Modular fixed-point profile buoy

A modular buoy technology, which is applied in the direction of buoys, special-purpose ships, warships, etc., can solve the problems of high manpower and material resources consumption, limited buoy function diversity, inconvenient maintenance and re-upgrade, etc., to avoid corrosion and facilitate functions Effect of upgrade and extension, easy repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

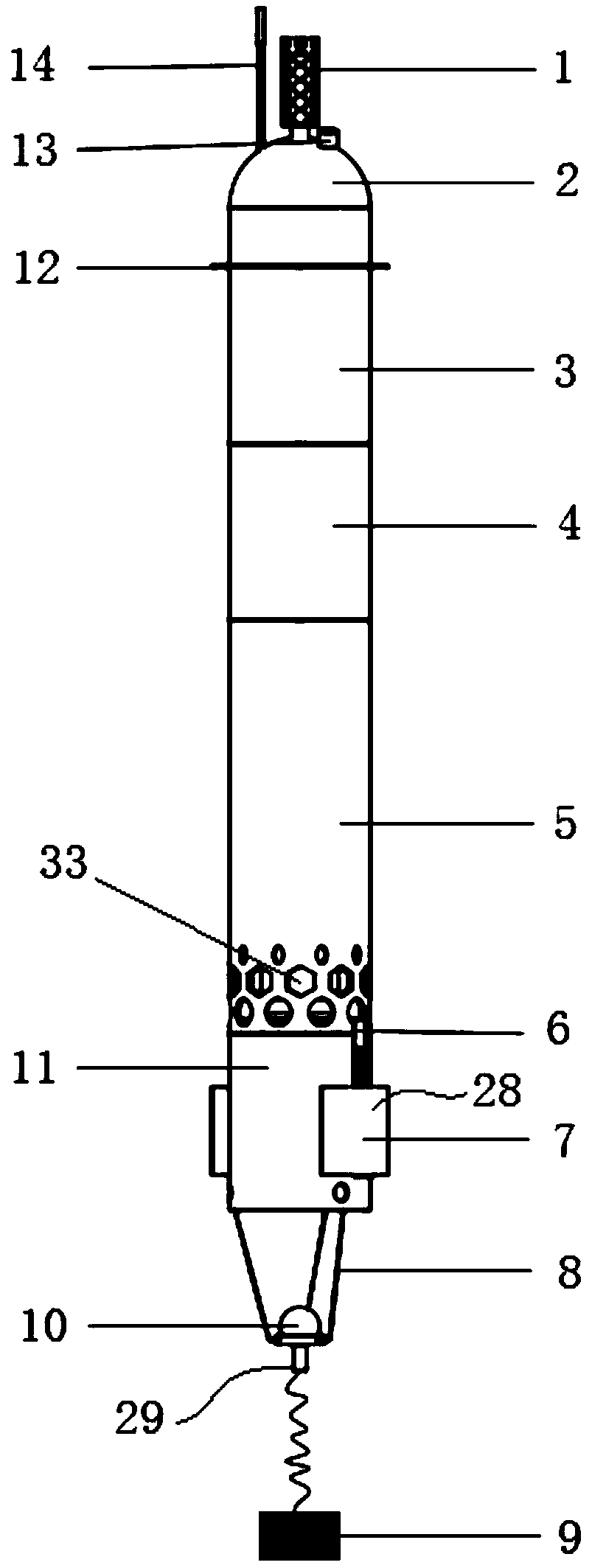

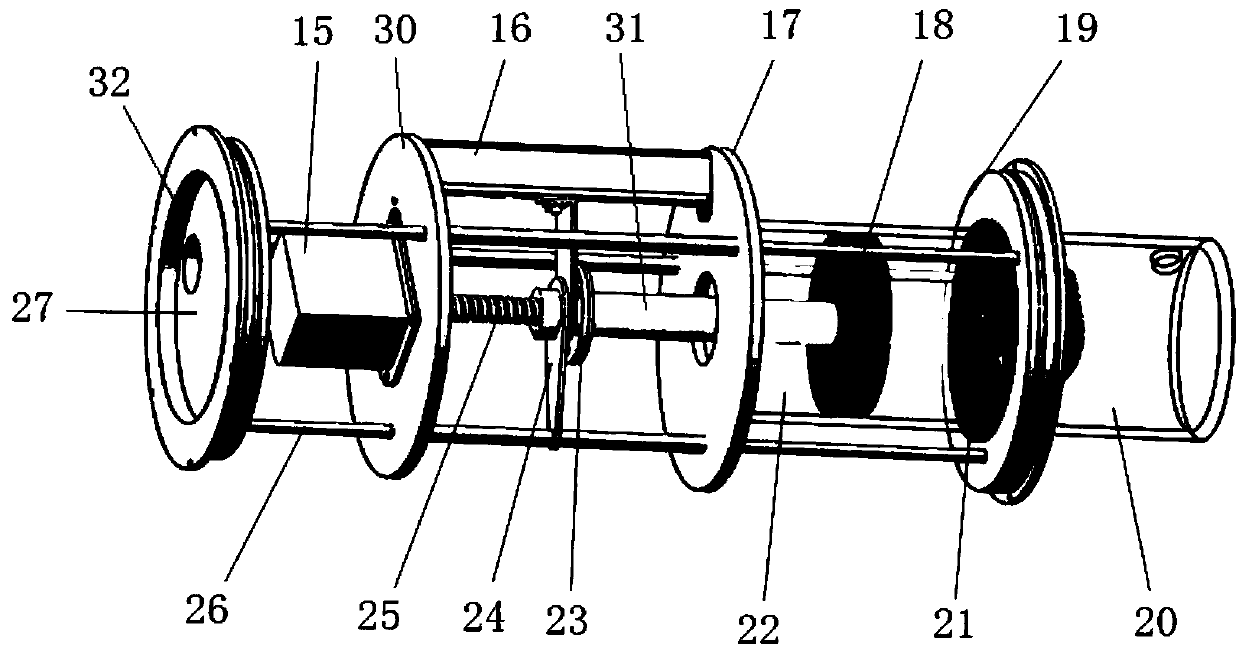

[0026] Such as Figure 1~2 As shown, the present invention includes a sensor module 2, a buoyancy material module 3, an electric control module 4, a buoyancy drive module 5 and a power module 11 connected sequentially from top to bottom, and an emergency dumping module is arranged on one side of the power module 11 28. An anchoring module 29 is provided at the lower end of the power module 11, such as figure 2 As shown, a buoyancy adjustment mechanism is provided inside the buoyancy driving module 5, and the buoyancy adjustment mechanism includes a buoyancy adjustment clear water tank 22 and a buoyancy adjustment sea water tank 20 separated by an isolation membrane 21, and the buoyancy adjustment clear water tank 22 Clear water and a reciprocatingly movable piston 18 are provided, and the buoyancy adjustment seawater cabin 20 is provided with a through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com