Method for preparing regular cubic particle SAPO-34 (Silicoaluminophosphate-34) molecular sieve and application thereof

A SAPO-34, cubic particle technology, used in molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and alkali-exchanged phosphates, etc., can solve the problems of difficult product morphology control, difficult molecular sieve slurry, high process costs, and achieve excellent catalytic performance. , to facilitate solid-liquid separation and improve the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

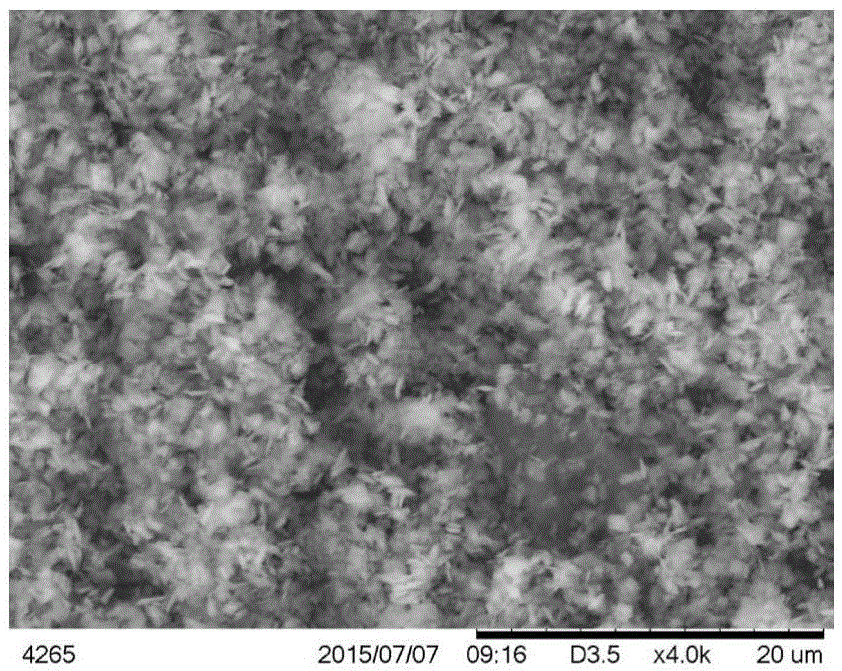

[0047] Embodiment 1 (raw material mol ratio is 35H 2 O: 1.0R: 0.2SiO 2 : 1.1P 2 o 5 :Al 2 o 3 )

[0048] Gel preparation: first mix 1767.6 grams of 25wt% tetraethylammonium hydroxide aqueous solution with 540.9 grams of distilled water in a water bath at 20°C with a stirring speed of 200 rpm, then slowly add 760.9 grams of 85wt% phosphoric acid and stir evenly, then slowly add 90.2 grams of 40wt% neutral silica sol, continue to stir evenly; then slowly add 425 grams of pseudo-boehmite, increase the stirring speed to 600 rpm and stir for 5 hours to make the solution gel; Shear at 13,000 rpm for 100 minutes on a plastidizer to prepare a homogeneous gel.

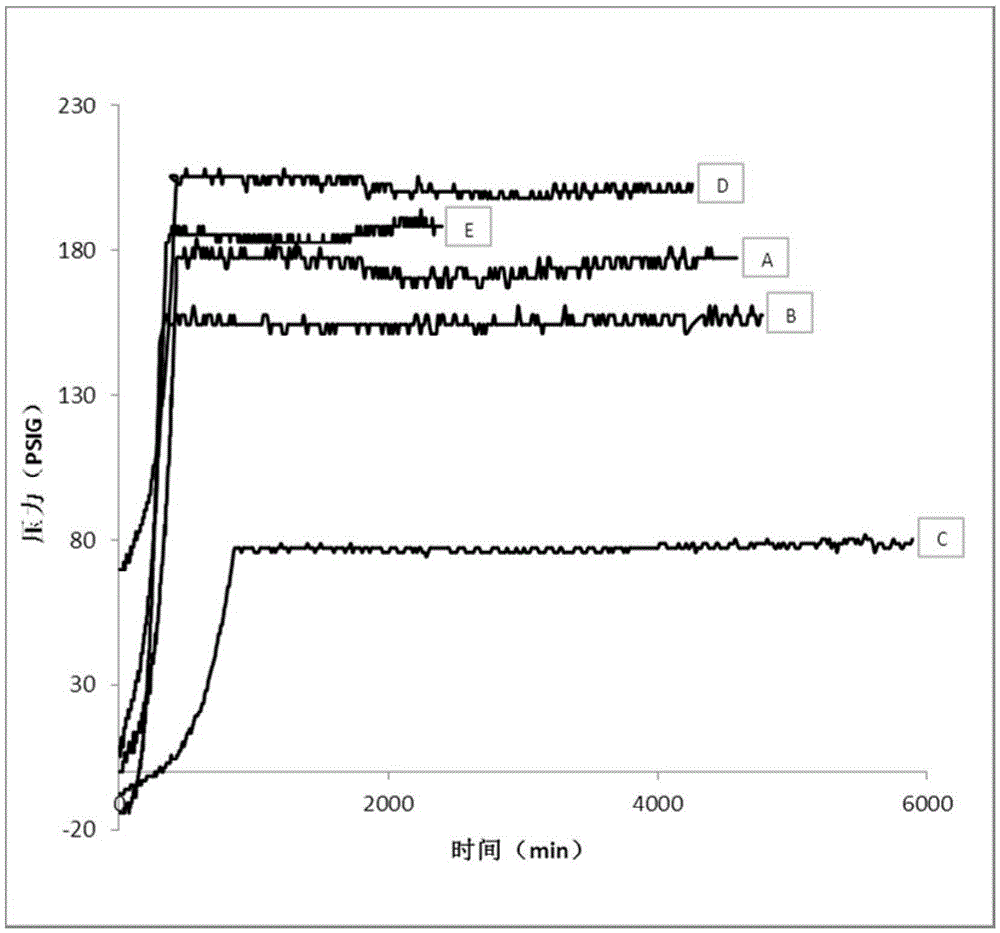

[0049] Aging: Take 600ml of the above-mentioned homogeneous gel and transfer it into a 2L dynamic hydrothermal reactor, and the filling rate of the reactor is 30% (v / v). Control the temperature at 30°C, and use a vacuum pump to pump the pressure inside the reactor into a negative pressure state. The gauge pressure displa...

Embodiment 2

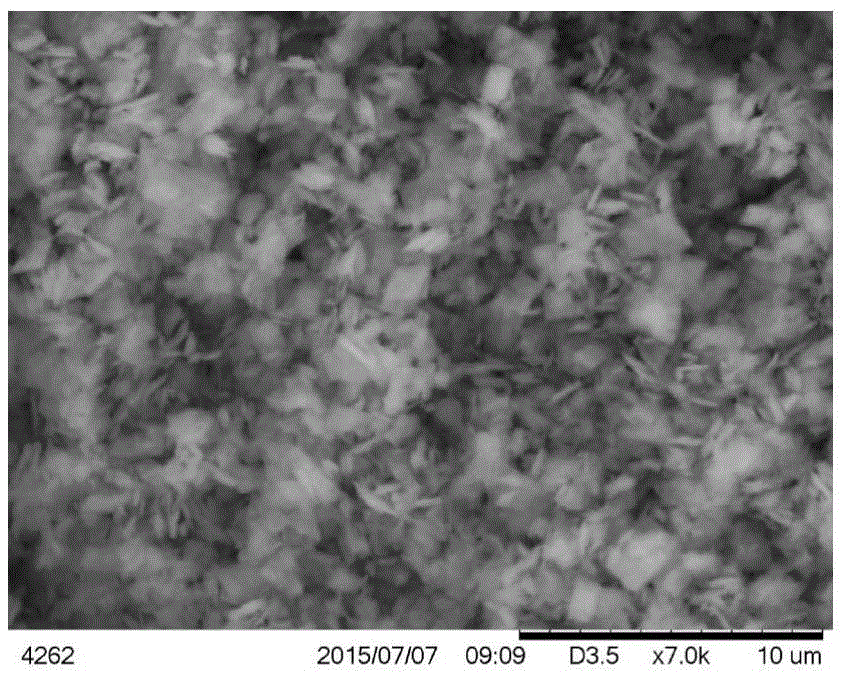

[0053] Embodiment 2 (material ratio is 40H 2 O: 1.5R: 0.1SiO 2 : 1.0P 2 o 5 :Al 2 o 3 )

[0054] Gel preparation: first mix 2209.5 grams of 30wt% tetraethylammonium hydroxide aqueous solution with 555.8 grams of distilled water, 10 ℃ ice-water bath, stirring speed 300 rpm, then slowly add 735 grams of 80wt% phosphoric acid and stir evenly, then slowly Add 51.5 grams of 35wt% neutral silica sol, and continue to stir evenly; then slowly add 425 grams of pseudo-boehmite, increase the stirring speed to 700 rpm and stir for 4 hours to make the solution into a uniform gel; The gel was sheared on a homogenizer at 15,000 rpm for 80 minutes, and the preparation of the gel was completed.

[0055] Aging: Take 1.4L of the above-mentioned homogeneous gel and transfer it into a 2L dynamic hydrothermal reactor, and the filling rate of the reactor is 70% (v / v). Control the temperature at 40°C, and use a vacuum pump to pump the pressure inside the reactor into a negative pressure state....

Embodiment 3

[0059] Embodiment 3 (material ratio is 28H 2 O: 1.3R: 0.08SiO 2 : 1.0P 2 o 5 :Al 2 o 3 )

[0060] Gel preparation: first mix 1795.2 grams of 32wt% tetraethylammonium hydroxide aqueous solution with 177.5 grams of distilled water in a 30°C water bath with a stirring speed of 250 rpm, then slowly add 717.1 grams of 82wt% phosphoric acid and stir evenly, then slowly add 48.1 grams of 30wt% neutral silica sol, continue to stir evenly; then slowly add 425 grams of pseudo-boehmite, increase the stirring speed to 800 rpm and stir for 2 hours, so that the solution becomes a uniform gel; then the uniform gel Shear on a homogenizer at 12,000 rpm for 90 minutes, and the gel is prepared.

[0061] Aging: Take 1L of the above-mentioned homogeneous gel and transfer it into a 2L dynamic hydrothermal reactor, and the filling rate of the reactor is 50% (v / v). Control the temperature at 50°C, and use a vacuum pump to pump the pressure inside the reactor into a negative pressure state. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com