Strip deflector and roll assembly

A technology of guiding baffles and strips, which is applied in the field of rolling components, can solve problems such as dense compressed air, high noise, and poor sealing effect, and achieve the effect of cost-effective, simple geometric structure, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

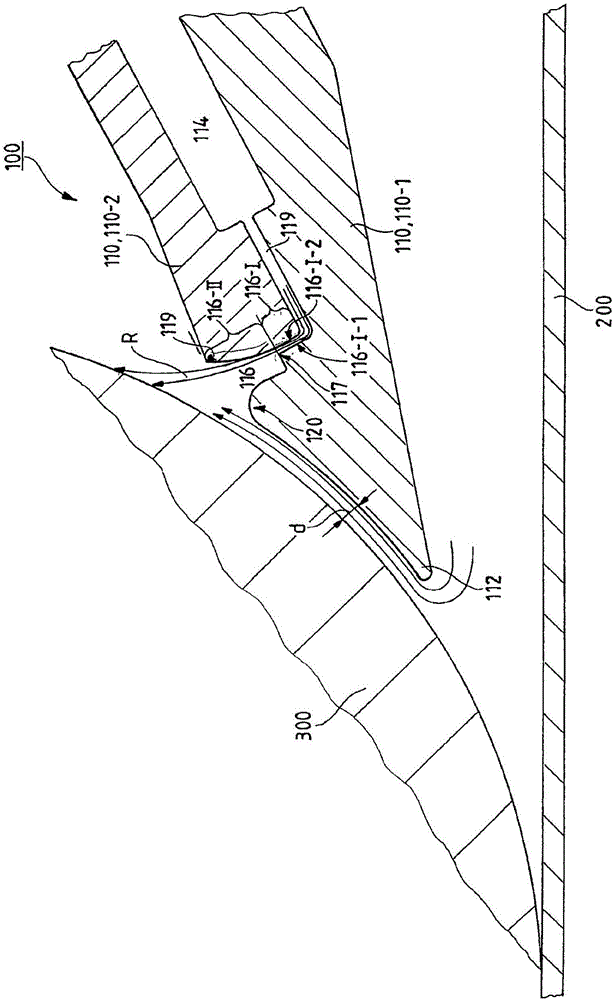

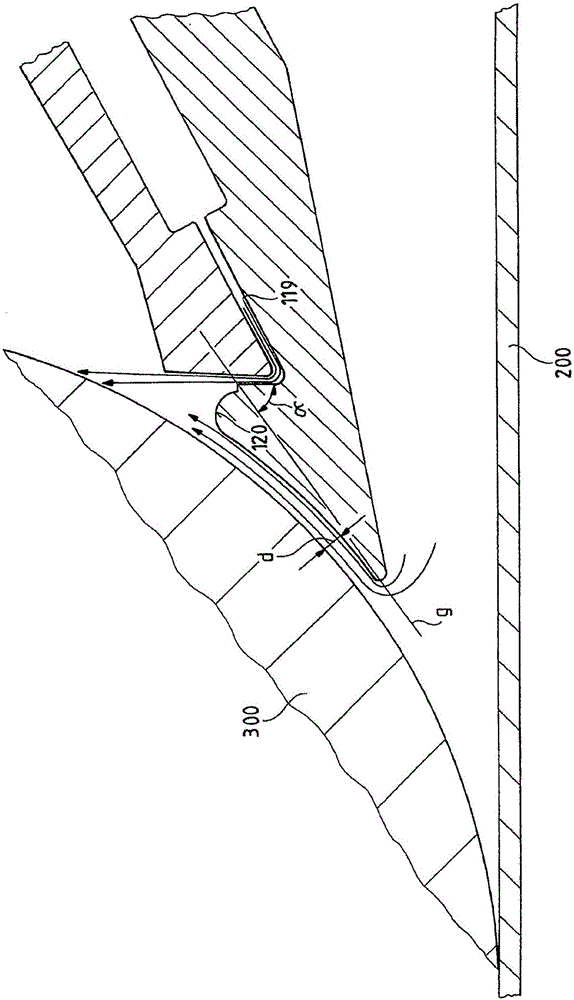

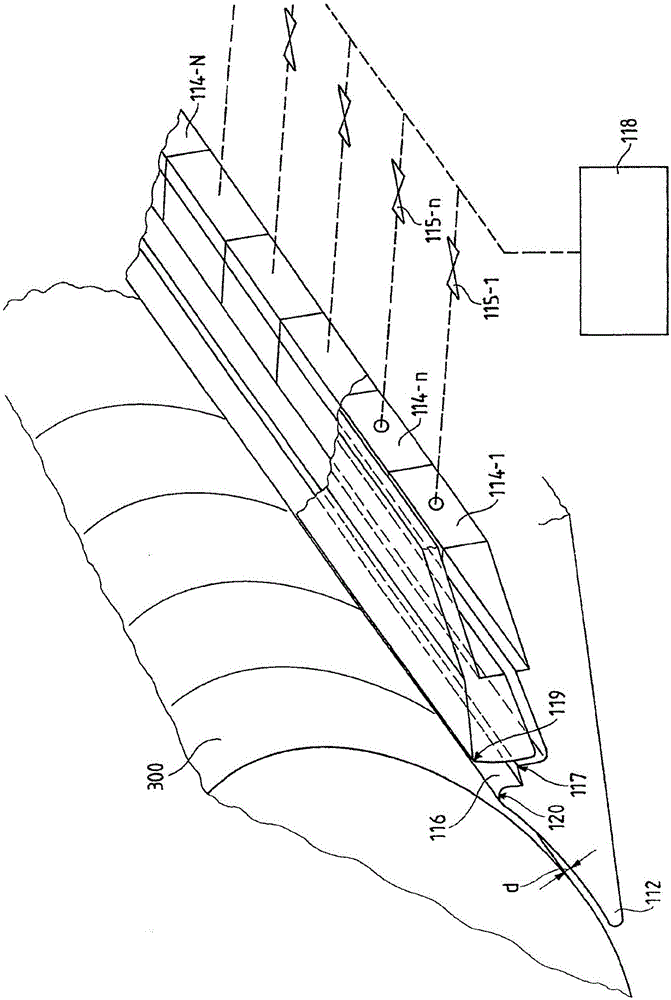

[0026] referenced below Figure 1 to Figure 3 The present invention will be described in detail in the form of examples. In all figures, the same technical elements are provided with the same reference signs.

[0027] exist figure 1 A rolling assembly according to the invention can be seen in FIG. 2 , whereby the strip guide baffle 100 according to the invention is arranged close to the barrel of a roll 300 . exist figure 1 At the lower region of , it can be seen that the metal strip 200 to be rolled or rolled is tangential to the roll barrel. The strip guide baffle 100 is arranged with its base body 110 at a distance from the rollers 300 via gaps. The gap width d is, for example, 1-9 mm.

[0028] The strip guide baffle 100 essentially comprises a base body 110 in which at least one compressed air chamber 114 and nozzles 116 connected in a flow-conducting manner to the compressed air chamber are formed in order to discharge the compressed air towards the roller body of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com