Layered multitime pressure regulating pulp conditioning casting method

A secondary grouting and grouting technology, applied in the engineering field, can solve the problems of grout running out, enhance soil strength and density, reduce project investment, etc., and achieve highly targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Take the reinforcement of the subgrade reinforced retaining wall of a national highway Jiehe overpass as an example. The overpass is constructed with reinforced earth retaining wall technology. The width of the approach bridge at the north and south ends is 14m, the length of the north end of the approach bridge is 156m, and the length of the south end of the approach bridge is 372m. The external bulging phenomenon of the wall gradually intensified, and longitudinal cracking occurred locally on the pavement.

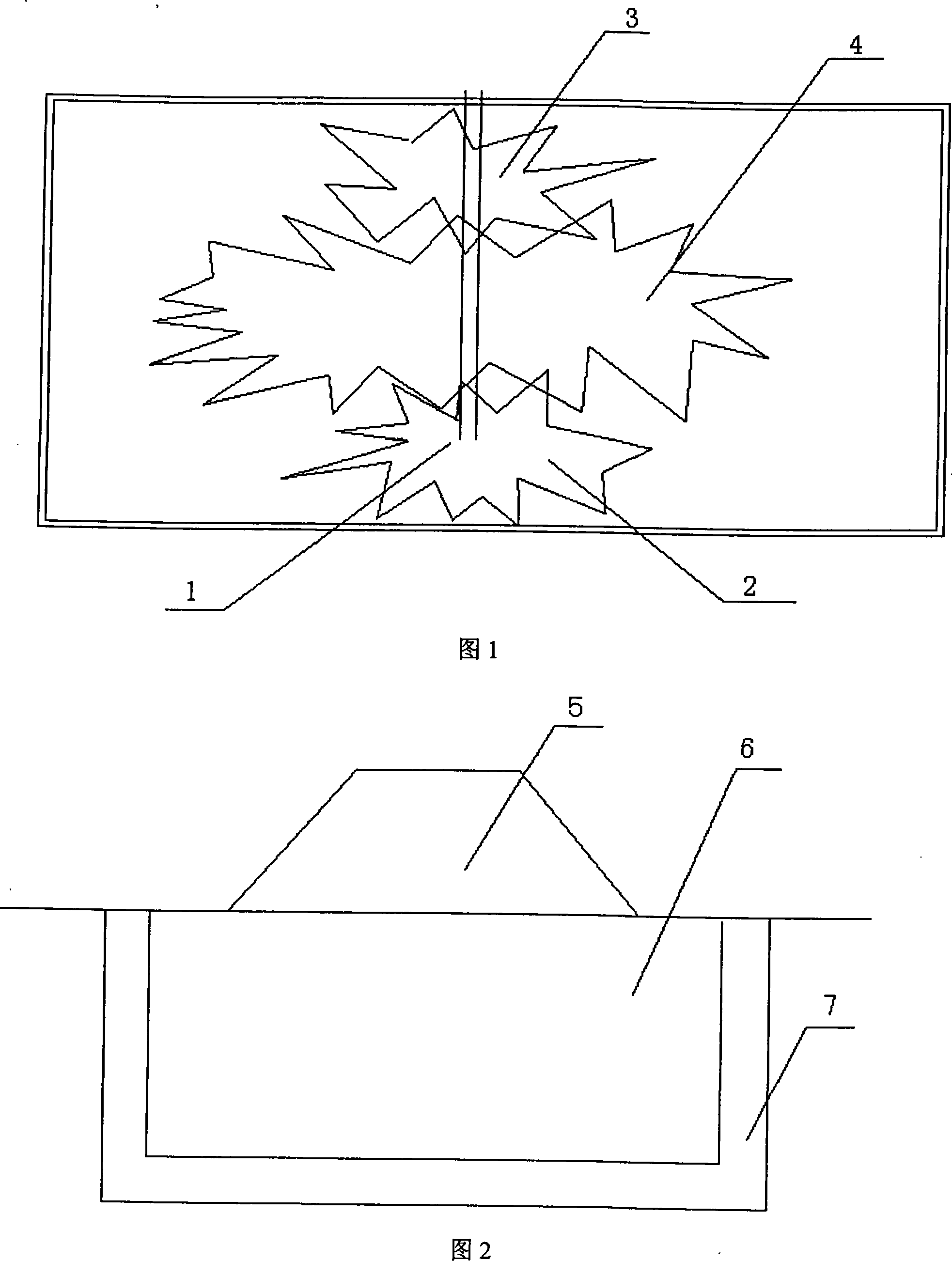

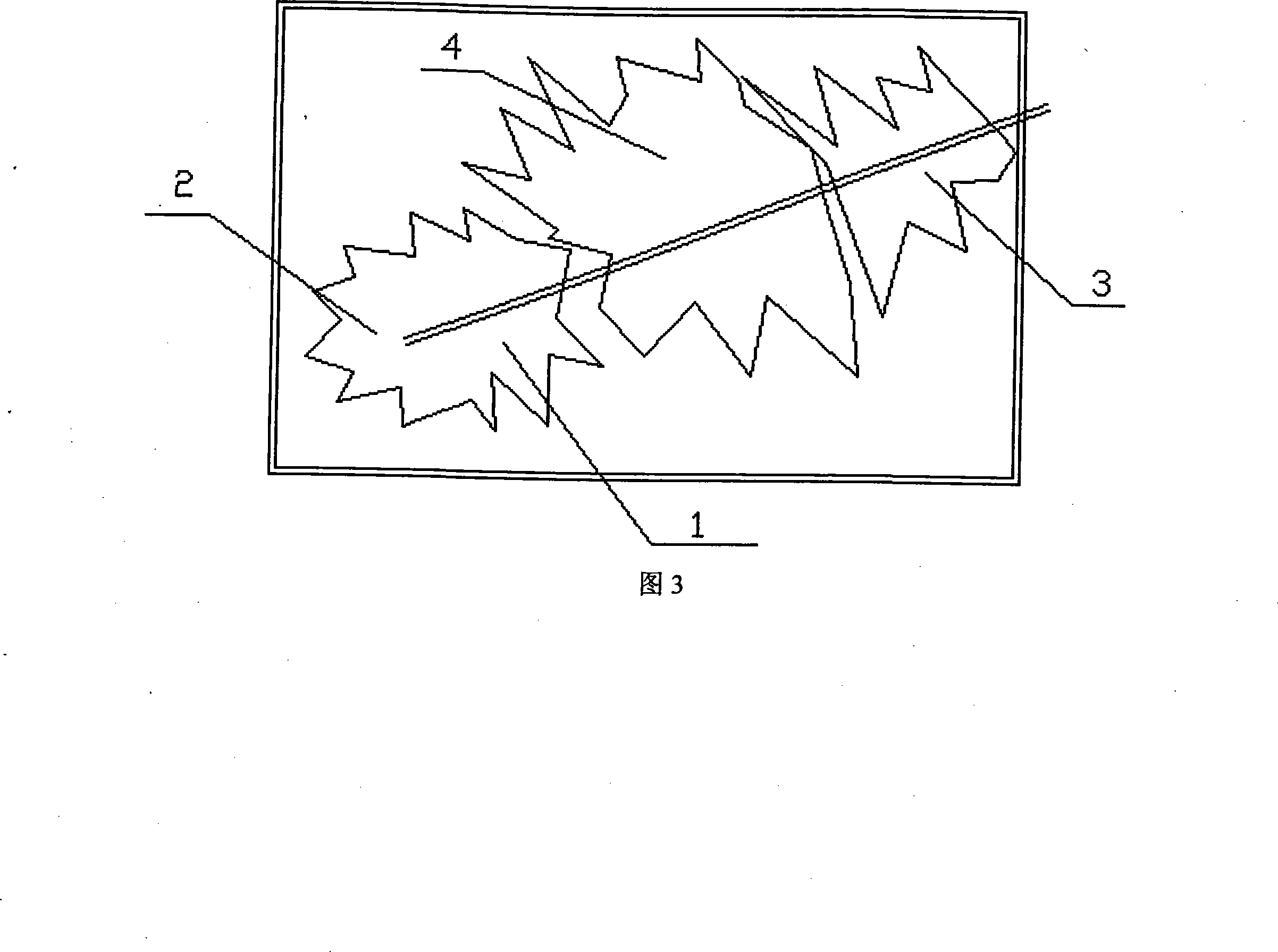

[0028] In the retaining wall filled with loam containing a large number of pebbles, the "layered multiple pressure adjustment and grouting method" was carried out. As shown in FIG. 2 , the structure 5 , the reinforcement area 6 and the pulp stop belt 7 are determined.

[0029] (1) Stake out the reinforcement area 6, and determine the position and depth of the stop belt 7;

[0030] (2) In the axial direction of the grouting hole, the distribution of the...

Embodiment 2

[0040] The same as Example 1, the difference is that the retaining wall is reinforced with prestressed bolts. Since the anchoring section is located in a loam layer containing a lot of pebbles, it cannot provide sufficient pullout resistance for the prestressed bolts. Therefore, the "layered and multiple pressure regulation and grouting grouting method" is adopted for the prestressed bolt to improve its ultimate ultimate bearing capacity.

[0041] The length of the primary grouting pipe is roughly the same as that of the bolt, and no processing is required; the length of the secondary grouting pipe is the same as that of the bolt, and the inner port is sealed. , seal the hole with tape; three times of grouting pipe, the length is 4m, the inner port is sealed, and every 0.4m within the range of 2m at the inner end, the holes are drilled and sealed with tape; four times of grouting, the grouting pipe is larger than the anchor The length of the rod is 2m short, within the range f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com