Automobile lock cylinder automatic assembly machine

A technology for automobile locks and assembly machines, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc. It can solve the problems of high labor intensity and low production efficiency, and achieve the effects of reasonable layout, safe use, and cheap gas source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

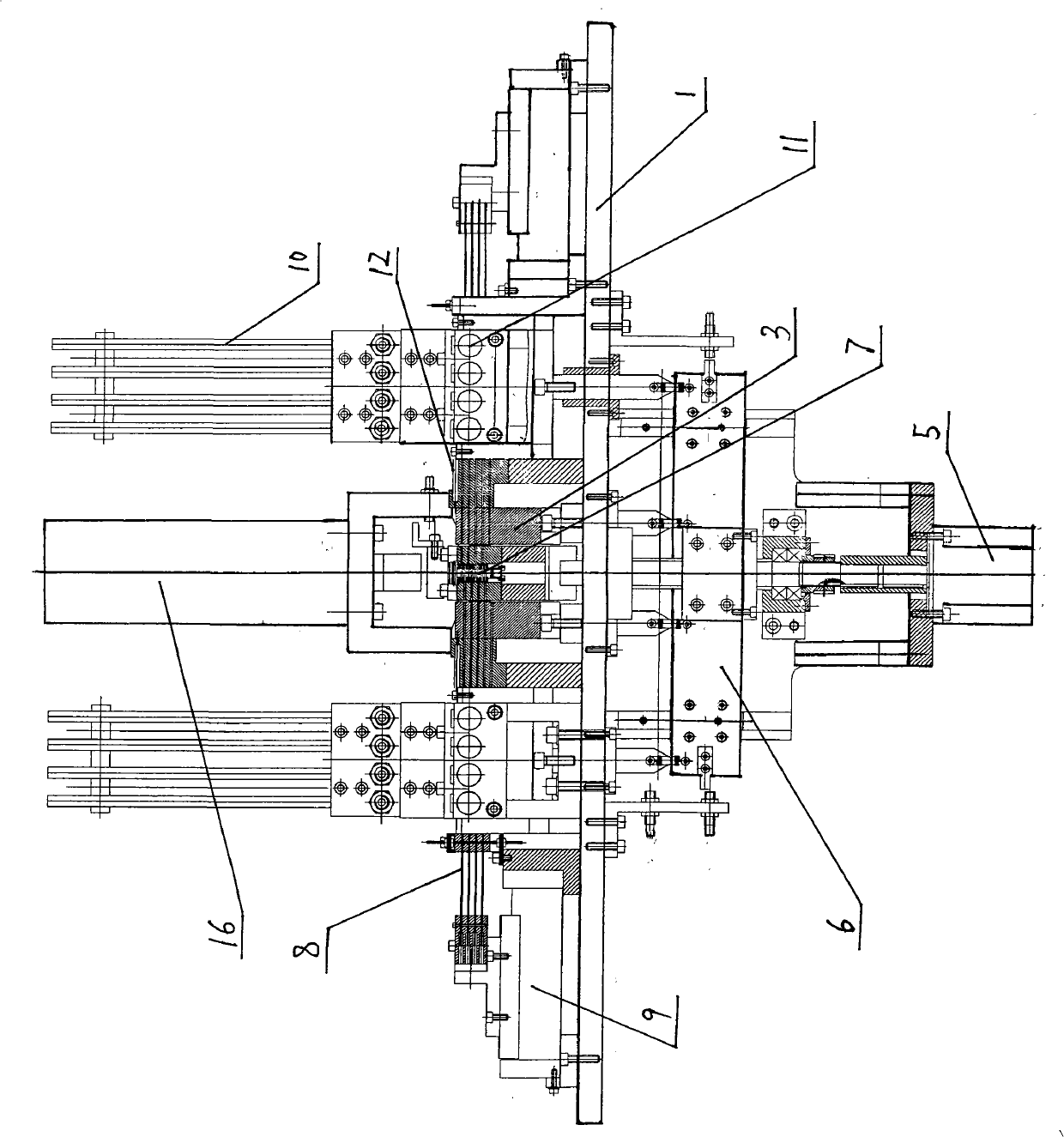

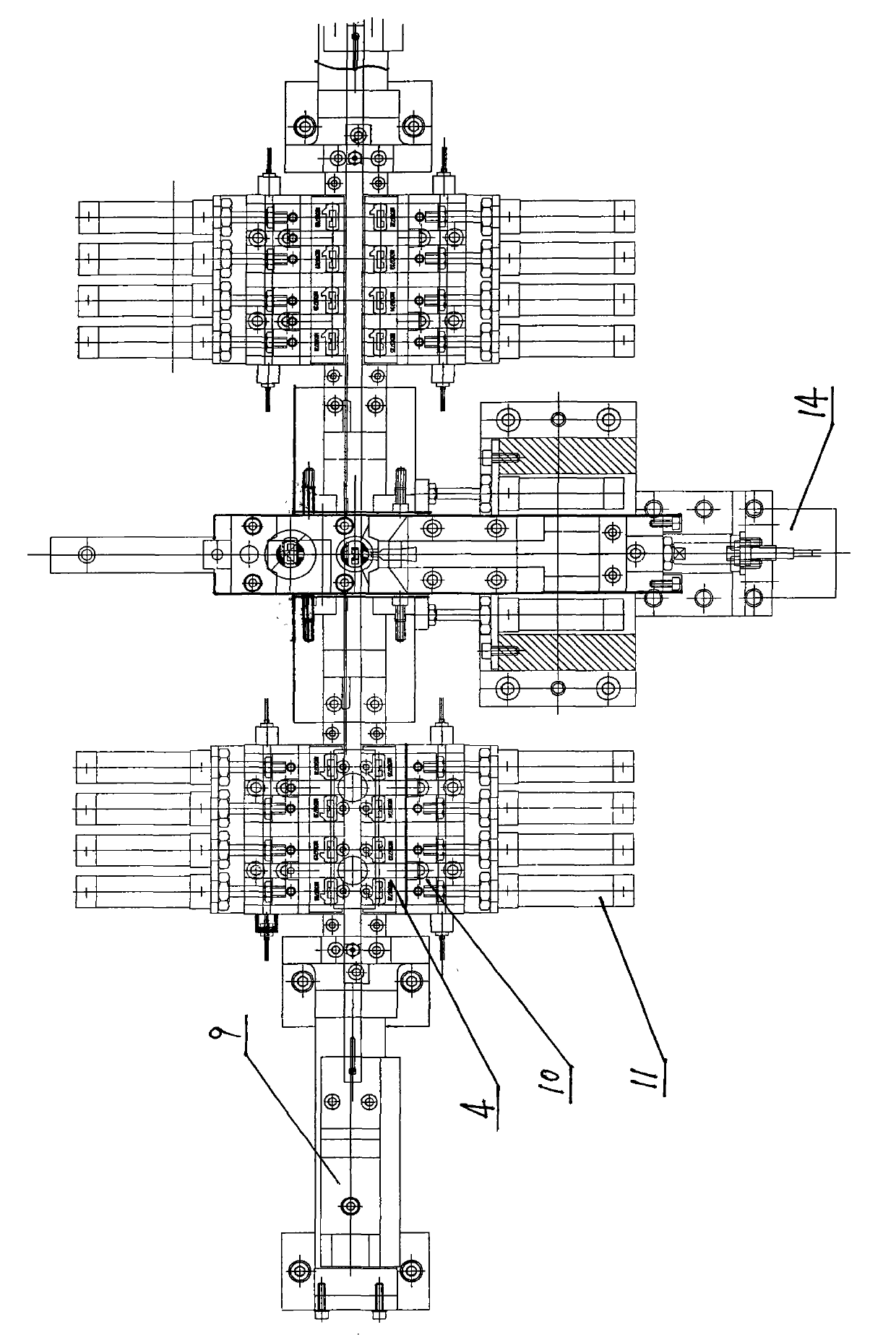

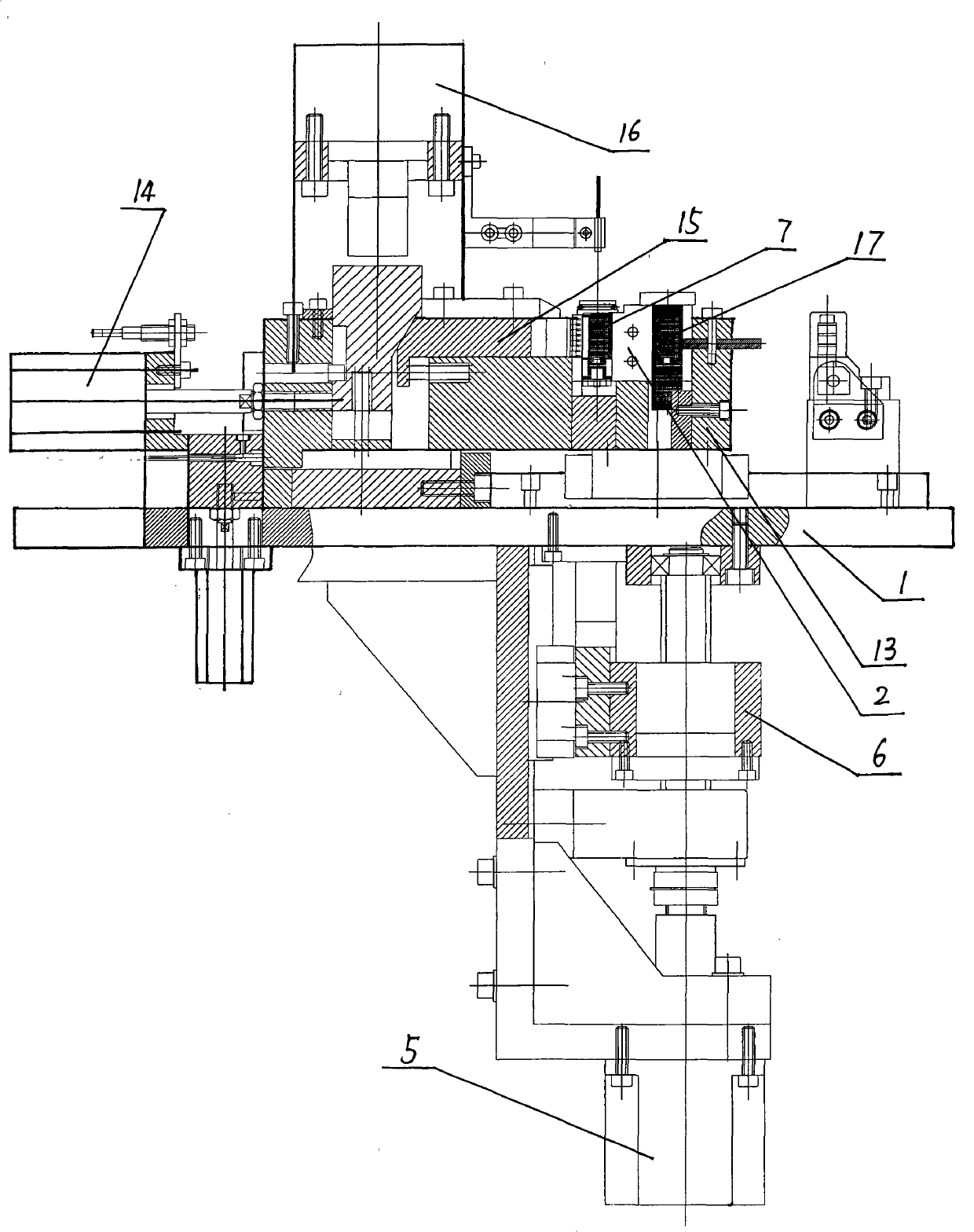

[0012] Referring to Fig. 1, Fig. 2 and Fig. 3, the automatic assembly machine for automobile lock cylinders includes a frame platform 1, on which a lock cylinder clamp 2 is installed, and one side of the lock cylinder clamp 2 has springs that slide and fit with the frame platform 1 in turn Pre-installation bin 3, lock disc pre-installation bin 4, a lifting block 6 that can move up and down is slidingly installed under the frame table 1, and the lifting block 6 supports the spring pre-installation bin 3, lock disc pre-installation bin 4, and lifting block 6 Driven by the servo motor 5 below it, the servo motor 5 is connected with a threaded rod and threaded with the inner threaded hole on the lifting block 6; there is a horizontal lock channel corresponding to the position of the lock cylinder 7 in the lock plate pre-installation bin 4 , the side wall of each cleat channel is provided with a cleat feed port; there is a cleat push rod 8 in the cleat channel of the cleat pre-insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com