Cross runout device of grass cutter

A lawn mower and horizontal positioning technology, which is applied in the direction of lawn mowers, harvesters, cutters, etc., can solve the problems of low cutting efficiency, low power of lawn mowers, and limited use range, so as to improve operating efficiency , flexible operation and increased mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

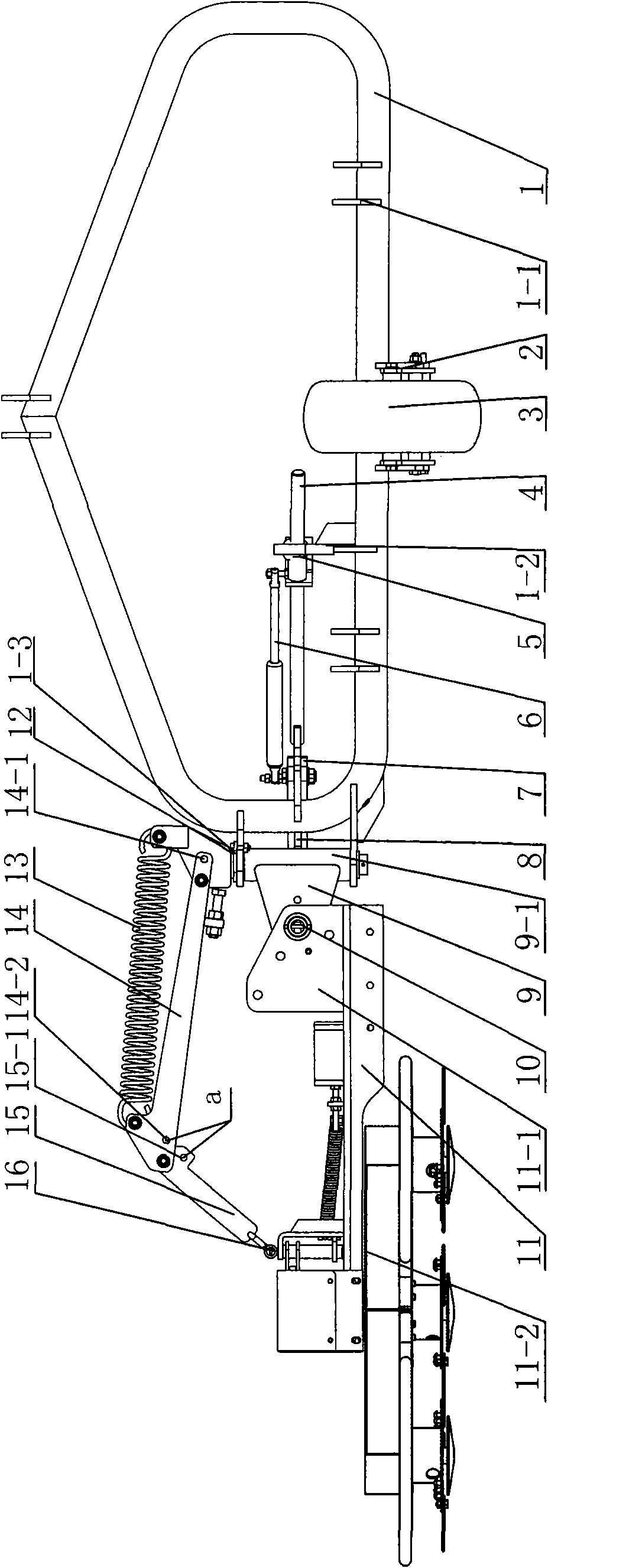

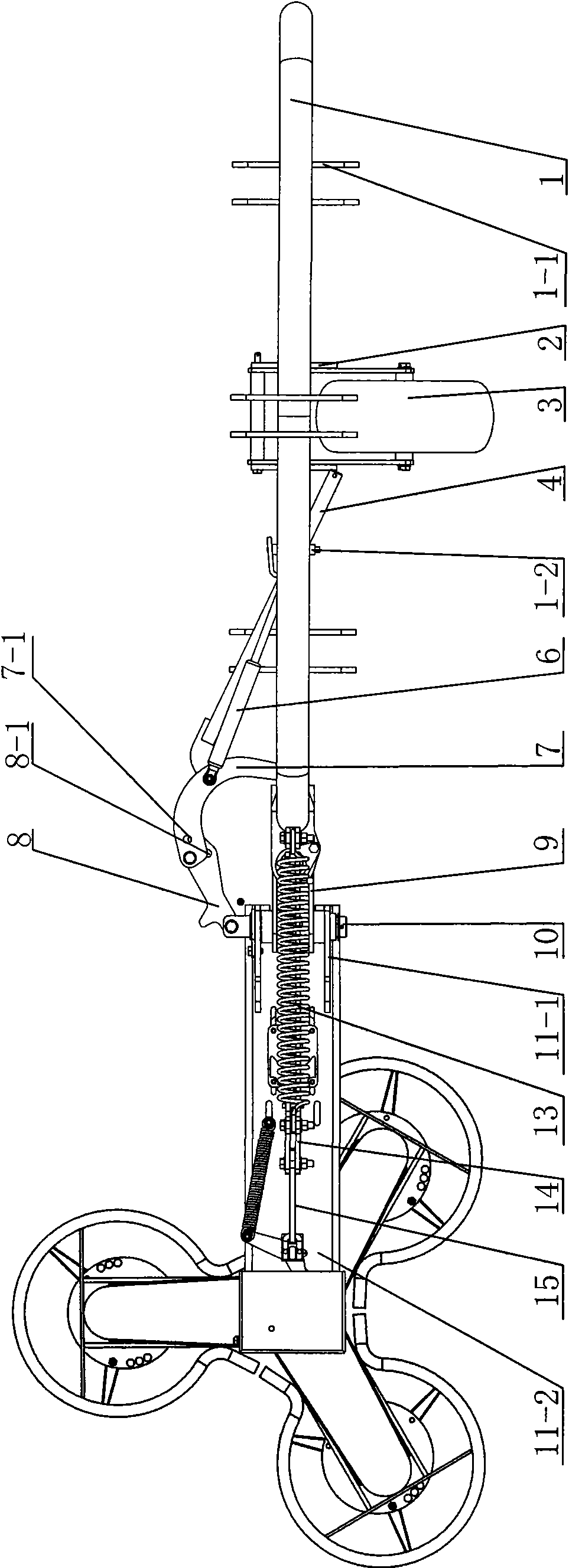

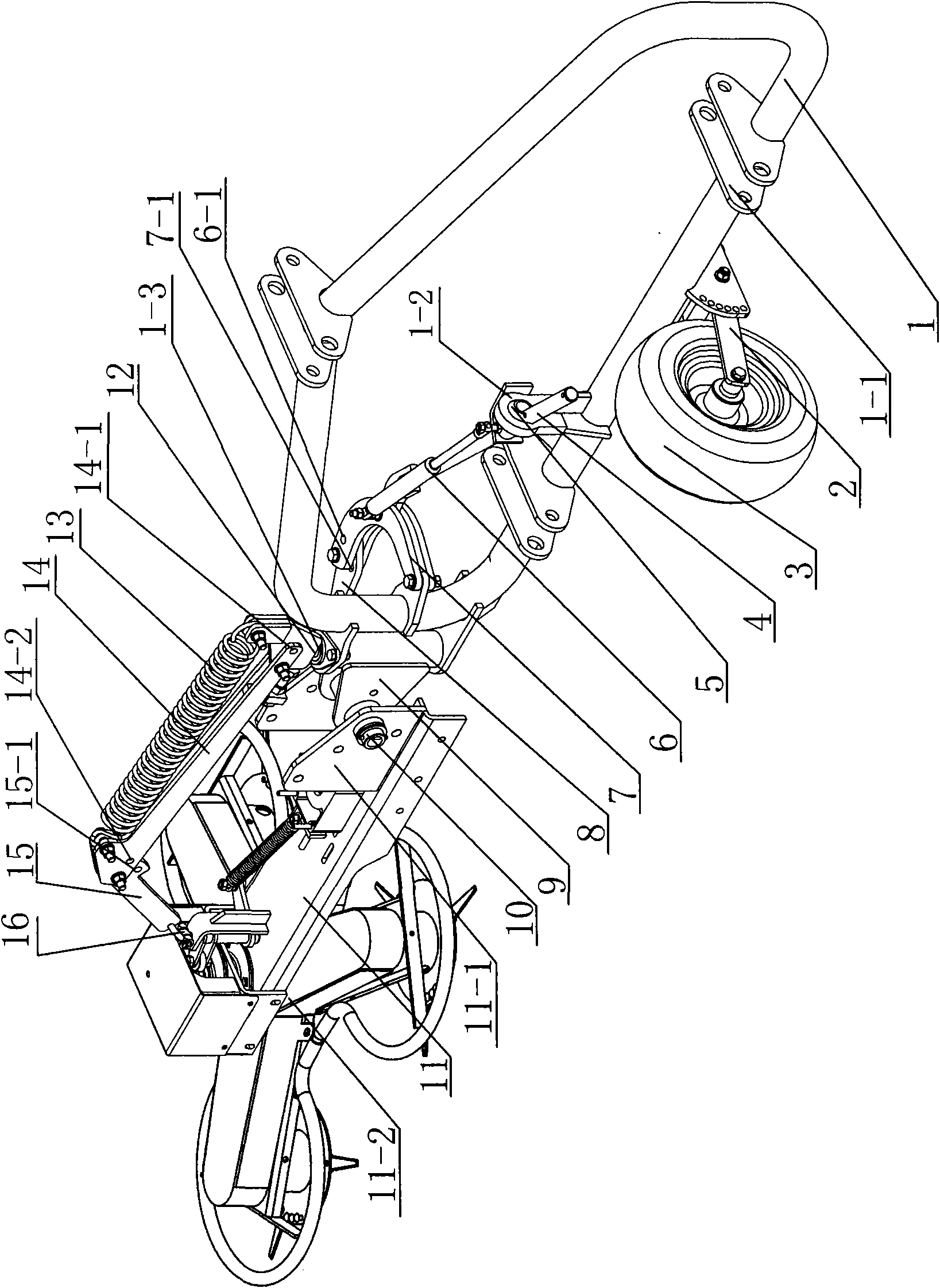

[0011] see Figure 1~3 As shown, the horizontal deflection device of the lawn mower of the present invention includes a body 11, a vertical shaft 12, a support 9, a swing mechanism, a deflection mechanism, and a suspension frame 1. The body 11 is provided on the side opposite to the blade holder 11-2 Connecting seat 11-1. Suspension frame 1 is provided with upper and lower suspension seats 1-1, which form a three-point connection with the tractor. Suspension frame 1 is placed horizontally on the side of the tractor. The suspension frame 1 of the present invention has a closed ring structure and is suspended The front fork 2 is also installed at the bottom of the frame 1, the walking wheel 3 is installed on the front fork 2, and the standpipe 1-3 is fixed on one side of the suspension frame 1, and the vertical shaft 12 is vertically installed in the standpipe 1-3 holes. The rotating sleeve 9-1 of 9 is sleeved on the riser 1-3. Both the vertical shaft 12 and the rotating sleeve 9-1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com