Patents

Literature

48results about How to "Meet different job requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid supply vehicle

ActiveCN101885307ALower suction heightImprove inhalation performanceFluid removalItem transportation vehiclesVehicle frameSewage

The invention discloses a liquid supply vehicle, which comprises a frame with a cab. The lower part of the frame is provided with wheels, the rear upper part of the frame is provided with a bedplate, a power driving device is arranged on the bedplate, a centrifugal pump is arranged below the bedplate, the power driving device is in transmission connection with the centrifugal pump, and an inlet and an outlet of the centrifugal pump are connected with a suction pipe and a discharge pipe respectively. The liquid supply vehicle has the advantages of improving the self-sucking effect of a fracturing truck, improving the operation efficiency of the fracturing truck and shortening the operation time, along with reasonable design, simple structure, easy assembly and manufacture, and also can be used for liquid delivery in other industries of flood drainage, sewage clearing and the like.

Owner:ZYT GASOLINEEUM EQUIP

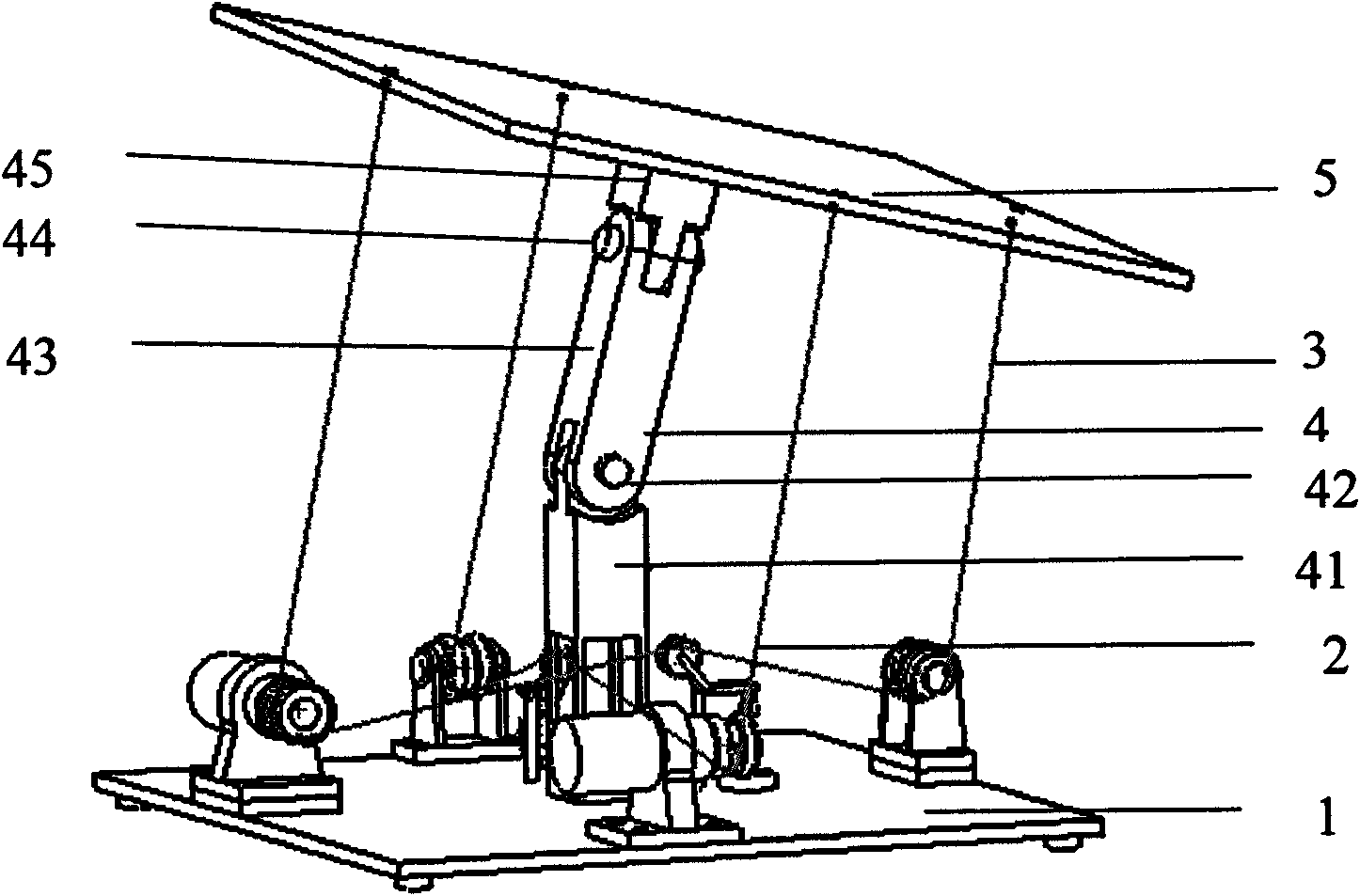

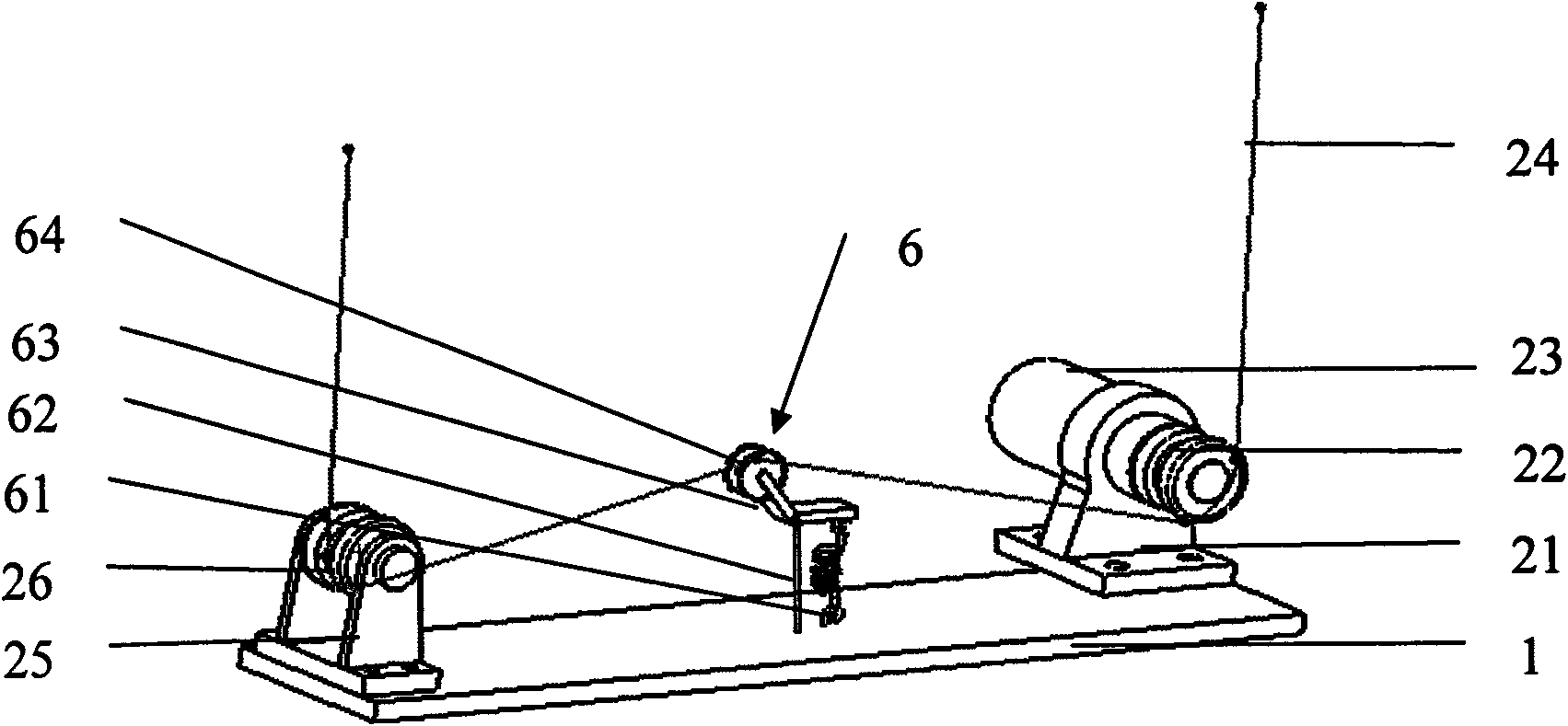

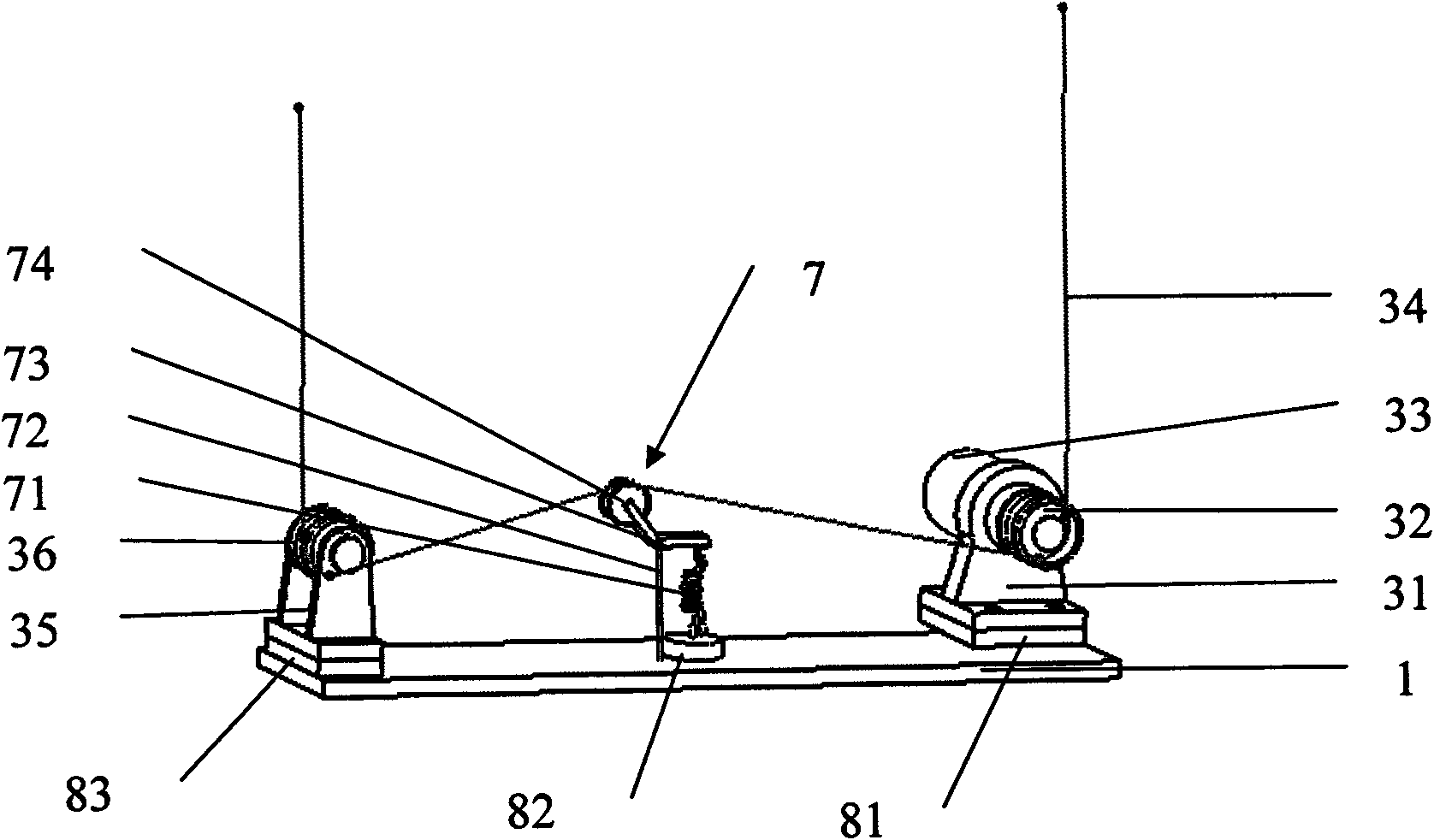

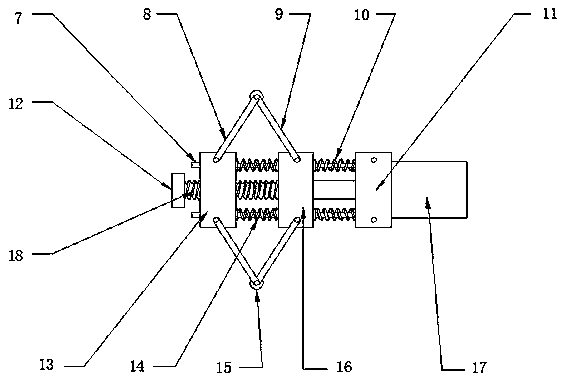

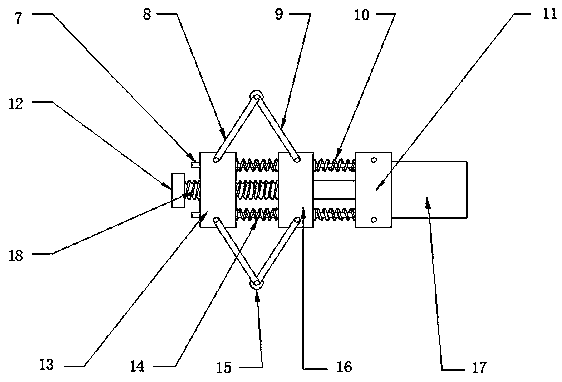

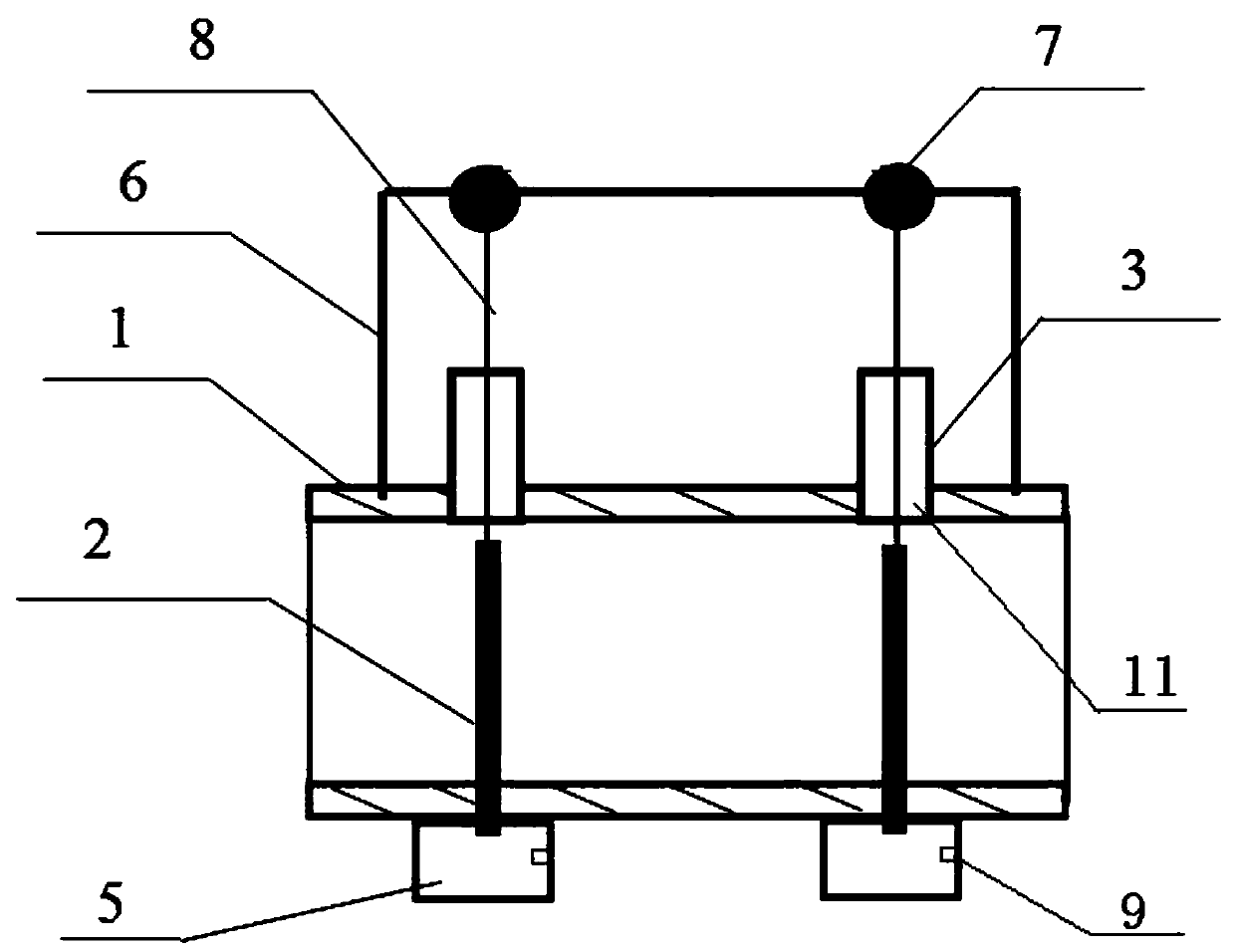

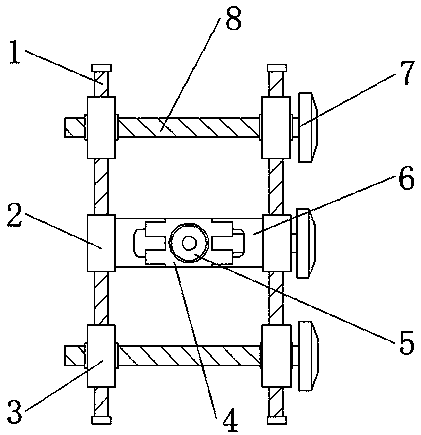

Two-degree freedom rope traction and parallel-connection mechanism

InactiveCN101664924AEffective tensionAvoid redundant drivesProgramme-controlled manipulatorMotor driveEngineering

The invention relates to a two-degree freedom rope traction and parallel-connection mechanism which comprises a rack and a dynamic platform. The mechanism is characterized by also comprising an intermediate branched chain and two groups of rope traction branched chains, the intermediate branched chain is formed by hinging two rotational joints which are vertical mutually and is installed at the center position between the rack and the dynamic platform; the two groups of rope traction branched chains have the same structures and are installed between the rack and the dynamic platform in a crossway by taking the intermediate branched chain as a center, and each group of rope traction branched chains is driven by a motor fixed on the rack, and the motor drives a rope to drive the dynamic platform through a tension mechanism and a pulley mechanism to rotate around the intermediate branched chain, thereby realizing that the dynamic platform can rotate in two mutually vertical directions. The invention is a non-redundant drive and has simple mechanism and can be controlled easily.

Owner:天津捷力安建筑机械有限公司

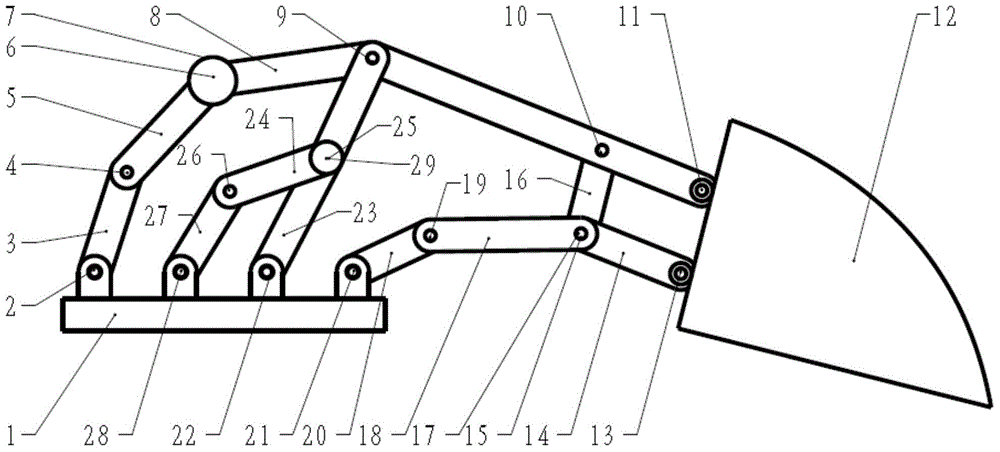

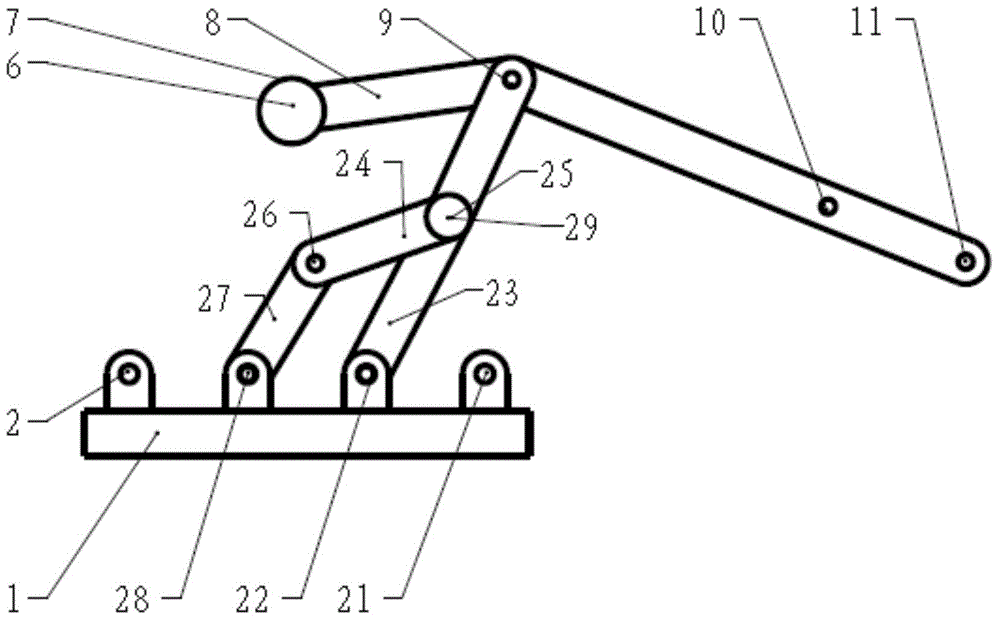

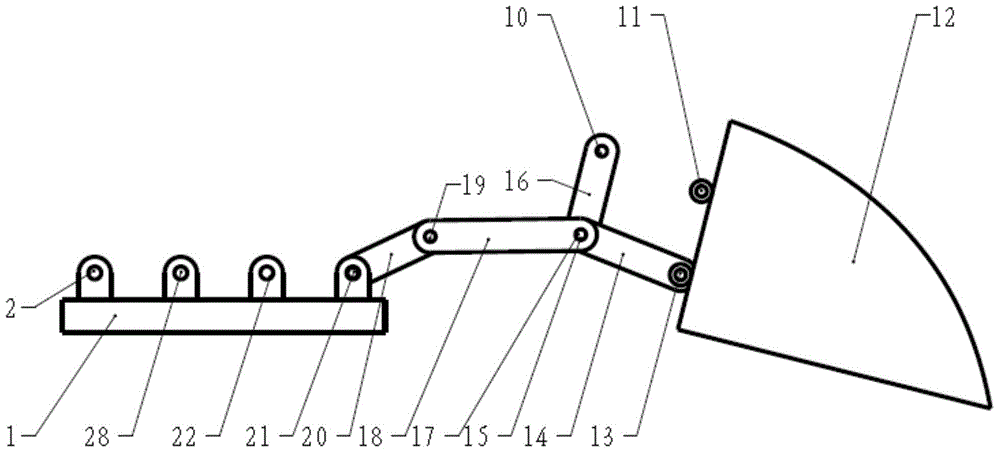

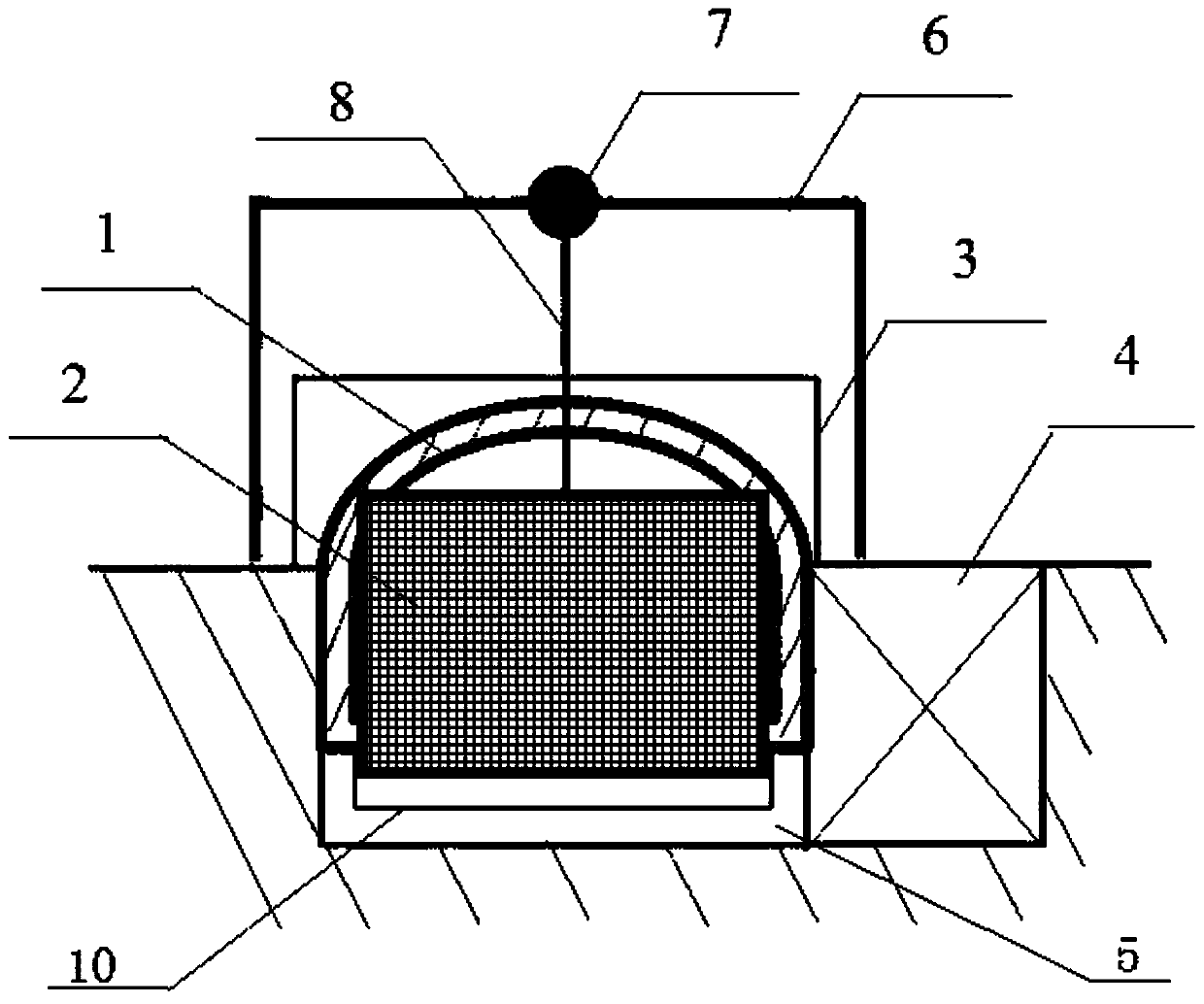

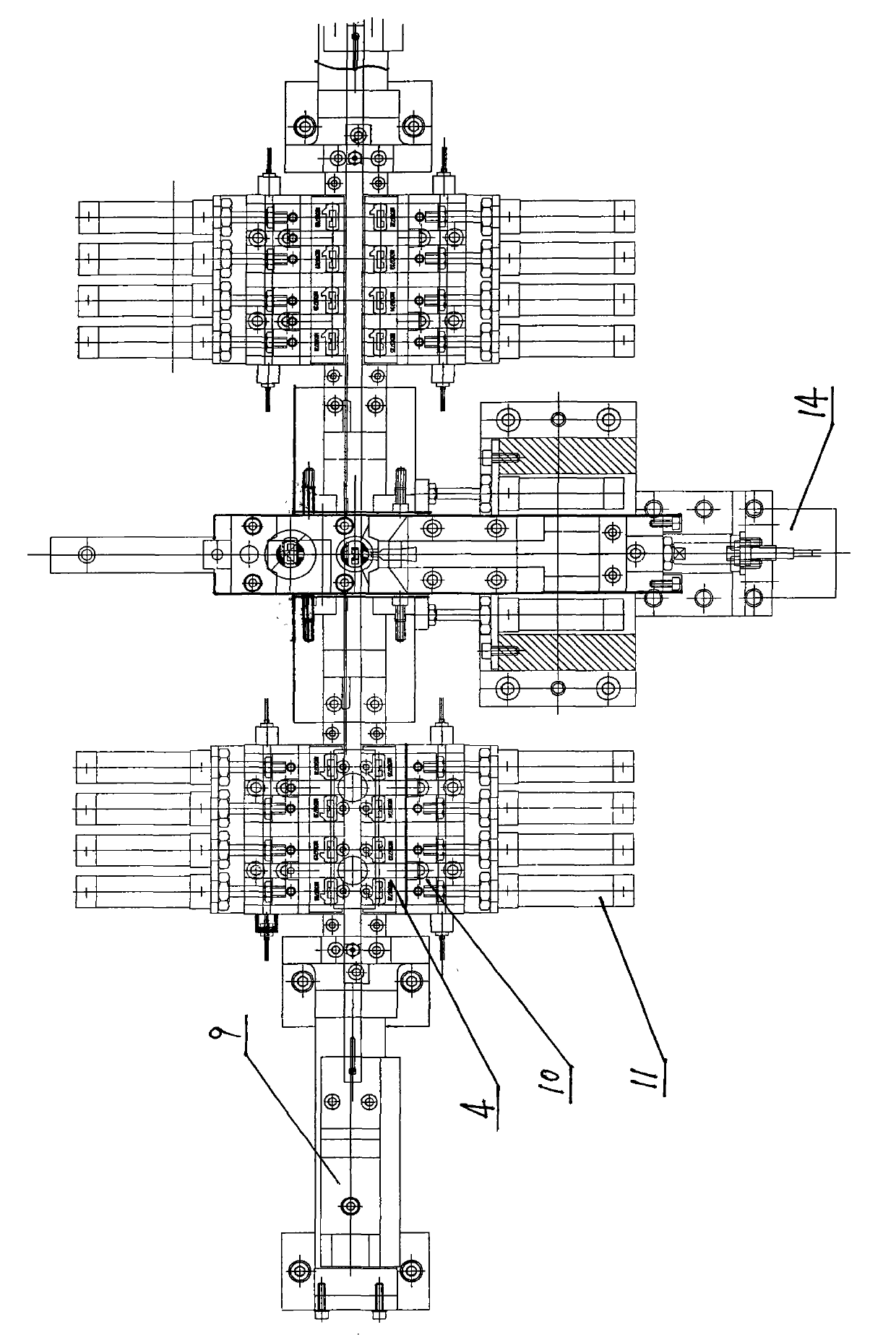

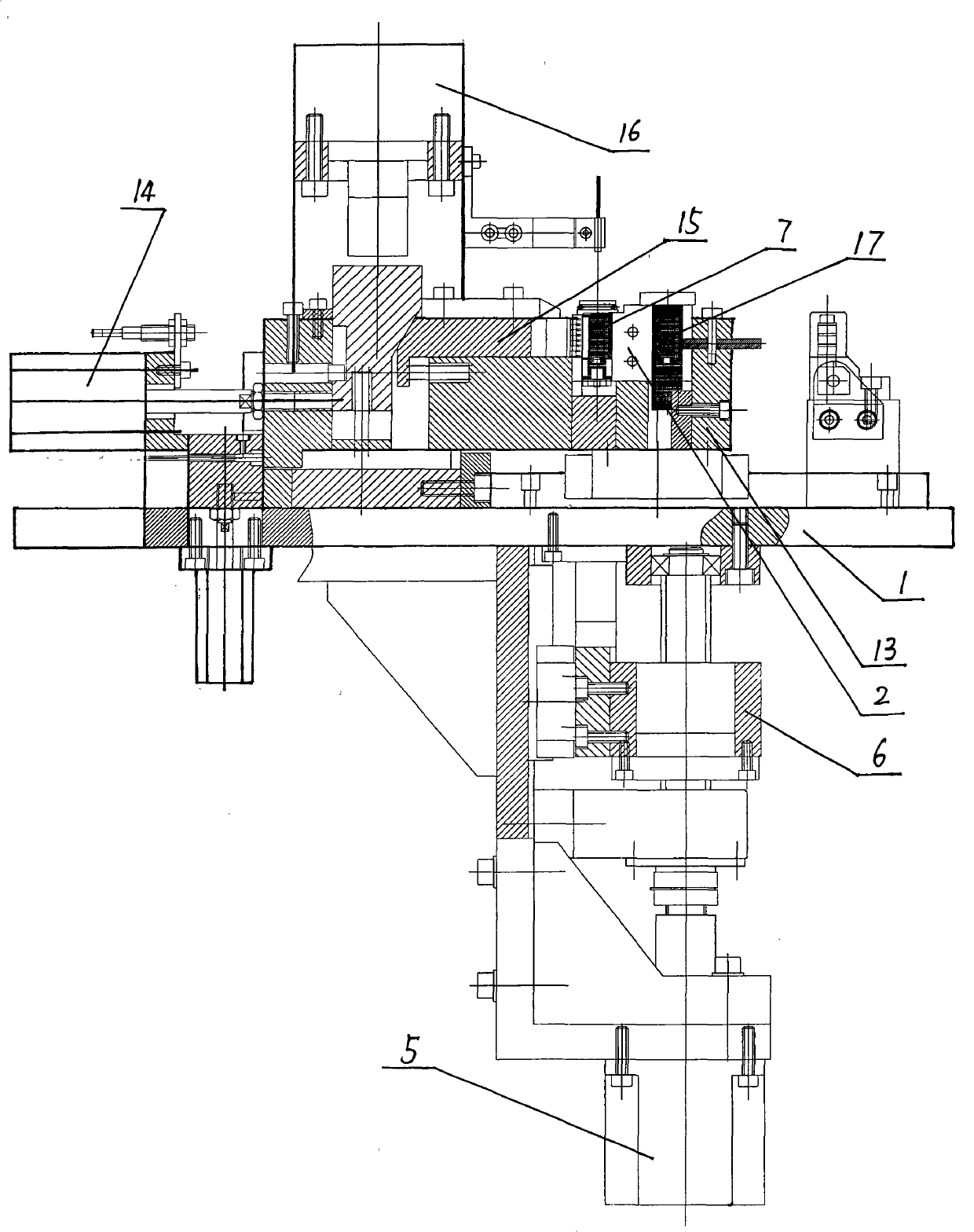

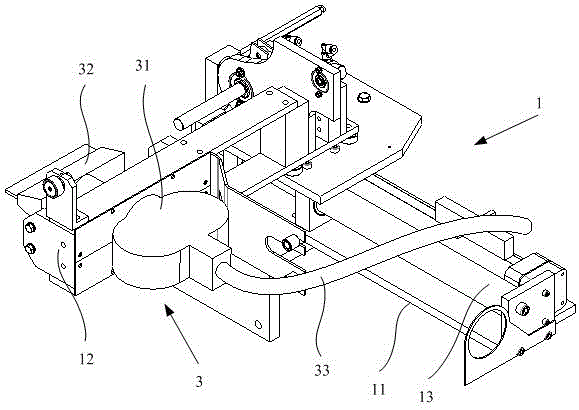

Multi-degree-of-freedom metamorphism controllable excavation mechanism comprising parallelogram bucket maintaining mechanism

ActiveCN104452840AMeet different job requirementsLower control costsMechanical machines/dredgersThree degrees of freedomMulti degree of freedom

The invention discloses a multi-degree-of-freedom metamorphism controllable excavation mechanism comprising a parallelogram bucket maintaining mechanism. The multi-degree-of-freedom metamorphism controllable excavation mechanism comprises a rack, a big arm swing mechanism, a bucket rod raising and dropping mechanism, a bucket overturning mechanism and two electromagnetic locking devices. The big arm swing mechanism comprises a big arm and a swing mechanism. The bucket rod raising and dropping mechanism comprises a bucket rod and a raising and dropping mechanism. The bucket overturning mechanism comprises a bucket and an overturning mechanism. The electromagnetic locking devices are mounted on a revolute pair and achieve the active metamorphism function by electromagnetically locking the revolute pair. According to the multi-degree-of-freedom metamorphism controllable excavation mechanism comprising the parallelogram bucket maintaining mechanism, a link transmission mechanism is used for replacing traditional hydraulic transmission, so the defects that a hydraulic system of a hydraulic excavator is complex, prone to oil leakage and the like can be overcome; due to the fact that the electromagnetic locking devices are mounted on the revolute pair, active metamorphism can be realized according to different working conditions; the flexibility of the hydraulic excavator is obtained, and excavation operation at three degrees of freedom can be achieved just through two driving rods, so that the manufacturing cost of the excavation mechanism is lowered, and the excavation mechanism is suitable for manufacturing various excavators and other engineering machinery.

Owner:GUANGXI UNIV

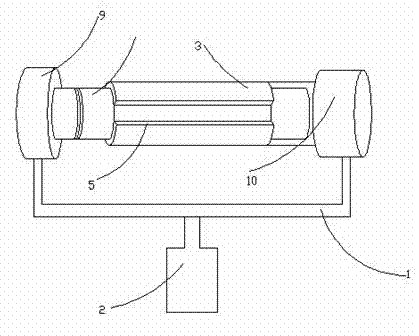

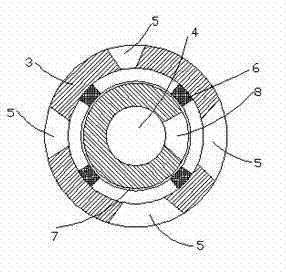

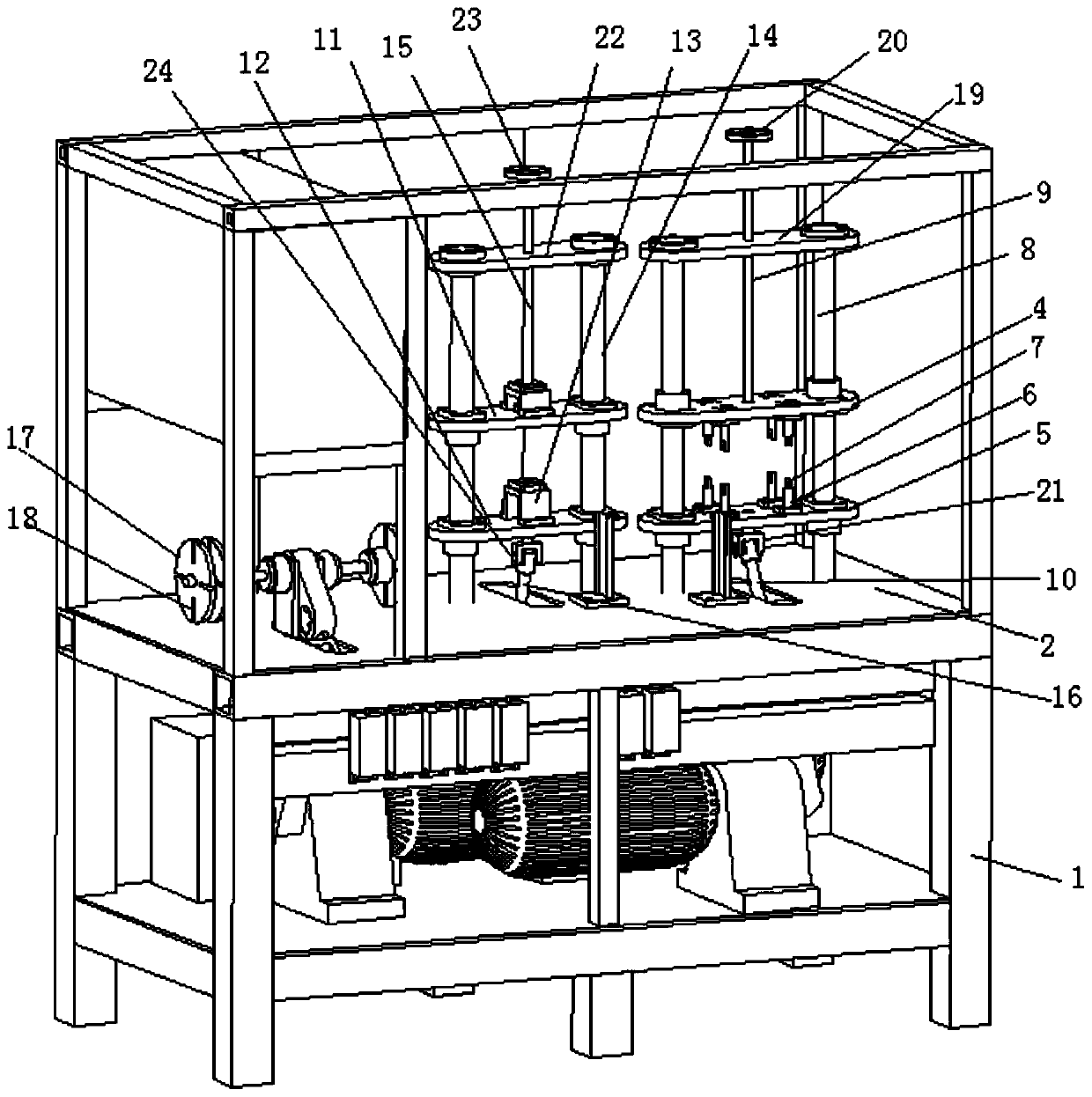

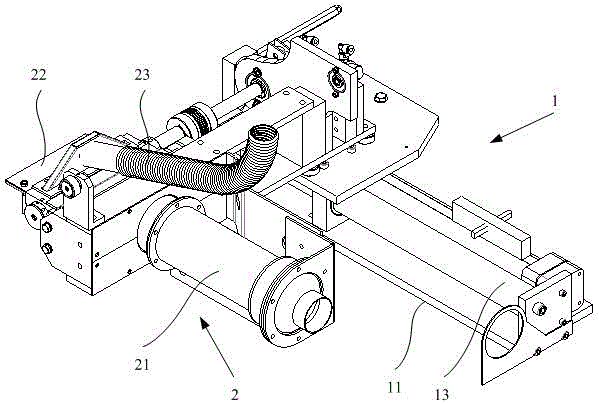

Air suction device on embroiderer rack

ActiveCN104233668ARealize the wind suction effectMeet actual job needsAuxillary devicesEngineeringDrive motor

The invention discloses an air suction device on an embroiderer rack. The air suction device is characterized by comprising an air suction pipe and an air suction pump connected with the air suction pipe, the air suction pipe is provided with a steam cylinder through a bracket and comprises an outer pipe and an inner pipe, a plurality of different air suction openings are formed in the pipe wall of the outer pipe, fixed strip-shaped rubber platforms are arranged on the two sides of the air suction openings on the inner wall and are connected with a fixing plate together, the inner pipe is connected on the inner wall of the fixing plate through a bearing, one end of the inner pipe is an open end and is connected with the air suction pump, an air outlet is arranged on the pipe wall of the inner pipe, the other end of the inner pipe is a closed end, a first drive motor is arranged at the closed end, a second drive motor is arranged at one end of the outer pipe, and the first drive motor and the second drive motor are arranged on the bracket. The air suction device of the embroiderer rack forms an air suction surface, so that the operation range is regulated, the air suction amount is also regulated, the practical operation requirements are met, the cost is saved, and the energy consumption is reduced.

Owner:汕头市坤兴刺绣有限公司

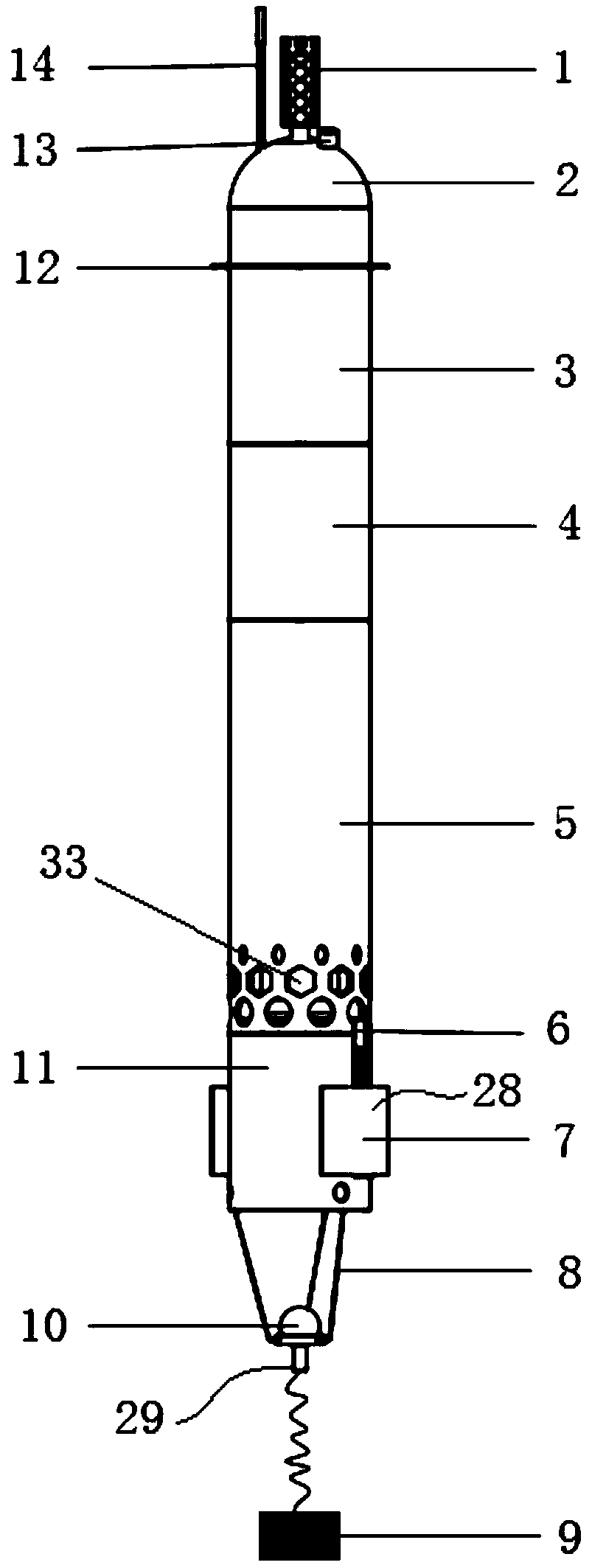

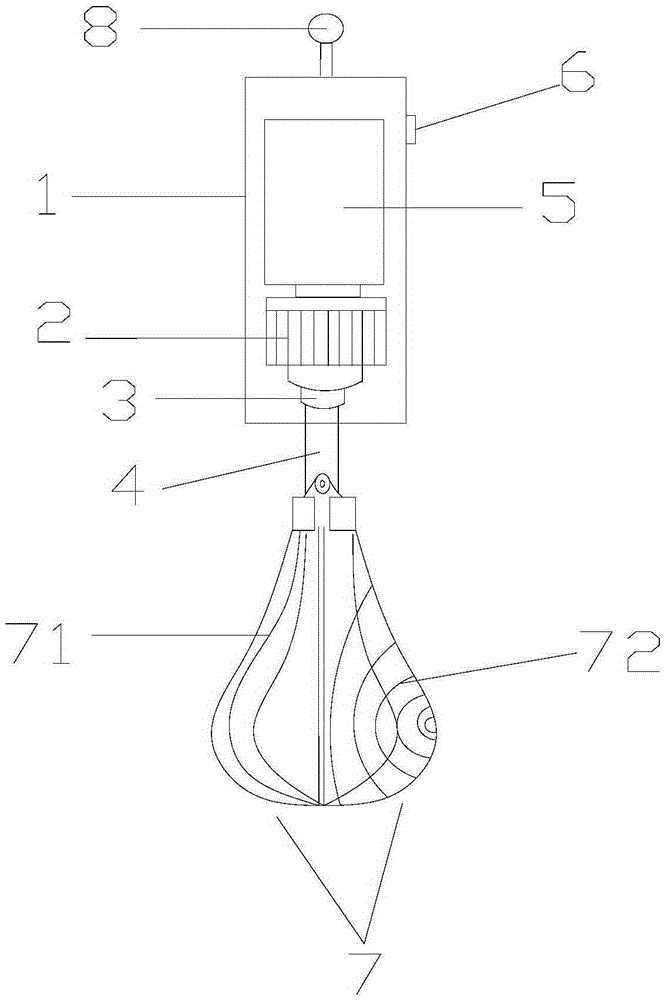

Modular fixed-point profile buoy

PendingCN109878639AEasy maintenanceMeet different job requirementsWaterborne vesselsBuoysLoad rejectionComputer module

The invention relates to the field of marine environment monitoring, and in particular to a modular fixed-point profile buoy that comprises sensor modules which are sequentially connected and mutuallyindependent inside, a buoyancy material module, an electric control module, a buoyancy driving module and a power supply module; an emergency load rejection module is arranged on one side of the power supply module; an anchoring module is arranged at the lower end of the power supply module; a buoyancy adjusting mechanism is arranged in the buoyancy driving module; the buoyancy adjusting mechanism comprises a buoyancy adjusting clear water cabin and a buoyancy adjusting seawater cabin which are separated through an isolating membrane; clear water and a piston capable of moving in a reciprocating mode are arranged in the buoyancy adjusting clear water cabin; a through hole is formed in the buoyancy adjusting seawater cabin, and in addition, a plurality of hollow holes are formed in the lower end of a shell of the buoyancy driving module. The modular fixed-point profile buoy comprises a plurality of independent module units, different operation requirements can be met, the buoyancy adjusting structure is simple, the buoy cost is greatly reduced, and in addition, the anchoring module with a force unloading ring is further arranged, so that long-term fixed-point monitoring is achieved.

Owner:SHANGHAI OCEAN UNIV

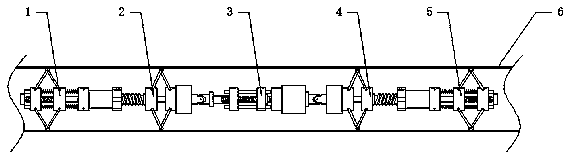

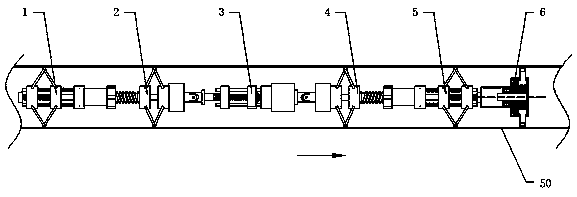

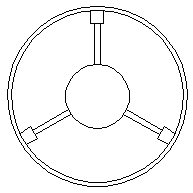

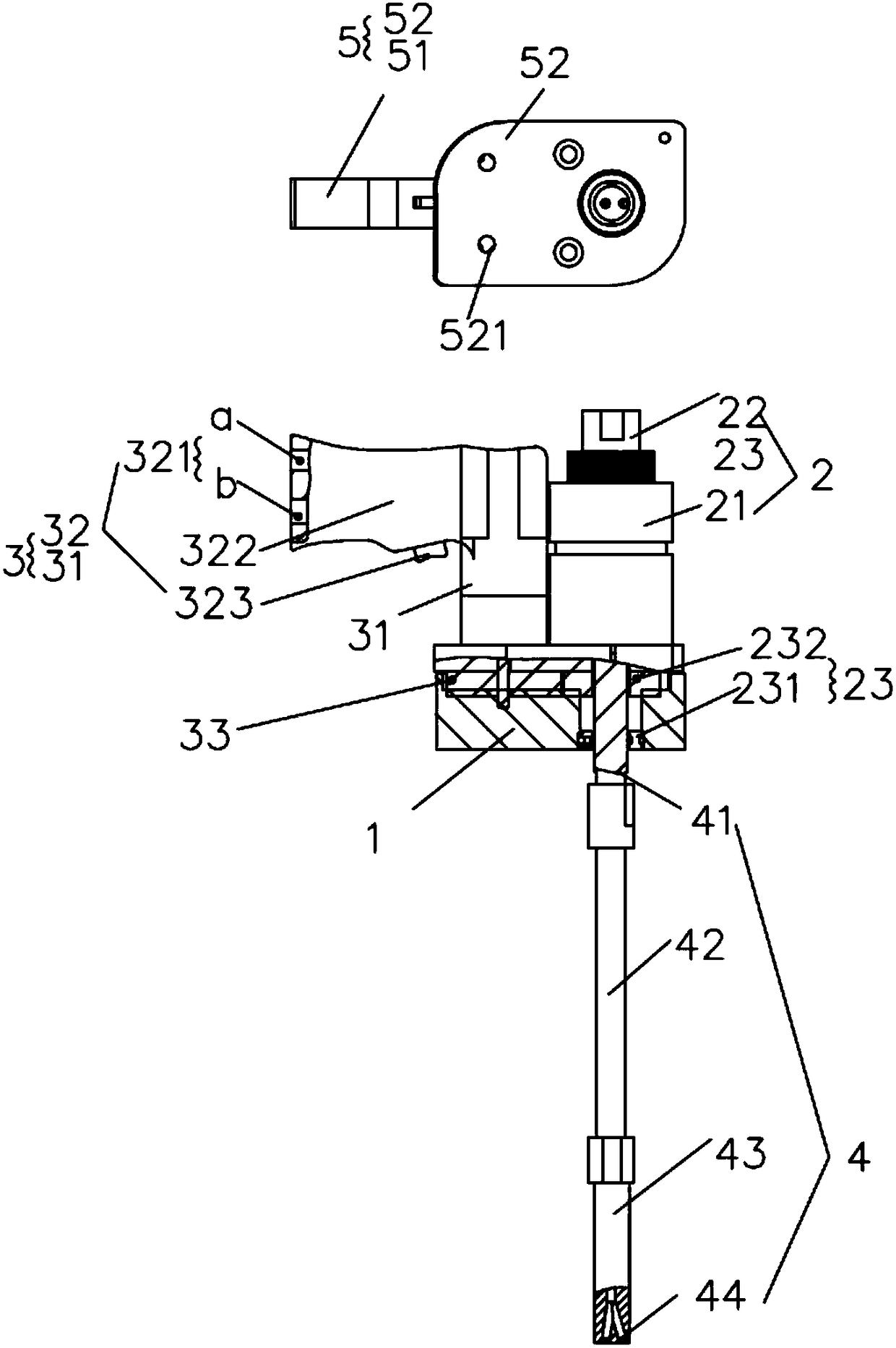

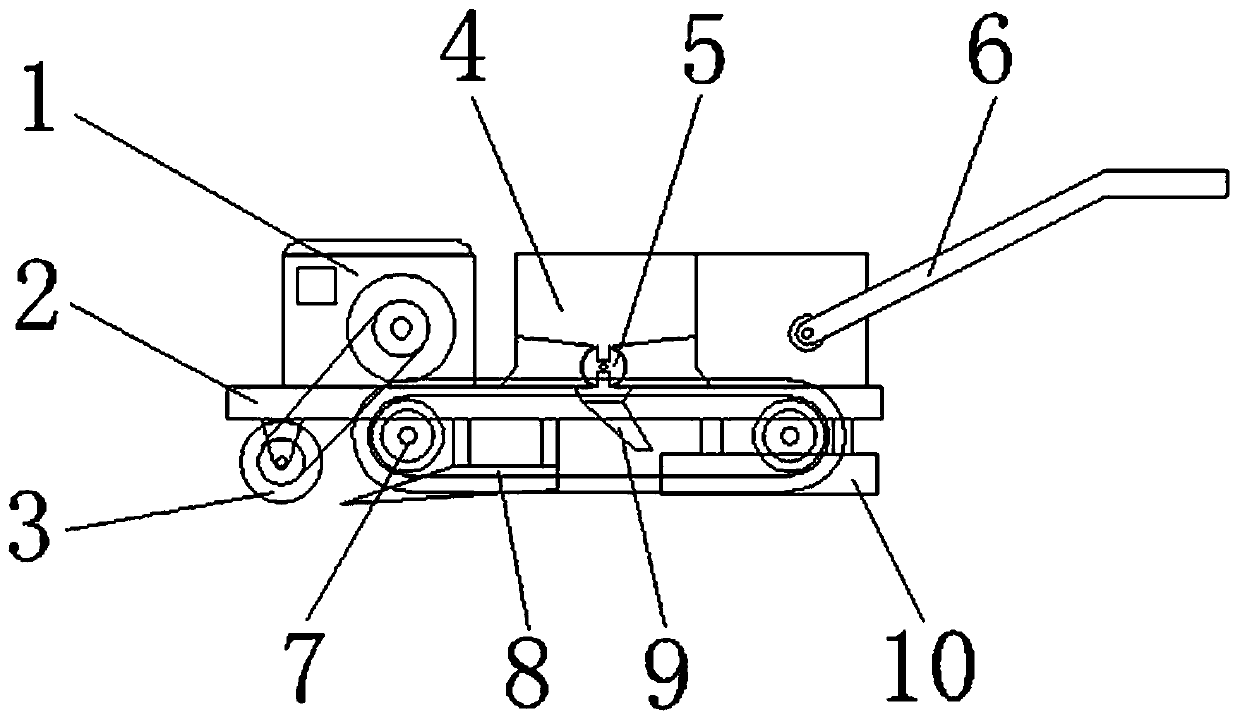

Walking device of ventilation pipeline cleaning robot

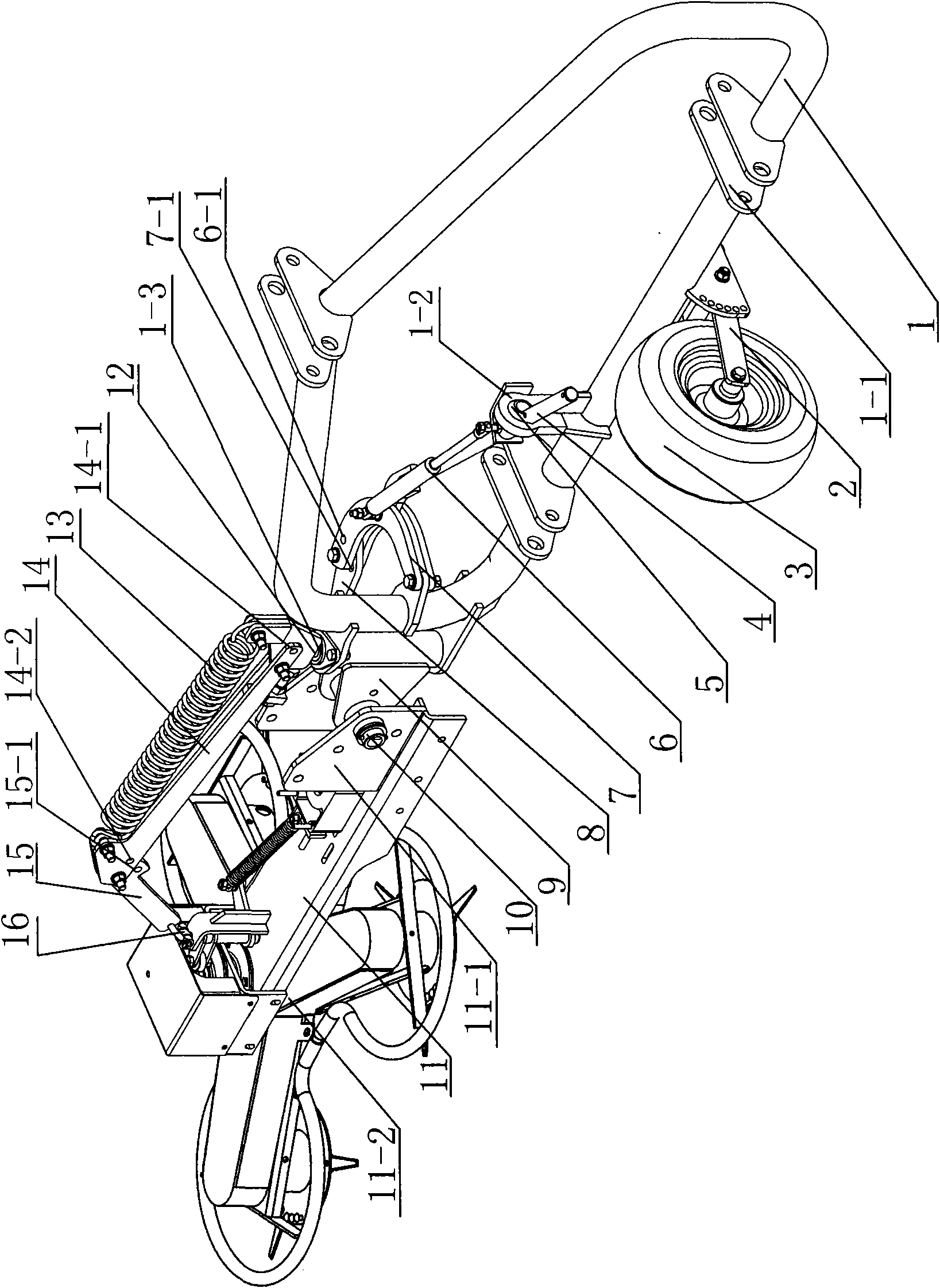

InactiveCN110681657AGreat sporty tractionMeet different job requirementsHollow article cleaningControl systemControl engineering

The invention discloses a walking device of a ventilation pipeline cleaning robot. The walking device comprises a supporting structure, a maintaining structure, a driving structure and a control system. The supporting structure comprises a front supporting structure and a rear supporting structure, the maintaining structure comprises a front maintaining structure and a rear maintaining structure,one end of the front maintaining structure and one end of the rear maintaining structure are connected with the two ends of the driving structure, the other end of the front maintaining structure is connected with the front supporting structure, the other end of the rear maintaining structure is connected with the rear supporting structure, and the supporting structure, and the maintaining structure and the driving structure are connected with the control system through a signal transmission unit, and adopt motors to drive screw nut mechanisms to achieve walking and supporting of the cleaningrobot in a ventilation pipeline. The walking device has the enough large drive traction force, pipe diameter adaptation, pipe bending passing capacity and climbing capacity, and different work needs of various ventilation pipelines can be met.

Owner:东莞市奇趣机器人科技有限公司

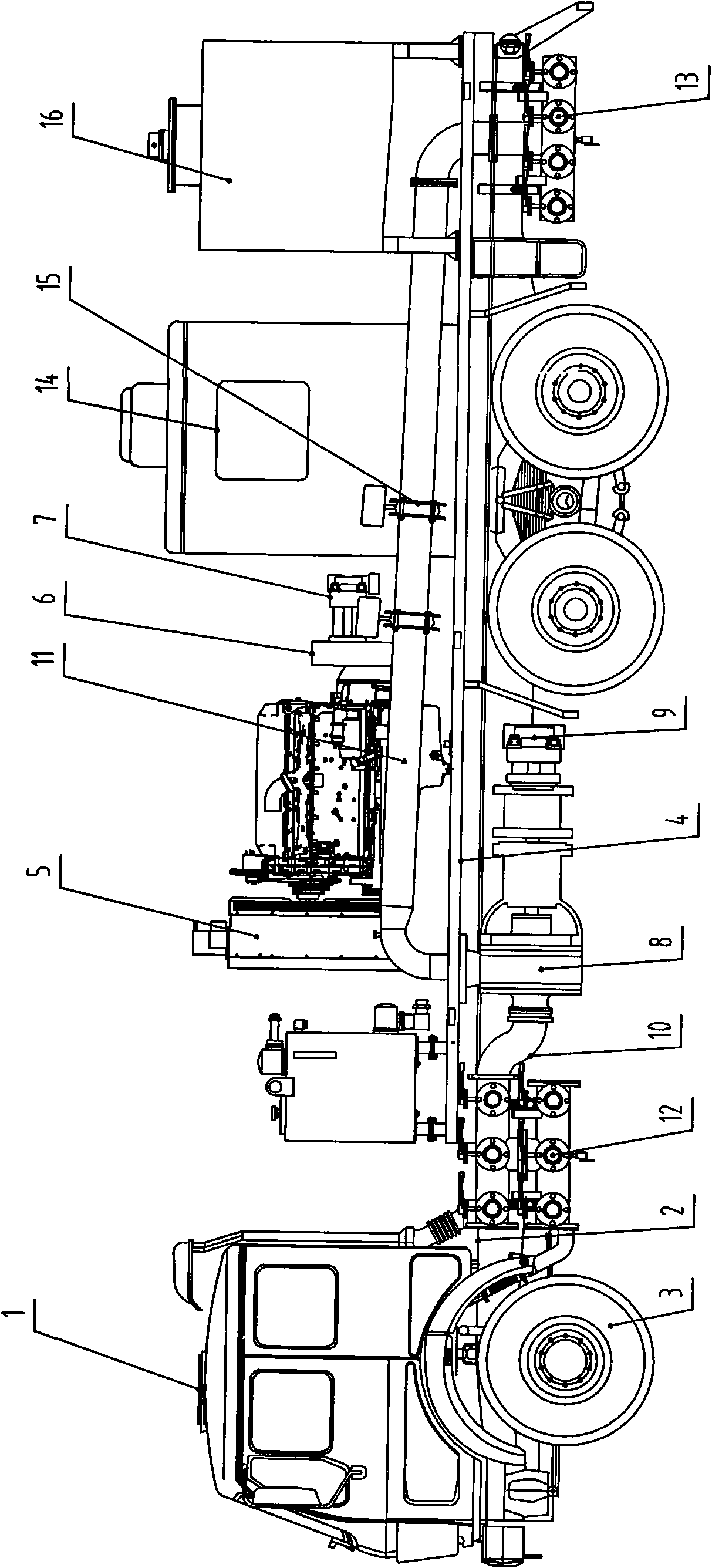

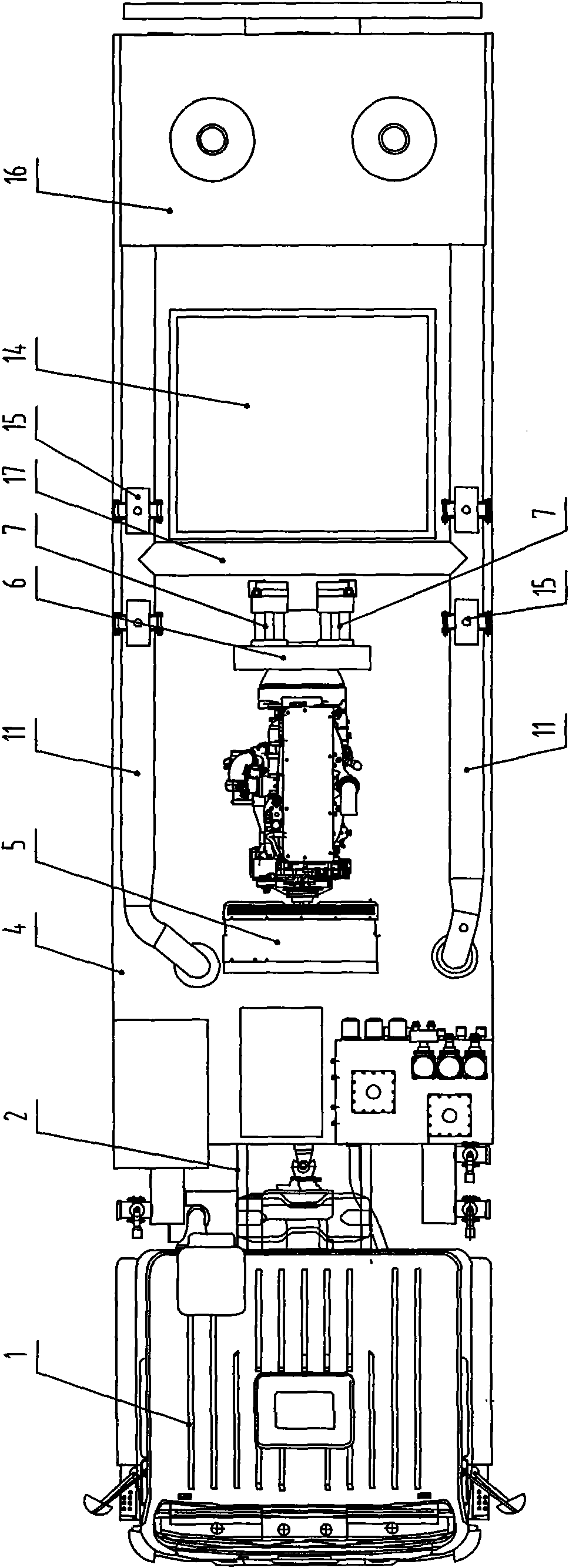

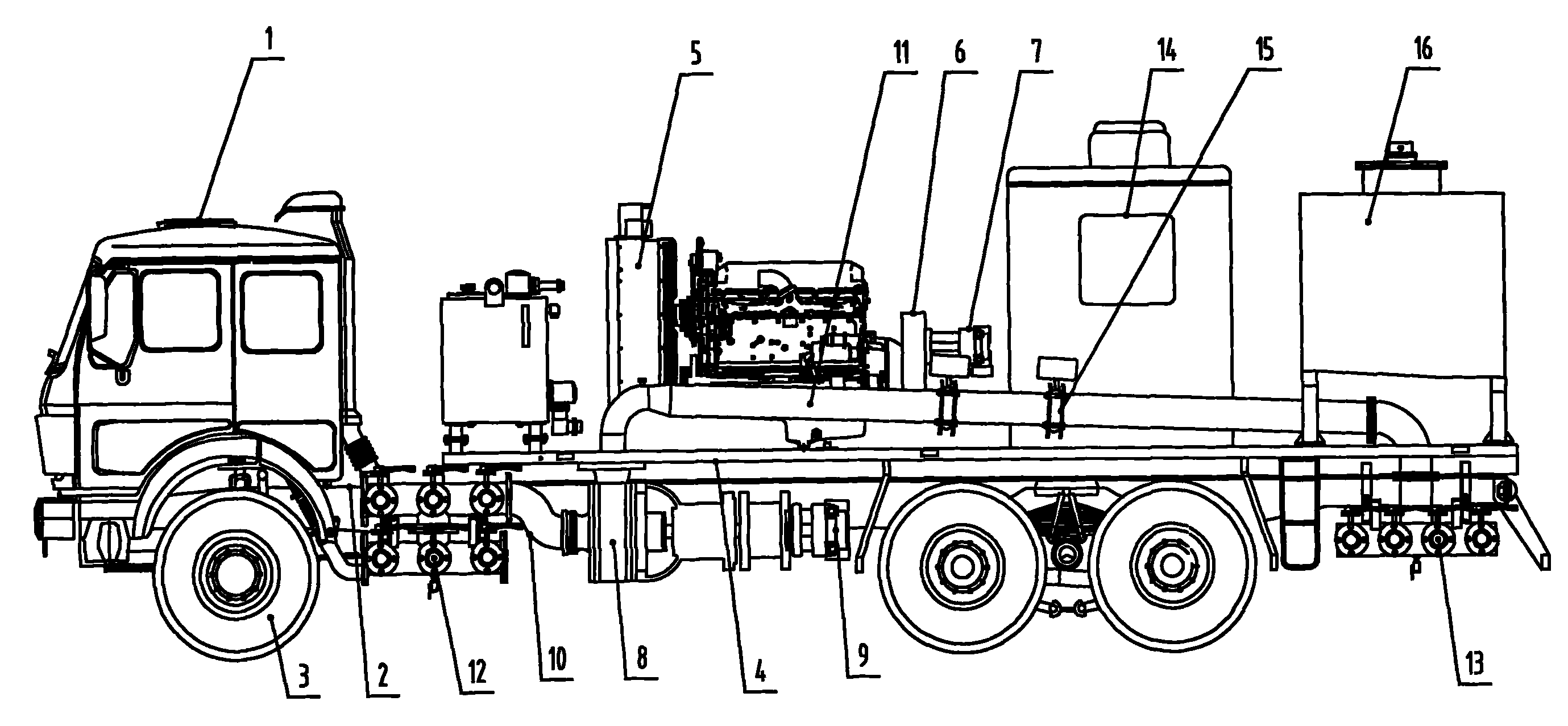

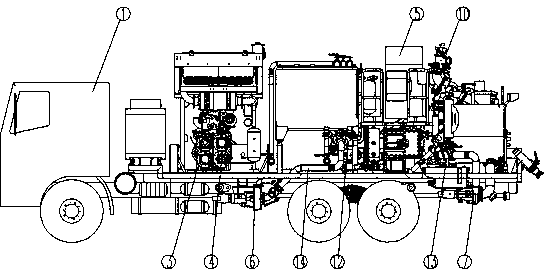

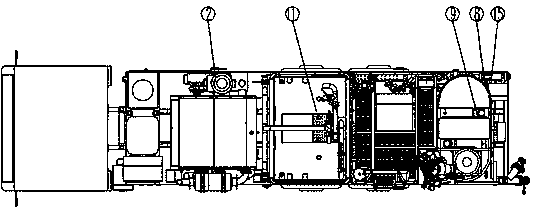

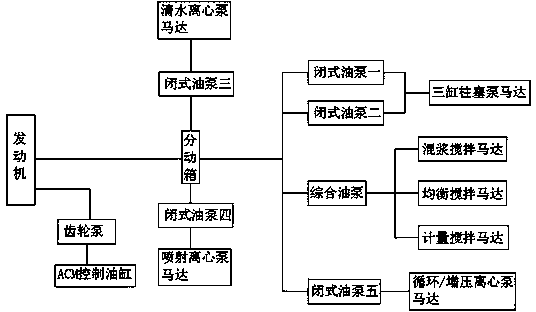

All-hydraulic well cementing truck

InactiveCN104005730AReduce volumeIncrease output powerItem transportation vehiclesSealing/packingHydraulic motorWell cementing

The invention belongs to the technical field of petroleum drill and exploitation, relates to a key device for well cementation operation, and in particular relates to an all-hydraulic well cementing truck. The all-hydraulic well cementing truck is characterized in that a ride engine is taken as a power source and a hydraulic system is used for driving a hydraulic motor so as to drive devices such as a high-pressure plunger pump to act. Compared with a traditional well cementing truck utilizing the ride engine and a torque converter as main power outputs, the all-hydraulic well cementing truck is simple in structure, more flexible in overall layout, novel and reasonable in design, low in cost and simple to control, and the all-hydraulic well cementing truck is wider in output flow range because the high-pressure plunger pump is capable of realizing stepless speed change; the all-hydraulic well cementing truck is capable of meeting the requirements of various different operations.

Owner:四机赛瓦石油钻采设备有限公司

Air conduit cleaning robot

InactiveCN110695024AGreat sporty tractionMeet different job requirementsHollow article cleaningControl systemElectric machinery

The invention discloses an air conduit cleaning robot which comprises supporting structures, keeping structures, a driving structure, a cleaning assembly and a control system. One end of each supporting structure is connected with one end of the corresponding keeping structure. The keeping structures are connected with the driving structure. The cleaning assembly is installed at the front end of the front supporting structure. The supporting structures, the keeping structures, the driving structure and the cleaning assembly are connected with the control system through a signal transmission unit. Motor drive screw nut mechanisms are adopted for the supporting structures, the keeping structures and the driving structure correspondingly so that the robot can walk and be supported in conduits. The cleaning assembly cleans the inner walls of the conduits, and the air conduit cleaning robot has large enough driving traction force, pipe diameter adaptability, elbow passage capacity and climbing capacity and can meet the cleaning requirements of various air conduits.

Owner:东莞市奇趣机器人科技有限公司

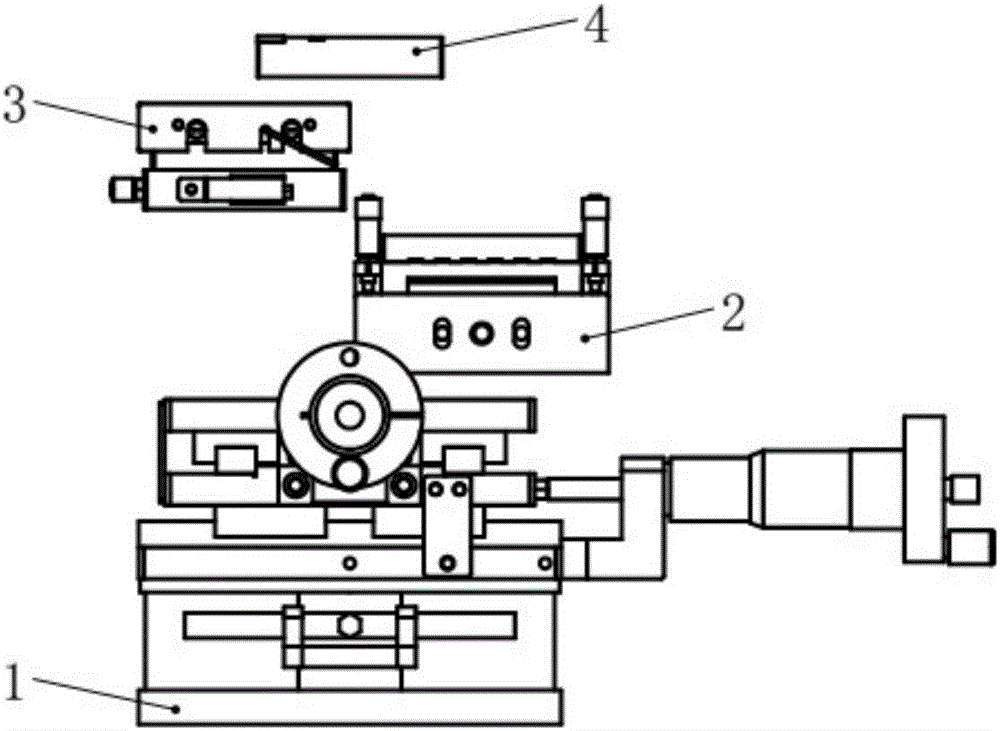

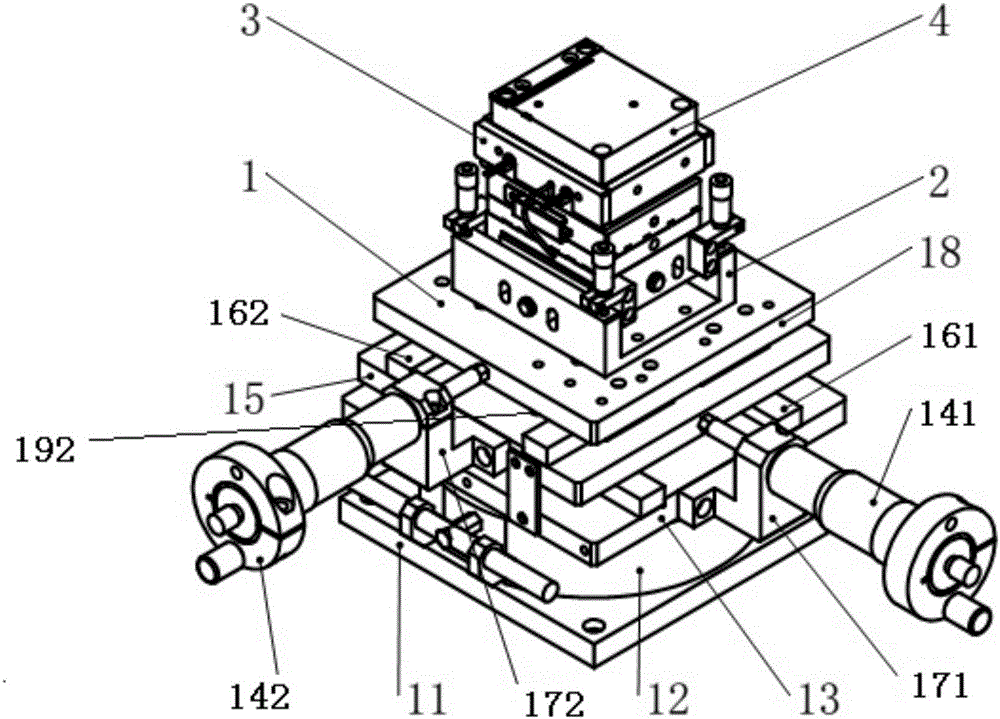

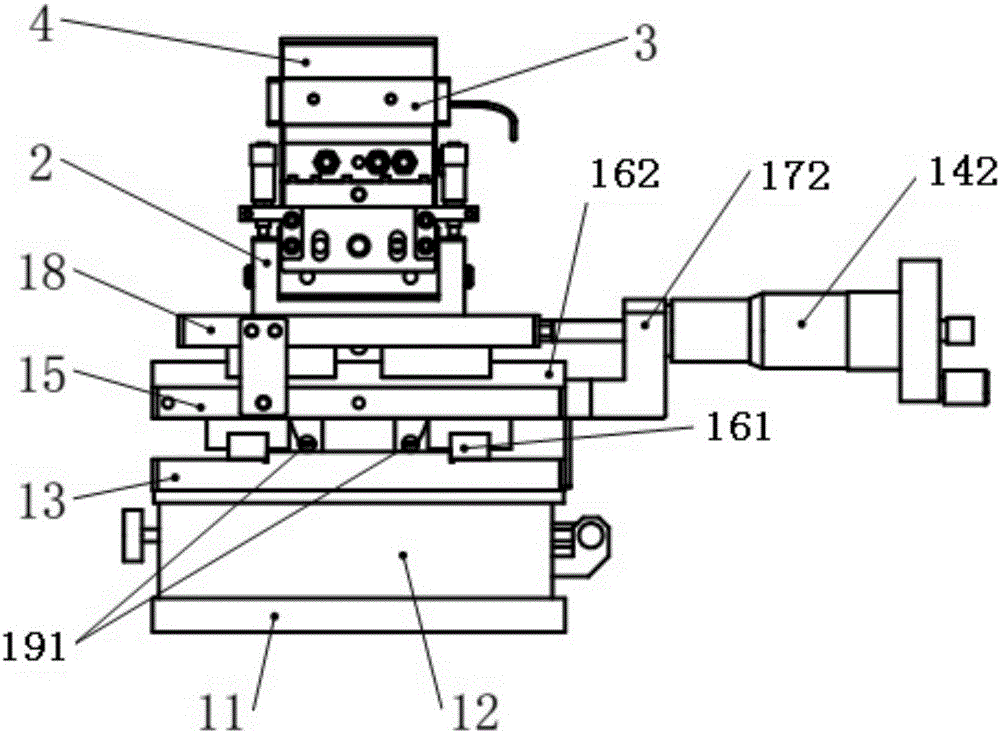

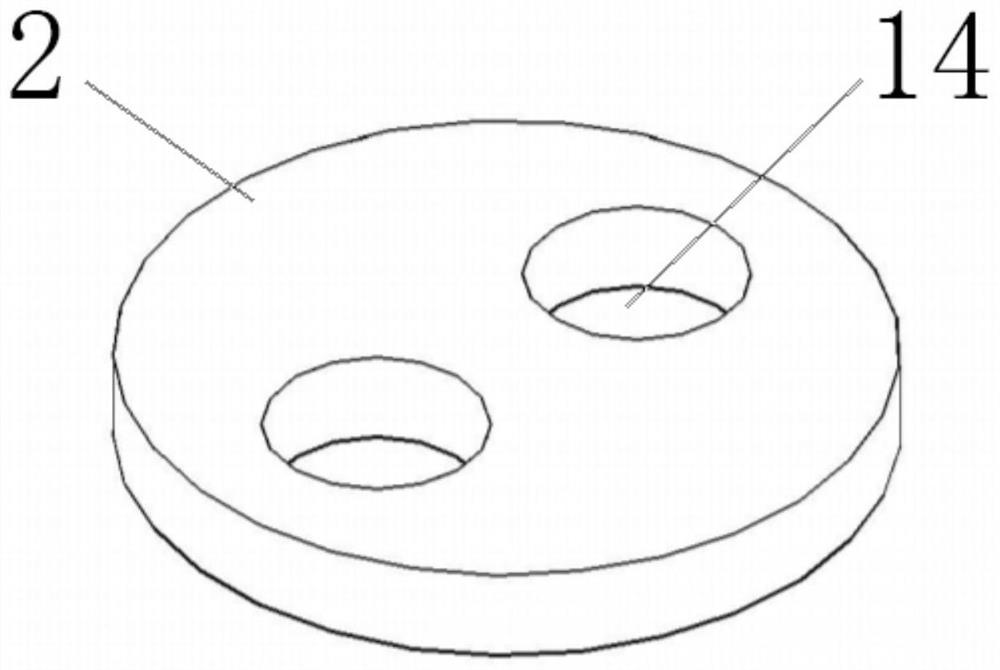

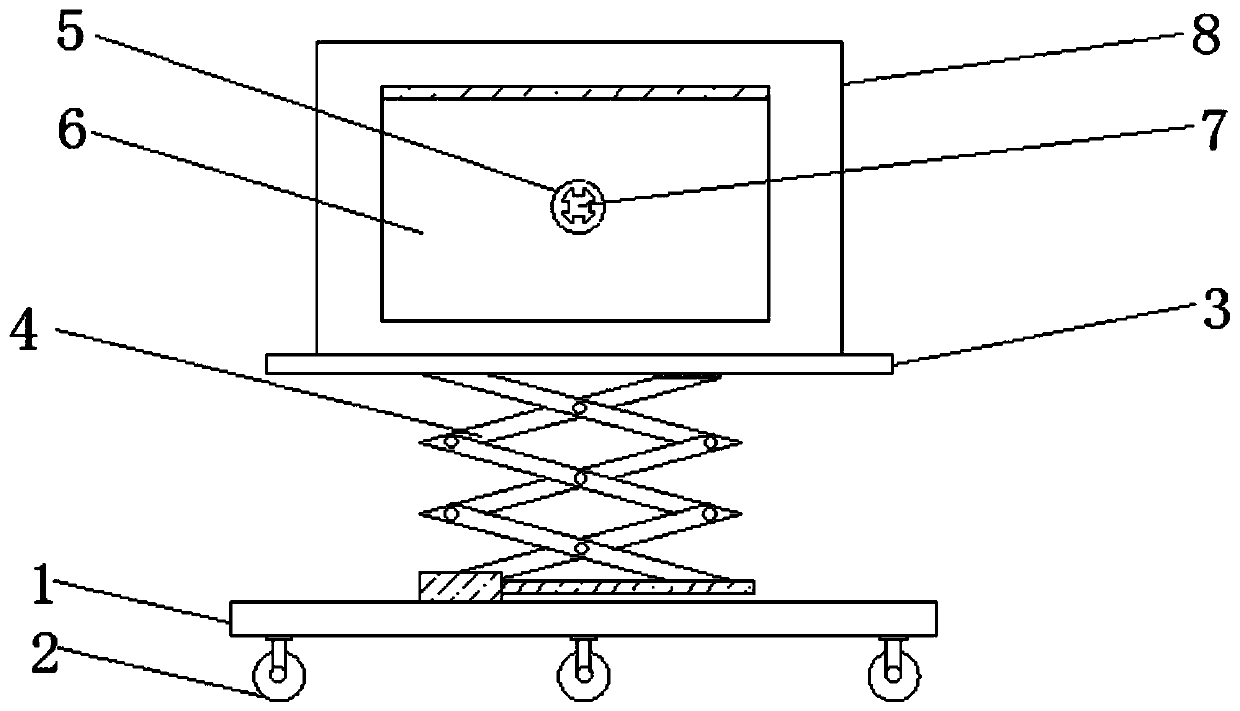

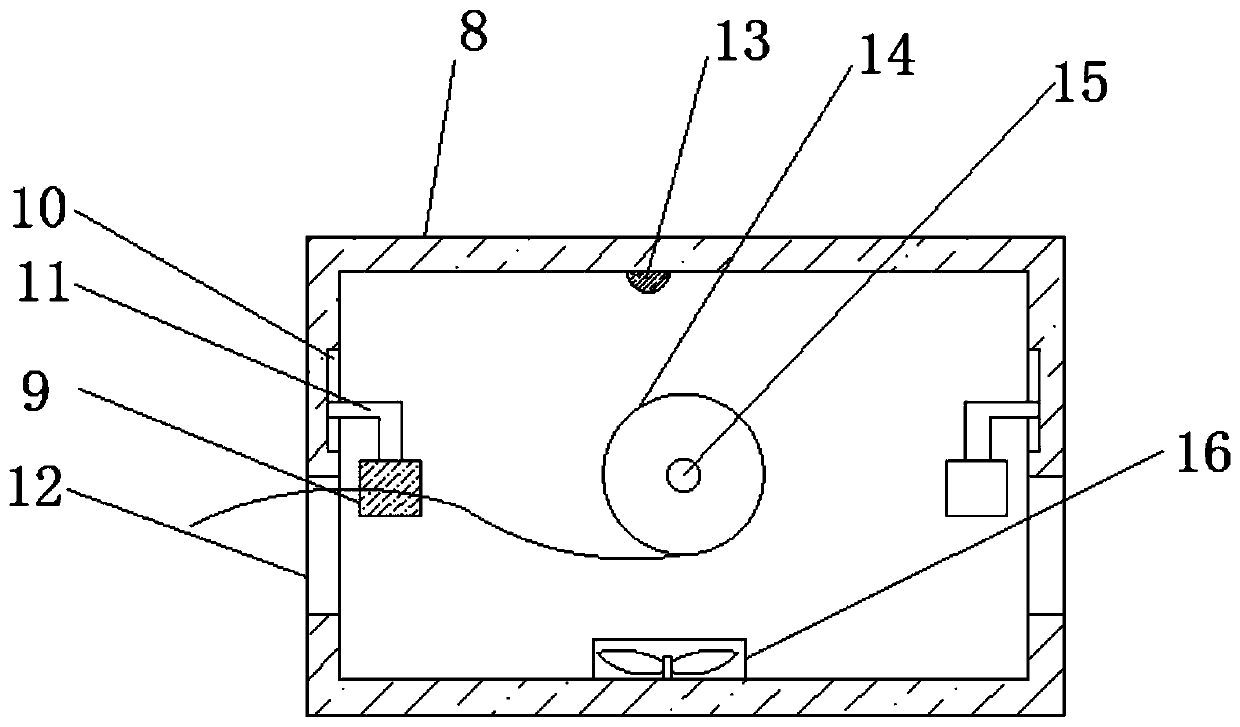

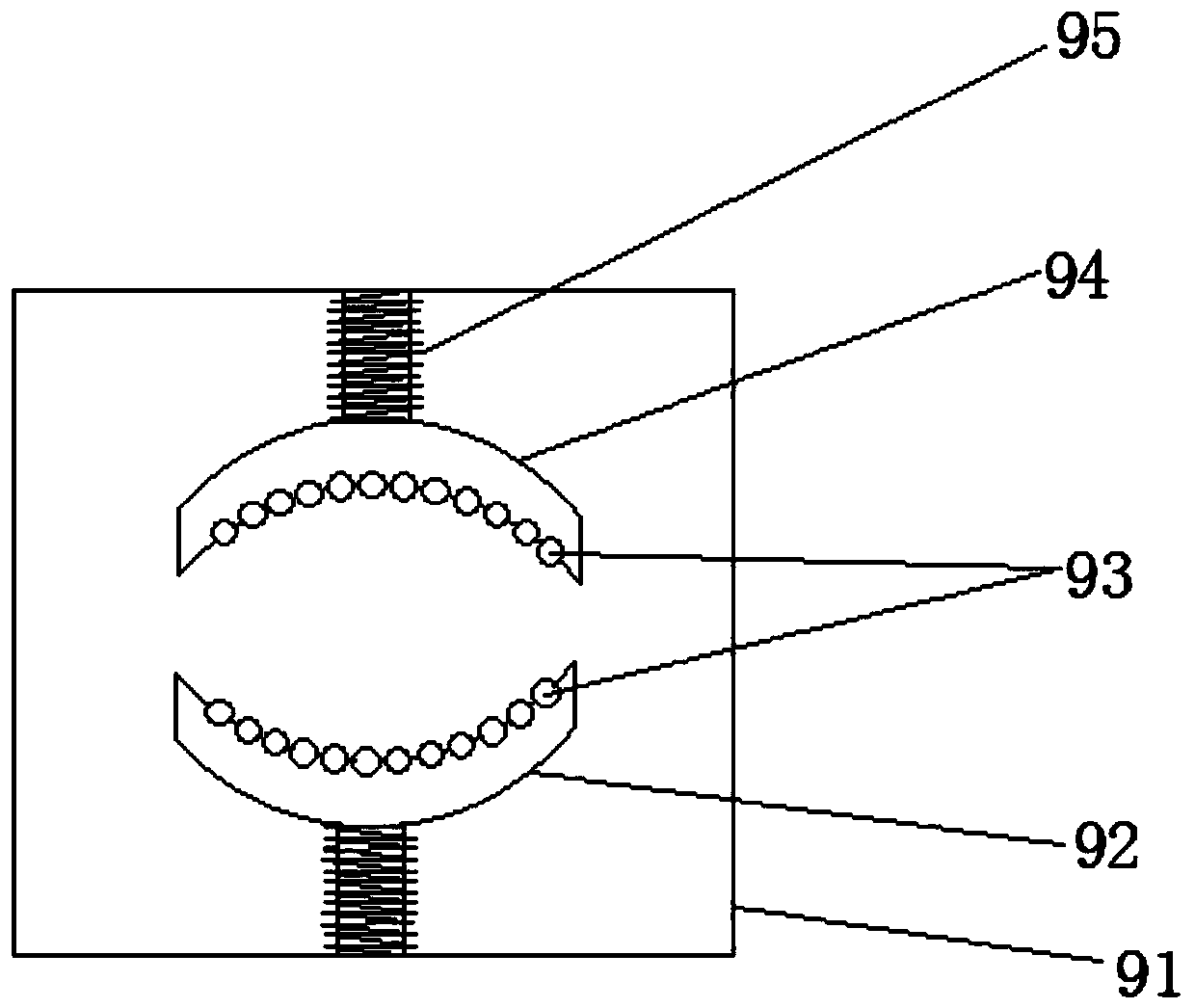

Modularly-design multi-functional heating table mechanism

ActiveCN105097572AImprove interactivityImprove interchangeabilitySemiconductor/solid-state device manufacturingState of artModularity

The invention relates to a modularly-designed multi-functional heating table mechanism which comprises a movement base table (1) and a jig (4), wherein the jig (4) is arranged on the movement base table (1), a workpiece matched with the jig (4) is placed on the jig (4), the movement base table (1) comprises a fixed bottom plate (11), a Theta-axis sliding table (12), a first carrying platform (13), a second carrying platform (15) and a third carrying platform (18), the Theta-axis sliding table (12) is arranged on the fixed bottom plate (11) and does Theta-direction rotation movement around a Z-axis, the first carrying platform (13), the second carrying platform (15) moving along a y-axis and the third carrying platform (18) moving along an x-axis are sequentially arranged on the Theta-axis sliding table (12) from bottom to top, during working, the Theta-axis sliding table (12), the second carrying platform (15) and the third carrying platform (18) are respectively adjusted, the jig (4) is moved onto an appointed station, and the workpiece on the jig is processed. Compared with the prior art, the modularly-designed multi-functional heating table mechanism has the advantages of multiple functions, high processing accuracy, low manufacturing cost and the like.

Owner:SHANGHAI WEISONG IND AUTOMATION

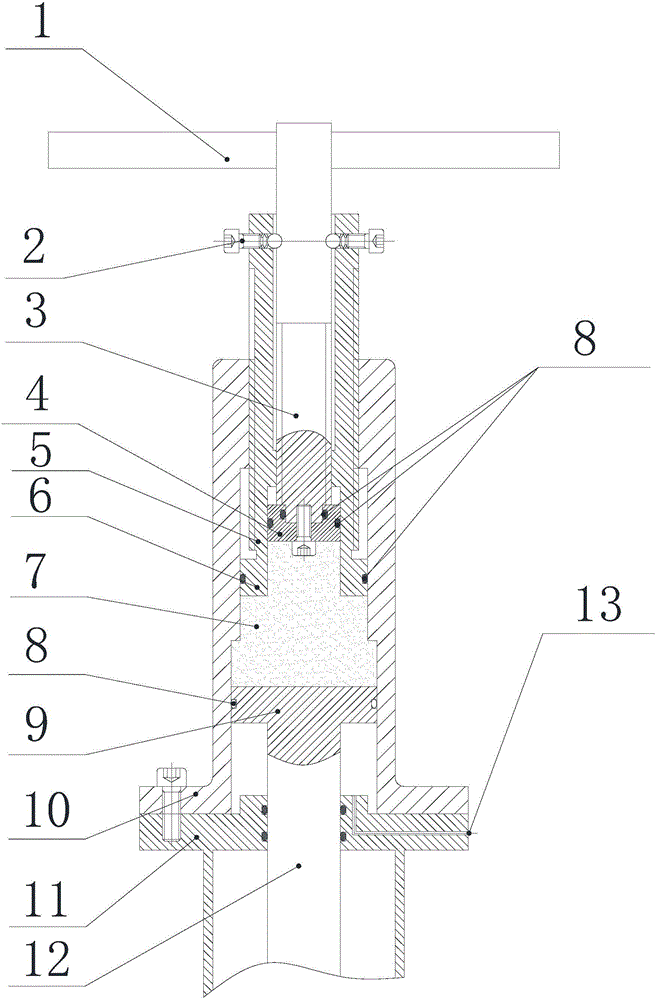

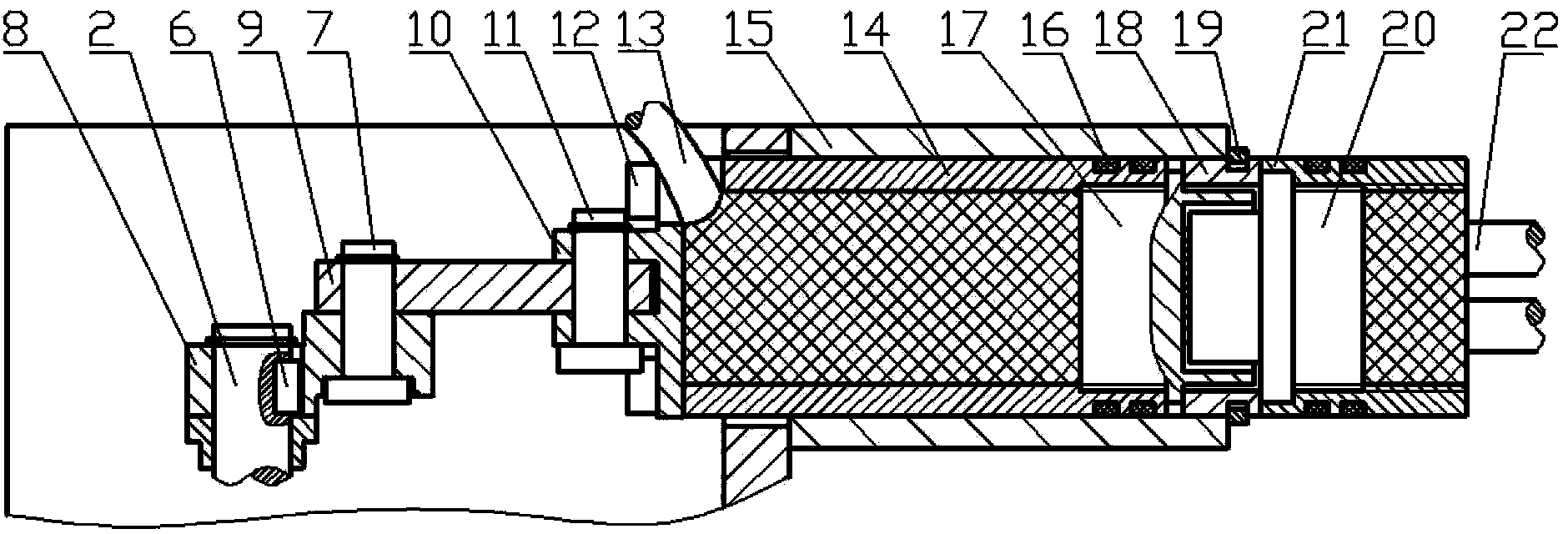

Valve hydraulic hand wheel

InactiveCN105090602AAchieve closureIncrease the bearing areaOperating means/releasing devices for valvesLiquid mediumHydraulic action

The invention provides a valve hydraulic hand wheel. The valve hydraulic hand wheel comprises a driving valve rod, a driven valve rod and a shell. One end of the driving valve rod is arranged in the shell, and the other end of the driving valve rod extends out of the shell. A driving valve rod piston is arranged at the end, arranged in the shell, of the driving valve rod. One end of the driven valve rod is arranged in the shell, and the other end of the driven valve rod extends out of the shell and is connected with a valve element of a valve. A driven valve rod piston is arranged at the end, arranged in the shell, of the driven valve rod. A liquid medium is sealed between the driving valve rod piston and the driven valve rod piston. The driving valve rod drives the driven valve rod to move through the hydraulic action of the liquid medium. The driven valve rod drives the valve element to move so that the valve can be opened or closed. The hydraulic mode is adopted in the valve hydraulic hand wheel, on the basis of the pascal law, the driving valve rod is driven to move, the liquid medium is pushed by the driving valve rod piston so that the pressure intensity can be generated in the liquid medium and the driven piston rod piston can be pushed, the driven valve rod drives the valve element to move, and the valve is opened or closed.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD +1

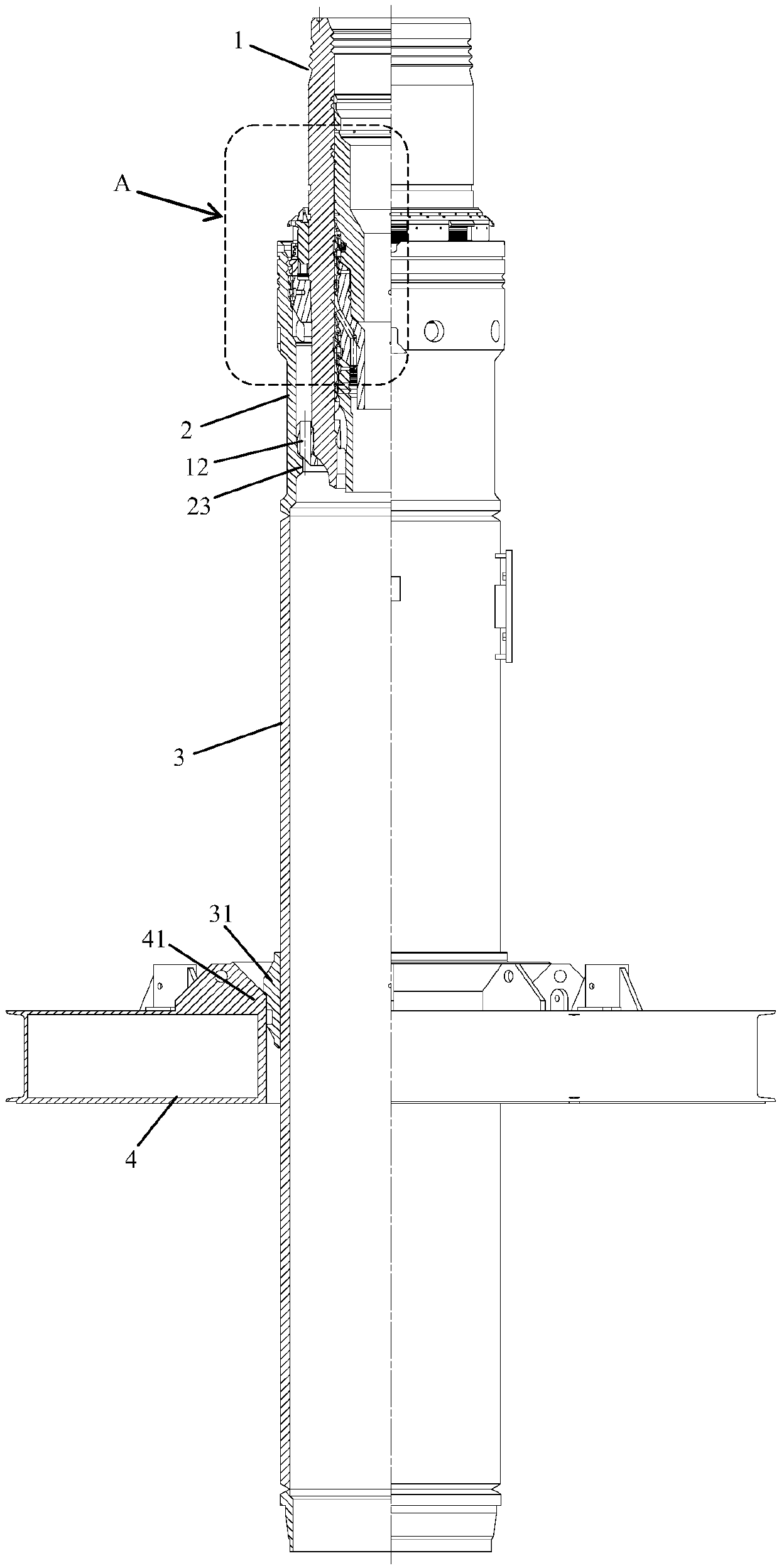

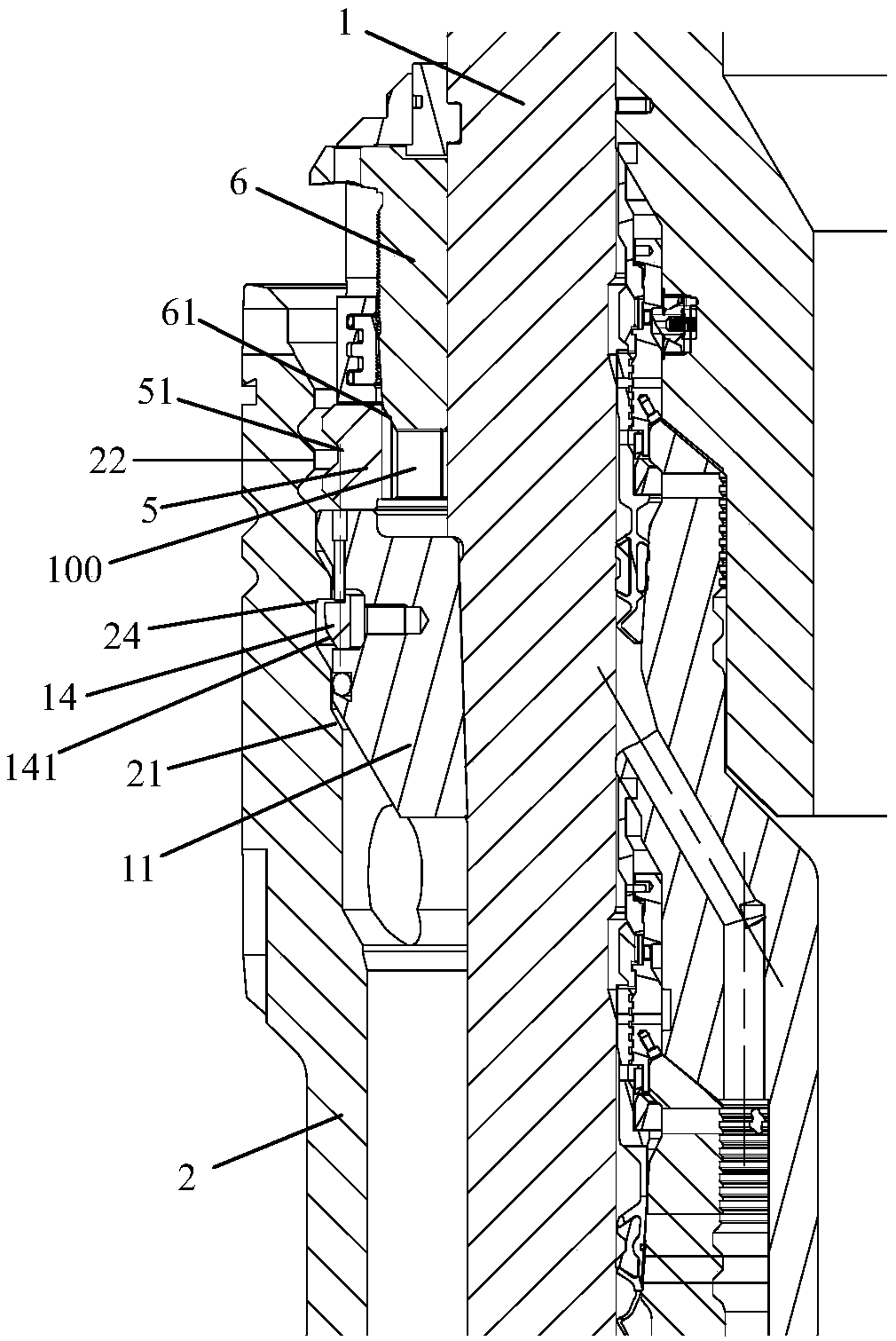

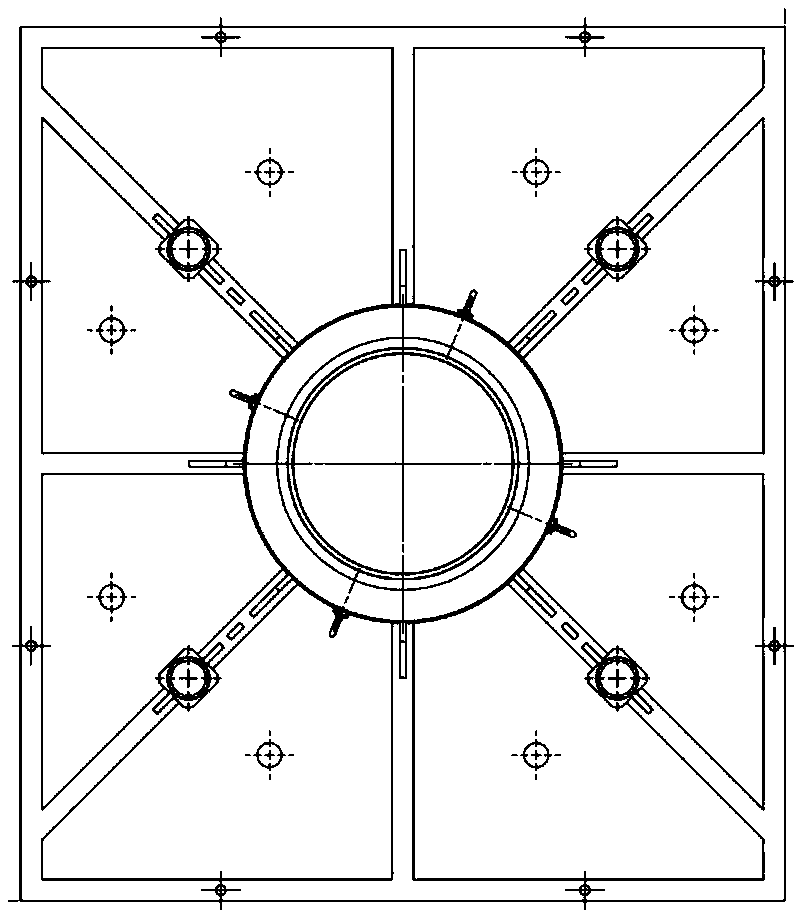

Underwater wellhead device special for deepwater gas field

InactiveCN109611050AFirmly connectedExtend your lifeSealing/packingStress distributionLocking mechanism

The invention discloses an underwater wellhead device special for a deepwater gas field. The underwater wellhead device special for the deepwater gas field comprises a high-pressure wellhead, a low-pressure wellhead and an extension sleeve connected to the low-pressure wellhead. A first bearing ring is arranged on the outer side wall of the high-pressure wellhead, and the high-pressure wellhead islapped on a first supporting part of the inner side wall of the low-pressure wellhead through the first bearing ring. A forced locking ring is arranged above the first bearing ring, a groove is formed in the radial outer side wall of the forced locking ring, a gap exists between the radial inner side wall of the forced locking ring and the outer side wall of the high-pressure wellhead, and an annular locking mechanism is wedged downward into the gap. By adopting the technical scheme, the high-pressure wellhead and the low-pressure wellhead can be locked together forcibly so as to strengthen the connection between the high-pressure wellhead and the low-pressure wellhead, the load transmission and stress distribution are improved, and the service life of the high-pressure wellhead and the service life of the low-pressure wellhead are prolonged.

Owner:CHINA NAT OFFSHORE OIL CORP +1

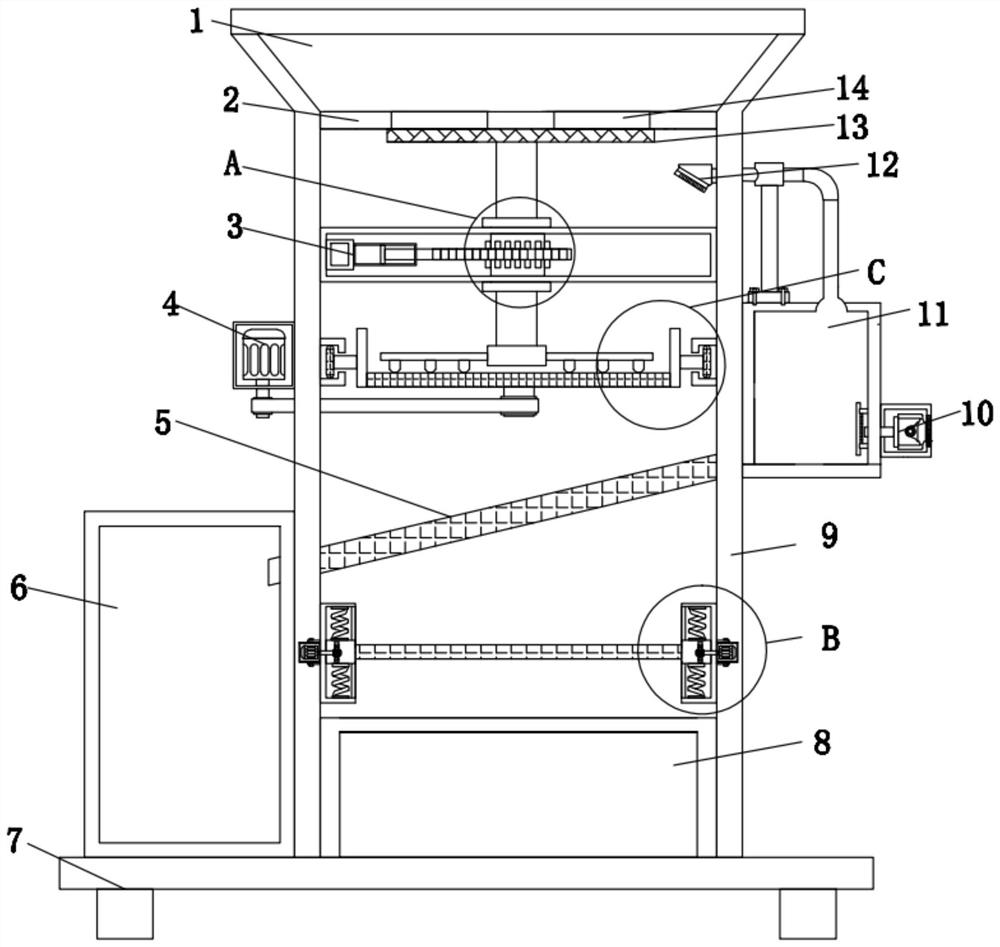

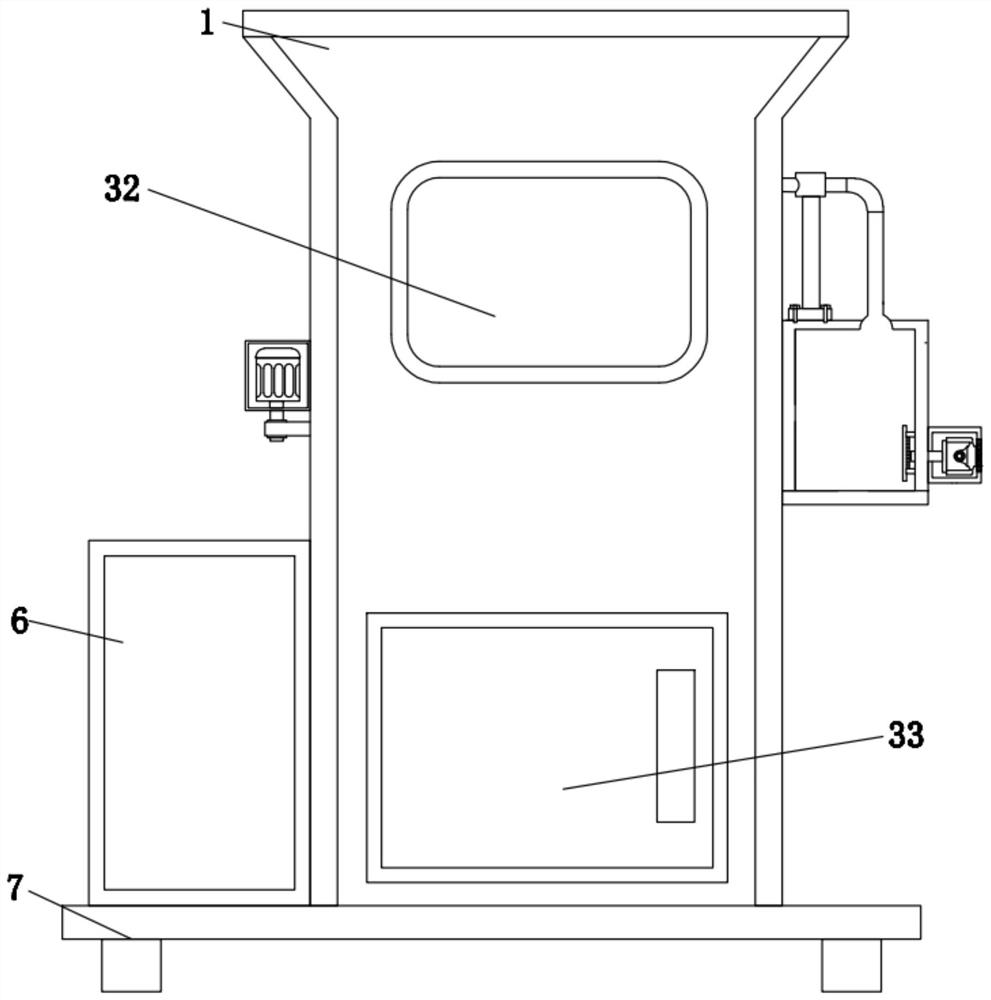

Novel sand screening device for constructional engineering

InactiveCN111672738AAvoid accumulationSpeed up sievingSievingGas current separationGear wheelMechanics

The invention discloses a novel sand screening device for constructional engineering. The device comprises a sand inlet groove, a screening plate, a bottom plate and a shell, wherein the shell is arranged at the top of the bottom plate, a mounting frame is transversely arranged at the upper end of the inner wall of the shell, a mounting shaft is vertically arranged in the center of the mounting frame, a second gear is arranged in the position, on the outer side of the mounting shaft, in the mounting frame, an electric piston rod is arranged on one side of the interior of the mounting frame, asecond rack matched with the second gear is transversely arranged at the output end of the electric piston rod, the top end of the mounting shaft extends to the outer side of the mounting frame and isprovided with a striker plate, a mounting plate is fixedly connected to the position, above the striker plate, of the inner wall of the shell, and the sand inlet groove is formed in the top end of the shell. According to the device, through ingenious structural design, intermittent falling is achieved, a transverse rod and a protruding strip can be driven to stir back and forth, sand accumulationis effectively prevented, and meanwhile, sand screening can be accelerated, and the working efficiency is improved.

Owner:覃报

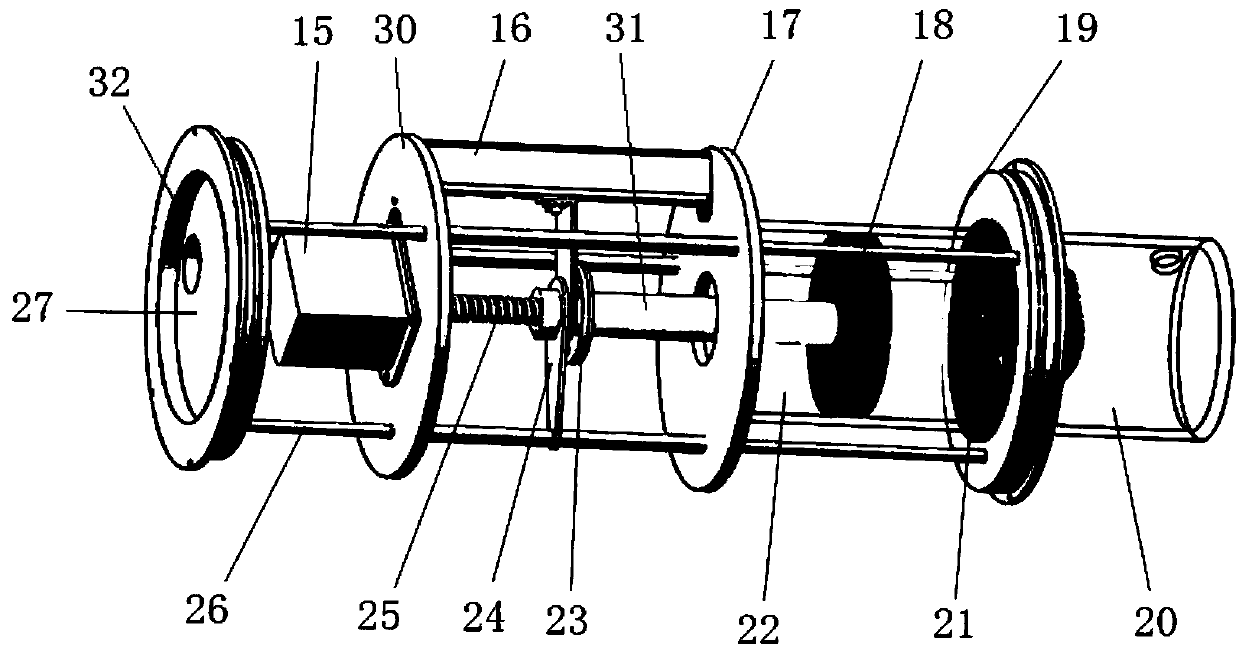

Frame for taking up and paying off cables

PendingCN109775480AChange the retracting angleMeet different job requirementsEngineeringSelf locking

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

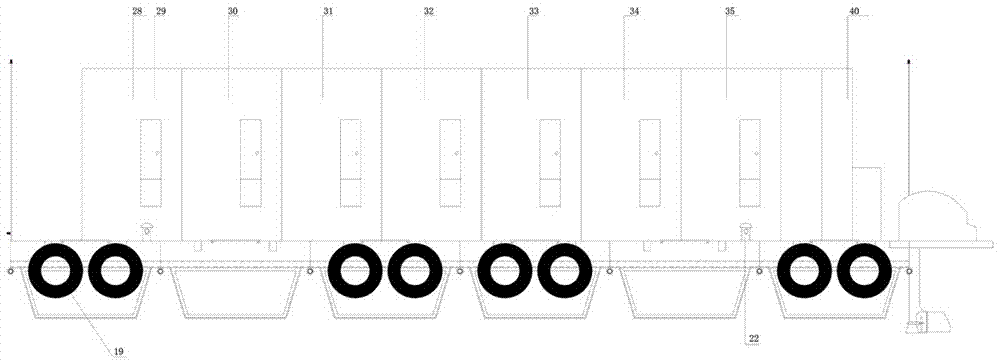

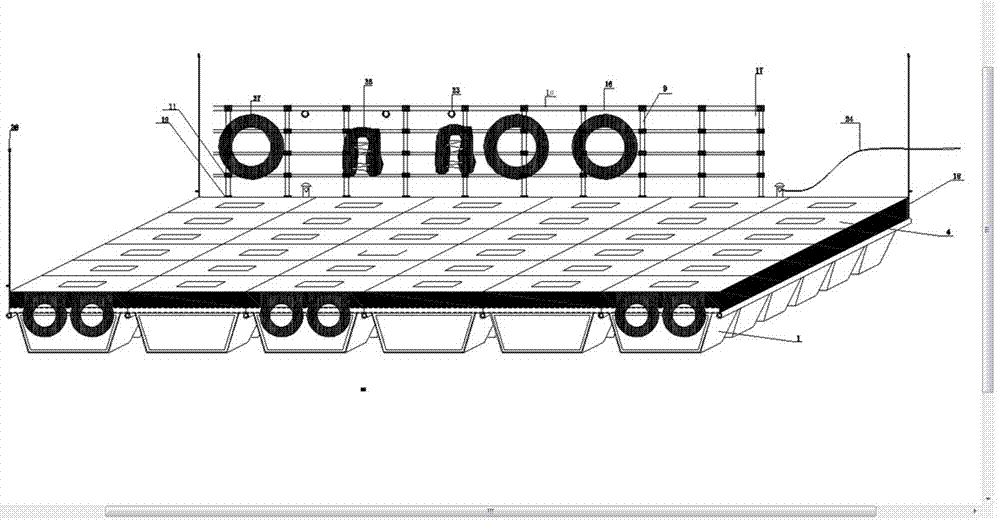

Combined type water working platform

The invention relates to a combined type water working platform. The combined type water working platform comprises a power and control system and a traction and fixing device and comprises a floating body cabin, cabin cover decks, fixing rods and a guardrail; the floating body cabin is a combined type floating body cabin; the cabin cover decks are mounted on the upper surface of the floating body cabin; deck planes are formed at the upper part of the combined type floating body cabin; fixing rod inserting holes are formed in the bottom, at four edges, of the cabin cover decks; the adjacent cabin cover decks are connected with each other through the fixing rods; guardrail upright inserting holes and cabin cover plates are arranged at the upper parts of the cabin cover decks; the guardrail is a combined type guardrail and comprises uprights, cross rods and guardrail doors; fastening screws and sockets are arranged on the cross rods; the adjacent cross rods are connected with each other through the sockets; the uprights are connected with the cross rods through the fastening screws; the uprights at the bottom are inserted into the guardrail upright inserting holes; and the guardrail doors sleeve the side surfaces of the uprights. The combined type water working platform has the advantages of modularization, reliable connection, light weight, small volume of the combined and folded platform, small storage space, corrosion resistance, wear resistance and high safety.

Owner:辽宁华三建设工程技术有限公司

Multi-station spring detection test bed

PendingCN110160769AEasy to controlImprove work efficiencyMachine part testingEngineeringTorsion spring

The invention discloses a multi-station spring detection test bed. The test bed comprises a rack, a detection table is erected on the rack, and a tension spring detection station, a pressure spring detection station and a torsion spring detection station are sequentially arranged on the detection table, wherein the tension spring detection station comprises an upper pull plate and a lower pull plate which move up and down, upright posts which are mutually corresponding and used for hanging two ends of a spring are respectively arranged on the corresponding end surfaces of the upper pull plateand the lower pull plate, and hanging holes are respectively arranged at the end parts of the upright posts; the pressure spring detection station comprises an upper pressure plate and a lower pressure plate which move up and down, the corresponding end surfaces of the upper pressure plate and the lower pressure plate are respectively provided with an upper spring clamping seat and a lower springclamping seat which are correspondingly matched with each other, and the upper spring clamping seat and the lower spring clamping seat are respectively provided with a clamping hole which is corresponding to each other; and the torsion spring detection station comprises a torsion spring clamping plate, and clamping grooves which are radially arranged and used for clamping springs are distributed on the torsion spring clamping plate. The multi-station spring detection test bed has the advantages of convenience in control, high working efficiency, capability of simultaneously realizing online work of tension, pressure and torsion, stability in work and the like.

Owner:HEFEI HEAN MACHINERY MFG

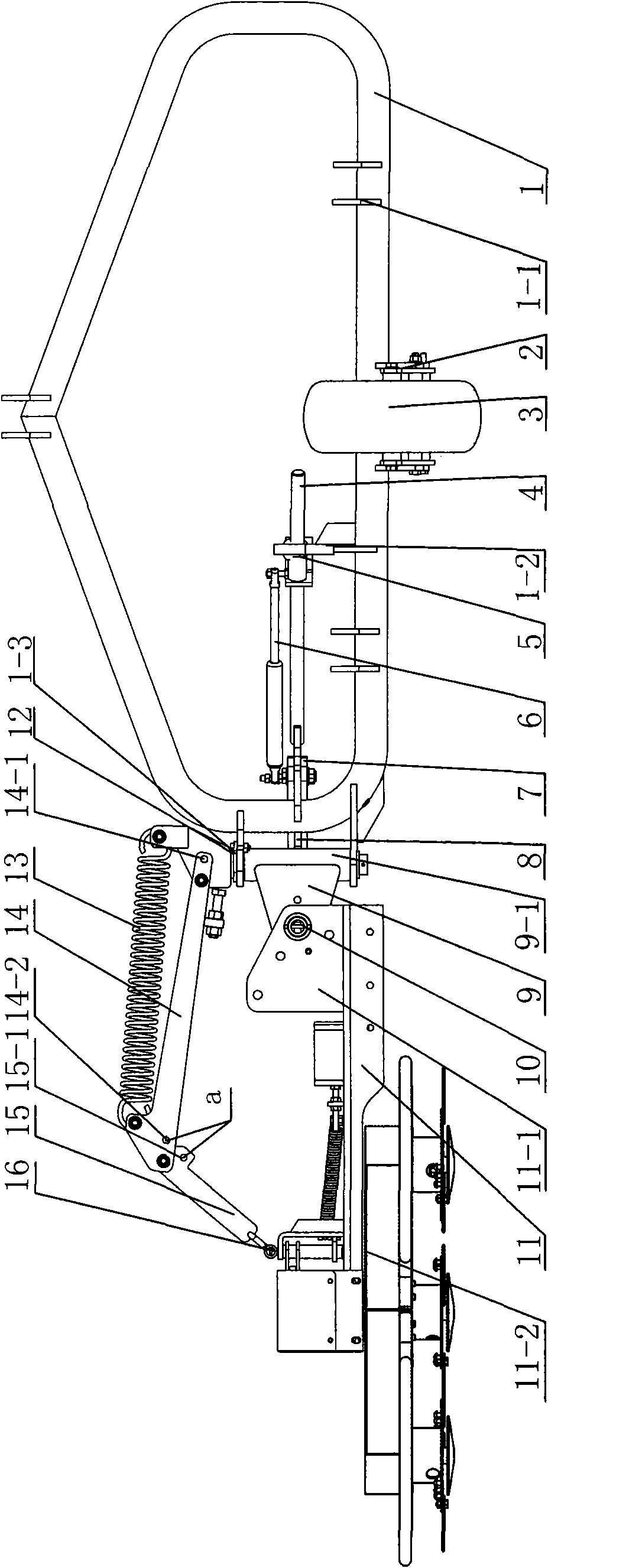

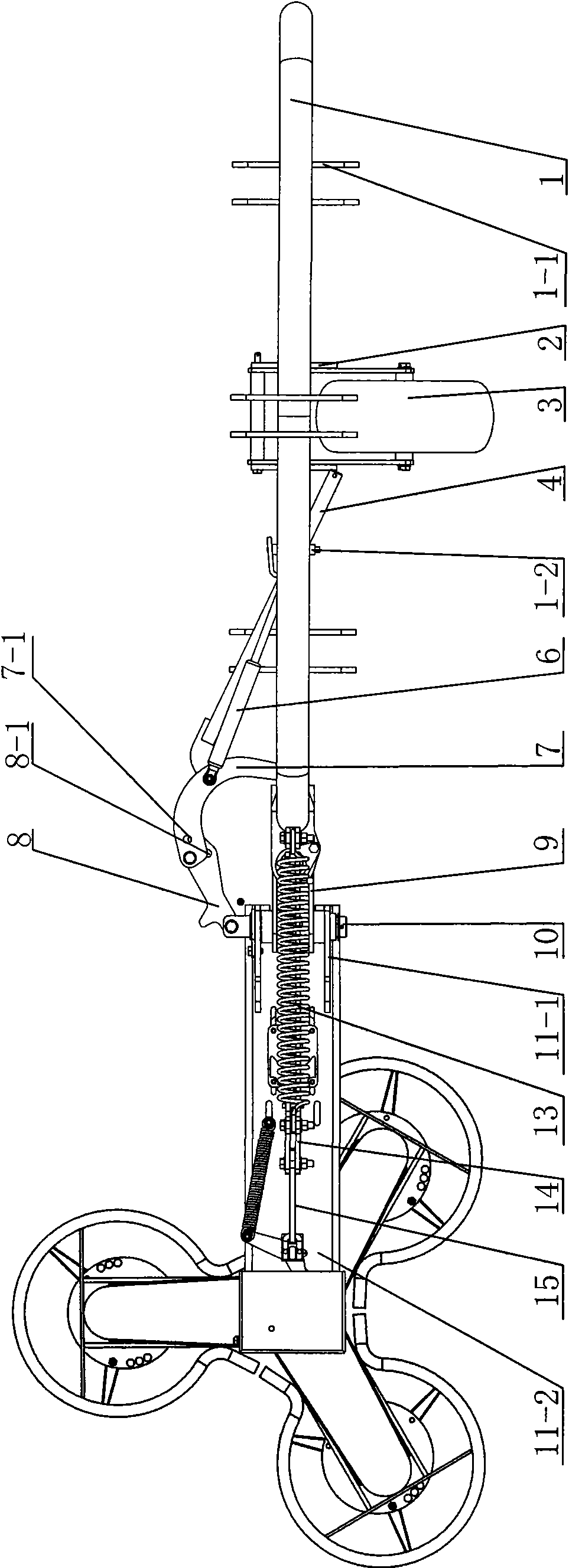

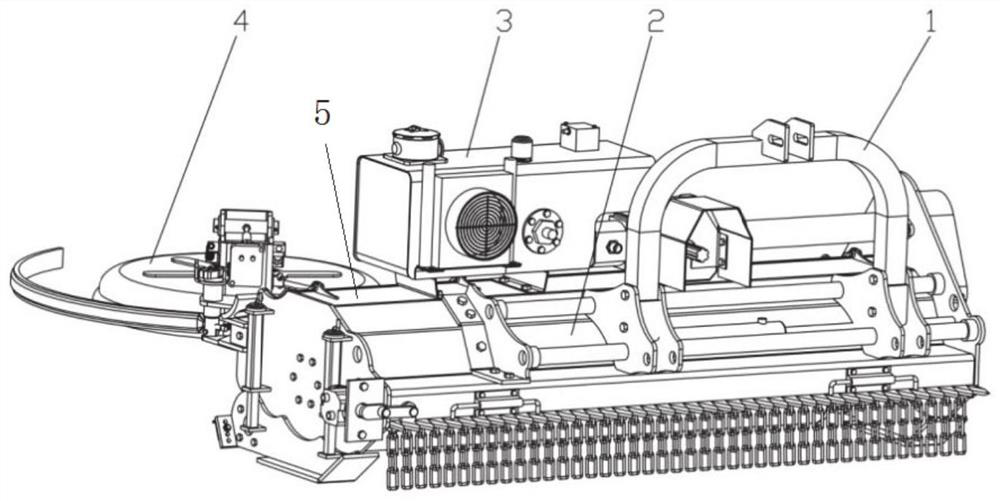

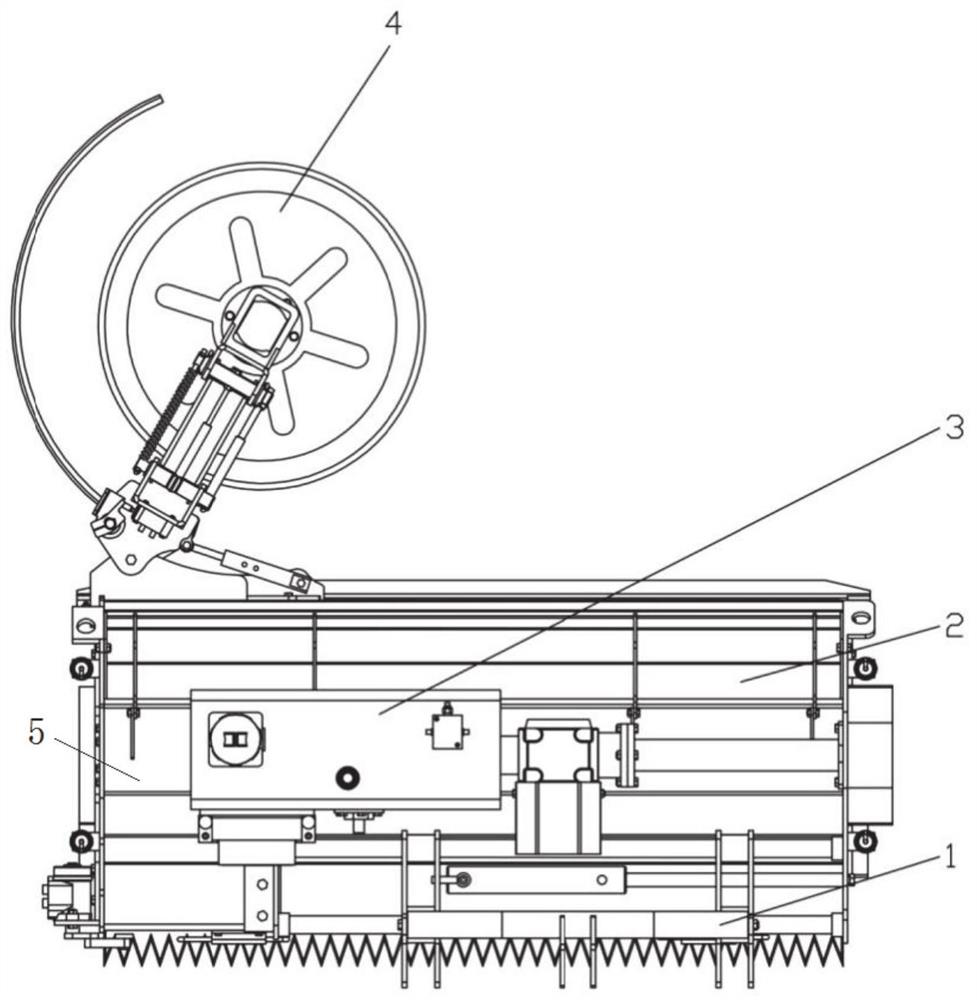

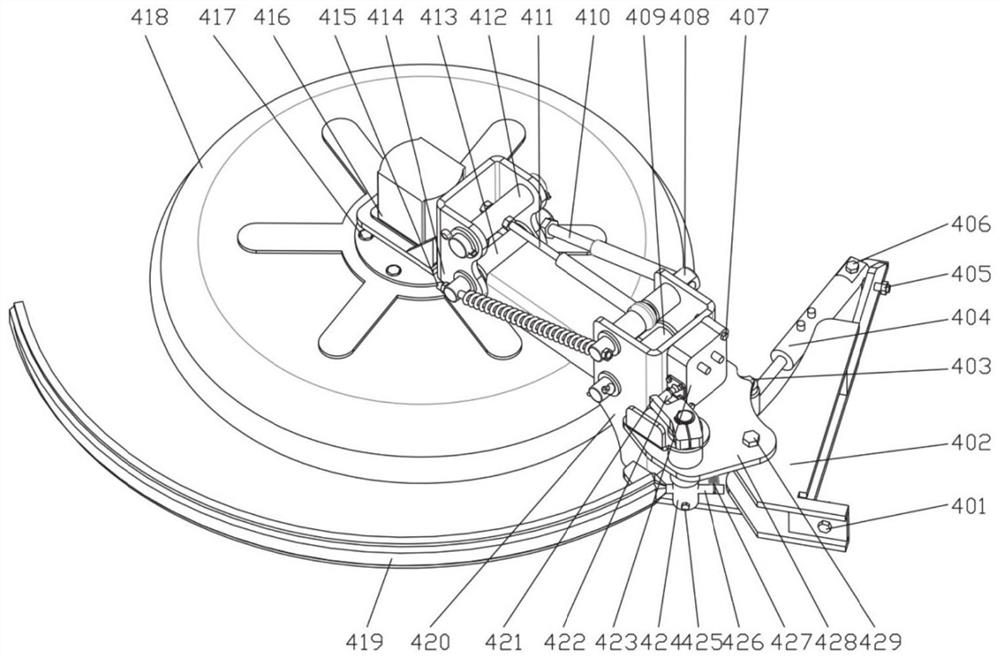

Cross runout device of grass cutter

ActiveCN101548611AImprove mobilityImprove work efficiencyLawn-mowersAgricultural undercarriagesVertical tubeSpherical joint

The invention relates to a cross runout device of a grass cutter, wherein one side of a suspension bracket is fixed with a vertical pipe; a vertical shaft and the teleflex of a support saddle are vertically installed on the vertical pipe; a connecting seat of the machine body is hinged on the support saddle through a lateral pin; a swing mechanism comprises a first connecting rod, a guide bar and a horizontal driving piece; two ends of the first connecting rod which is positioned outside the support saddle are respectively hinged on the lateral pin and the suspension bracket; the guide bar and one end of the horizontal driving piece are hinged on the first connecting rod; the other end of the horizontal driving piece is connected with the guide bar; the guide bar is connected with the suspension bracket through a spherical joint; a deflection mechanism comprises a front connecting rod of the machine body, a back connecting rod of the machine body, and a deflection driving piece; the front connecting rod of the machine body and the back connecting rod of the machine body which are hinged are respectively hinged on the machine body and the vertical shaft; and the deflection driving piece arranged at the upper part of the back connecting rod of the machine body is respectively connected with the back connecting rod of the machine body and the vertical shaft. Under the situation that a tractor is fixed by trifilar suspension, the cross runout device can conveniently change the working width of the grass cutter, lead the grass cutter to deflect and tilt, and realize multiaspect cutting operation.

Owner:常州汉森机械股份有限公司

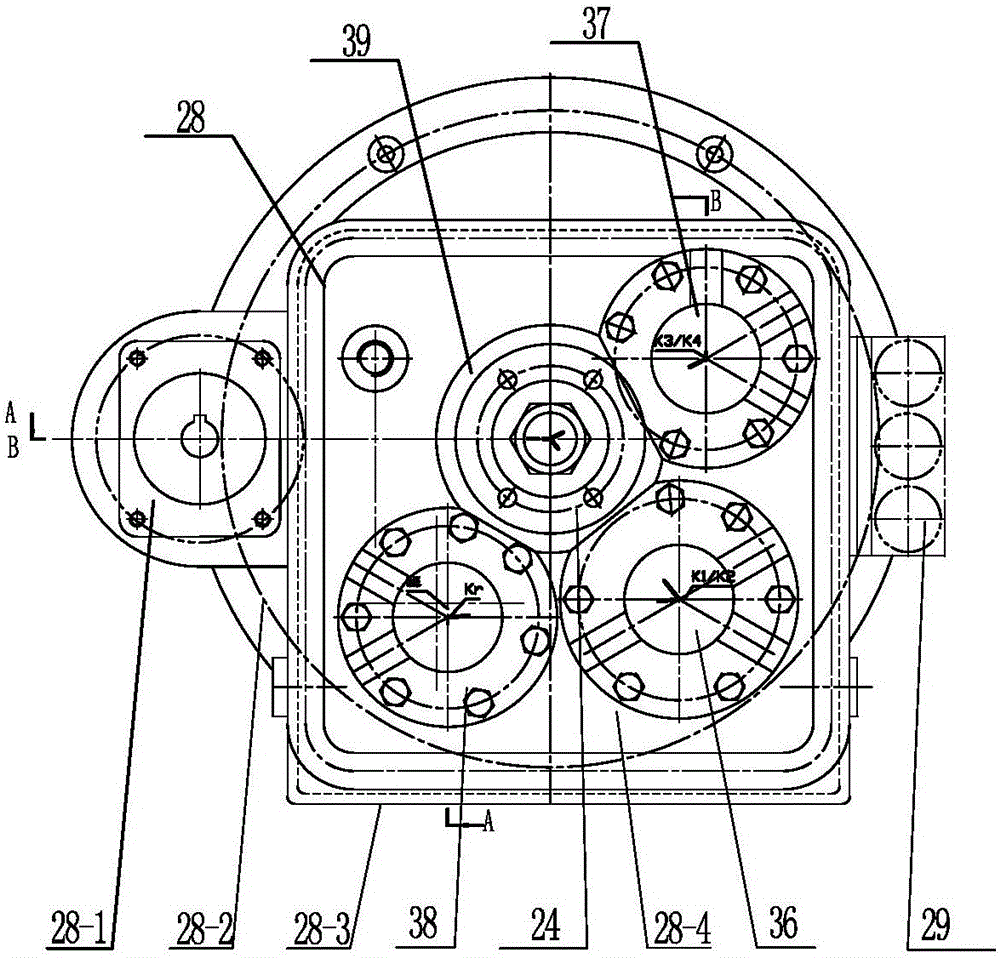

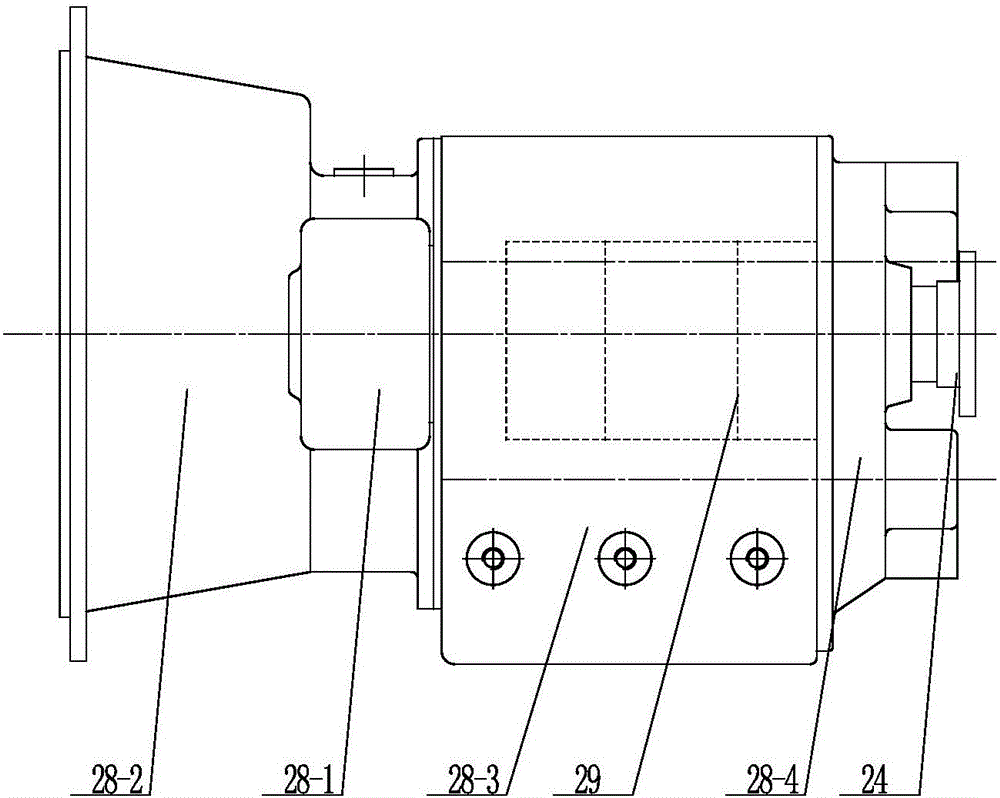

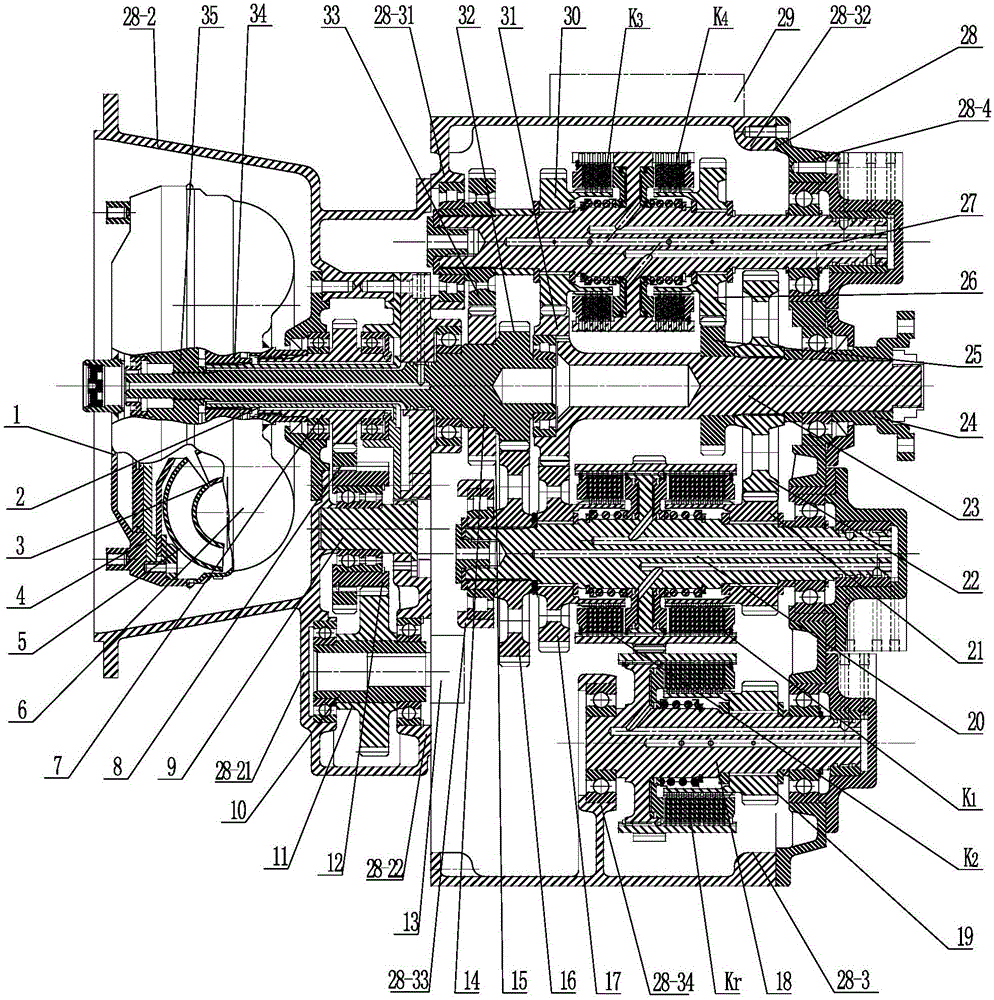

Hydrodynamic transmission for light vehicle

PendingCN106678326AMeet different working conditionsAdjustable speed ratioFluid gearingsGearing detailsPower take-offClutch

The invention relates to a hydrodynamic transmission for a light vehicle. An oil pump driving sleeve and a supporting shaft are installed on a box body; an oil pump arranged in the box body is connected with the oil pump driving sleeve; a power take-off window is formed in the position, at the horizontal part of an input shaft, of the box body; a connection gear arranged on a guide wheel base in a sleeving mode is engaged with an oil pump connection gear arranged on the pump driving sleeve through two power takeoff gears on the supporting shaft; a first shaft and a second shaft are each provided with a wet clutch and a corresponding driving gear; driven gears installed on the first shaft and the second shaft are engaged with two input gears of the input shaft correspondingly; all driving gears on the first shaft and the second shaft are engaged with an output shaft gear, a high-gear output gear and a low-gear output gear on an output shaft correspondingly; and a reverse-gear clutch Kr and a reverse-gear driving gear on a reverse-gear shaft are engaged with the wet clutch on the first shaft and the low-gear output gear correspondingly, and are matched with a lockup clutch, so that output with six forward gears and one reverse gear is achieved. The hydrodynamic transmission is ingenious and compact in structure and flexible in operation, has the multiple gears, and can adapt to different working conditions of the light vehicle.

Owner:邓亚民

Ultrahigh-pressure water jet spraying device

PendingCN108247910AEasy to installEasy to usePlastic recyclingGrain treatmentsElectric energyWater jet

The invention relates to the technical field of water jet spraying equipment, in particular to an ultrahigh-pressure water jet spraying device. The ultrahigh-pressure water jet spraying device comprises a fixed base, a high-pressure water inlet mechanism, a gas pressure mechanism, a high-pressure water outlet mechanism and a sealing plate mechanism, wherein the high-pressure water inlet mechanismis arranged on the fixed base; the gas pressure mechanism is arranged on the fixed base and arranged beside the high-pressure water inlet mechanism; the high-pressure water outlet mechanism is arranged at the lower end of the fixed base; the sealing plate mechanism is detachably arranged on the fixed base. The ultrahigh-pressure water jet spraying device improves the tyre cracking efficiency, reduces consumption of electric energy, can adjust the thickness of water jet, the size of rotating gas pressure, and the quantity of a cutter head water outlets, can meet different operation requirementsand has the characteristics of being convenient to mount and use, and the like.

Owner:DONGGUAN BINGNENG RUBBER CO LTD +1

Pull-out type glass kiln flue gas dust removal device and application

InactiveCN111330377ASmall and portableImprove work efficiencyGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention relates to a pull-out type glass kiln flue gas dust removal device and application. The invention belongs to the technical field of glass production. The device comprises a flue, a grid,a transmission frame, transmission wheels, a transmission chain and a motor, wherein a reverser and a main gate plate are arranged on the flue; between the reverser and the main gate plate, an opening is formed in the position, 0.5-1 m away from the reverser, of the upper portion of the flue; slots are formed in two sides of an opening of the flue; the grid is inserted into the flue through the opening; a corresponding rectangular ash collecting pit is dug in the bottom of the flue on the lower side of the grid; an ash digging pit is formed in one side of the flue and communicated with the ash collecting pit; the transmission frame is installed above the opening of the flue, the transmission frame is a cuboid frame, a plurality of cross beams are arranged on the upper side of the transmission frame, motors are installed on the cross beams, output shafts of the motors are connected to transmission wheels, and the transmission wheels are connected to the grid through transmission chains. According to the invention, the grid is arranged in the flue to perform pre-dedusting on the flue gas before the flue gas enters a desulfurization and denitrification device, so that the purpose ofreducing solid particles carried in the flue gas is achieved, the working efficiency of cloth bag dedusting, desulfurization, denitrification and other flue gas subsequent treatment devices is improved, and the service lifetime of the cloth bag dedusting, desulfurization, denitrification and other flue gas subsequent treatment devices is prolonged.

Owner:QILU UNIV OF TECH

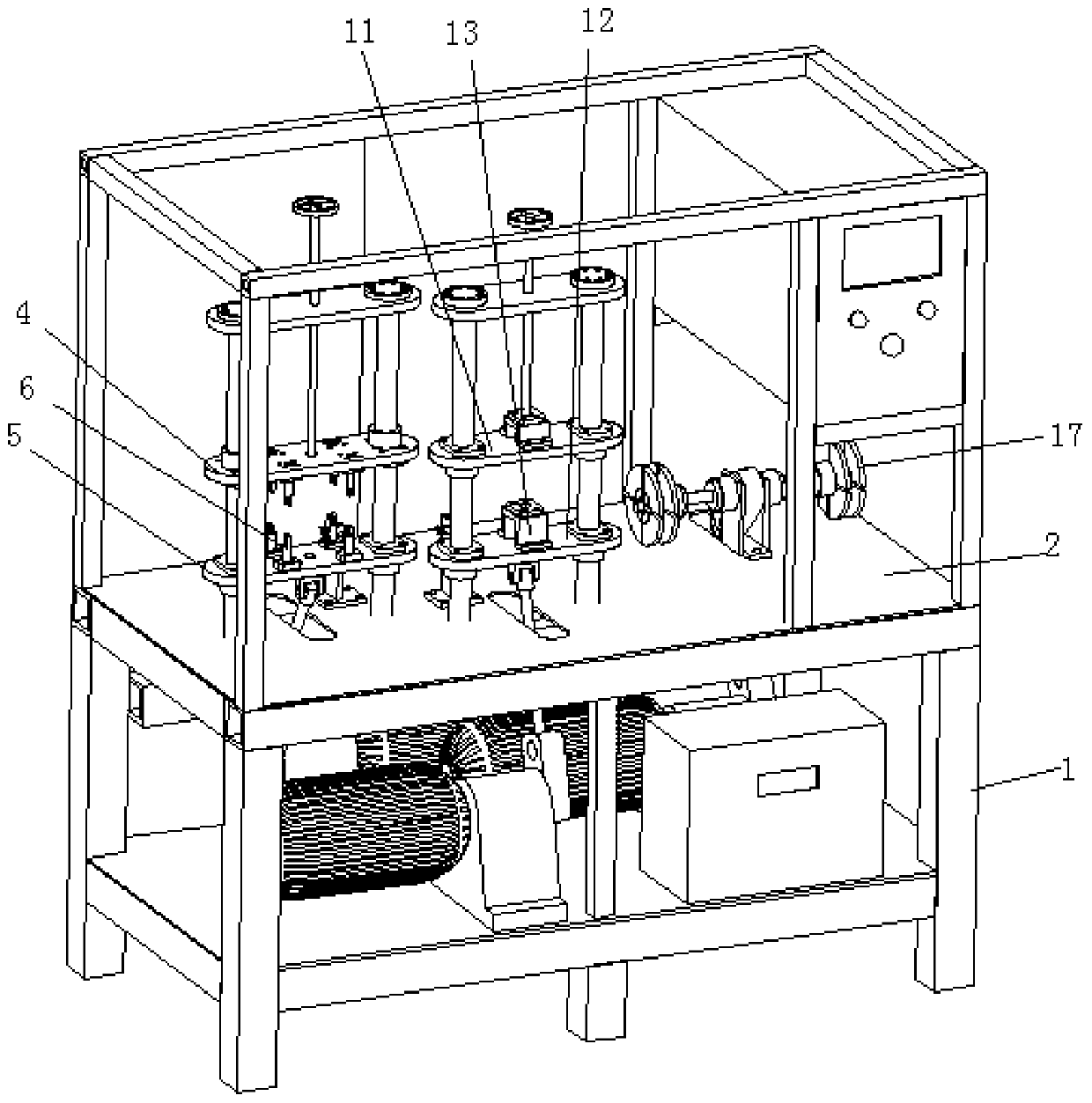

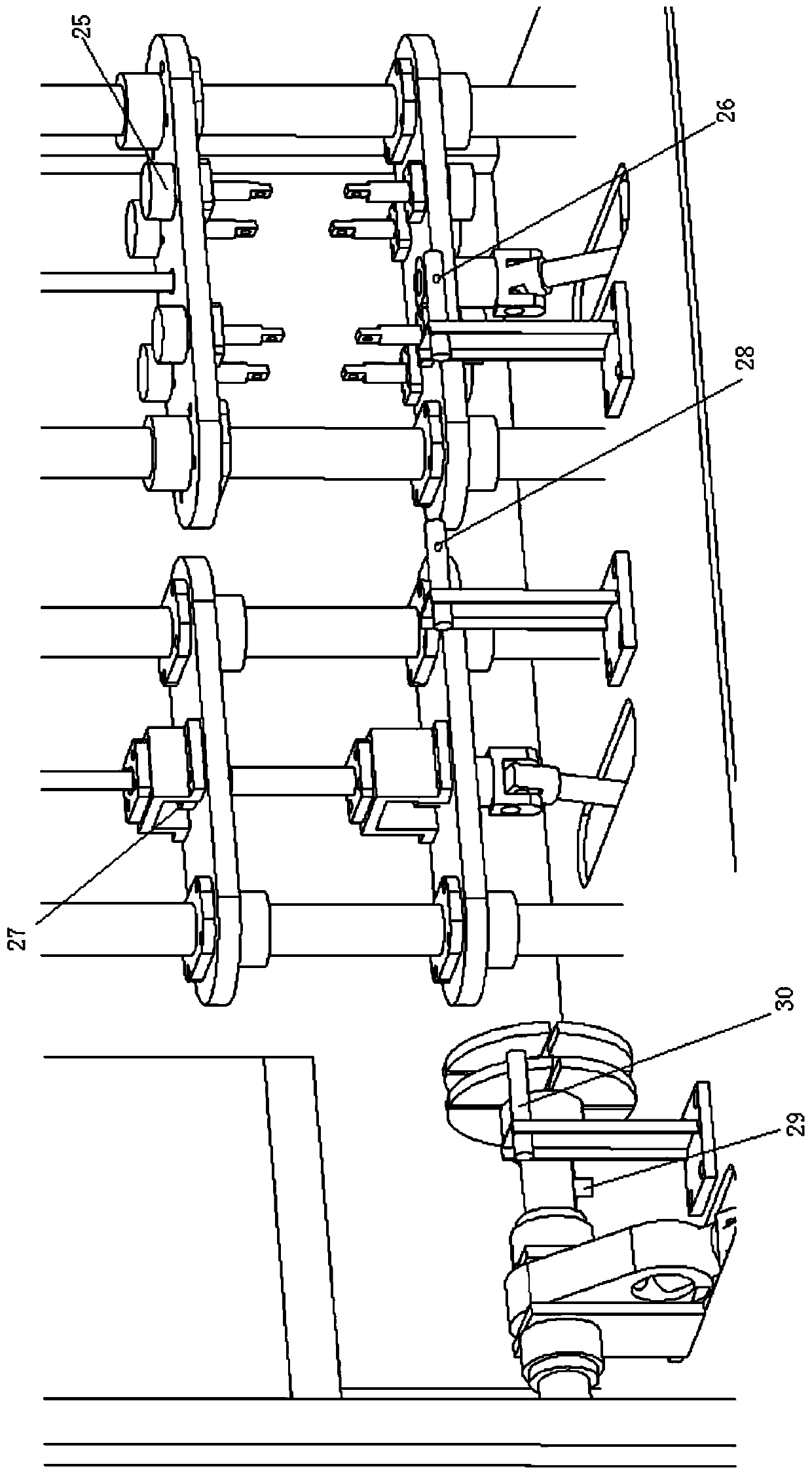

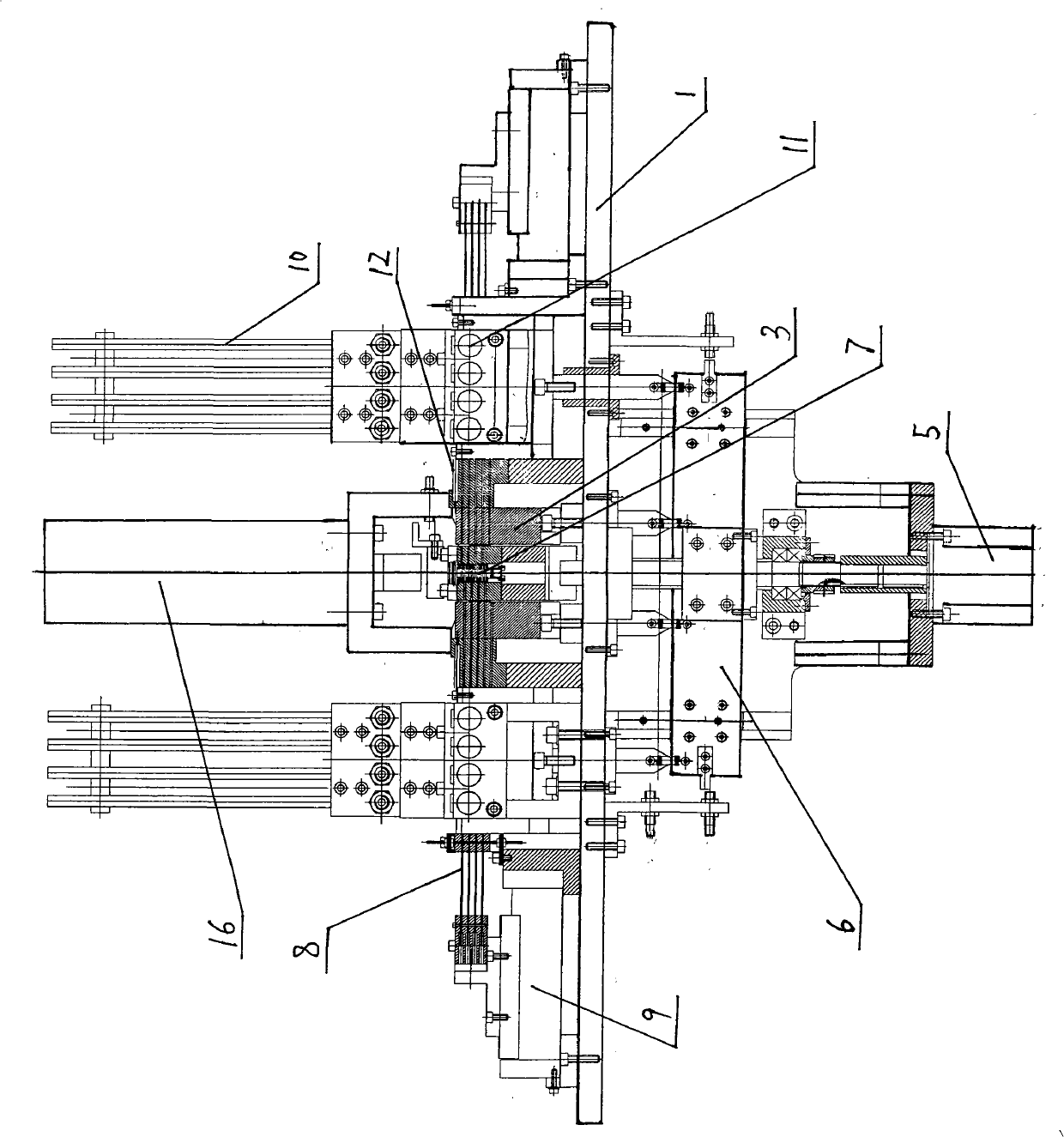

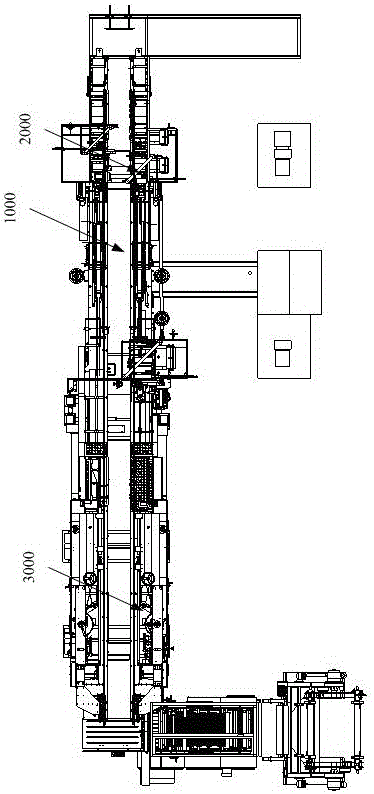

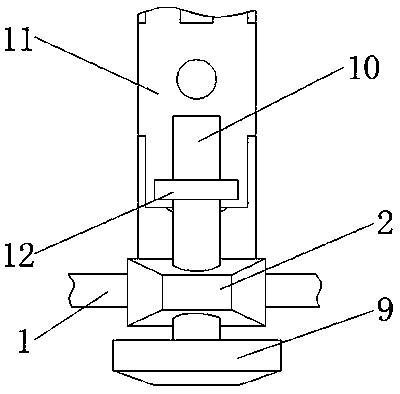

Automobile lock cylinder automatic assembly machine

InactiveCN101513713BAutomated Assembly ScienceNo pollutionAssembly machinesEngineeringAssembly machine

An automobile lock cylinder automatic assembly machine is disclosed in the invention, which includes a frame table, a lock cylinder clamp is installed on the frame table, one side of the lock cylinder clamp is provided with a spring preassemble bin sliding fit with the frame table and a lock plate preassemble bin subsequently. A lifting block capable of vertically moving is slidingly arranged below the frame table and is used for supporting the spring preassemble bin and the lock plate preassemble bin; a horizontal lock plate passage corresponding to the lock plate position of the lock cylinder is disposed in the lock plate preassemble bin; a lock plate push rod is provided in the lock plate passage of the lock plate preassemble bin and is connected with a cylinder disposed outside the lock plate preassemble bin, a lock plate material bin is installed above the rear side of the lock plate preassemble bin, a material feed tank is arranged on the lower end of the lock plate material bin. A charging ram is in slidingly fit with the material feed tank, and a horizontally contraposed lock plate disposed in the lock plate material bin is arranged on the charging ram. The invention replaces the manual assembly method, the assembly efficiency of the automobile lock cylinder can be greatly increased, meanwhile, due to the electric and pheumatic power, environment pollution can be prevented.

Owner:合肥安达数控技术有限责任公司

Packaging bag production line

ActiveCN104290352BImprove versatilityMeet different job requirementsBox making operationsPaper-makingValve openingPlug nozzle

The invention provides a packaging bag production line comprising a main conveyor line and a valve opening forming device. The valve opening forming device comprises a mounting platform, a hot sealing mechanism and a glue spraying mechanism. The mounting platform comprises a support frame, a mounting base and a cylinder; the support frame is mounted on the main conveyor line; the mounting base is slidably connected to the support frame; the cylinder is connected between the mounting base and the support frame; the mounting base is provided with a mounting through hole. The hot sealing mechanism comprises a blower nozzle and a heating cylinder. The glue spraying mechanism comprises a glue nozzle, a quantitative feeding pump and a glue incoming pipe. After the hot sealing mechanism is mounted on the mounting platform, the heating cylinder is detachably fixed in the mounting through hole; the blower nozzle is inserted into the mounting through hole and communicated with the heating cylinder. After the glue spraying mechanism is mounted on the mounting platform, the quantitative feeding pump is detachably fixed in the mounting through hole; the glue nozzle is inserted into the mounting through hole and communicated with the quantitative feeding pump. The packaging bag production line meets the requirements of hot sealing and gluing processes and is more universal.

Owner:青岛晨峰智能装备有限公司

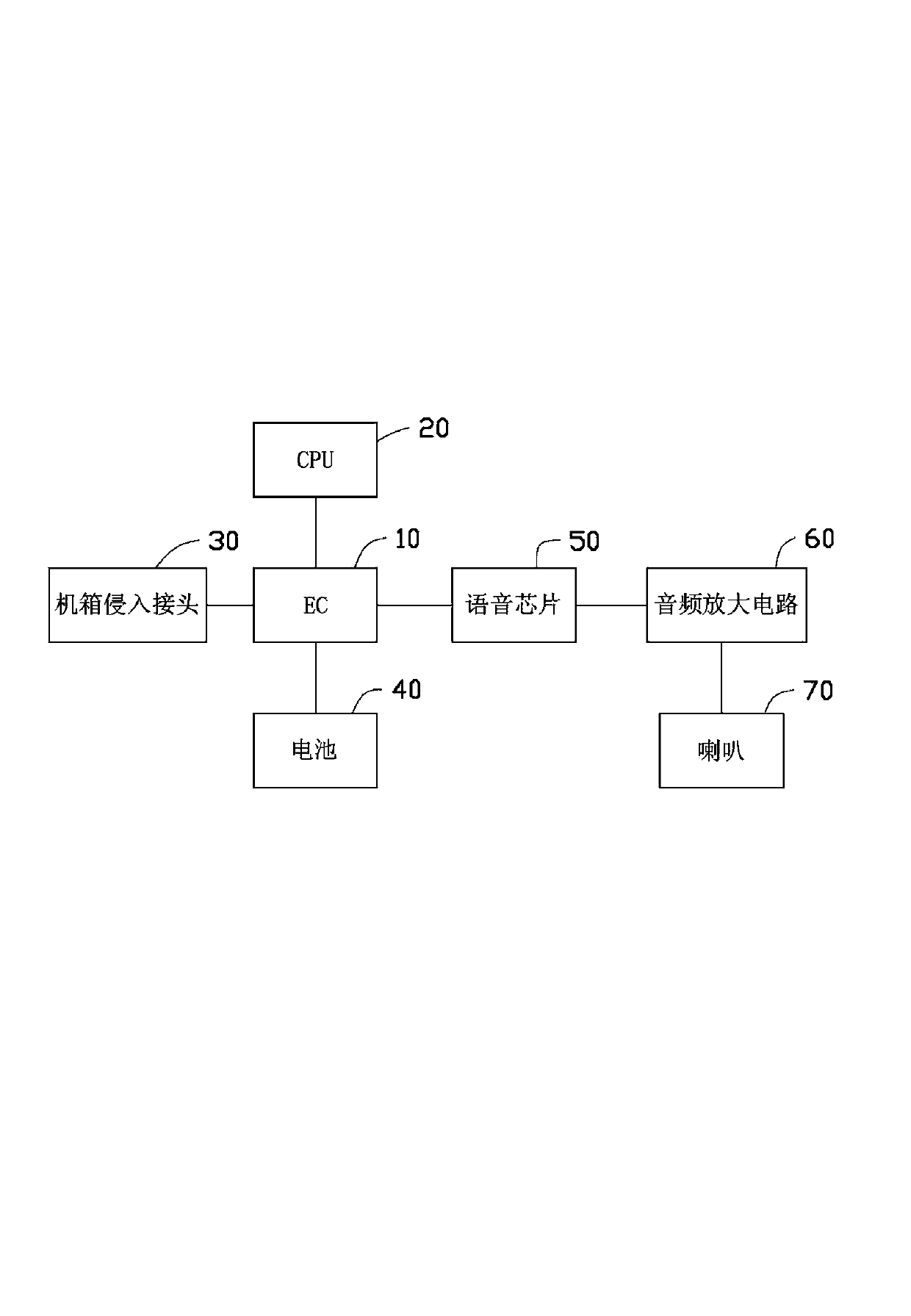

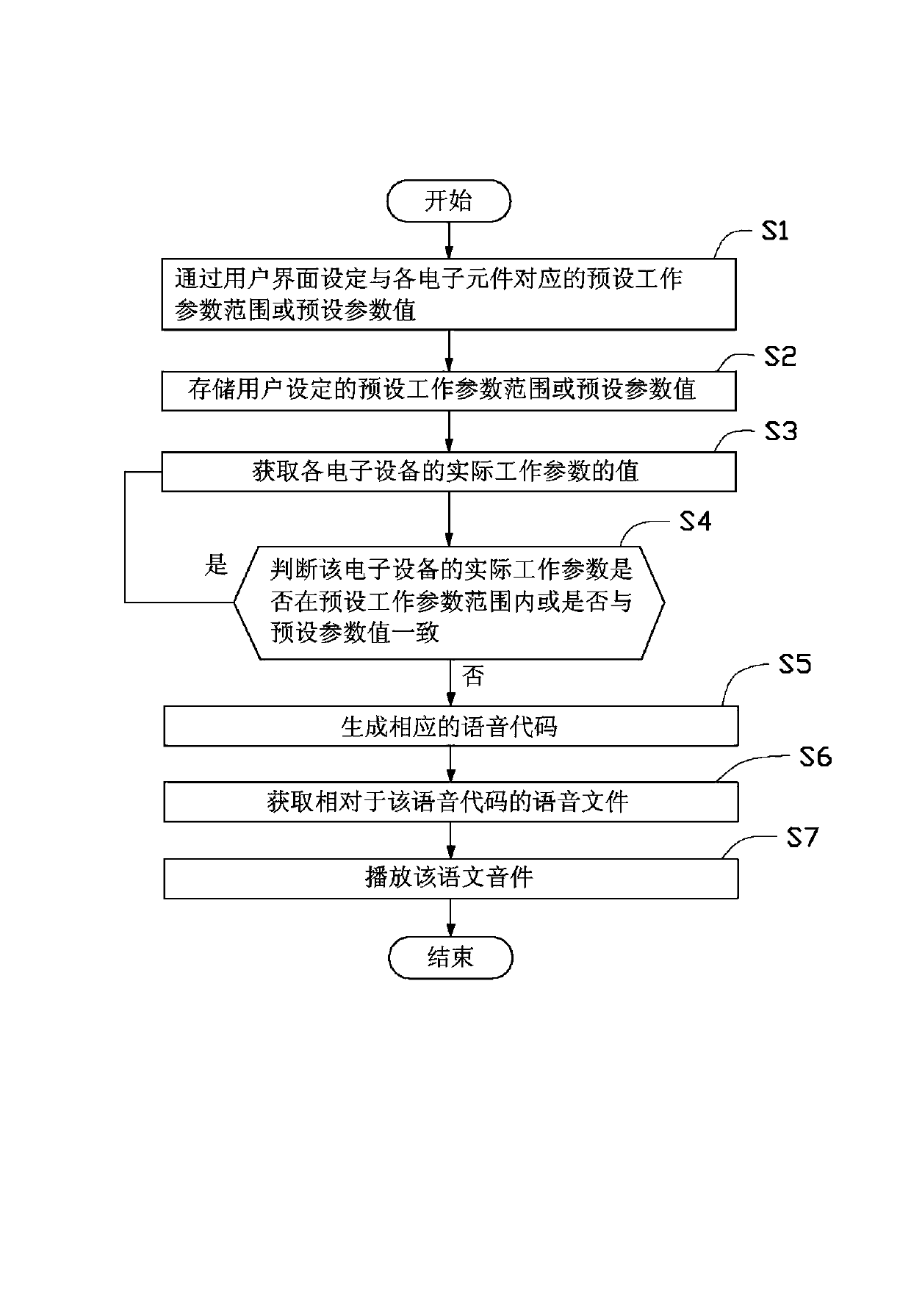

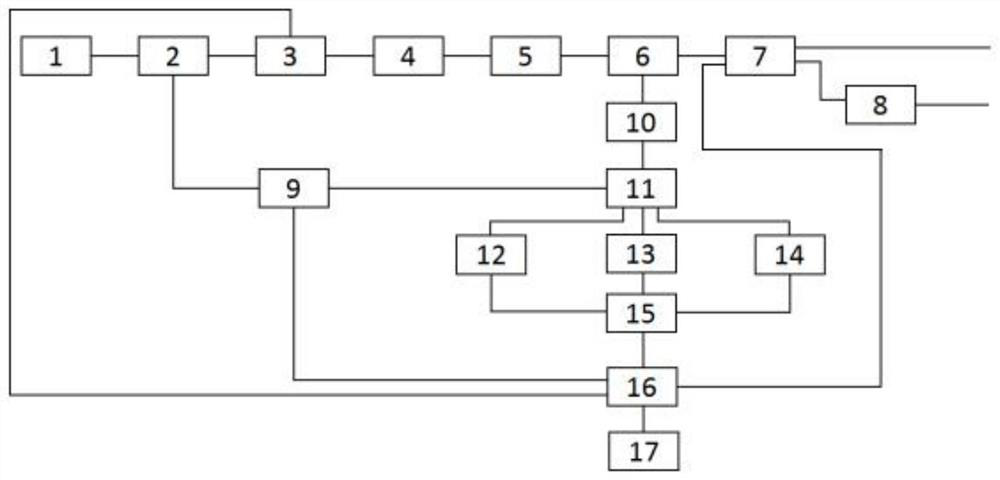

Abnormity warning system and method

InactiveCN103377108AEasy to judgeMeet different job requirementsHardware monitoringAlarmsDisplay deviceElectronic component

An abnormity warning system comprises a CPU (Central Processing Unit), an embedded controller and a voice chip, wherein the CPU is used for displaying a user interface for setting a preset working parameter range corresponding to a first electronic component through a display device; the embedded controller is used for storing the preset working parameter range and for obtaining and comparing whether the standard working diameter of the electronic component is within the corresponding preset working parameter range, and if the standard working diameter of the electronic component is not within the corresponding preset working parameter range, the embedded controller generates and outputs a voice code; the voice chip is used for receiving the voice code, selects a corresponding voice file from a plurality of pre-stored voice files according to the voice code, and plays the voice file through a loudspeaker. The abnormity warning system can meet different working requirements and facilitate the judgment of a user about the electronic component which works abnormally according to the voice prompt. In addition, the invention also provides an abnormity warning method.

Owner:HONG FU JIN PRECISION IND WUHAN CO LTD +1

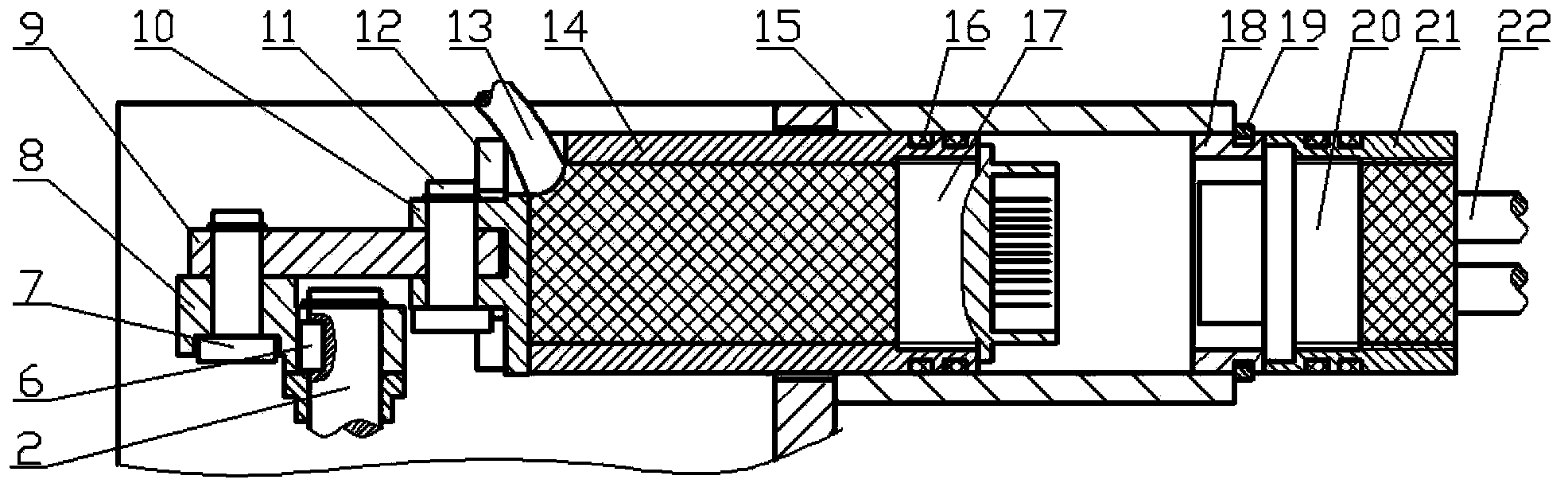

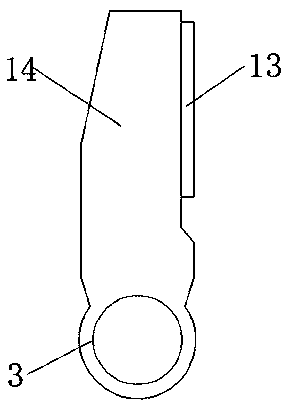

Underwater cable pulling-out mechanism

InactiveCN102904110BSmall separation abilityReliable separationCoupling device detailsEngineeringElectrical and Electronics engineering

The invention aims to provide an underwater cable pulling-out mechanism which comprises a power shaft, a crank, a connecting rod, a socket plate, a socket sleeve, a cable pulling-out sleeve and a cable pulling-out shaft sleeve; the crank is connected with the connecting rod; the connecting rod is connected with the socket plate which is connected with the socket sleeve; the socket sleeve can slide in a reciprocating mode in the cable pulling-out sleeve; the cable pulling-out shaft sleeve is installed at the end part of the socket sleeve, and the cable pulling-out shaft sleeve is provided with a C-shaped ring; a plug sleeve which is used for placing the cable plug is installed beside the cable pulling-out shaft sleeve; the cable socket is installed in the socket sleeve; and the power shaft is connected with the crank. The underwater cable pulling-out mechanism does not need to overcome external water pressure; the required separating force is small; the pulling-out process has nothing to do with the gravity of abandoned equipment, and is driven by the crank; the separation is reliable; and when a plurality of cable pulling-out units are adopted, the sequential pulling-out of multiple cables can be realized.

Owner:三亚哈尔滨工程大学南海创新发展基地

Distributed Fiber Optic Acoustic and Vibration Fusion Sensing System

ActiveCN111486937BMeet different job requirementsLow costSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiber couplerPhotodetector

Owner:武汉光谷航天三江激光产业技术研究院有限公司

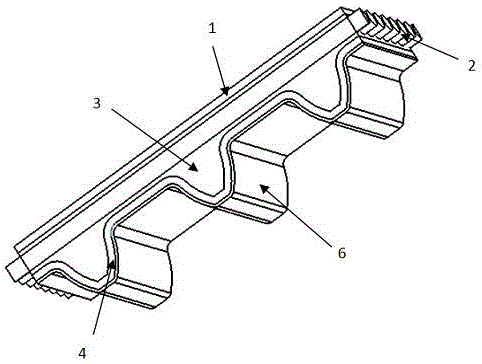

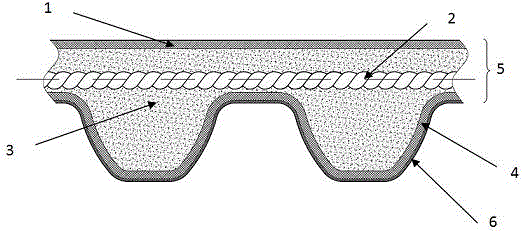

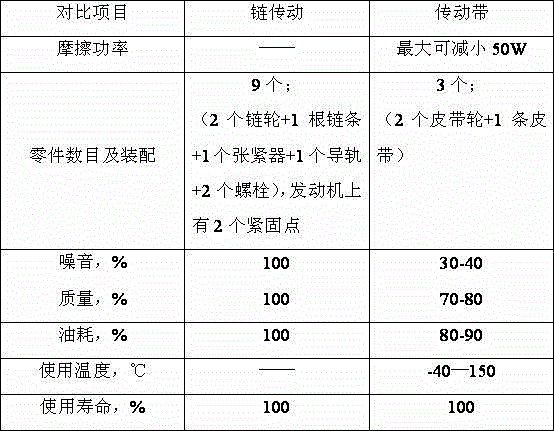

Automobile timing driving belt for oil immersion

ActiveCN103075464BMeet different job requirementsSimple structureFibre typesDriving beltsElastomerNitrile rubber

Owner:NINGBO FENGMAO FAR EAST RUBBER

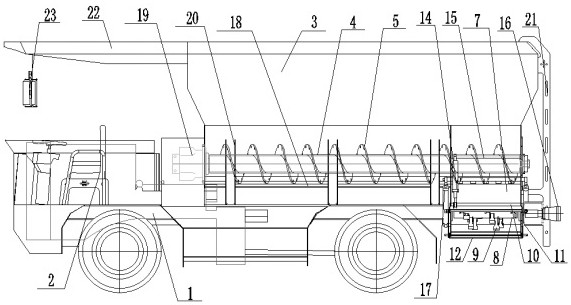

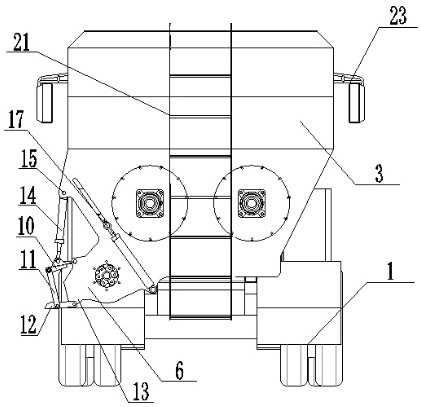

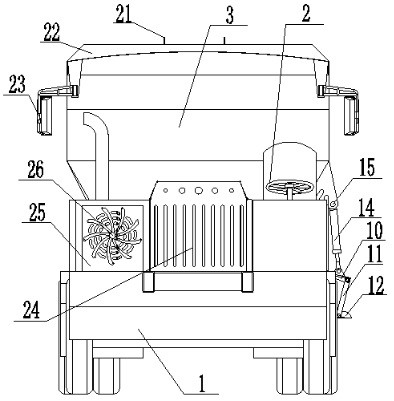

Self-propelled throwing vehicle for pasture

PendingCN113951161AMeet different job requirementsAnimal feeding devicesCrop livestockLivestock breeding

The invention belongs to the technical field of livestock breeding machinery, and particularly relates to a self-propelled throwing vehicle for a pasture. The self-propelled throwing vehicle for the pasture comprises a vehicle body, wherein a cab is mounted at the front part of the vehicle body, and a box body is mounted at the middle rear part of the vehicle body. The self-propelled throwing vehicle for the pasture is characterized in that an auger shaft is mounted in the box body, auger blades are mounted on the auger shaft, a throwing cavity is connected to the bottom of the tail end of the box body, a door opening baffle is arranged between the throwing cavity and the box body, a throwing hammer shaft is mounted in the throwing cavity, a throwing hammer is mounted on the throwing hammer shaft, the upper portion of a throwing cavity outlet is hinged with the inner side of a discharging cover plate, the lower portion of the outer side of the discharging cover plate is hinged with the top of a discharging connecting rod, the bottom of the discharging connecting rod is hinged with the outer side of a discharging supporting plate, the two ends of the inner side of the discharging supporting plate are hinged with the extension plates respectively, and the extension plates are mounted on the two sides of the throwing cavity outlet. The self-propelled throwing vehicle for the pasture has the beneficial effects that the size of the throwing cavity outlet is adjusted, and meanwhile, the self-propelled throwing vehicle is suitable for different throwing thicknesses and widths through linkage adjustment of the discharging cover plate and the discharging supporting plate.

Owner:泰安意美特机械有限公司

Egg beater

InactiveCN105286666AEasy to separateSimple and quick effective separation of egg white and egg yolkKitchen equipmentYolkPhysical hard work

The invention discloses an egg beater. The egg beater comprises an egg net and a grab handle, and the egg net is arranged at one end of the grab handle; the egg beater further comprises a motor, a switch and a battery box, wherein the motor is arranged in the grab handle, a motor shaft of the motor is connected with the egg net, a button of the switch is arranged on the outer side of the grab handle, the battery box is arranged in the grab handle, and whether the battery box is conducted to the motor or not is controlled through the switch; the egg net comprises a stirring net body and a separating net body which are connected through a hinge. According to the egg beater, the structural design is reasonable, egg white and egg yolk of an egg can be beaten to be fully blended into egg liquid through the egg net, and the egg white and the egg yolk can be beaten separately to bubbling; the egg white and the egg yolk can further be effectively separated in a simple and rapid mode for selection and use, and the work efficiency of separating the egg white from the egg yolk is improved; the egg can be beaten manually and electronically, different work requirements can be met, and manual labor is reduced.

Owner:农继荣

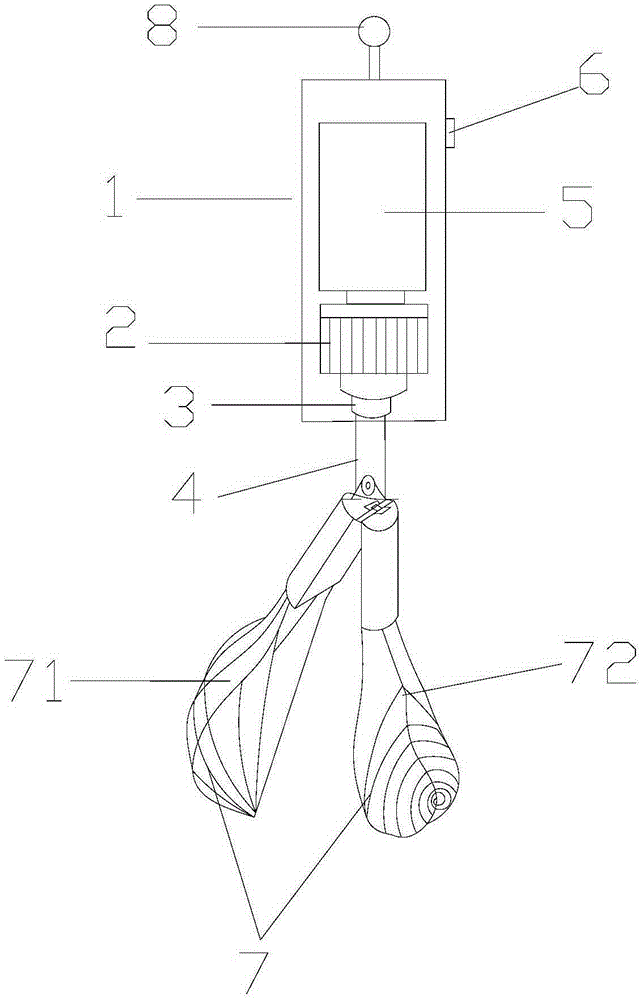

Orchard ridge surface obstacle avoiding and weeding device and orchard weeding machine

PendingCN114080872AChange horizontal widthControl swing angleAgricultural machinesSoil-working equipmentsAgricultural engineeringFruit tree

The invention provides an orchard ridge surface obstacle avoiding and weeding device and an orchard weeding machine, and belongs to the technical field of agricultural machinery. The device comprises a movable frame; one end of the moving frame is connected with the obstacle-avoiding weeding mechanism; the obstacle avoiding weeding mechanism comprises a first connecting frame, a second connecting frame and a third connecting frame; the first connecting frame is connected with the moving frame; the second connecting frame is connected with the first connecting frame through a first telescopic piece; the horizontal rotation of the second connecting frame is controlled through the telescopic movement of the first telescopic piece; the third connecting frame is connected with the rotary cutter head; the third connecting frame and the second connecting frame are connected through a first telescopic piece and a second telescopic piece; the swing angle of the rotary cutter head is adjusted through telescopic movement of the first telescopic piece, and the height of the rotary cutter head is controlled through telescopic movement of the second telescopic piece. Through the device, the rotating frame can be controlled to rotate to adjust the transverse breadth of the device, it is guaranteed that the obstacle avoiding weeding mechanism does not make contact with fruit tree trunks on the ridging face to achieve the obstacle avoidance function, and meanwhile the height and the swing angle of the rotary cutter head can be adjusted.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Slotting device for boards used in furniture production and processing

InactiveCN108466198AChange positionSatisfy the angle requirementWork holdersEngineeringMechanical engineering

The invention discloses a slotting device for boards used in furniture production and processing. The slotting device for the boards used in furniture production and processing comprises a guiding rod. A locking seat is arranged on the outer side of the guiding rod. The locking seat is fixed to the guiding rod in a clamped mode. A fixed claw is arranged at the bottom end of the locking seat. The fixed claw is fixedly connected with the locking seat. An anti-skid pad is arranged under the fixed claw. The anti-skid pad is fixed to the fixed claw in a bonded mode. A fixed screw is arranged on theinner side of the guiding rod. A sliding block slides between fixed plates, the position of a fixed seat is changed, slotting operation can be carried out at the position deviating from the center tomeet the different operation requirements; and the sliding block slides between the fixed plates, relative distance is conveniently changed when a pressing claw is adjusted, the pressing use of the device is facilitated, the use of the slotting device is more convenient, the requirements of different construction operation angles can be met, the workload of the staff is reduced, and the slottingefficiency of the slotting device is improved.

Owner:陈恩媚

Tillage and seeding machine for tea gardens

InactiveCN107852876AVersatileMeet different job requirementsSpadesPlantingTerrainAgricultural engineering

The invention relates to a tillage and seeding machine for tea gardens and belongs to the technical field of agricultural machinery. Seeds are stored in a seed storage box; a diesel engine is driven;the direction of the tillage and seeding machine is controlled through a handlebar; a soil-loosening roller rotates to loosen soil when the tillage and seeding machine travels; a soil digger digs holes in the soil to facilitate seeding; a seed conveyer rotates to convey the seeds from the seed storage box to a discharge port into the holes; an earthing device at the tail of the tillage and seedingmachine covers the seeds with soil; therefore, seeding is completed. The diesel engine is used as a driving device, has high power and long service life and is applicable to operations in mountain tea gardens; tracks are used herein as a travelling device; mountain tea gardens are mostly built on slopes that are steep, the tracked travelling device provides the tillage and seeding machine with great land grip during slope operations, the tillage and seeding machine rarely rolls over during operating, and the tillage and seeding machine has improved working efficiency and stability.

Owner:李竑靓

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com