Patents

Literature

59results about How to "Has acid resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

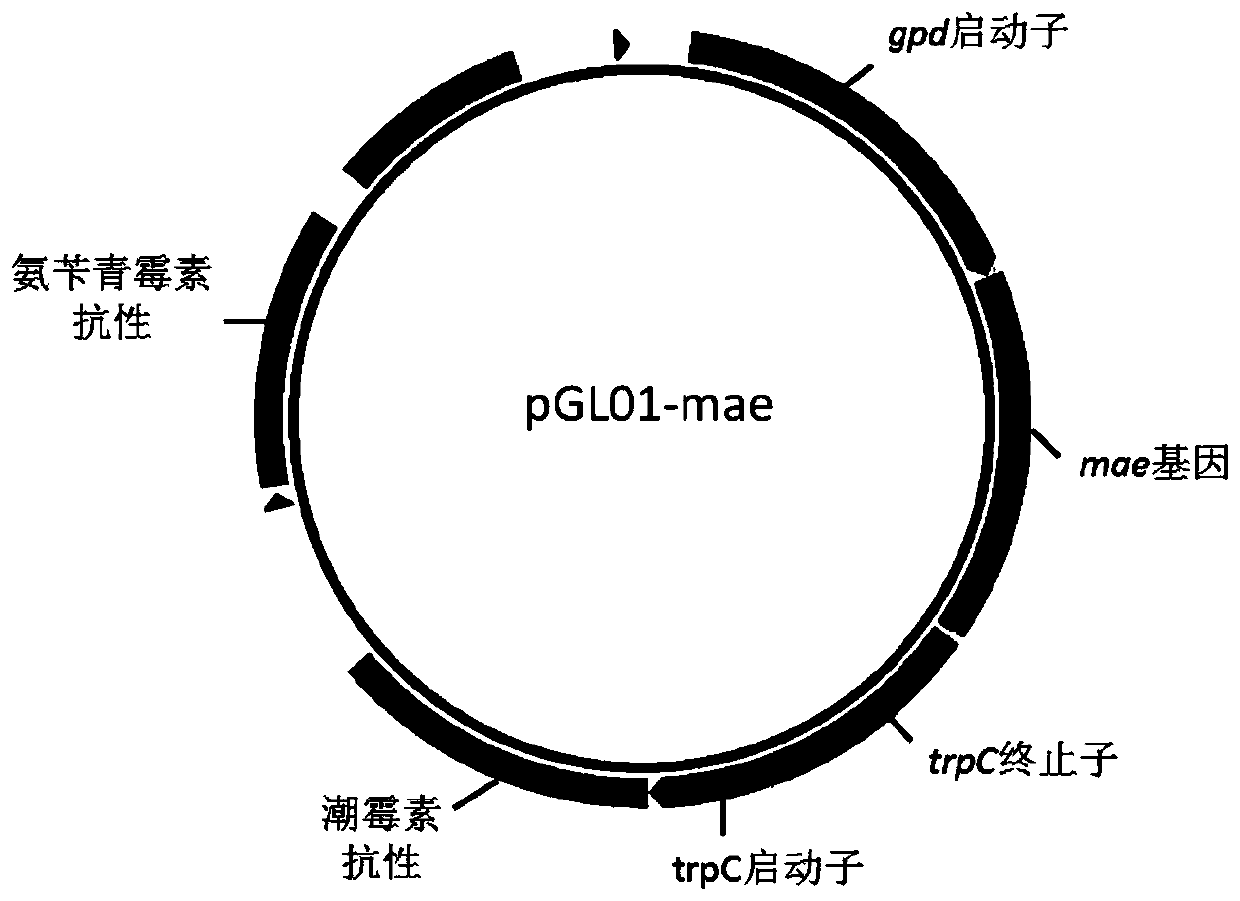

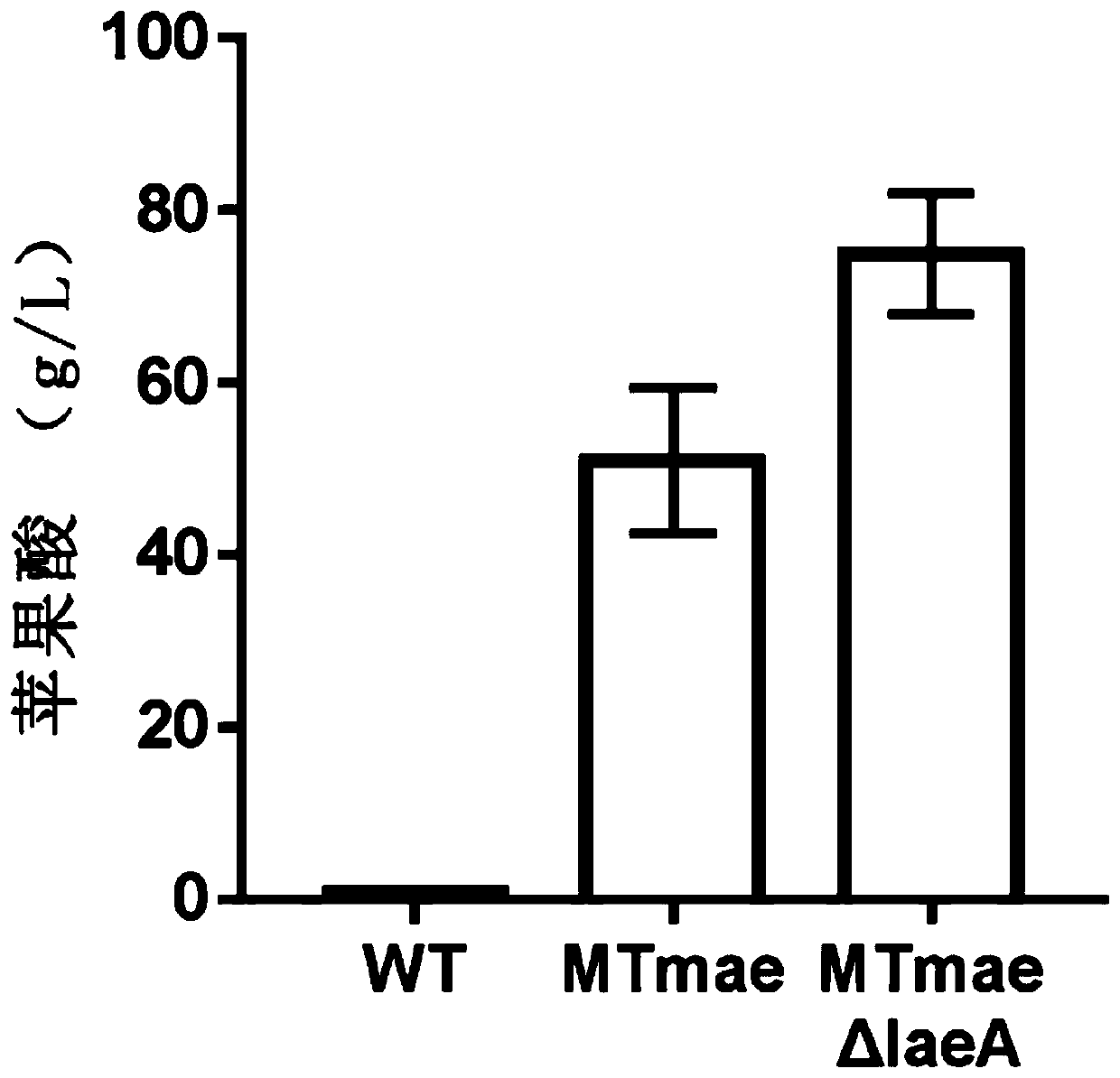

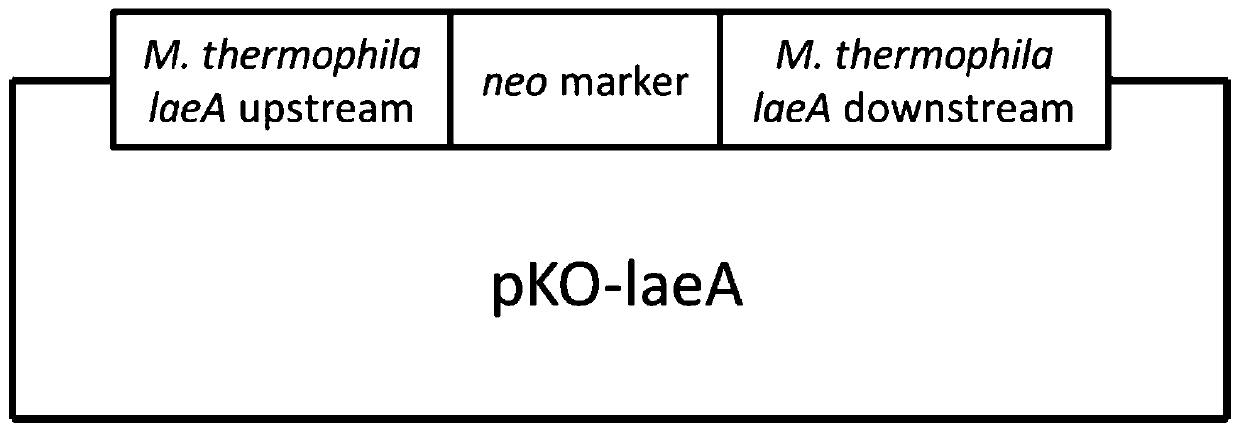

Genetically engineered bacterium producing malic acid and method for producing malic acid

ActiveCN109797111AIncrease productionHas acid resistanceFungiTransferasesBiotechnologyGenetically engineered

The invention provides a genetically engineered bacterium producing malic acid and a method for producing the malic acid. The genetically engineered bacterium is obtained by increasing the expressionor activity of diacid transporter in the recipient bacterium and decreasing the expression or activity of methyltransferase laeA in the recipient bacterium. By the arrangement, the yield of the malicacid is effectively increased, furthermore, use of a neutralizer is effectively avoided by introducing the acid-resistant engineered bacterium.

Owner:SHANGHAI DONGGENG CHEM TECH CO LTD

Feed capable of improving oxidation resistance of hen

InactiveCN106333127AImprove antioxidant capacityImprove immunityFood processingAnimal feeding stuffCalcium bicarbonateVegetable oil

The invention discloses a feed capable of improving oxidation resistance of a hen. The feed comprises the following raw materials: maize meal, soya bean meal, citrus pulp, blood meal, fish meal, seaweed meal, earthworm powder, peanut meal, rice bran, bone meal, a rape seed cake, calcium hydrogen, corn gluten meal, calcium hydrophosphate, shell powder, vegetable oil, natural zeolite, calcium bicarbonate, traditional Chinese medicine extraction powder, beta-glucan, cellulase, a premix and an amino acid mixture. The feed capable of improving the oxidation resistance of the hen contains rich protein, starch, cellulose and microelements, and can promote growth of the hen and the digestive ability and oxidation resistance of the hen.

Owner:全椒县金凤凰禽业养殖专业合作社

Preparation method for colorful polyurethane plastic and construction process for colorful polyurethane plastic track

ActiveCN104710593AHigh hardnessIncrease reaction rateWax coatingsGround pavingsAcrylic resinSports facility

The invention discloses a preparation method and a construction process for a colorful polyurethane plastic track, and belongs to the technical field of sports facilities. The preparation method for colorful polyurethane plastic comprises the following steps: uniformly stirring 10 to 15 parts of polyether polyol, 10 to 30 parts of hydroxylated acrylic resin, 10 to 30 parts of paraffin, 2 to 4 parts of a chain extender and 0.1 to 0.5 part of an age resistor, and raising temperature to 90 to 100 DEG C; adding 30 to 50 parts of a filler, 2 to 9 parts of a pigment and 0.1 to 0.5 parts of an age resistor, and performing uniform stirring; starting a colloid grinder to grind the materials into particle sizes of smaller than 400 meshes; continuing heating, and performing dehydration for 2 to 3 hours under the conditions of temperature of 90 to 100 DEG C and vacuum degree of lower than 0.095Mpa. According to the preparation method and the construction process, with the adoption of the high-functionality polyether polyol, reaction is accelerated, the hardness of a formed film is increased, and construction time is shortened; by the hydroxylated acrylic resin, high glossiness and higher weather resistance and color retention are achieved, and the service life is prolonged.

Owner:山东世纪联合新材料科技有限公司

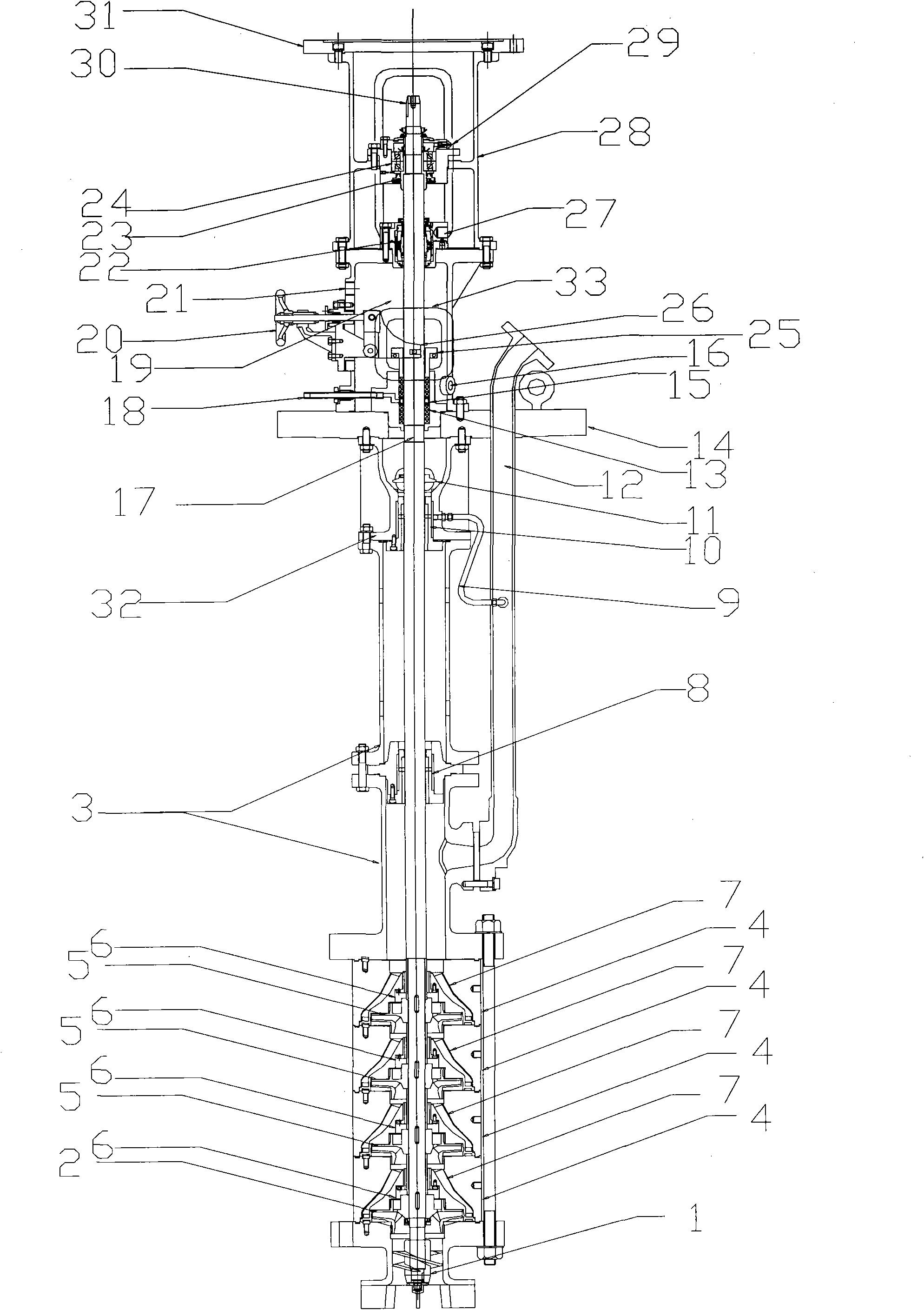

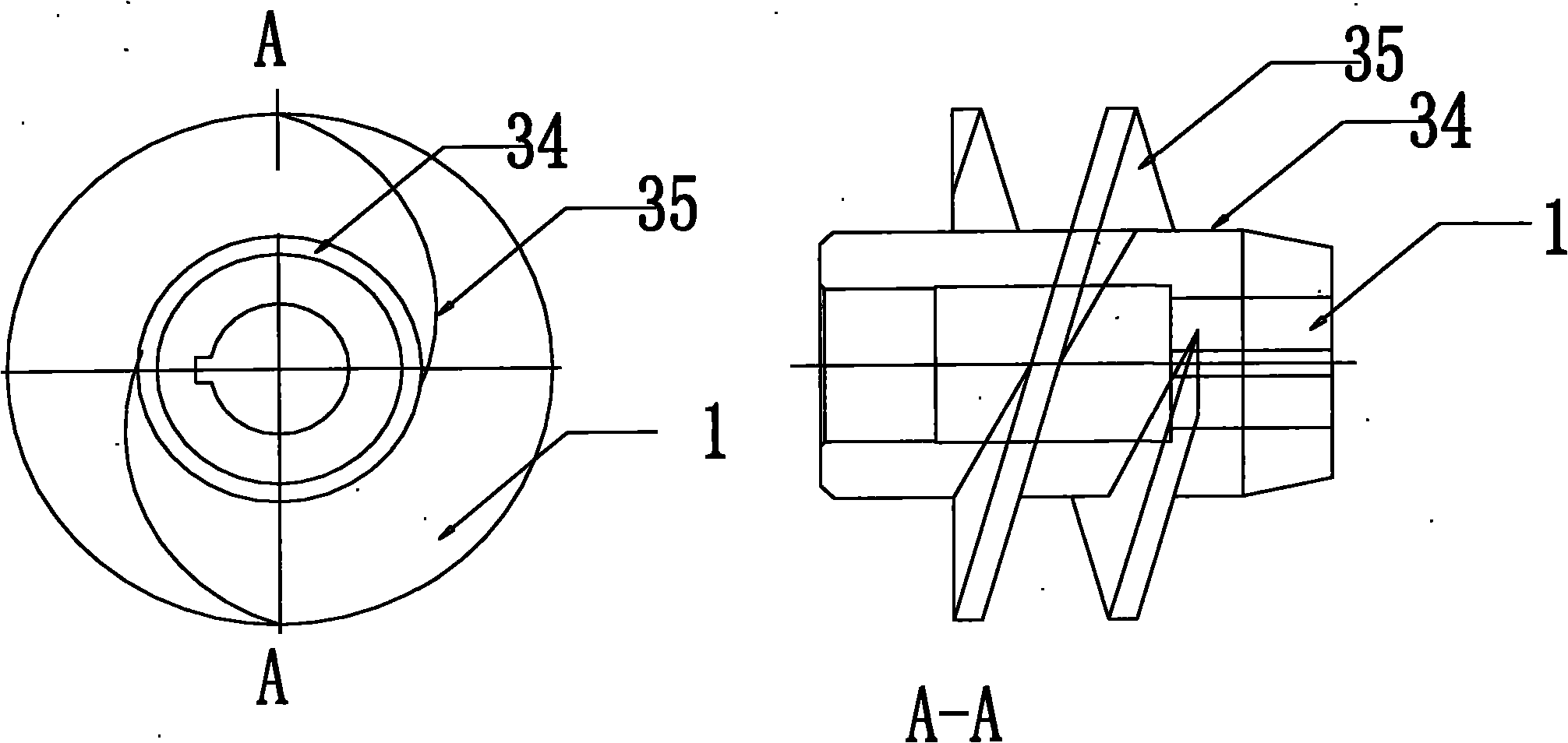

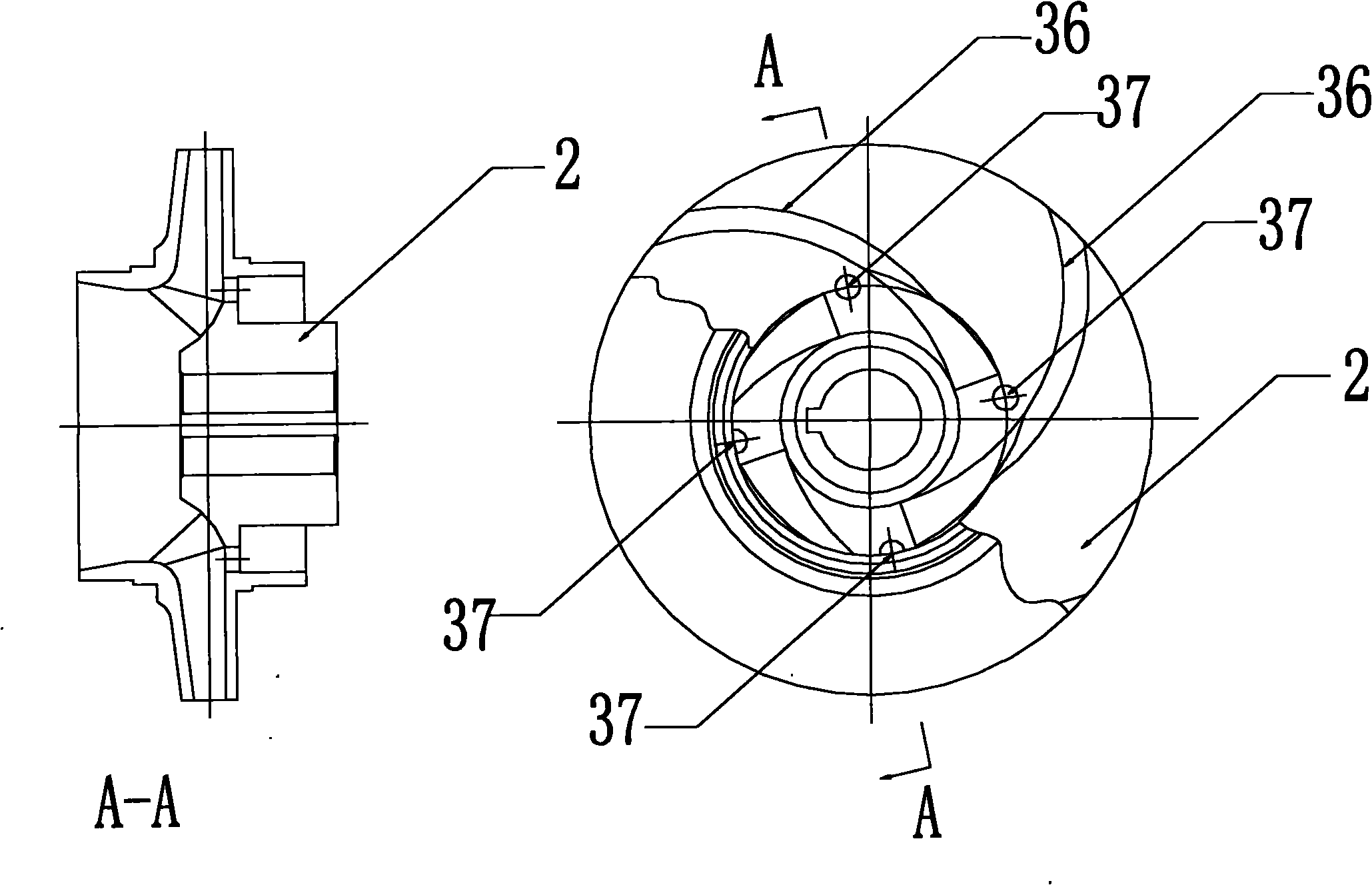

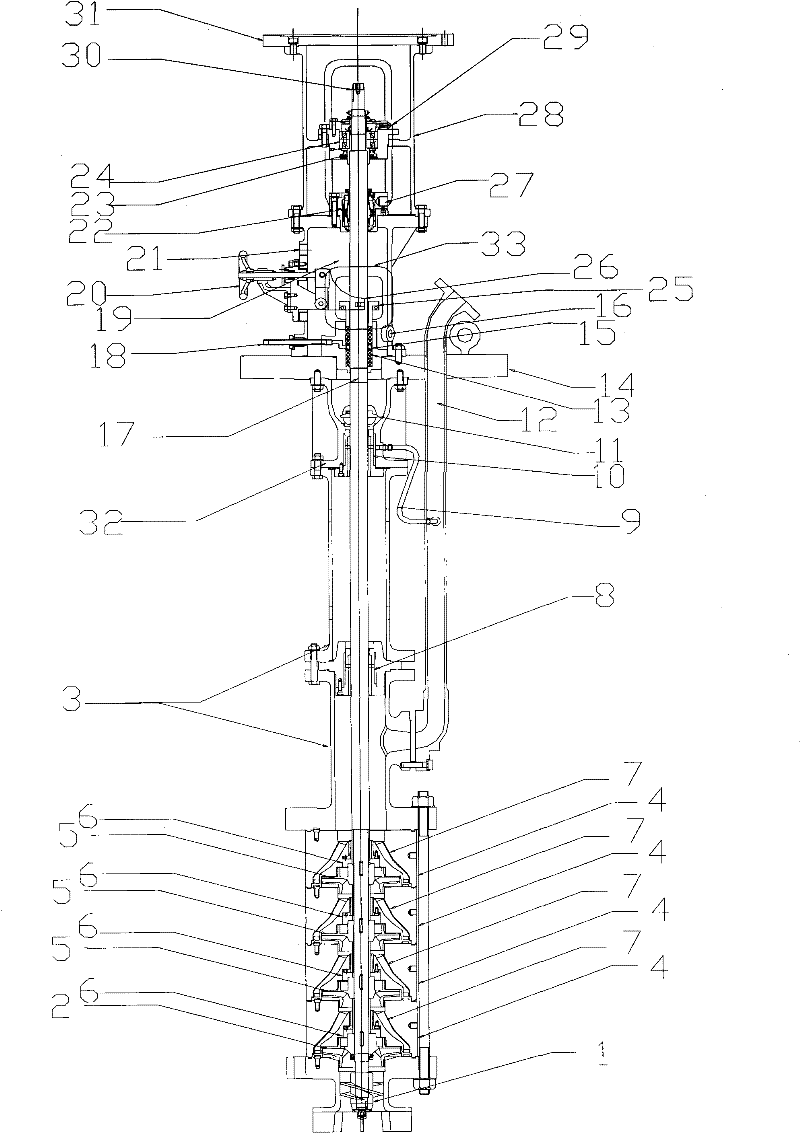

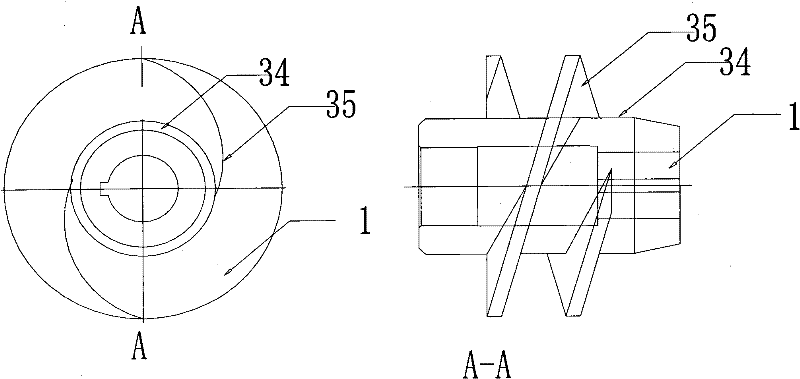

Multi-stage axial flow submerged pump with long shaft and method for conveying phosgene

InactiveCN102062107AExtended use timeExtended service lifeSpecific fluid pumpsPump componentsImpellerEngineering

The invention relates to a multi-stage axial flow submerged pump with a long shaft and a method for conveying phosgene, which are mainly used for pressurizing and conveying the phosgene or chlorine gas. The submerged pump is provided with an inducer (1), a primary impeller (2), a secondary impeller (5), an auxiliary sliding bearing and shaft sleeve (6), a lower main sliding bearing and shaft sleeve (8), an upper main sliding bearing and shaft sleeve (10), a seal cavity (19) and a bearing bracket (28). The lower end of a packing box (13) is provided with an emergency seal rubber pneumatic bag (17); a double-end face mechanical seal (22) is sleeved on a pump shaft (30); a radial balancing hole (37) is arranged on the impeller; and the auxiliary sliding bearing and shaft sleeve (6) is made from silicon carbide. When both of the mechanical seal and the packing seal become invalid, high pressure nitrogen gas ensures that the emergency seal rubber pneumatic bag (17) is inflated to clasp the shaft so as to quickly block leakage of the conveyed phosgene.

Owner:甘肃银光聚银化工有限公司 +1

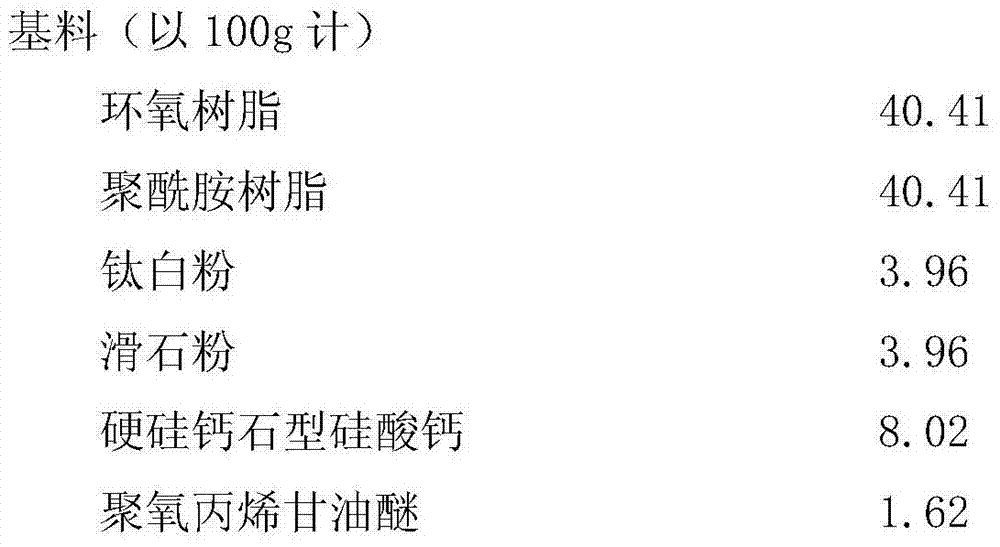

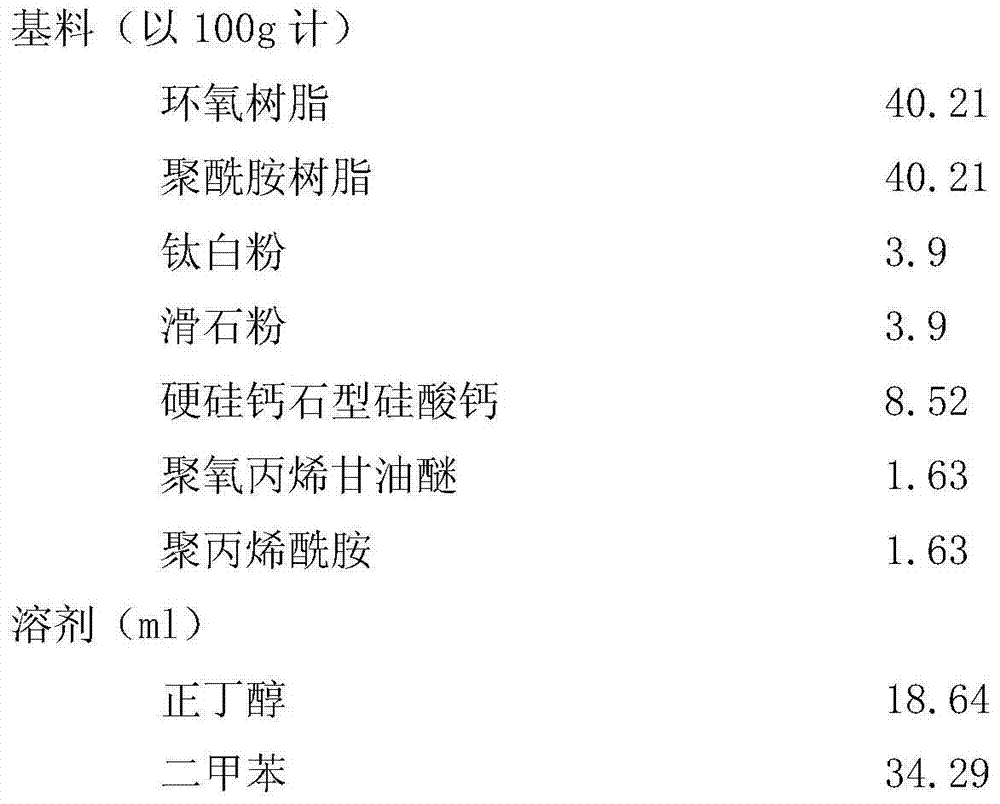

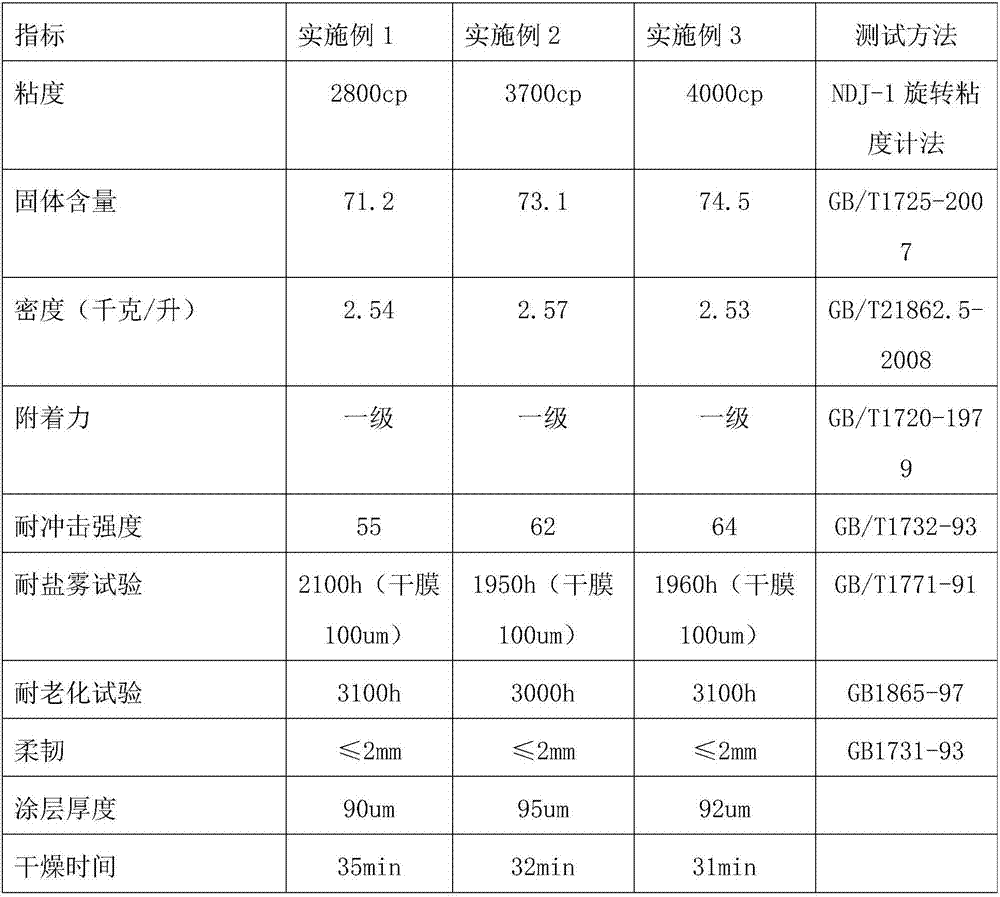

Anticorrosion heat-insulation paint and preparation method thereof

ActiveCN104774528AAddress impact resistanceSolve the strength problemAnti-corrosive paintsPolyamide coatingsCalcium silicateEpoxy

The invention discloses an anticorrosion heat-insulation paint and a preparation method thereof. The paint comprises a base material and a solvent. The base material comprises an expoxy heat-insulation paint, auxiliary pigment and filling materials, a heat-insulation filling material, an antifoaming agent and a dispersant. The expoxy heat-insulation paint is composed of the following components in parts by weight: 40.21 to 40.61 parts of epoxy resin (the membrane), 40.21 to 40.61 parts of polyamide resin (curing agent), 3.76 to 4.16 parts of titanium dioxide, 3.76 to 4.16 parts of talcum powder, 7.52 to 8.52 parts of xonotlite-type calcium silicate (heat-insulation filling material), 1.61 to 1.63 parts of polyoxypropylene glycerol ether (antifoaming agent), 1.61 to 1.63 parts of polyacrylamide (dispersant), 11.86 to 15.1 parts of n-butanol, and 26.05 to 29.49 parts of xylene. After curing, the paint forms an enclosed micro-porous and netted fiber structure on the substrate, has the characteristics of good anticorrosion performance, strong adhesive force, and high compressive strength, and thus solves the problems of bad impact-resistant performance and low adhesive force on wall of conventional barrier heat-insulation paints. Moreover, the paint is convenient for construction, can be painted or brushed, and has strong plasticity.

Owner:锌盾化工无锡有限公司

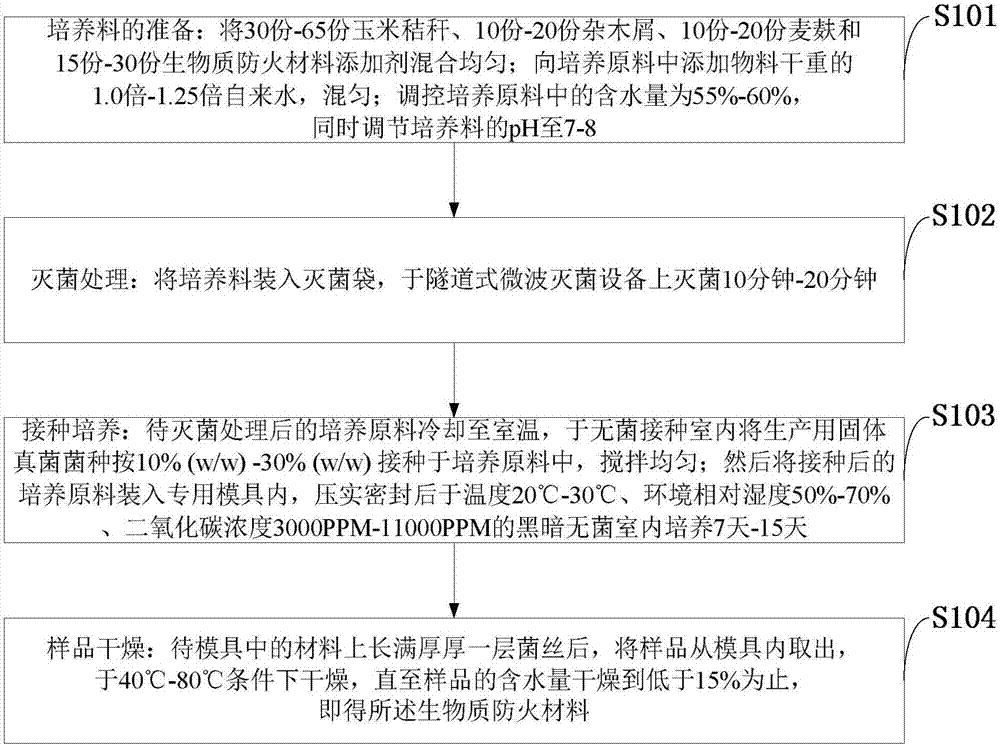

Fungi-based biomass fireproof material with cornstalk as main material and preparation method thereof

InactiveCN107118579AAnti-agingCorrosion resistantFungiMicroorganism based processesThermal insulationAdditive ingredient

The invention relates to a fungi-based biomass fireproof material with cornstalk as a main material and a preparation method thereof. The fireproof material is composed of the following ingredients (by weight): 30-65 parts of cornstalk, 10-20 parts of weed tree sawdust, 10-20 parts of wheat bran and 15-30 parts of a biomass fireproof material additive. A preparation method of the material comprises the following steps: preparation of a culture medium; sterilization treatment; and inoculated culture. By using biomass materials such as cornstalk and the like as raw materials and by the utilization of rapid growth of fungal hypha and strong kink force of mycelium, the biomass materials such as cornstalk and the like are converted into an environment-friendly biomass fireproof material. The preparation method of the biomass thermal insulation material is simple; production cost is low; and the product has good strength, good compactness and good fireproof performance. The material of the invention is an environment-friendly biomass fireproof material with market prospect and potential.

Owner:SHENZHEN ZEQINGYUAN TECH DEV SERVICE CO LTD

Universal smooth clay drawing board

ActiveCN103740201ASunfastHas acid resistanceLiquid surface applicatorsAnti-corrosive paintsEmulsionPropylene glycol

The invention discloses a universal smooth clay drawing board which is prepared through the processes: 180-220 parts of deionized water, 1.5-2.5 parts of defoaming agent, 18-22 parts of propylene glycol and 4.5-5.5 parts of dispersing agent into a reaction kettle, and uniformly stirring all the components; adding 145-155 parts of titanium dioxide, 140-160 parts of kaoline and 180-220 parts of talcum powder, dispersing for 1h, adding 340-360 parts of pure acrylic emulsion, and uniformly stirring; adding a multifunctional assistant AMP-95 to adjust the pH value to 7.0, and adding the 1.5-2.5 parts of defoaming agent, 9-11 parts of film-forming additive, 45-55 parts of thickening agent ASE-60 and 1-1.5 parts of thickening agent TT935 while stirring to obtain a coating for curtain coating; and carrying out curtain coating on a base material to obtain the universal smooth clay drawing board. A clay coating of the drawing board is sunproof, acid-resistant and corrosion-resistant so as to ensure that a work is not cracked or faded after being stored and placed for a long term; the clay coating can be thickened or thinned randomly so as to be beneficial to the perfect presentation of details of the work.

Owner:WUXI PHOENIX ARTIST MATERIALS

Low thermal conductivity wall thermal insulation coating and its preparation method

InactiveCN107163831ASolve insulation problemsAddress impact resistanceFireproof paintsAnti-corrosive paintsEpoxyThermal insulation

The invention discloses a low thermal conductivity wall thermal insulation coating and its preparation method and relates to the technical field of building materials. The low thermal conductivity wall thermal insulation coating is prepared from 75 to 85 parts of polyamide resin, 55 to 65 parts of epoxy resin, 45 to 55 parts of modified hollow ceramic beads, 35 to 40 parts of silica airgel, 30 to 33 parts of talc powder, 25 to 27 parts of glass wool, 20 to 23 parts of an inorganic additive, 15 to 20 parts of an infrared reflective pigment, 15 to 18 parts of aids and 85 to 95 parts of deionized water. The low thermal conductivity wall thermal insulation coating can form a low thermal conductivity protection layer on the wall after curing and has good corrosion resistance, cohesiveness and compressive strength.

Owner:合肥市淑芹美装饰工程有限公司

High-crack-resistance building waterproof material and preparation method thereof

InactiveCN106751696AMoisture-proof, leak-proof and seepage-proofAvoid erosionBuilding insulationsHigh resistanceEpoxy

The invention discloses a high-crack-resistance building waterproof material and a preparation method thereof. The high-crack-resistance building waterproof material is prepared from the following raw materials in parts by weight: 30-50 parts of polyether tribasic alcohol, 10-15 parts of petroleum asphalt, 5-10 parts of fluorocarbon resin, 8-15 parts of nano magnesium oxide, 12-15 parts of organic silicon modified epoxy resin, 12-18 parts of aluminum potassium sulfate dodecahydrate, 15-25 parts of hydroxyethyl cellulose, 4-9 parts of Portland cement, 10-20 parts of talcum powder, 2-10 parts of polyoxyethylene, 1-8 parts of magnesium stearate, 11-17 parts of acrylate, 2-8 parts of steel slag micropowder and 1-8 parts of trimethyl trimellitate. The high-crack-resistance building waterproof material integrates the heat-insulating property and waterproofness, has the advantages of higher compression resistance, long service life, favorable high-temperature resistance, certain elongation percentage, high crack resistance, low cost, favorable binding property, low oxidation and aging tendency, high tensile strength, favorable waterproof effect and the like, can form a waterproof layer on the object surface to effectively avoid the object oxidation, and can be used as a waterproof material for interior architecture. The high-crack-resistance building waterproof material has the advantages of simple formula, low cost and favorable properties, and is suitable for large-scale production.

Owner:芜湖浩权建筑工程有限公司

Anti-aging coating for power device and preparation method thereof

InactiveCN107189674AWear-resistantWaterproof and anti-agingFireproof paintsAntifouling/underwater paintsGas phaseMicrosphere

The invention discloses an anti-aging coating for a power device and a preparation method thereof and relates to the technical field of coatings. The anti-aging coating is prepared from 55-65 parts of polyamide resin, 55-60 parts of organic silicone modified epoxy resin, 20-25 parts of thermoplastic expansion hollow microspheres, 18-20 parts of hydrophobic gas-phase silica, 15-17 parts of nano titanium dioxide, 13-15 parts of aluminum nitride, 13-15 parts of talcum powder, 20-25 parts of additive and 55-65 parts of water. The anti-aging coating has abrasion-resisting, waterproof, anti-aging, acid and alkali resistance properties, the preparation method is simple, the power device is effectively protected, and the service life is prolonged.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

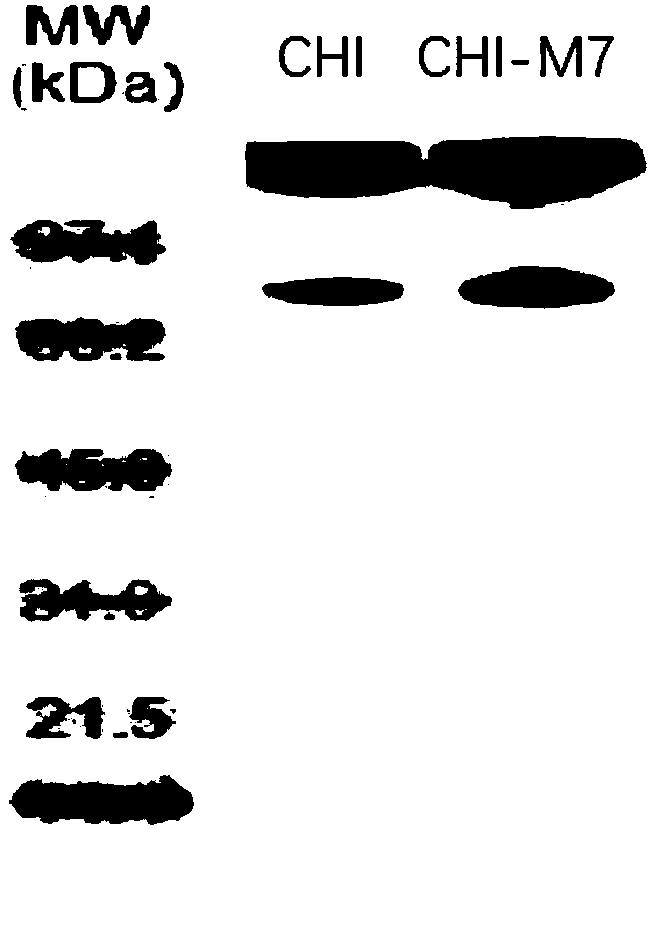

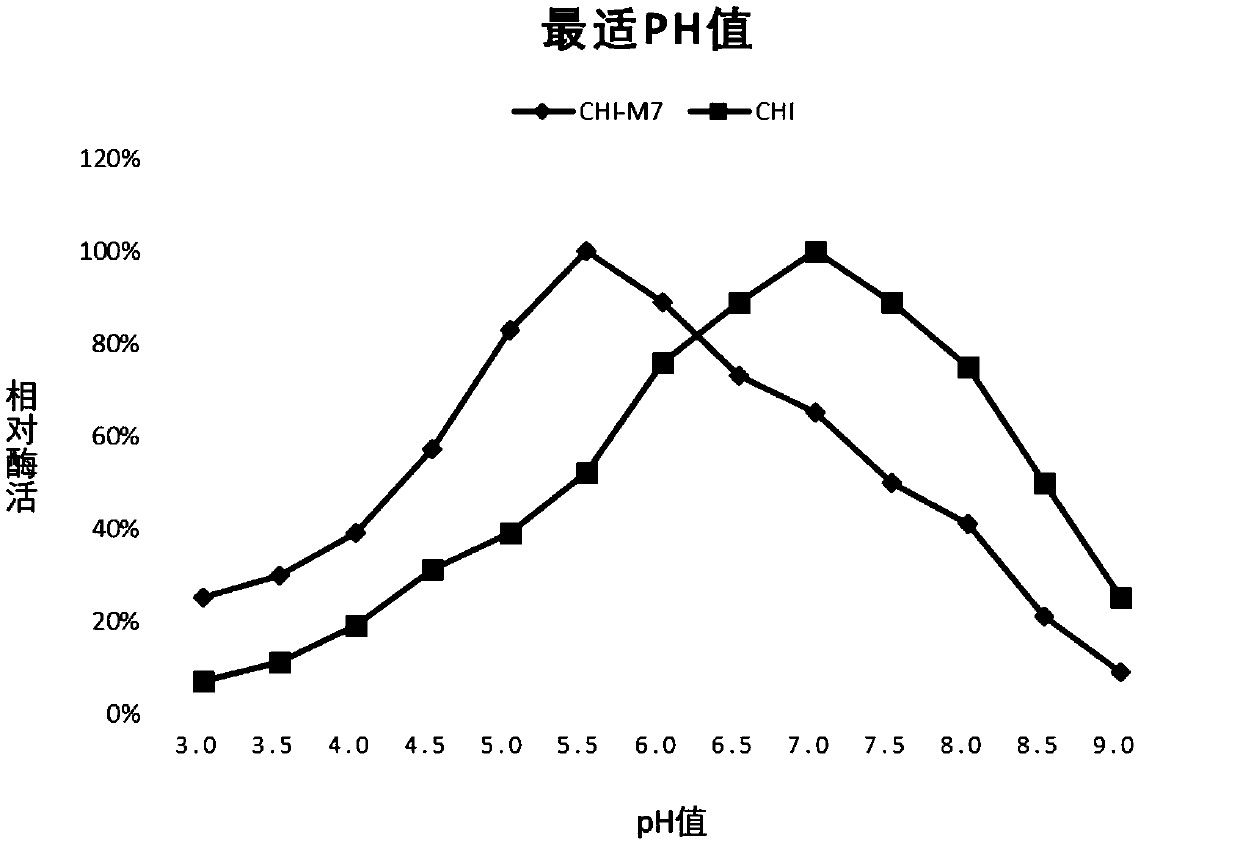

Acid-resisting mutant of low-temperature resistant chitinase and application thereof

ActiveCN109576249AAbsolute Enzyme Activity EnhancementHas acid resistanceBacteriaMicroorganism based processesMicroorganismWild type

The invention acquires a mutant with 7 amino acid locus mutations, compared with a wild type chitinase, by screening from mutants after mutation is introduced through PCR into acid-resisting chitinasescreened from marine microorganisms in the prior art. The most adaptive pH detection shows that the most adaptive pH value of the mutant is 1.5 lower than that of wild type chitinase and is more beneficial to application of enzyme in hydrolysis of chitin.

Owner:DALIAN UNIV

High-viscosity waterproof material for architecture and preparation method therefor

The invention discloses a high-viscosity waterproof material for architecture and a preparation method therefor. The high-viscosity waterproof material contains the following raw materials in parts by weight: 20-35 parts of acrylic resin, 8-12 parts of rosin resin, 3-7 parts of redispersible latex powder, 15-20 parts of talcum powder, 8-12 parts of silicate and 3-5 parts of antioxidant. The high-viscosity waterproof material has the advantages of low cost, good viscosity, difficulty in oxidating and aging, high tensile strength, long service life, good waterproof effect and the like and can serve as a good waterproof material for interior architecture.

Owner:唐秀克

Heat-insulated composite waterproof material for buildings and preparation method thereof

InactiveCN106752183AImprove waterproof functionGood waterproof effectFireproof paintsOrganosiliconMagnesium

The invention discloses a heat-insulated composite waterproof material for buildings and a preparation method thereof. The heat-insulated composite waterproof material is prepared from the following materials in parts by weight: 30-50 parts of polyether-tribasic alcohol, 10-15 parts of petroleum resin, 5-10 parts of fluorocarbon resin, 8-15 parts of nanometer magnesium oxide, 12-15 parts of organosilicon-modified epoxy resin, 12-18 parts of aluminum potassium sulfate dodecahydrate, 15-25 parts of synthetic rubber, 4-9 parts of wood fiber, 10-20 parts of talcum powder, 2-10 parts of polyvinyl alcohol, 1-8 parts of methyl silicone oil, 11-17 parts of acrylic ester, 2-8 parts of wood flour and 1-8 parts of trimethyl trimellitate. According to the heat-insulated composite waterproof material and the preparation method disclosed by the invention, the heat-insulated property and the waterproof property are integrated, the compression strength is stronger, the service life is long, the high-temperature resistance is excellent, certain elongation is achieved, the cracking resistance is strong, a waterproof layer is formed on the surface of an object, the oxidation of the object can be effectively avoided, the cost is low, the bonding property is good, the oxidation and the ageing are not easy, the tensile strength is high and the waterproof effect is good and the like; the heat-insulated composite waterproof material can be used as a waterproof material for indoor buildings, adopts a simple formula, is low in cost and excellent in property and is suitable for large-scale production.

Owner:芜湖浩权建筑工程有限公司

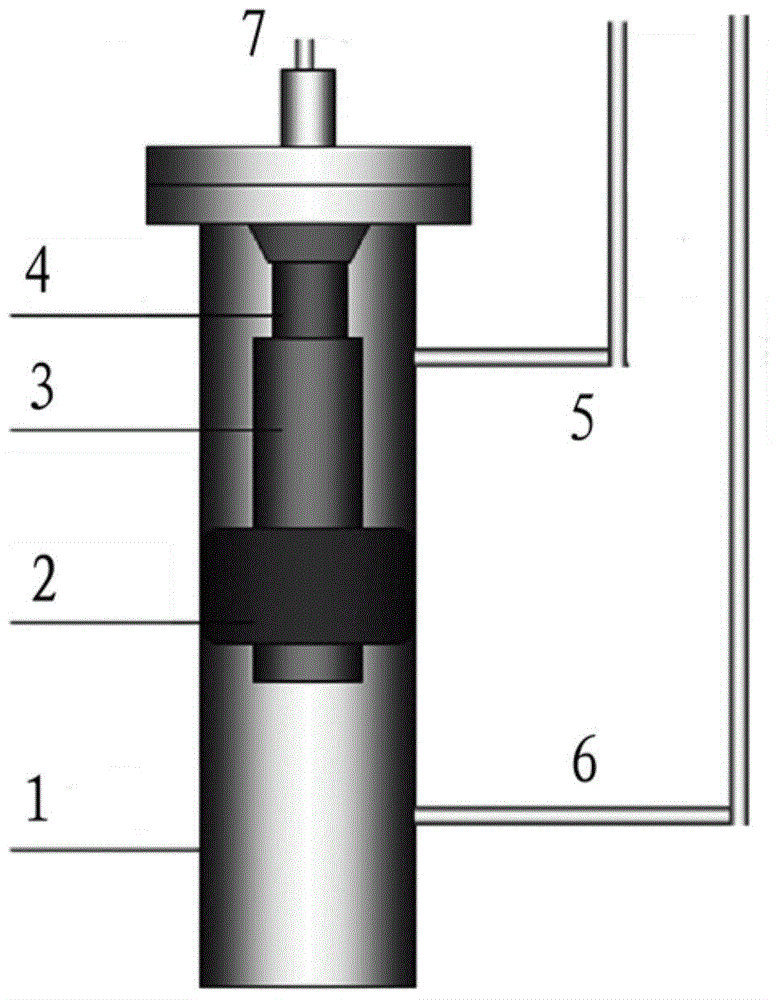

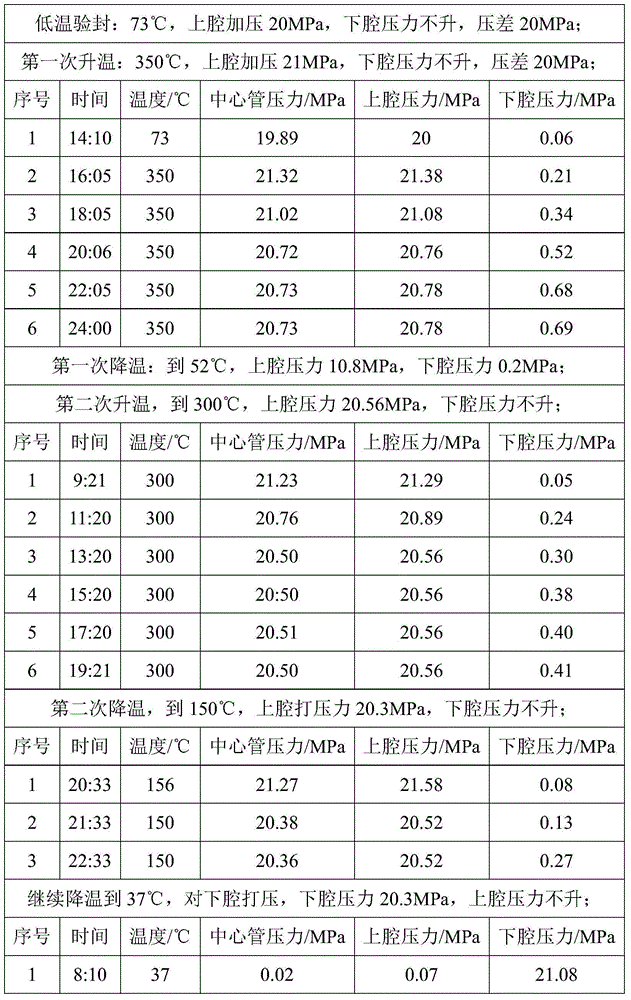

Multi-round high-and-low temperature thermal recovery packer rubber sleeve and production method thereof

The invention discloses a multi-round high-and-low temperature thermal recovery packer rubber sleeve and a production method thereof. The rubber sleeve comprises a flexible graphite rubber sleeve body, and a modified polytetrafluoroethylene outer sleeve is sleeved on the outside of the flexible graphite rubber sleeve body. The rubber sleeve overall has good mobility and compactness, high-and-low temperature seal can be achieved, and cracks can be prevented. The adaptation temperature is in a range of minus 20 DEG C to 360 DEG C, and the seal performance within the temperature range reach more than 20 MPa; the rubber sleeve can meet requirements for sealing of the packer in the high-temperature steam injection and cooling oil recovery work conditions when being used on a down-hole packer for pacing oil-casing circular space, and the rubber sleeve can still bear high-pressure seal effectively under the high temperature and low temperature multi-time alternative changes; the high-pressure-bearing seal performance reliability can be maintained in the high and low temperatures after multi-round steam huff and puff, and the rubber sleeve is particularly applicable to processes of oil field steam huff and puff, steam driving and the like in heavy-oil thermal recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inorganic fire-prevention rust-prevention coating for steel structures and preparation method thereof

InactiveCN103205143AImprove high temperature resistanceHigh temperature resistance solutionFireproof paintsAlkali metal silicate coatingsMetasilicateGranularity

The invention discloses an inorganic fire-prevention rust-prevention coating for steel structures and a preparation method thereof. The coating is a mixture of powder and colloid. The weight ratio of power to colloid is 1:(0.8-1.2). The colloid is potassium metasilicate. The powder is prepared from the following components in percentage by weight: 5-40% of magnesium mountain powder, 5-40% of talcum powder, 4-35% of silica powder and 4-25% of silicon aluminium powder. The granularity of the magnesium mountain powder is 2500-6500 meshes, the granularity of the talcum powder is 2000-6000 meshes, the granularity of the silica powder is 3000-8000 meshes, and the granularity of the silicon aluminium powder is 600-2000 meshes. According to the preparation method of the inorganic fire-prevention rust-prevention coating for steel structures, provided by the invention, the powder and the colloid are mixed uniformly. The inorganic fire-prevention rust-prevention coating for steel structures has good high-temperature-resistant performance and good rust-prevention effect.

Owner:王建文

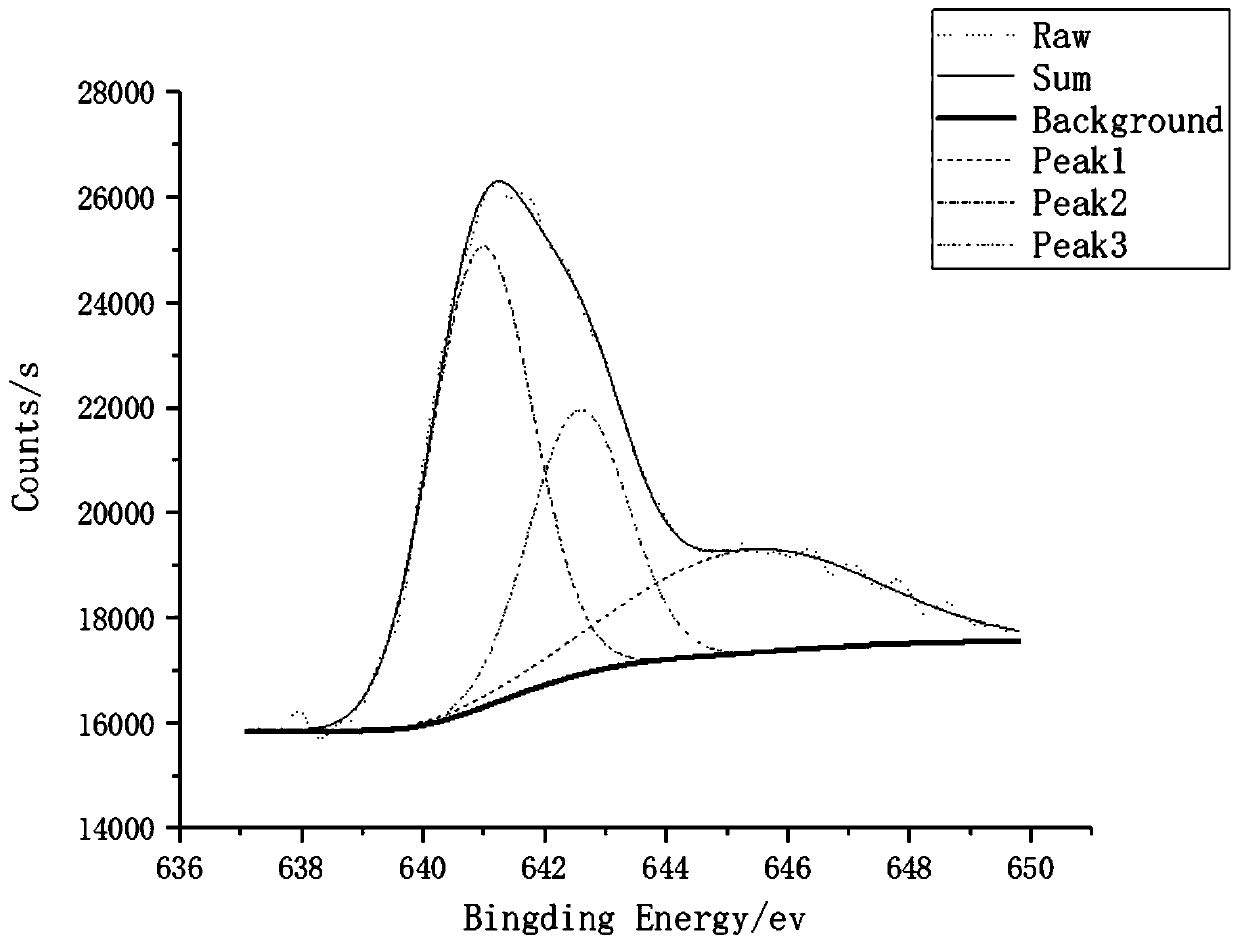

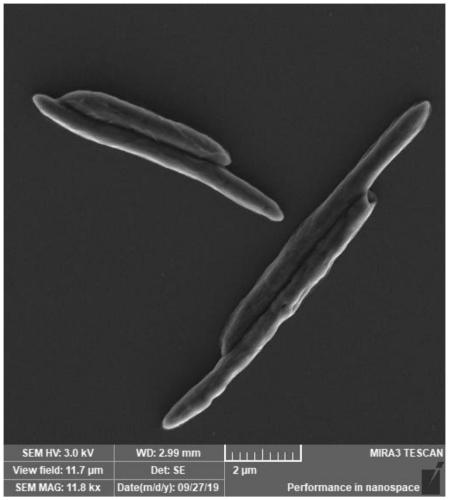

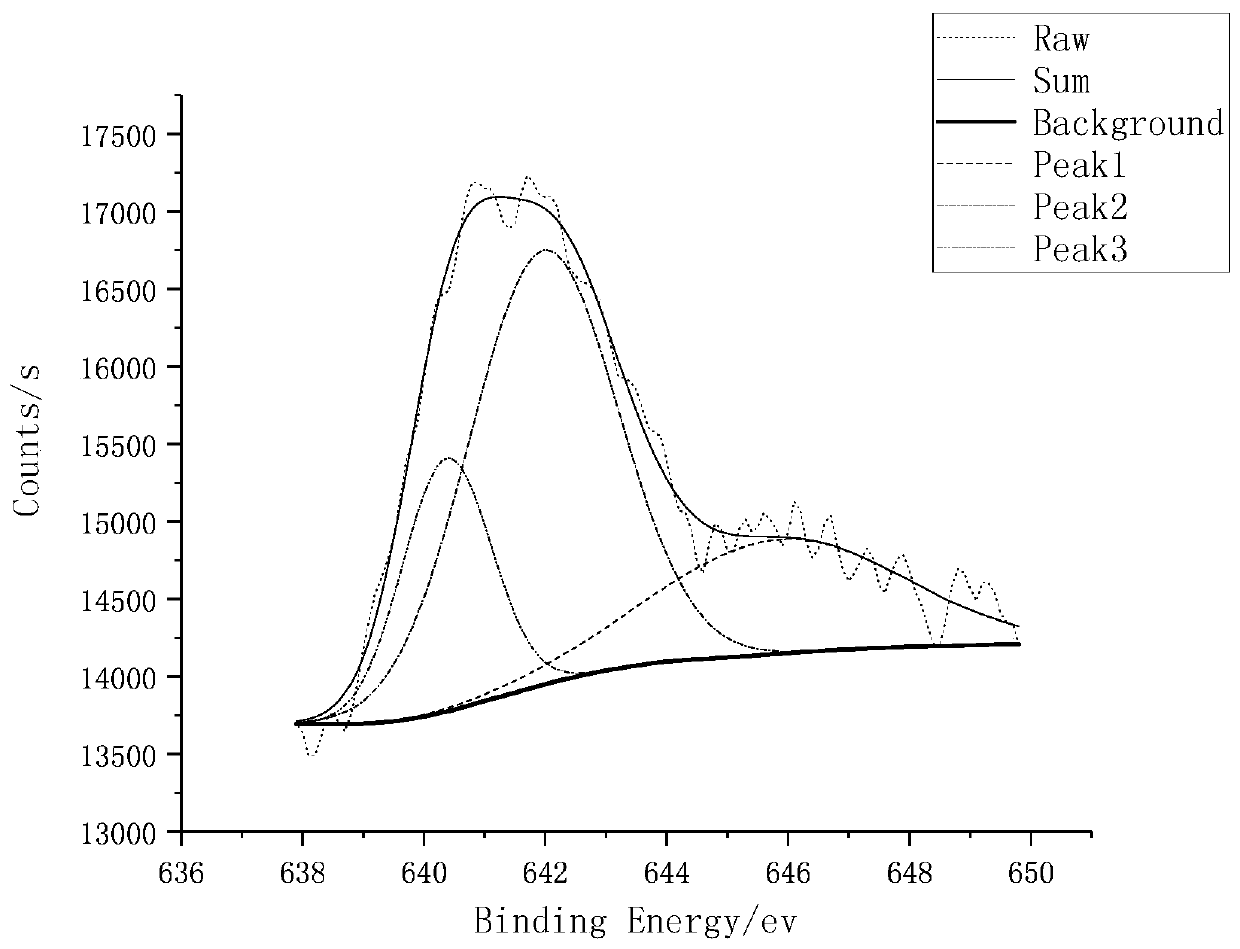

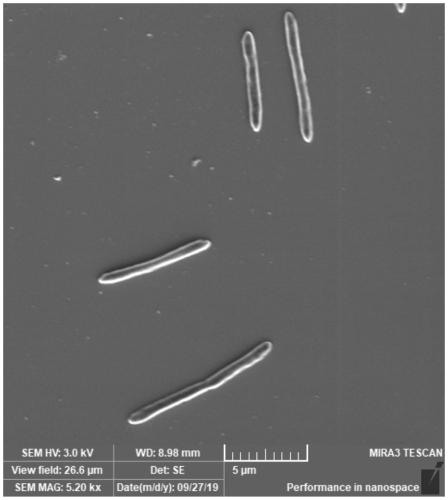

Acid-resistant and facultative anaerobic manganese oxidizing bacteria and application thereof

ActiveCN111378596AHigh manganese oxidation capacityEfficient removalWaste water treatment from quariesBacteriaMicroorganismIndustrial waste water

The invention discloses acid-resistant and facultative anaerobic manganese oxidizing bacteria and an application thereof. The bacteria are brevibacillus brevis, which is classified and named as Brevibacillus brevis MM2, has been collected in the Guangdong Microbial Culture Collection Center, has the collection number of GDMCC NO:60819 and is collected in October 23, 2019. The Brevibacillus brevisMM2 is acid-resistant, facultative anaerobic and stronger in environment adaptability, can be used for removing heavy metals in acidic mine wastewater or acidic industrial wastewater, can adapt to wastewater in different dissolved oxygen conditions, and is also suitable for a biological in-situ remediation technology in an oxygen-deficient environment.

Owner:HEFEI UNIV OF TECH

Manganese oxidizing bacteria capable of being used for high-efficiency demanganization and application of manganese oxidizing bacteria

ActiveCN111378597AHigh manganese oxidation capacityEfficient removalBacteriaWater contaminantsBiotechnologyMicroorganism

The invention discloses manganese oxidizing bacteria capable of being used for high-efficiency demanganization and an application of the manganese oxidizing bacteria. The bacteria are bacillus, the classification name is Brevibacillus sp.MM1, the Brevibacillus sp.MM1 is preserved in Guangdong Microbial Culture Collection Center, the preservation number is GDMCC NO:60818, and the preservation dateis October 23, 2019. The Brevibacillus sp.MM1 provided by the invention has higher manganese oxidizing ability, and can efficiently remove Mn<2+> in a water body or solid substrate under acidic and neutral conditions, can remove multiple heavy metals such as iron, copper, zinc, chromium, cadmium and arsenic, and has broad application prospects.

Owner:HEFEI UNIV OF TECH

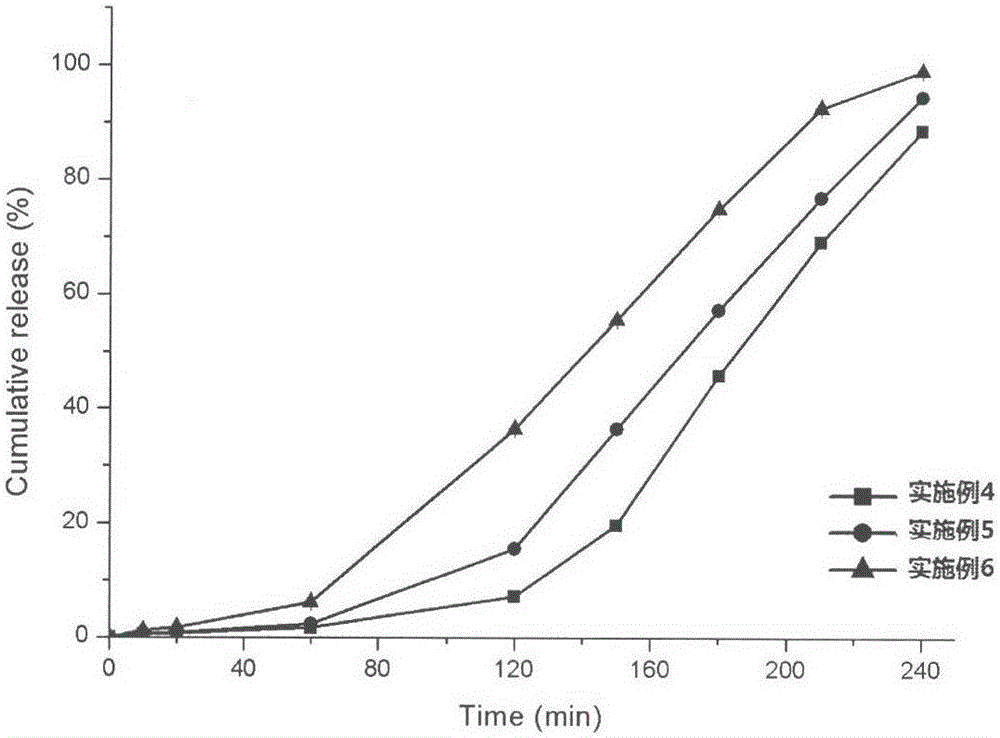

Enteric plant soft capsule and preparation method thereof

InactiveCN109602718AControl decompositionDissolution inhibitionPharmaceutical non-active ingredientsCapsule deliveryPullulanDecomposition

The present invention relates to an enteric plant soft capsule and a preparation method thereof. The enteric plant soft capsule comprises a capsule shell, the capsule shell comprises an inner capsuleshell and an outer capsule shell, the inner capsule shell and the outer capsule shell are in a gap arrangement, the gap is provided with a plurality of support bodies for maintaining the gap; the outer capsule shell comprises the following raw materials in parts by weight: 50-70 parts of sesbania gum, 10-15 parts of hydroxypropyl cellulose, 15-20 parts of konjac gum and 1-5 parts of an acid mediator; and the inner capsule shell comprises the following raw materials in parts by weight: 50-70 parts of sesbania gum, 10-15 parts of hydroxypropyl cellulose, 5-8 parts of pullulan, 3-6 parts of starch and 15-20 parts of konjac gum. The preparation method can well control decomposition of the outer capsule shell in gastric juice, prevents a filler in the inner capsule shell from being decomposed due to dissolving out, and at the same time reduces dissolving-out of content caused by capsule shell damages, and the capsule has greater softness.

Owner:JIANGSU ZODIAC MARINE BIOTECH

Universal clay drawing board with wrinkled surface

InactiveCN104861811ASunfastHas acid resistanceLiquid surface applicatorsAnti-corrosive paintsCorrosion resistantContrast ratio

The invention discloses a universal clay drawing board with a wrinkled surface. A poplar board or a birch board is taken as a base material. A preparation process of the drawing board comprises steps as follows: (1) producing a prime coating; (2) producing an interlayer coating; (3) producing a surface coating; sequentially coating the coatings onto one surface of the base material by a shower-coating machine through showering to produce the universal clay drawing board with the wrinkled surface. The drawing board is applicable to coloring by various pigments and has the characteristics that the drawing board is sun-proof, acid-resistant and corrosion-resistant, an art work can be stored and placed for a long time without cracking and fading, the surface of the drawing board can be thickened or thinned at will, and perfect presentation of details such as the contrast, the quality, the texture, the tone and the like of the work is facilitated.

Owner:WUXI PHOENIX ARTIST MATERIALS

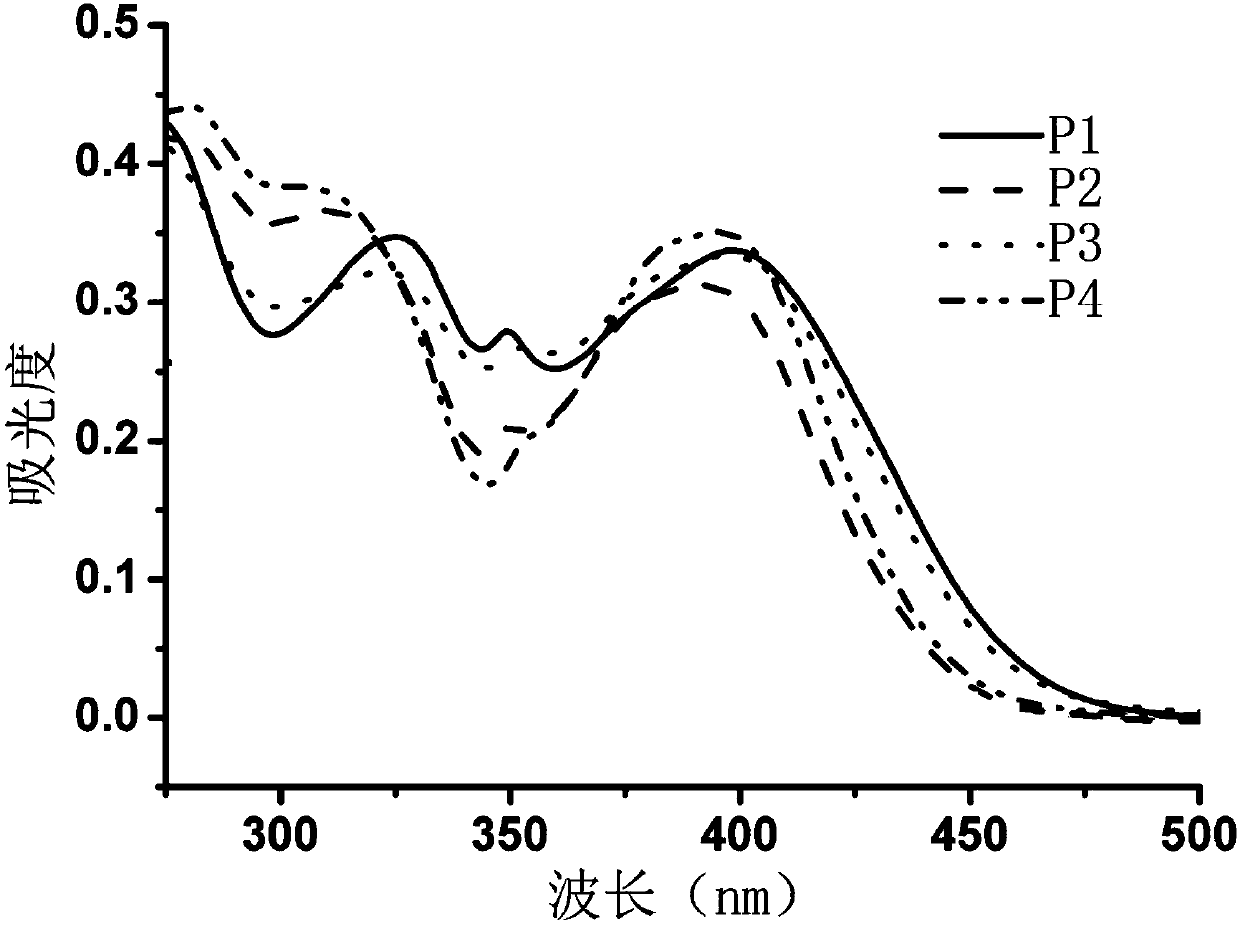

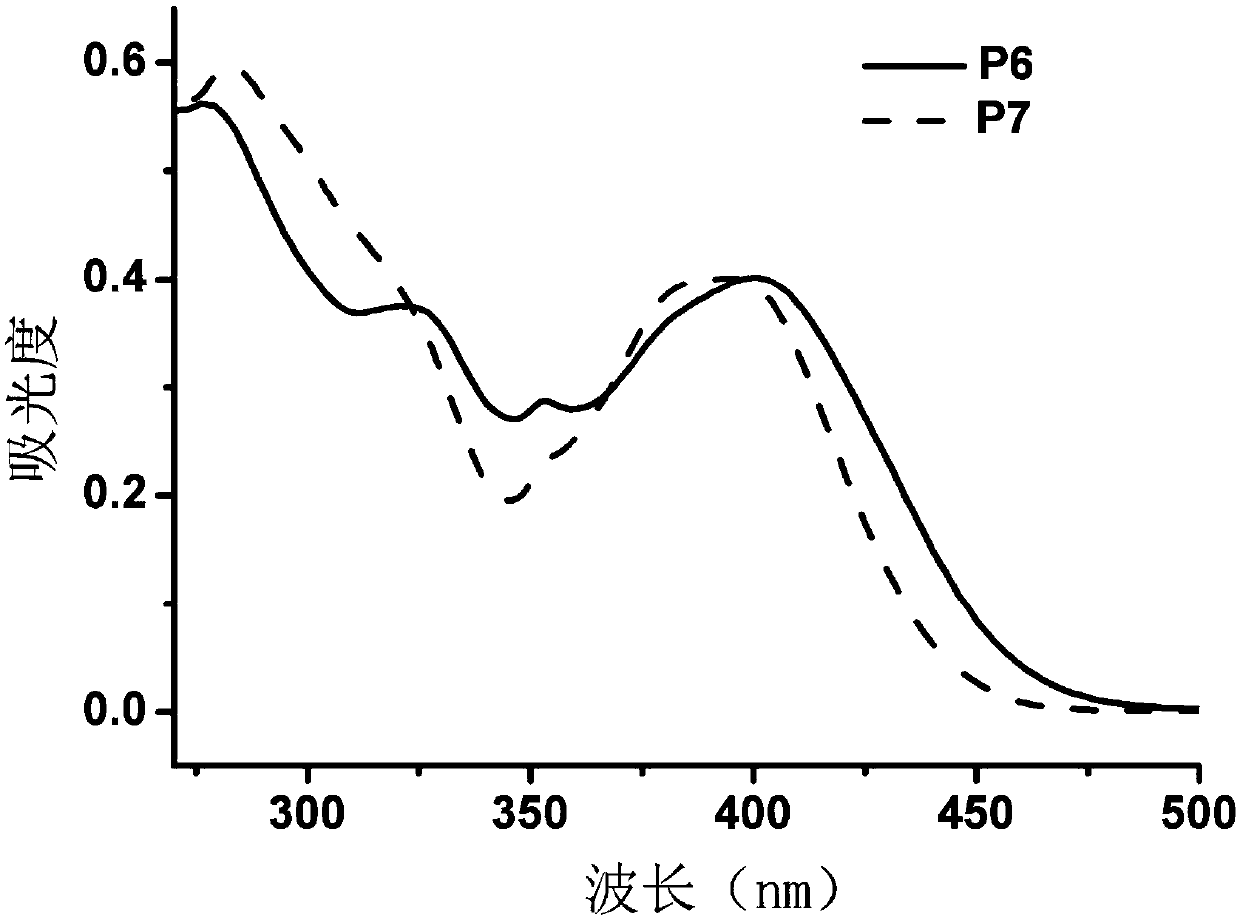

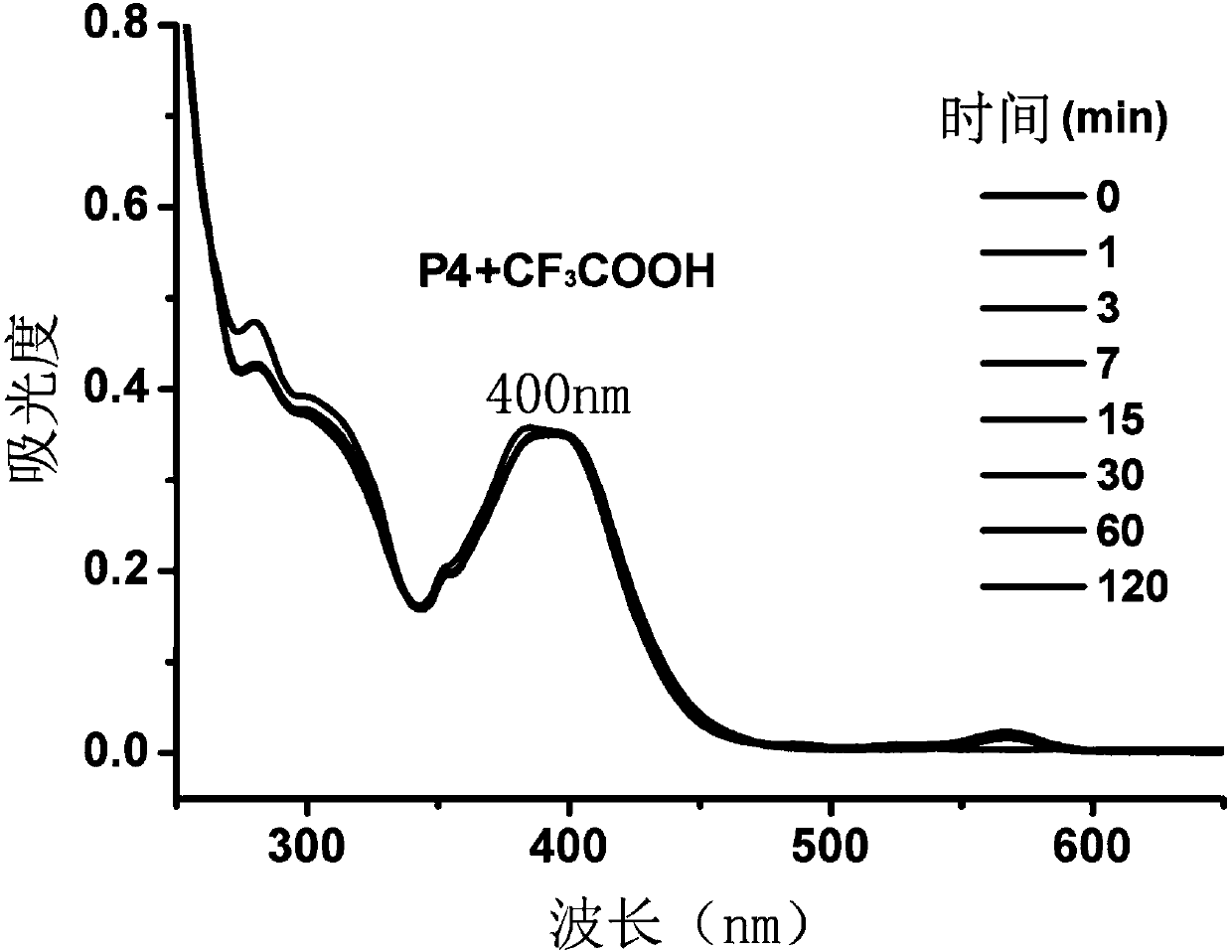

Visible light photo-controlled acid-resistant fluorescent molecular switch and synthesis method thereof

ActiveCN110272428AHas acid resistanceUndisturbedOrganic chemistryNaphthalimide/phthalimide dyesSynthesis methodsStructural formula

The invention provides a visible light photo-controlled acid-resistant fluorescent molecular switch and a synthesis method thereof. The specific molecular structure of the molecular switch is 3-primary amine or secondary amine substituted rhodamine spiroamide as a basic structural unit, and the structural formula of the molecular switch is represented by formula (1). The 3-primary amine or secondary amine substituted rhodamine spiroamide of the invention has acid resistance, and also retains the photoactivation performance, so like photoactivated acid-resistant fluorescent molecular switch dyes can be used in a living cell super-resolution imaging technique, and are not interfered by the acidic environment. The 3-primary amine or secondary amine substituted rhodamine spiroamide dye also can be used in fields of sensing and detection as a molecular fluorescent probe.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Check valve body suitable for acid solutions

InactiveCN106678408AAppropriate ratio of ingredientsAppropriate ratioFurnace typesAnti-corrosive paintsMetallurgyMolten steel

The invention discloses a check valve body suitable for acid solutions. A method includes the steps of preparing and casting molten steel comprising, by weight percentage, C not less than 2.14% and not larger than 2.24%, Si not less than 0.45% and not larger than 0.65%, Mo not less than 0.5% and not larger than 0.7%, P not less than 0.015% and not larger than 0.035%, S not less than 0.015% and not larger than 0.035%, Cr not less than 0.75% and not larger than 0.95%, Co not less than 0.25% and not larger than 0.35%, Ni not less than 1.6% and not larger than 1.8%, Cu not less than a trace amount and not larger than 0.20%, and the balance iron and inevitable impurities. The alloy composition proportion of the valve body material is appropriate, an acid-resistant coating on the inner wall of the valve body has the acid-proof property, and therefore the check valve body suitable for the acid solutions is long in service life, safe and reliable.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Fireproof wall paint and preparation method thereof

InactiveCN105062238AFire resistantHas acid resistanceFireproof paintsPigment treatment with organosilicon compoundsDefoaming AgentsMaterials science

The invention provides fireproof wall paint. The fireproof wall paint comprises raw materials in parts by weight as follows: 30-40 parts of water, 0.5-1 part of a dispersing agent, 0.3-0.5 parts of a wetting agent, 0.5-1 part of a defoaming agent, 0.5-1 part of a preservative, 1-2 parts of an anti-freezing agent, 0.5-1 part of a scrubbing-resistant agent, 1-2 parts of quartz powder, 10-15 parts of modified talcum powder, 10-20 parts of titanium dioxide, 0.2 parts of a PH (potential of hydrogen) regulator, 1 part of a coalescing agent, 0.5-1 part of a thickening and flattening agent and 25-35 parts of a styrene-acrylic emulsion. The invention further provides a preparation method of the fireproof wall paint. The preparation method comprises steps as follows: the dispersing agent, the wetting agent, the defoaming agent, the preservative, the anti-freezing agent, the scrubbing-resistant agent, the quartz powder, the modified talcum powder and titanium dioxide are added to water sequentially and stirred uniformly at the stirring speed of 1,000 revolutions / min, the mixture is ground to reach the fineness of 25-35 mu m, the PH regulator, the coalescing agent, the thickening and flattening agent and the styrene-acrylic emulsion are added, the viscosity of the mixture is adjusted to 110 KU, the contrast ratio is 0.95, the PH value is 7-8, and a wall paint product is obtained. The wall paint has excellent stability.

Owner:刘民钦

Sound-insulation ceramic tiles

The invention discloses sound-insulation ceramic tiles and belongs to building decoration materials. The ceramic tiles are prepared from, by weight, 28-41 parts of clay, 12-24 parts of feldspar, 8-20.5 parts of powdery quartz, 3.3-4.8 parts of chalk powder, 3-4.35 parts of magnesite, 2.85-4.15 parts of talcum powder, 2.4-3.9 parts of nepheline syenite, 2.28-3.76 parts of pyrophyllite, 2.1-3.53 parts of spodumene, 1.85-4 parts of fibrous brucite and 0.01-0.025 part of beryl. The problem that existing ceramic tiles are poor in sound-insulation effect can be solved.

Owner:柳州市国正机电物资有限责任公司

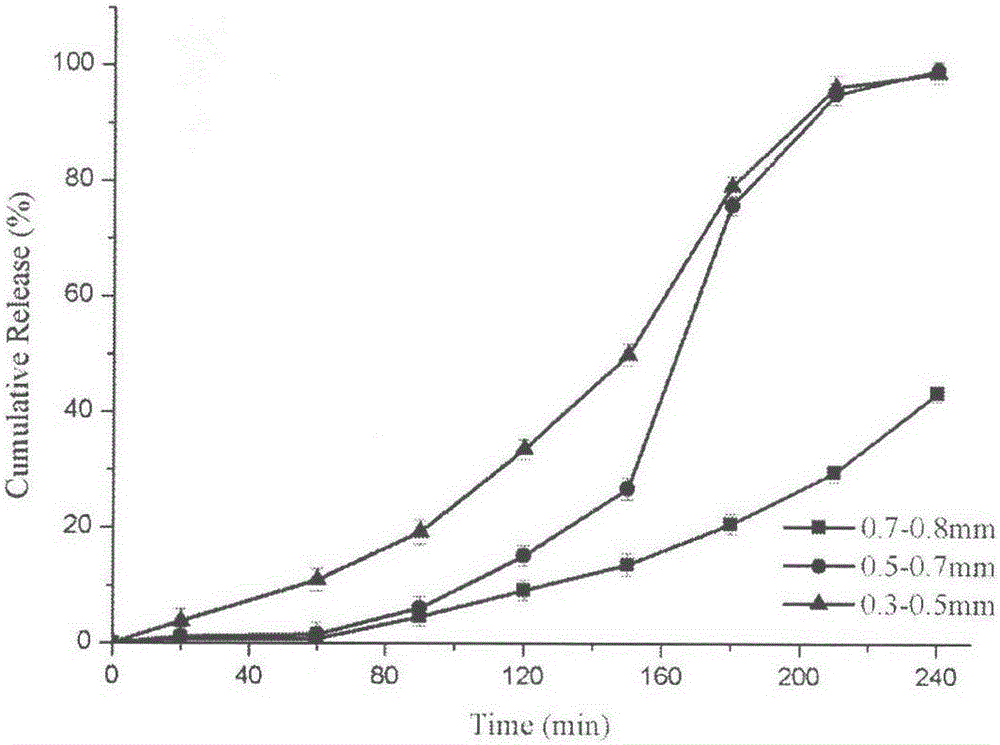

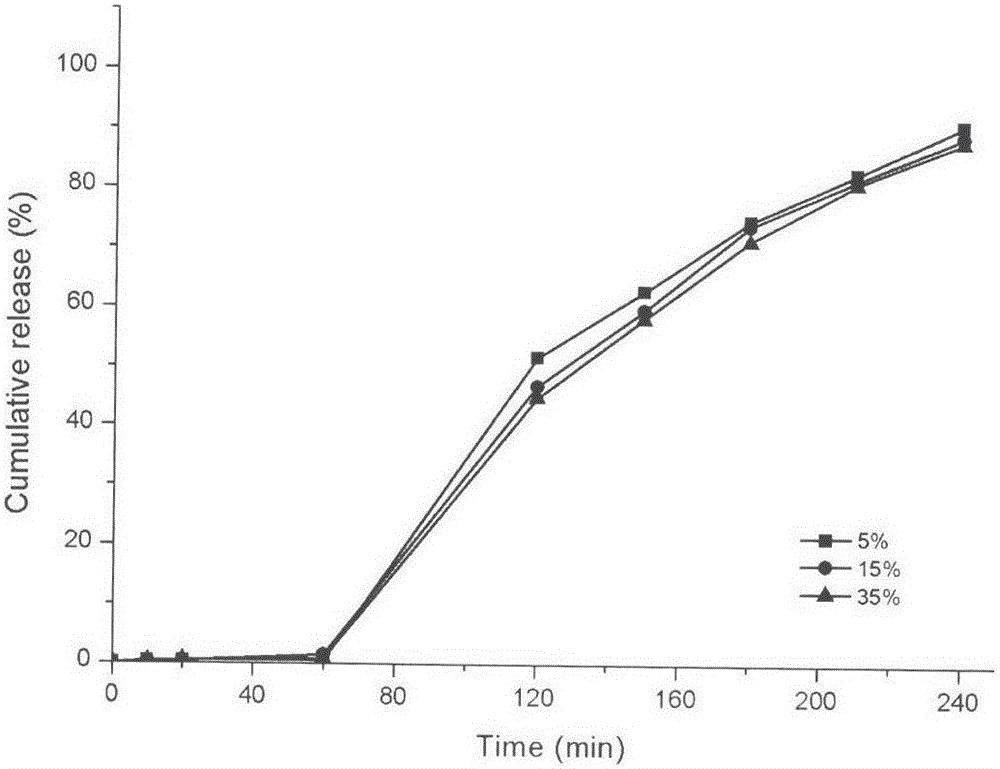

(R)-Lansoprazole time-selection pulse controlled-release pellet preparation and preparation method thereof

InactiveCN105796531AHas acid resistancePH dependentOrganic active ingredientsDigestive systemPulse controlControl release

The invention discloses an (R)-Lansoprazole time-selection pulse controlled-release pellet preparation and a preparation method thereof.The basic structure of the preparation comprises a blank pellet core, a medicine layer, a swelling layer and an enteric controlled release layer from inside to outside.The swelling layer contains swelling materials and a binding agent, and the enteric controlled release layer contains enteric materials and sustained-release materials.Compared with routine technologies, the release rate of the pellets, prepared through the preparation method, in a 0.1 mol / L hydrochloric acid solution is smaller than 10% of labeled amount within two hours of tolerance, certain time lag is presented at the upper end of the small intestine, and then quick pulse controlled-release is conducted.Adopted adjuvant is easy to get, the production technology is simple and controllable, and the preparation is suitable for industrial production.

Owner:CHINA PHARM UNIV

Method for preparing heavy metal ion adsorption resin by taking chitosan oligosaccharide as porogen

ActiveCN102716724BLarge specific surface areaImprove mechanical propertiesOther chemical processesAqueous solutionCHITOSAN OLIGOSACCHARIDE

The invention relates to a method for preparing heavy metal ion adsorption resin by taking chitosan oligosaccharide as porogen. The method comprises the following steps: preparing a mixed solution of chitosan and chitosan oligosaccharide; adding the mixed solution into a dispersion phase with an emulsifier, reacting for 30 to 50 minutes, then adding a pre-crosslinking agent for reaction to obtain pre-crosslinked resin; separating and drying, adding the pre-crosslinked resin into the crosslinking agent solution for secondary crosslinking, and thus obtaining secondary crosslinked resin; and adding the secondary crosslinked resin into a diluted hydrochloric acid aqueous solution with a concentration of 0.1 mol / L for reaction to release an adsorption bit occupied by the pre-crosslinking agent, fully deacidifying, separating and drying, and thus obtaining the heavy metal ion adsorption resin. The method is easy to operate; the preparation process is stable; and the cost is low. Due to pre-crosslinking and secondary crosslinking, the acid resistance and the mechanical performance of the heavy metal ion adsorption resin are improved; due to the reaction with diluted acid, the adsorption bit is fully released; the chitosan oligosaccharide is used as porogen, the specific surface area is increased; the adsorption performance of the heavy metal ion adsorption resin is improved; and the method can be widely applied to environment-friendly fields.

Owner:OCEAN UNIV OF CHINA

Anticorrosive paint used in waste gas treatment equipment and preparation method thereof

InactiveCN107987577AHigh mechanical strengthImprove oxidation stabilityAnti-corrosive paintsSodium BentoniteAntioxidant

The invention provides an anticorrosive paint used in waste gas treatment equipment and a preparation method thereof, and relates to the technical field of anticorrosive materials. The anticorrosive paint comprises the following raw materials in parts by weight: acrylic acid, n-butyl acetate, N-methyl pyrrolidone, VAE emulsion, laurinol polyoxyethylene ether, acetone, palygorskite, lithium-based bentonite, nanometer silica, nanometer titania, ethylene glycol monomethyl ether, polyurethane, graphite, talcum powder, acetylacetone, a thickener, a flatting agent, a phenol antioxidant and a compatilizer; the preparation method comprises the following steps: (1) weighing the raw materials; (2) preparing a base material; (3) preparing a mixed nanometer material; (4) preparing the modifier; (5) mixing, stirring, cooling and packaging. The anticorrosive paint overcomes the disadvantages that the anticorrosive base treatment requirement is high, the coating is too thick and is easy to crack, thepaint film is greatly influenced by temperature and humidity during curing, the curing time is long and the paint is low in weather resistance and not high in adhesive property existing in the anticorrosive paint used in the waste gas treatment equipment in the prior art.

Owner:中科协创环境科技江苏有限公司

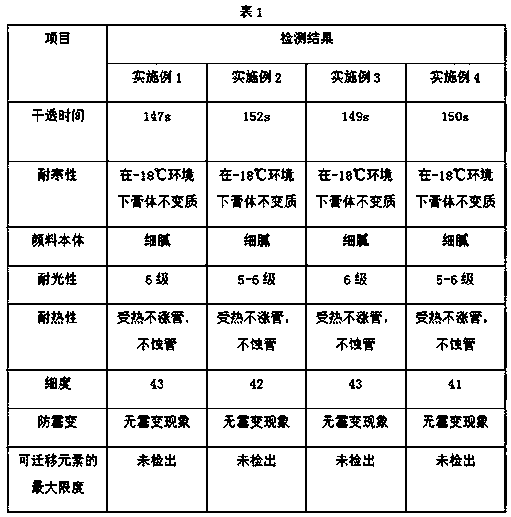

Red pigment for wall surface painting and preparation method of red pigment

InactiveCN109486265AThe coloring ingredients are safe, non-toxic and environmentally friendlyHigh yieldAntifouling/underwater paintsArtist's paintsWater basedDefoamer

The invention relates to the technical field of pigment production processes, in particular to a red pigment for wall surface painting and a preparation method of the red pigment. The red pigment forwall surface painting comprises the following raw materials in parts by weight: 40-50 parts of an anemone red pigment extract, 55-65 parts of polyacrylic acid emulsion, 10-15 parts of arabian jasmineflower powder, 3-5 parts of oxidized hydroxypropyl starch, 30-40 parts of talcum powder, 1-3 parts of a water-based defoamer BEK-750, 3-5 parts of D-mannitol, 3-5 parts of sodium benzoate, 1-3 parts of fungicide, 2-4 parts of propylene glycol, 6-8 parts of sodium alginate and 55-60 parts of water. The prepared pigment is safe and environmentally friendly, is stable in quality, high in coloring power, bright in color and abundant and saturated in color, and the pigment has high color retention and flexibility; and the red pigment for wall surface painting has the characteristic of rapid drying,is bright in color, high in coloring power and long in storage time, cannot fade out due to solarization when used in an outdoor environment, is environmentally friendly and nontoxic when used in anindoor environment, is easy to store for a long time, and is quite suitable for wall surface painting of a school.

Owner:陈琼燕

Heavy metal blocking fiber net/high polymer composite waterproof coiled material and preparation method thereof

PendingCN113263805ASmall vertical permeability coefficientGood mechanical propertiesLamination ancillary operationsSynthetic resin layered productsVinyl acetateHigh-density polyethylene

The invention relates to technical application of geotechnical materials, in particular to a heavy metal blocking fiber net / high polymer composite waterproof coiled material and a preparation method thereof. The composite waterproof coiled material specifically comprises a modified high polymer layer and three-dimensional fiber net layers arranged on the upper side and the lower side of the modified high polymer layer. The modified high polymer layer is prepared from the following raw materials: 10 to 30 parts of modified ethylene-vinyl acetate copolymer, 30 to 50 parts of high density polyethylene and 10 to 30 parts of metallocene polyethylene; the modified ethylene-vinyl acetate copolymer is obtained by initiating crosslinking modification of an ethylene-vinyl acetate copolymer and butyl xanthic acid; and the three-dimensional fiber web layers are obtained by opening, carding to form a web, laying the web and needling PET fibers. The composite material can adsorb heavy metal ions and achieve heavy metal blocking, has good mechanical properties, is resistant to high temperature and acid and alkali, and can be widely applied to geotechnical materials for soil pollution environment treatment.

Owner:湖南盛业土工材料制造有限公司

Multi-stage axial flow submerged pump with long shaft and method for conveying phosgene

InactiveCN102062107BExtended service lifeEasy to adjustSpecific fluid pumpsPump componentsCarbide siliconImpeller

Owner:甘肃银光聚银化工有限公司 +1

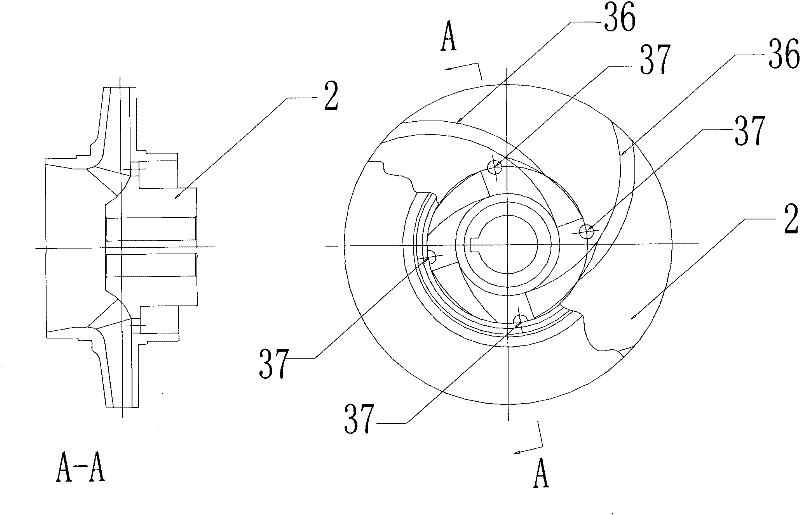

Self-adhesive waterproof coiled material and production process thereof

PendingCN112480840AIncrease elasticityGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolyester

The invention discloses a formula of a self-adhesive waterproof coiled material. The formula comprises asphalt, rubber oil, a styrene thermoplastic elastomer, butadiene styrene rubber, tire rubber powder, talcum powder, a polyester tire, 4000 kg of asphalt, 1200 kg of rubber oil, 400 kg of a styrene-series thermoplastic elastomer, 200 kg of butadiene styrene rubber, 1350 kg of tire rubber powder,2850 kg of talcum powder and 200 g of a polyester tire. The invention relates to a self-adhesive waterproof coiled material and a production process thereof, and belongs to the field of building materials. In the material, the rubber oil has the characteristics of improving the elasticity, the flexibility, the processability and the mixing property of rubber; the viscosity, rigidity, softening temperature and cohesion bonding strength of the material can be strictly controlled and changed by the styrene thermoplastic elastomer; and talcum powder has excellent physical and chemical characteristics of lubricity, fire resistance, acid resistance, insulativity, high melting point, inactive chemical property, good covering power, softness, good gloss, strong adsorption capacity and the lik. Inconclusion, the construction of the waterproof roll is facilitated, and meanwhile the bonding effect and the high-temperature resistance of the waterproof roll are improved.

Owner:开来湿克威防水科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com