Linear motor multi-cylinder reciprocating pump with coupled gear and rack

A linear motor, rack and pinion technology, applied in the direction of pumps, piston pumps, mechanical equipment, etc., can solve the problems of high working temperature, motor failure, and high running speed of the motor mover, and achieve small fluctuations in pump pressure and displacement, and realize Large displacement, high pump pressure and reduced motor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further illustrate the present invention below in conjunction with accompanying drawing.

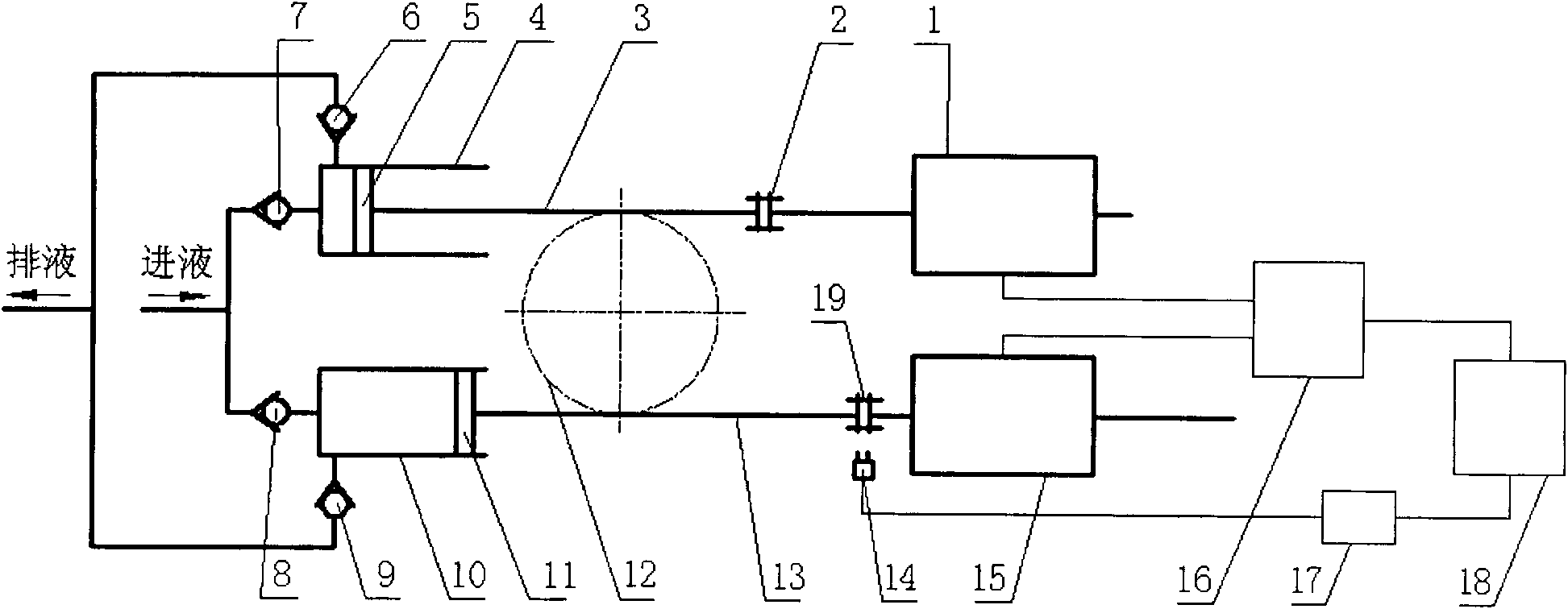

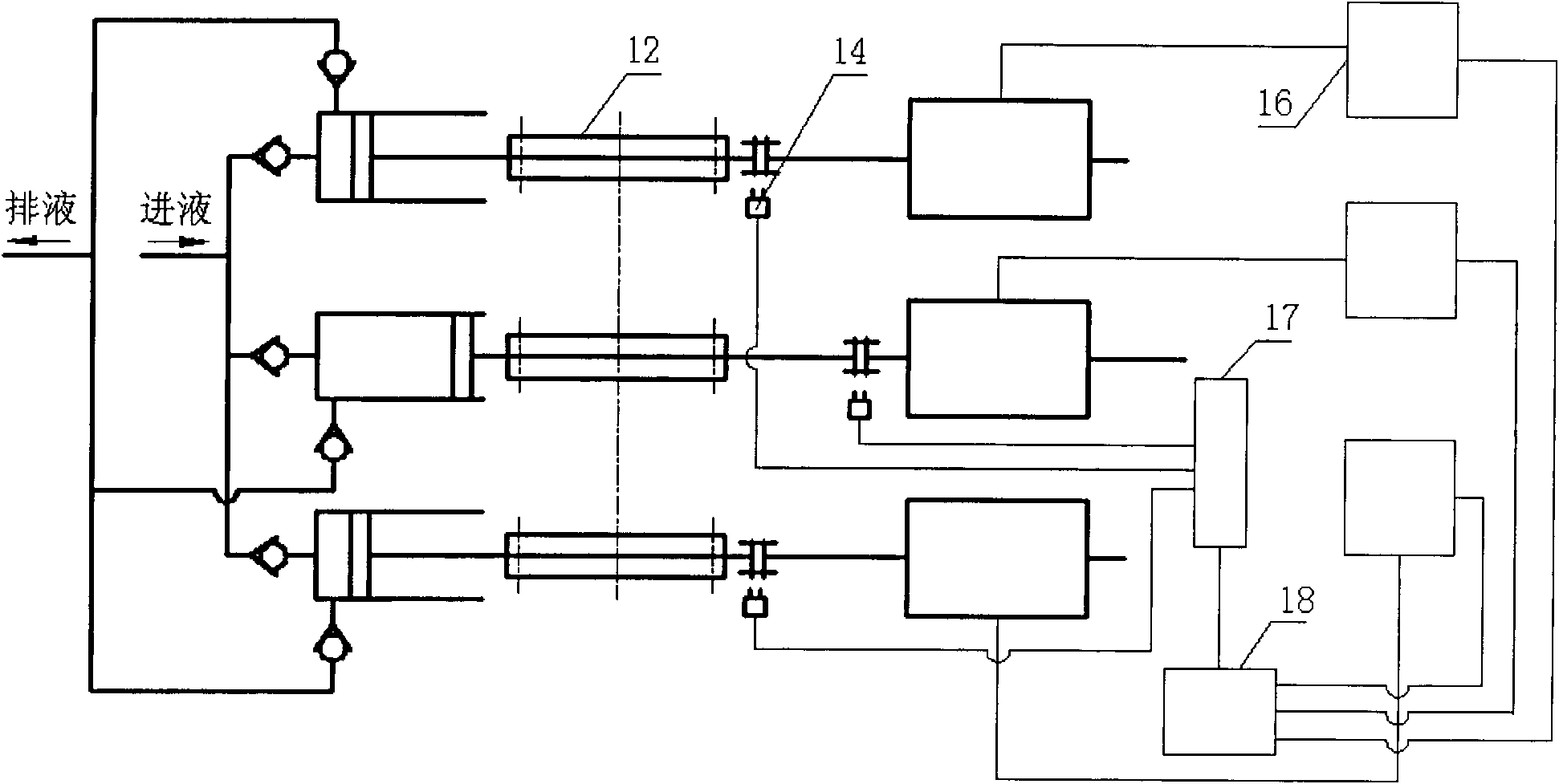

[0014] exist figure 1 , figure 2 Among them, the linear motor multi-cylinder reciprocating pump coupled with rack and pinion of the present invention mainly consists of linear motors (1, 15), shaft couplings (2, 19), piston rods (3, 13), working fluid cylinders (4, 10 ), piston (5, 11), discharge valve (6, 9), suction valve (7, 8), gear 12, driver 16, data acquisition card 17, control computer 18 and other components. Linear motors (1, 15) and piston rods (3, 13) are arranged parallel to each other; the piston rods (3, 13) are equipped with racks, and a gear 12 is used to connect the teeth on the two piston rods (3, 13). The bars are engaged at the same time, and the two piston rods are arranged with a movement phase difference of 180°.

[0015] Alternate energization scheme for two motors in a basic unit:

[0016] exist figure 1 Among them, when the linear motor 1 is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com