A submersible cutting sewage pump with high-efficiency hydraulic characteristics

A sewage pump, high-efficiency technology, applied to special fluid pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problem of motor burnout of motor stator windings, blockage of pumping medium suction, and pumping lift drop and other problems, to achieve the effect of improving suction performance, avoiding winding, and widening high-efficiency area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

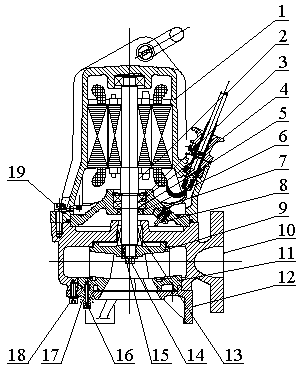

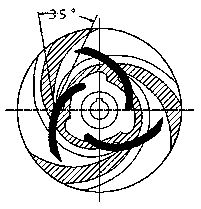

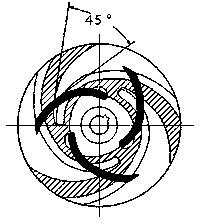

[0022] Embodiment: The structure of the submersible cutting sewage pump with high-efficiency hydraulic characteristics in this embodiment is as attached figure 1 As shown, it mainly includes a submersible motor 1, and its main feature is that the submersible motor 1 is connected to the pump body (volute 10) below it through the coupling section (lower bearing seat 7), and the pump A cooling and lubricating oil chamber is formed between the pump body (volute 10); a semi-open impeller 9 with a high-efficiency large flow channel and a rear cover is placed at the center of the lower part of the pump body (volute 10); see Figure 5 , 6 The inlet edge 903 of the semi-open impeller 9 blades with high efficiency and large flow channel adopts a 30-45° large-inclination guide design for the extension section from the rear cover plate to the front cover plate. The radial outlet center line of shell 10) is aligned at the same height; the lower end surface of the pump body (volute 10) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com