Solid-liquid separating method for fluidized bed heat exchanger

A fluidized bed heat exchanger, solid-liquid separation technology, applied in fluidized bed heat exchangers, separation methods, chemical instruments and methods, etc., can solve problems such as bad, blocked heat exchanger heat transfer performance, etc., to achieve The effect of obvious environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

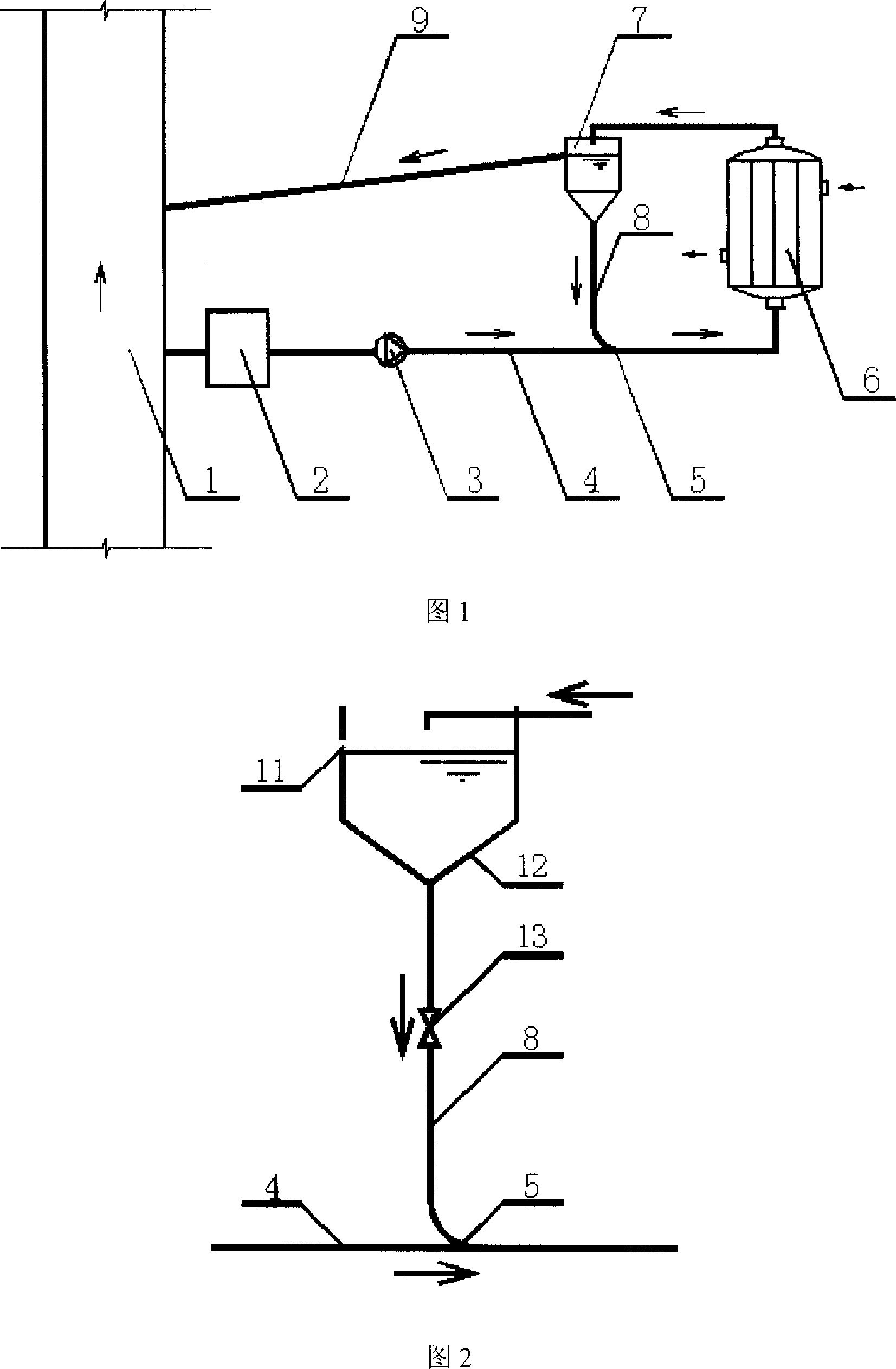

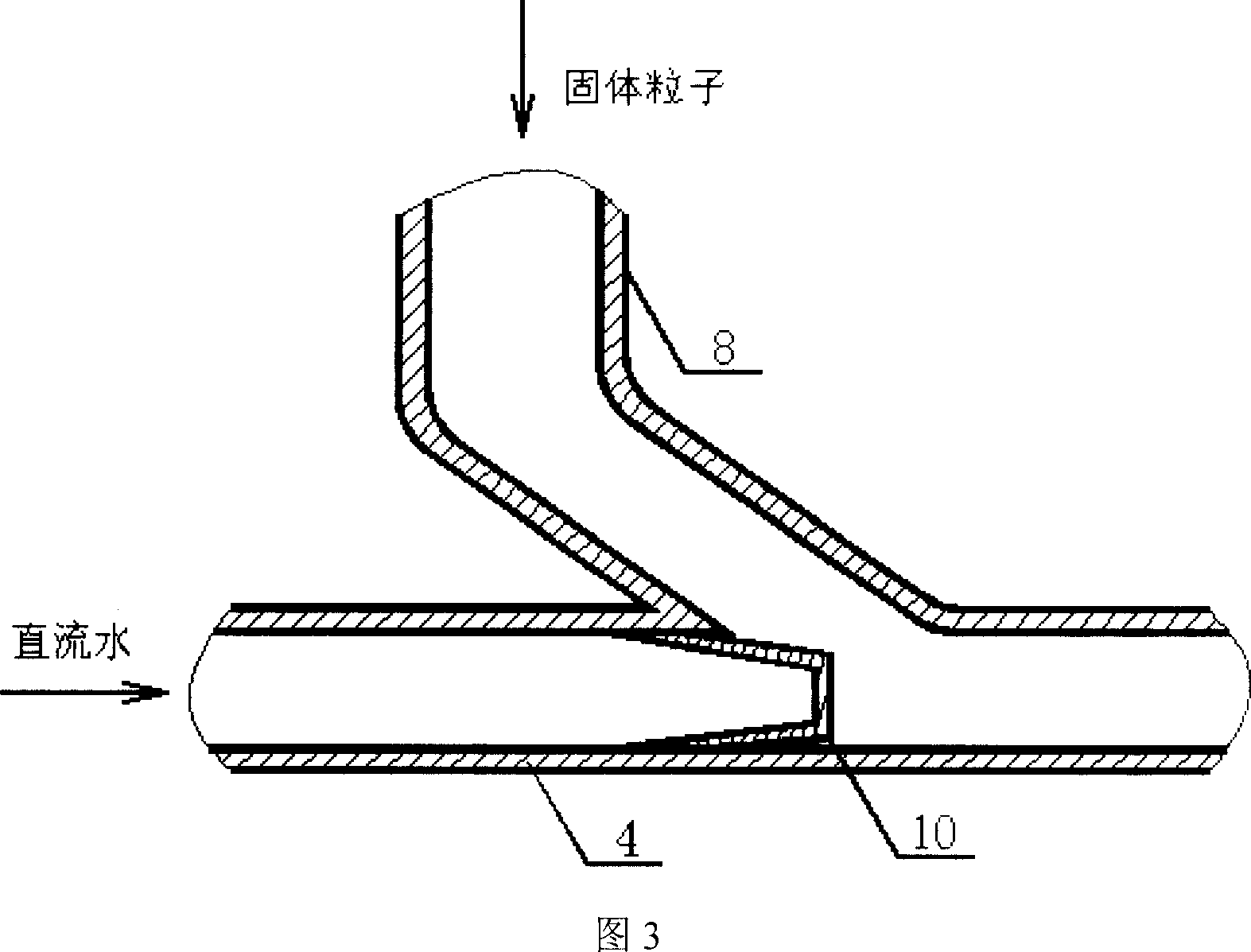

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0017] As shown in Figures 1, 2, and 3, firstly, the control valve 13 is opened, and the water pump 3 is started to suck the water source from the direct-flow water source pipe network 1 through the direct-flow water source inlet pipeline 4 into the automatic water intake and decontamination device 2. It is removed, and then enters the vertical fluidized bed heat exchanger 6 through the water inlet pipeline. Before the direct-flow water source enters the heat exchange equipment, solid particles are added to strengthen the heat exchange capacity of the equipment and prevent the formation of dirt. In the vertical fluidized bed heat exchange A non-powered gravity sedimentation solid-liquid separator 7 is installed on the straight-line water source outlet of the device 6 to separate these homogeneous particles, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com