Fungi-based biomass fireproof material with cornstalk as main material and preparation method thereof

A technology of corn stalks and fireproof materials, which is applied in the field of fungi-based biomass fireproof materials and its preparation, which can solve the problems of corn stalk resource surplus and achieve good covering power, low energy consumption and low volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

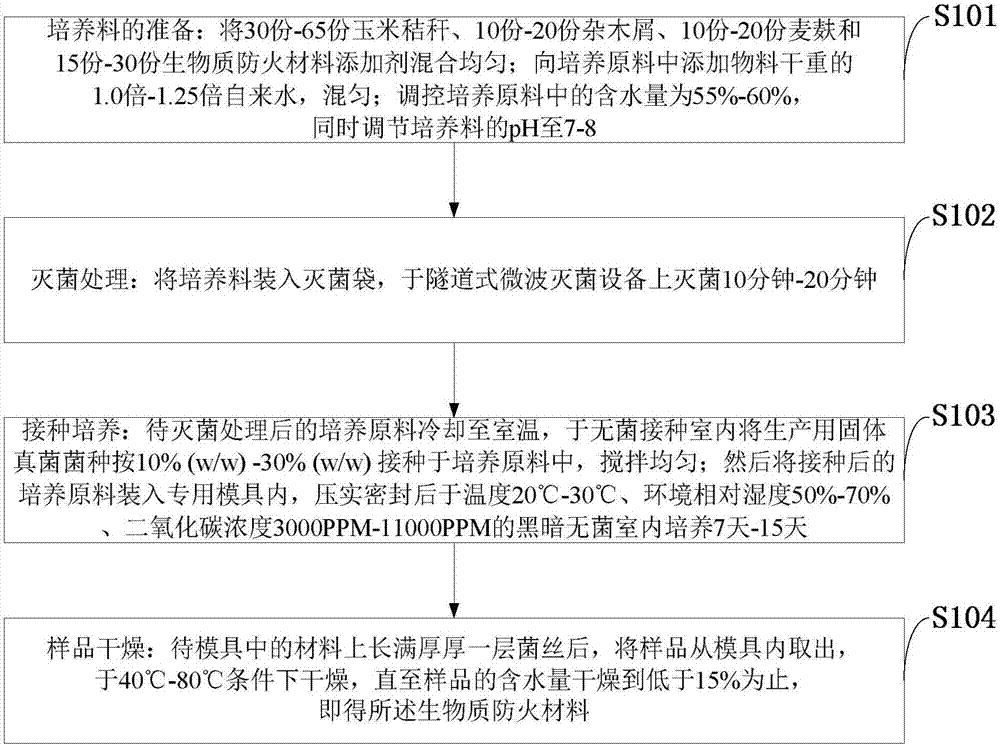

[0039] Such as figure 1 As shown, the preparation method of the fungal-based biomass fireproof material with corn stalks as the main ingredient provided by the embodiment of the present invention includes the following steps:

[0040] S101: Preparation of compost: Mix 30-65 parts of corn stalks, 10-20 parts of sawdust, 10-20 parts of wheat bran and 15-30 parts of biomass fireproof material additive; 1.0-1.25 times the dry weight of the material, tap water, mix well; adjust the water content in the culture material to 55%-60%, and adjust the pH of the culture material to 7-8 at the same time;

[0041] S102: Sterilization treatment: put the culture material into a sterilization bag, and sterilize it on the tunnel microwave sterilization equipment for 10 minutes to 20 minutes;

[0042] S103: Inoculation and cultivation: the culture raw materials to be sterilized are cooled to room temperature, and the solid fungal strains for production are inoculated in the culture raw material...

Embodiment 1

[0047] The specific steps for providing the fungal-based biomass fireproof material with corn stalks as the main ingredient in the embodiment of the present invention are as follows:

[0048] (1) Preparation of compost: Mix 45 parts of corn stalks, 15 parts of miscellaneous wood chips, 15 parts of wheat bran and 25 parts of biomass fireproof material additives; add tap water 1.0 times the dry weight of materials to the culture raw materials, and mix well; Regulate the water content in the culture material to be 55%, and adjust the pH of the culture material to 8 at the same time;

[0049] Corn stalks are crushed into granular materials with a particle size of 0mm-10mm, among which, the proportions of corn stalks with a particle size of 0mm-5mm and 5mm-10mm are 63% and 37% respectively; miscellaneous wood chips are leftovers of broad-leaved trees The granular material is crushed to a particle size of 0mm-5mm, wherein the miscellaneous wood chips with a particle size of 0mm-3mm ...

Embodiment 2

[0055] The specific steps of the fungal-based biomass fireproof material with corn stalks as the main ingredient provided by the embodiment of the present invention are:

[0056] (1) Preparation of compost: Mix 35 parts of corn stalks, 20 parts of miscellaneous wood chips, 18 parts of wheat bran and 27 parts of biomass fireproof material additives; add 1.25 times of the dry weight of the materials to the culture raw materials, and mix well; Control the water content in the culture material to 60%, and adjust the pH of the culture material to 8;

[0057] Corn stalks are crushed into granular materials with a particle size of 0mm-10mm, among which, the proportions of corn stalks with a particle size of 0mm-5mm and 5mm-10mm are 63% and 37% respectively; miscellaneous wood chips are leftovers of broad-leaved trees The granular material is crushed to a particle size of 0mm-5mm, wherein the miscellaneous wood chips with a particle size of 0mm-3mm and 3mm-5mm account for 31% and 69%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com