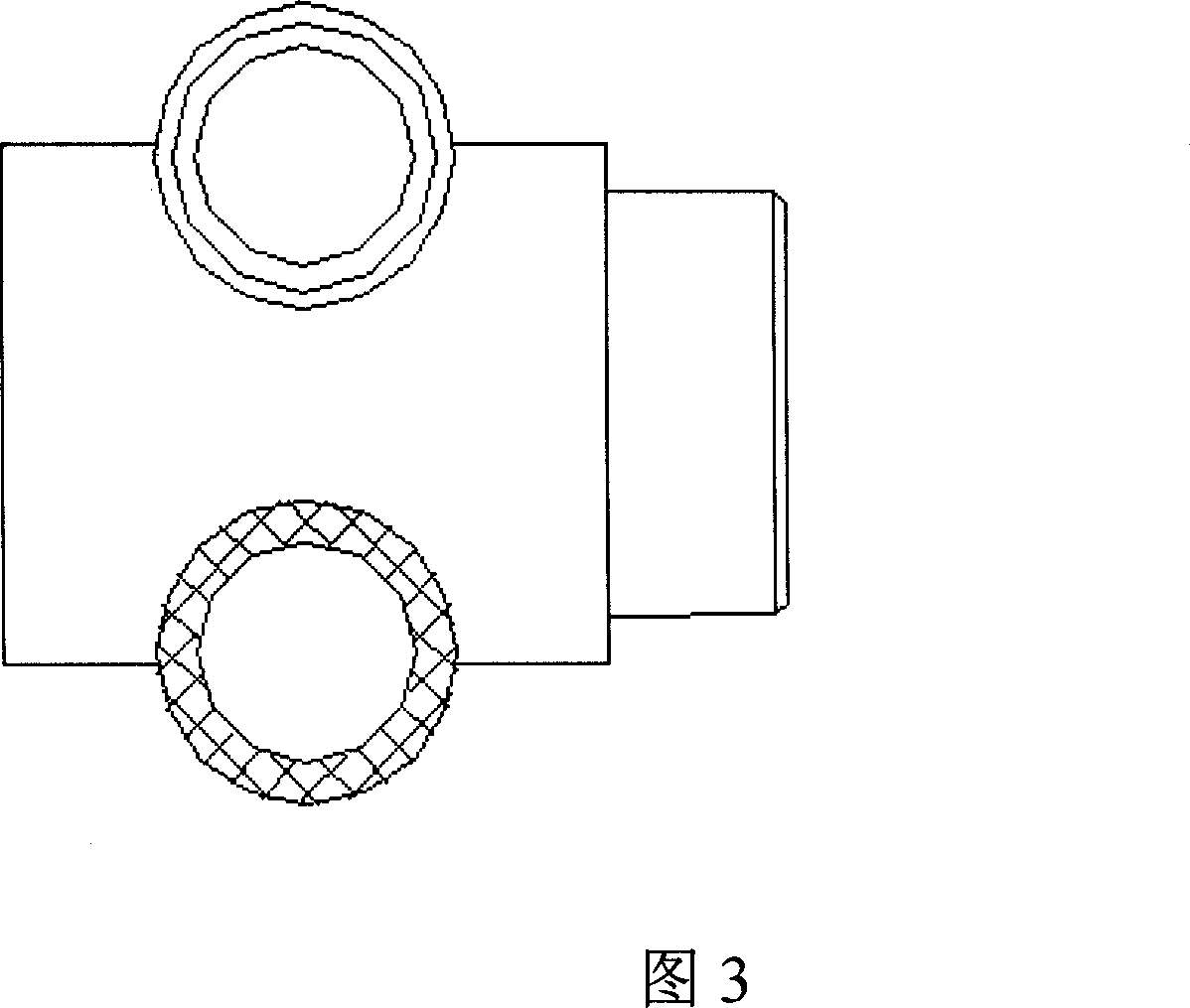

Image

Examples

Embodiment 1

[0030] Embodiment 1: with 100kg2000 order graphite powder, 90kg polypropylene (Yanshan chemical industry production, model is 4220), 3kg carbon fiber, 3.5kg aluminate coupling agent (Jining De Yali company production, model is DYL-3), 2kg Antioxidant (manufactured by ADK Company, model is 1076), mixed in a high-speed mixer, granulated through a twin-screw feeder (manufactured by Nanjing Keya Company, model is CKY-95), and then put into an injection molding machine for injection molding. Finally, it is welded and assembled by a hot-melt welding machine.

Embodiment 2

[0031] Example 2: Mix 100kg2000 mesh graphite powder, 105kg polypropylene, 8kg carbon fiber, 5.5kg aluminate coupling agent, 4kg antioxidant in a high-speed mixer, granulate through a twin-screw feeder, and then put into injection molding Injection molding in the machine, and finally welded and assembled by a hot-melt welding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com