Preparation method of direct N2O catalytic decomposition catalyst

A catalytic decomposition and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of insufficient thermal stability and easy sintering of transition metal composite oxides and other problems, to achieve the effect of high mechanical strength, wide application range and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

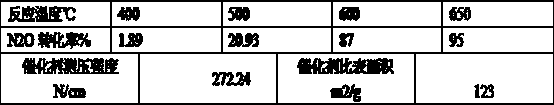

Embodiment 1

[0029] (1) Preparation of composite material carrier

[0030] Mix 500g of special pseudo-boehmite and 5g of activated carbon evenly, then knead the powder with 12g of nitric acid, 24g of acetic acid, and 350g of water to form a plastic body. The material is aged for 2 hours, and then extruded into a 3mm cylinder on the extruder. Then remove water at low temperature for 12 hours, then dry at 100°C for 24 hours, then put it into a muffle furnace for programmed temperature rise and segmental roasting, from room temperature to 200°C at a rate of 2°C / min, keep the temperature for 1 hour, and then increase the temperature at 1°C / min to 400°C, then raised the temperature to 550°C at 2°C / min, kept the temperature for 4 hours, and finally cooled naturally in the furnace to room temperature to obtain the composite material carrier S1.

[0031] (2) Preparation of the first layer of metal component solution

[0032] Weigh 17.39gZn(NO 3 )2.6H 2 O solid, 2.03gCu(NO 3 )2.3H 2 O solid, 1...

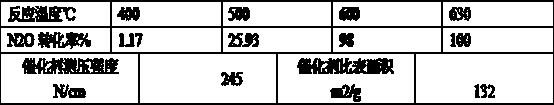

Embodiment 2

[0042] (1) Vector preparation

[0043] Mix 500g of special pseudo-boehmite and 5g of high-alumina cement powder evenly, then knead the powder with 12g of nitric acid, 24g of acetic acid, and 350g of water to form a plastic body. The material is aged for 2 hours, and then extruded into a 3mm cylinder on the extruder Then remove water at low temperature for 12 hours, then dry at 100°C for 24 hours, then put it into a muffle furnace for programmed temperature rise and segmental roasting, from room temperature at 2°C / min to 200°C, keep the temperature for 1h, and then at 1°C / min to 400°C, then to 550°C at 2°C / min, the temperature was maintained for 4h, and finally cooled to room temperature naturally in the furnace to prepare the composite material carrier S2.

[0044] (2) Impregnation and roasting of the first layer of metal component solution

[0045] Weigh 17.39gZn(NO 3 )2.6H 2 O solid, 2.03gCu(NO 3 )2.3H 2 O solid, 1.35gNi(NO 3 )2.6H 2 O solid, 4g of water, mix wel...

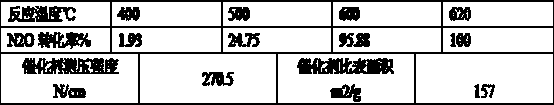

Embodiment 3

[0055] (1) Vector preparation

[0056] Mix 500g of special pseudo-boehmite and 5g of scallop powder evenly, then knead the powder with 12g of nitric acid, 24g of acetic acid, and 350g of water to form a plastic body. The mixture is aged for 2 hours, and the material is aged for 2 hours. Extrude into a 3mm cylinder, then remove water at low temperature for 12 hours, then dry at 100°C for 24 hours, then put it into a muffle furnace for programmed temperature rise and segmental roasting, from room temperature to 200°C at a rate of 2°C / min, and keep the temperature for 1h. Then the temperature was raised to 400°C at 1°C / min, and then to 550°C at 2°C / min, the temperature was maintained for 4 hours, and finally cooled to room temperature naturally in the furnace to prepare the composite material carrier S3.

[0057] (2) Impregnation and roasting of the first layer of metal component solution

[0058] Weigh 17.39gZn(NO 3 )2.6H 2 O solid, 2.03gCu(NO 3 )2.3H 2 O solid, 1.35g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com