Multi-stage axial flow submerged pump with long shaft and method for conveying phosgene

An axial and long-axis technology, which is applied in the field of long-axis multi-stage axial flow submerged pumps and pressurized transport of phosgene or chlorine gas, can solve the problems of low pressure resistance, difficult maintenance, and high cavitation allowance requirements. Achieve long service life and avoid volume loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples serve to further illustrate the method of the present invention. The spirit and scope of the present invention disclosed above are not limited by these examples.

[0034] preferred embodiment

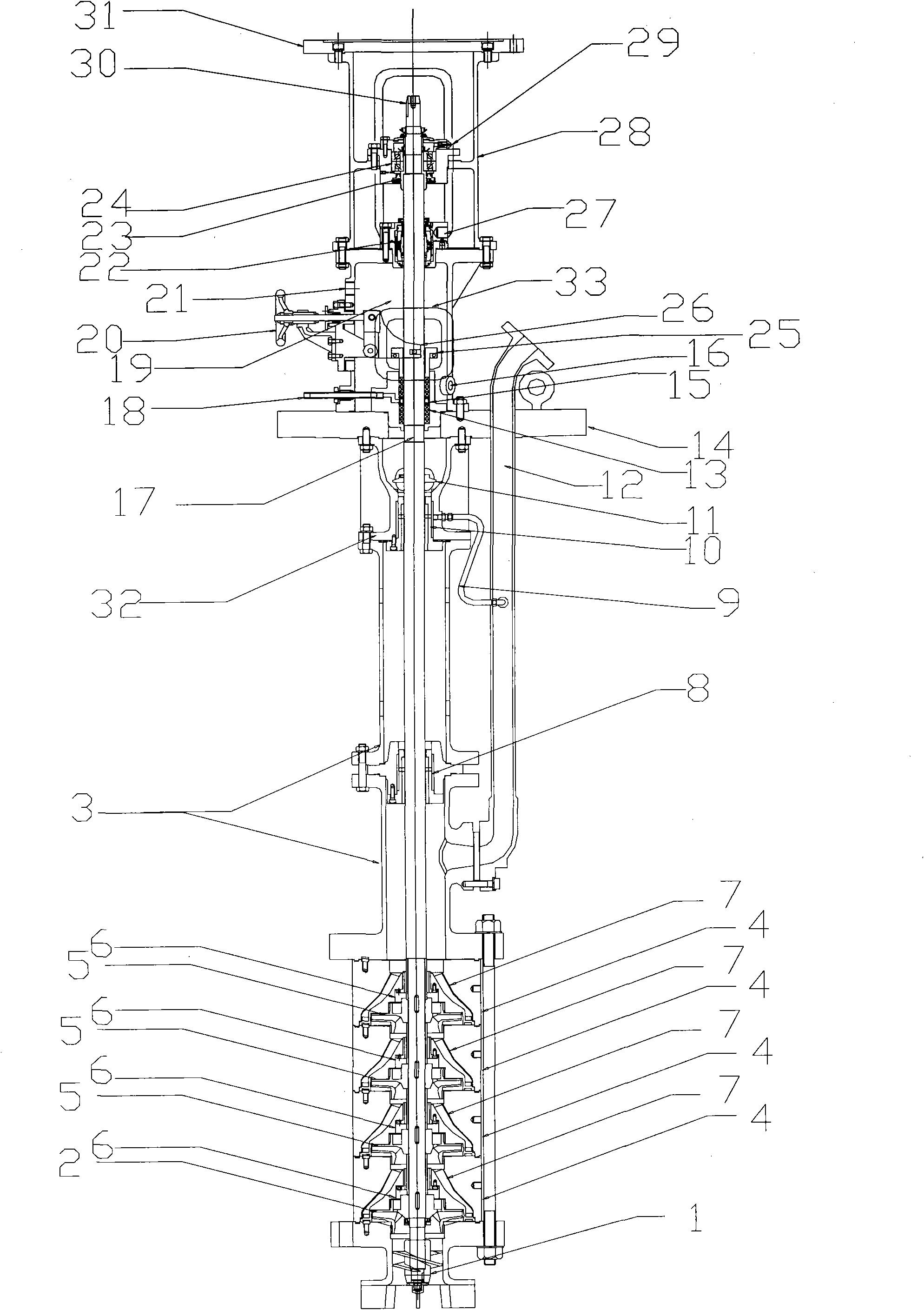

[0035] The invention is further illustrated by means of the drawings. exist figure 1 In the schematic cross-sectional view of the long-axis multi-stage axial flow submerged pump shown, the upper end of the pump body is a bearing bracket (28), which is equipped with a bearing and a shaft sleeve (24), a bearing oil seal (23), and a grease nozzle (29). . The lower end of the bearing bracket (28) is connected to the fixed sealing cavity (19), and the lower end of the sealing cavity (19) is fixed on the flange seat (14) of the pump body, and the stuffing box (13) and the rubber sealing air bag (17) are arranged on the flange seat ), wherein the nitrogen inlet pipe (18) communicates with the air seal ring (15) in the middle of the filler through the hole, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com