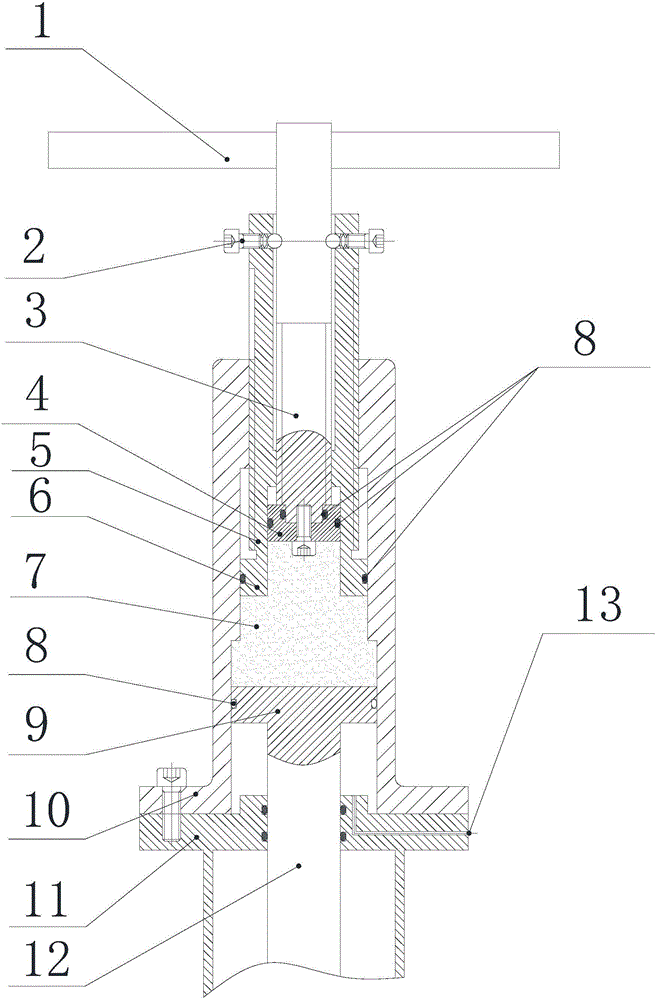

Valve hydraulic hand wheel

A hydraulic and valve technology, which is applied in the field of valve opening devices, can solve the problems of cumbersome, poor stress, and small installation space, and achieve the effects of broad market prospects, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] As a preferred embodiment of the present invention, the valve body 11 is provided with a vent hole 13, and the vent hole 13 is arranged at the joint between the valve body 11 and the housing 10; the vent hole 13 communicates with the driven valve stem piston 9 The area between the valve body 11 and the external environment. The main function of the vent hole 13 of the present invention is to prevent the lower end of the driven valve rod piston 9 from holding pressure, causing difficulty in closing. At the same time, when the valve is opened, the atmospheric pressure can be used to lift the valve rod. It is not very sealed to be connected with the valve body, and the same effect can also be achieved.

[0055] It should be understood by those skilled in the art that the present invention has the following three usage states:

[0056] 1. When the valve needs to be closed quickly at the initial stage of closing, A>A2;

[0057] 2. When the valve needs to be closed synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com