Multi-station spring detection test bed

A test bench, multi-station technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of inability to detect the torsion spring and compression spring, long time period, slow test speed, etc. , to achieve the effect of easy data collection and recording, high work efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

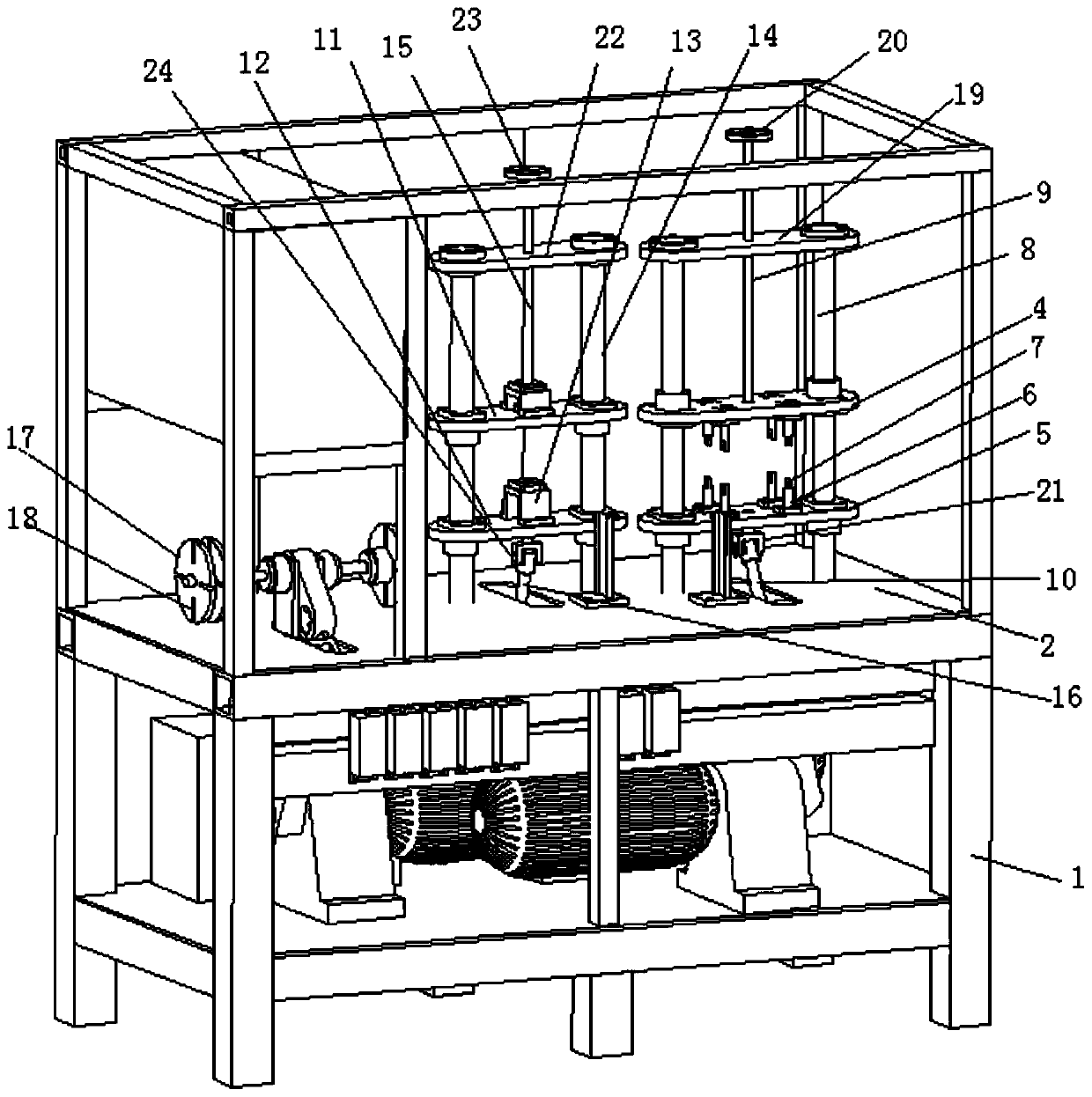

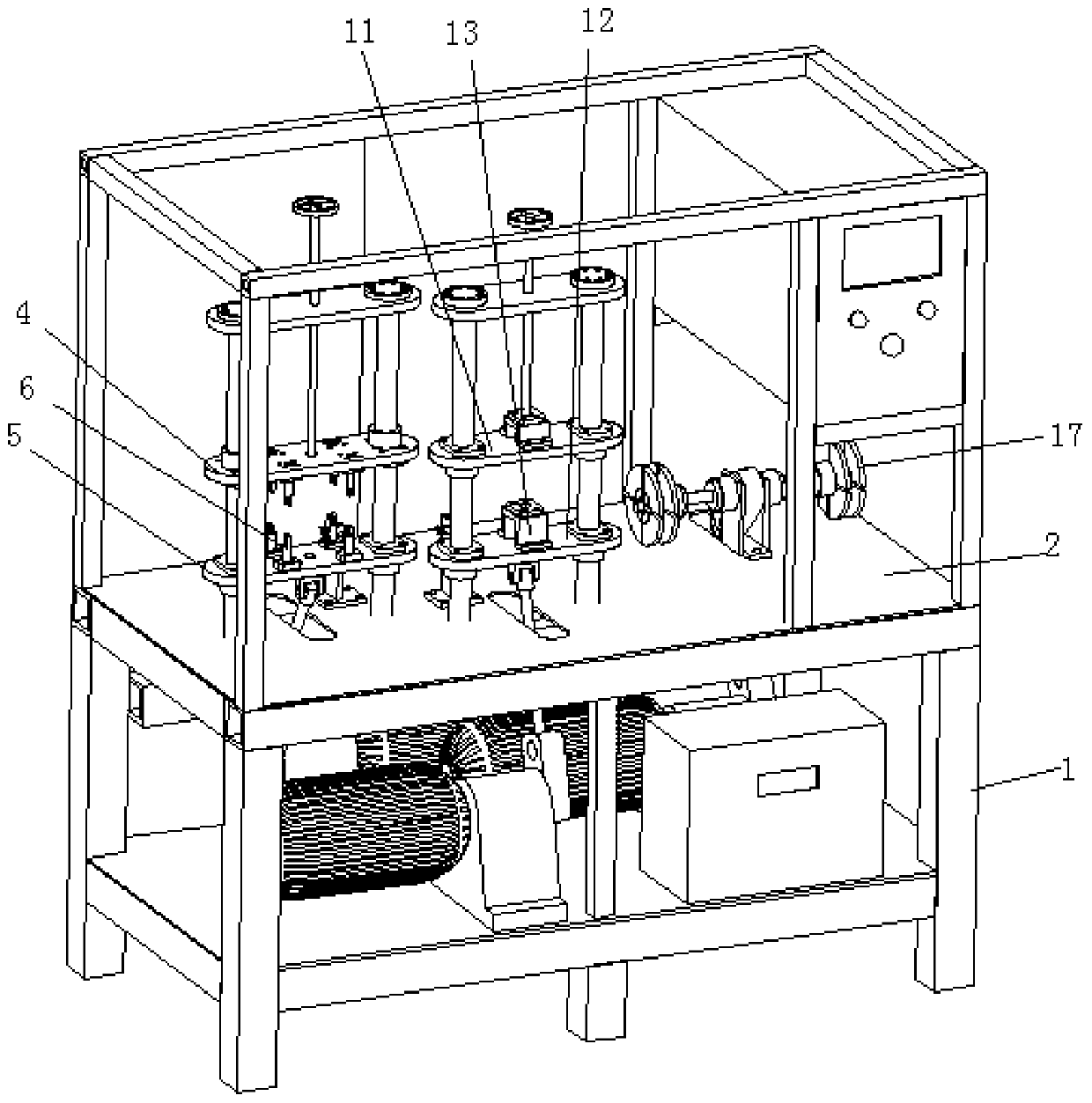

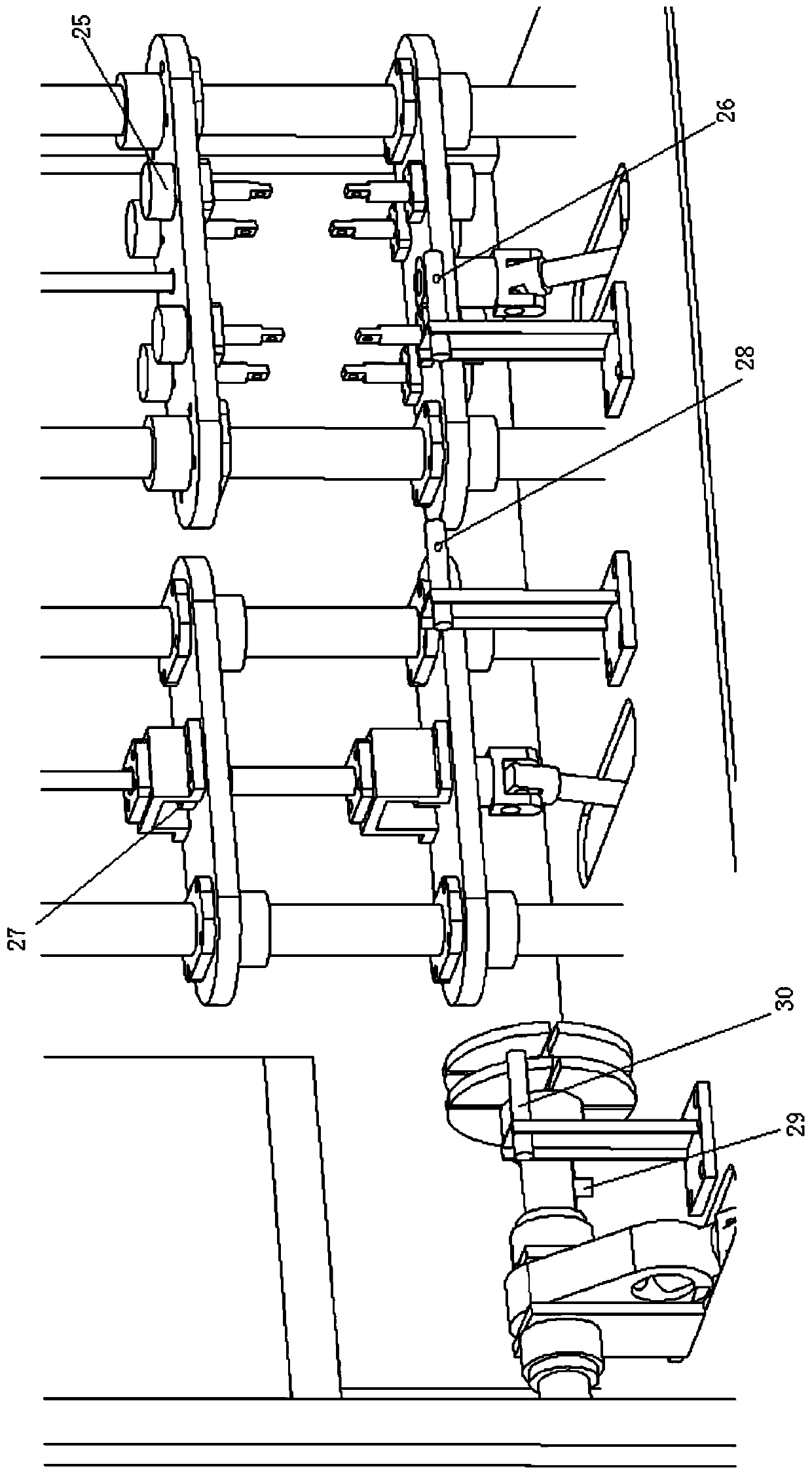

[0032] See attached picture.

[0033] A multi-station spring detection test bench includes a frame 1, and a detection platform 2 is set on the frame 1, and a tension spring detection station, a compression spring detection station and a torsion spring detection station are sequentially arranged on the detection platform 2. The spring detection station, the extension spring detection tooling includes the upper and lower plates 4,5 moving up and down, and the corresponding end faces of the upper and lower plates 4,5 are respectively equipped with columns 6 corresponding to the two ends of the suspension spring , the ends of the column 6 are respectively provided with suspension holes 7, and the upper and lower pull plates 4, 5 are guided by the guide rods 8 provided on both sides thereof, and the up and down movement of the upper pull plate 4 is driven by the adjustment screw rod 9 , the up and down movement of the pull-down plate 5 is driven by the motor through the cam mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com