Multi-round high-and-low temperature thermal recovery packer rubber sleeve and production method thereof

A technology of packers and rubber cartridges, applied in the field of multi-round high-low temperature thermal recovery packer rubber cartridges, to achieve the effects of convenient operation, stable quality, good fluidity and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

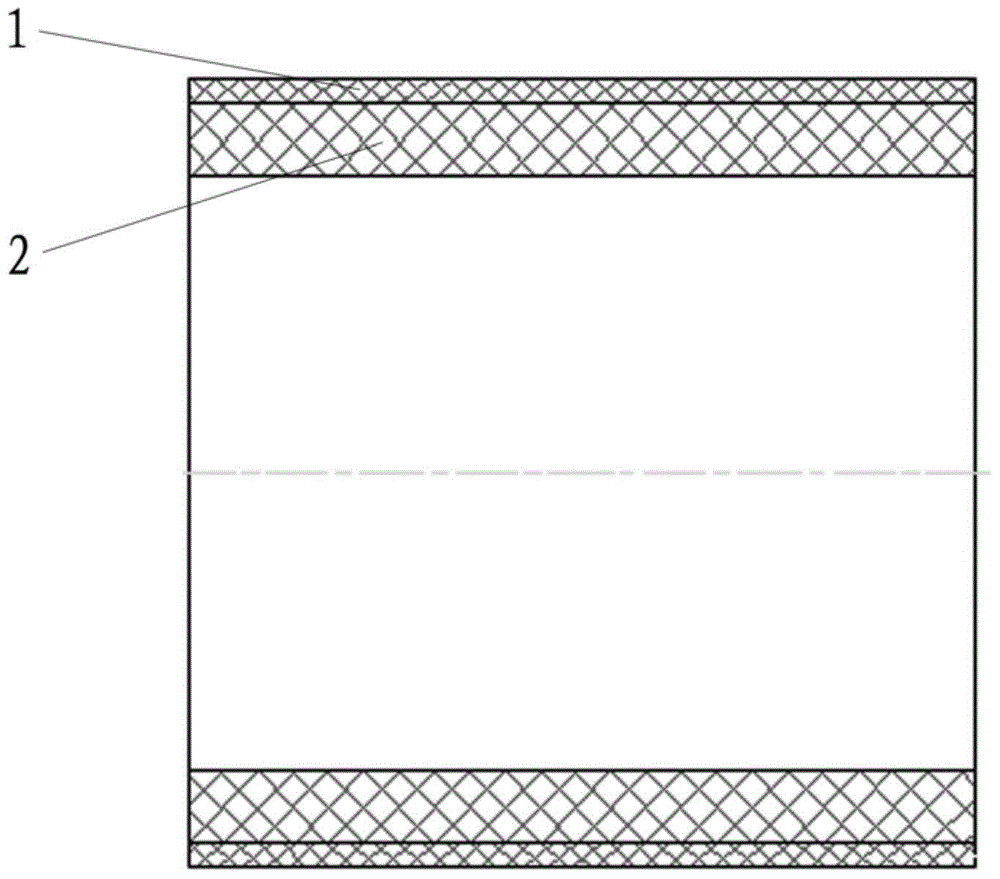

[0031] Multiple rounds of high and low temperature thermal recovery packer rubber cartridges, such as figure 1 As shown, it includes a flexible graphite rubber sleeve, and the outer sleeve of the flexible graphite rubber sleeve is covered with a modified polytetrafluoroethylene outer sleeve. The wall thickness of the flexible graphite rubber sleeve is 10 mm, and the wall thickness of the modified polytetrafluoroethylene outer sleeve is 1 mm.

[0032] The flexible graphite rubber cartridge contains the following components in weight percentage: 0.2% of talc powder, 0.2% of carbon fiber, and the balance is flexible graphite.

[0033] The modified polytetrafluoroethylene outer sleeve contains the following components in mass percentage: 10% of carbon fiber, 8% of graphite, 25% of tin bronze, and the balance is polytetrafluoroethylene.

[0034] The preparation method of the multi-round high and low temperature thermal recovery packer rubber cartridge in this embodiment includes t...

Embodiment 2

[0041]The multi-round high-low temperature thermal recovery packer rubber sleeve includes a flexible graphite rubber sleeve, and the outer sleeve of the flexible graphite rubber sleeve is covered with a modified polytetrafluoroethylene outer sleeve. The wall thickness of the flexible graphite rubber sleeve is 20 mm, and the wall thickness of the modified polytetrafluoroethylene outer sleeve is 2 mm.

[0042] The flexible graphite rubber cartridge contains the following components in weight percentage: 0.3% of talc powder, 0.1% of carbon fiber, and the balance is flexible graphite.

[0043] The modified polytetrafluoroethylene outer sleeve contains the following components in mass percentage: 8% carbon fiber, 10% graphite, 23% tin bronze, and the balance is polytetrafluoroethylene.

[0044] The preparation method of the multi-round high and low temperature thermal recovery packer rubber cartridge in this embodiment includes the following steps:

[0045] 1) After mixing flexibl...

Embodiment 3

[0051] The multi-round high-low temperature thermal recovery packer rubber sleeve includes a flexible graphite rubber sleeve, and the outer sleeve of the flexible graphite rubber sleeve is covered with a modified polytetrafluoroethylene outer sleeve. The wall thickness of the flexible graphite rubber sleeve is 30 mm, and the wall thickness of the modified polytetrafluoroethylene outer sleeve is 1.5 mm.

[0052] The flexible graphite rubber cartridge contains the following components in weight percentage: 0.5% of talc powder, 0.15% of carbon fiber, and the balance is flexible graphite.

[0053] The modified polytetrafluoroethylene outer sleeve contains the following components in mass percentage: 12% of carbon fiber, 6% of graphite, 27% of tin bronze, and the balance is polytetrafluoroethylene.

[0054] The preparation method of the multi-round high and low temperature thermal recovery packer rubber cartridge in this embodiment includes the following steps:

[0055] 1) After m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com