Preparation and degradation methods of hot-melt phenolic resin and composite material thereof

A technology of phenolic resin and composite materials, which is applied in the preparation and degradation of hot-melt phenolic resin and its composite materials, in the field of hot-melt phenolic resin and its composite materials, and can solve the problems of low reaction temperature and poor heat resistance stability. Achieve the effects of excellent mechanical properties, easy control of the production process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

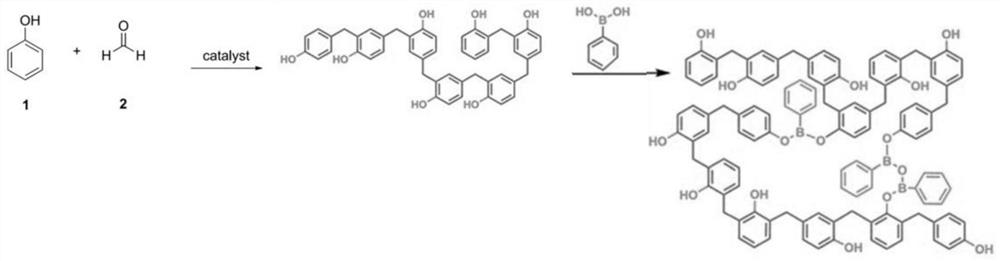

Method used

Image

Examples

Embodiment 1

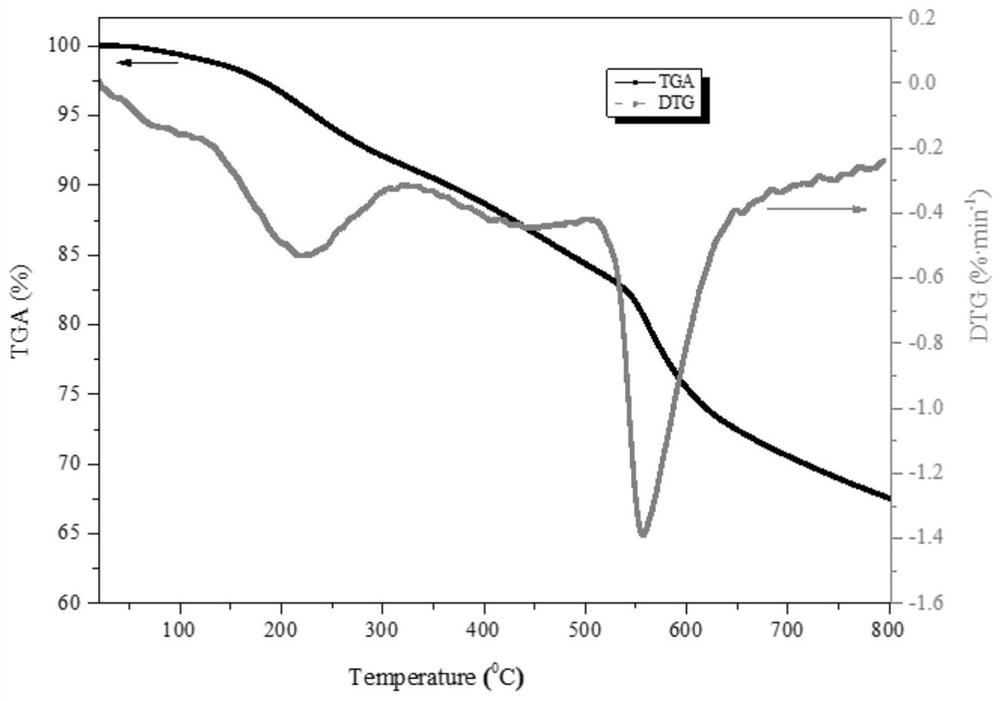

[0060] First put 95.6g of molten phenol into the flask, add 75.1g of 37wt% formaldehyde solution and 4.15g of potassium carbonate while stirring, slowly heat up to 98°C and reflux, react for 1.5 hours, cool down to 45°C, add 30.5g of phenylboronic acid g, then slowly heat up to the reaction system boiling reflux, reflux for 1 hour, start dehydration under reduced pressure, when the temperature of desolventization reaches 46 ° C, add modifier quartz sand 3g, toughening agent polyvinyl butyral 0.6g, Continue vacuuming to remove the solvent to obtain a hot-melt phenolic resin. Resin heat resistance such as figure 2 .

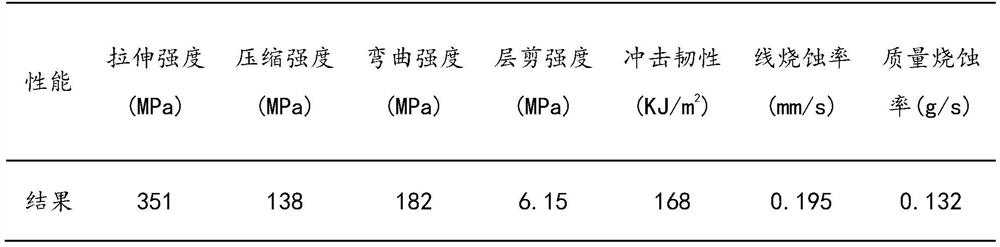

[0061] Take out the frozen hot-melt phenolic resin, place it in a blast oven at 60°C and heat it for 30 minutes to make it flow freely, pour it into the double rollers of the hot-melt prepreg machine, the film-forming temperature is 65°C, The film-forming line speed is 2 m / min, and the resin film is made. Composite the resin film and the basalt fiber cloth, the...

Embodiment 2

[0066] First put 95.6g of molten phenol into the flask, add 24.7g of paraformaldehyde and 5.3g of sodium carbonate while stirring, slowly heat up to 98°C and reflux, react for 2 hours, cool down to 56°C, add 27.2g of p-tolueneboronic acid g, then slowly warming up to the boiling reflux of the reaction system, reflux for 1 hour, and start dehydration under reduced pressure. When the temperature of desolventization reaches 48°C, add 5g of modifier aluminum hydroxide and 0.4g of toughening agent polyetherimide, Continue vacuuming to remove the solvent to obtain a hot-melt phenolic resin.

[0067] The hot-melt phenolic resin was cured at a constant temperature of 160° C. for 2 hours, and then at a constant temperature of 180° C. for 6 hours to obtain a cured product of the hot-melt phenolic resin. Immerse it in the degradation solution of ethanol and water (mass ratio: 3:1), heat at 90°C for 90 minutes, the degradation of the hot-melt phenolic resin is completed, and remove the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com