Underwater cable pulling-out mechanism

An underwater cable and cable technology, applied in circuits, electrical components, coupling devices, etc., can solve problems such as large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

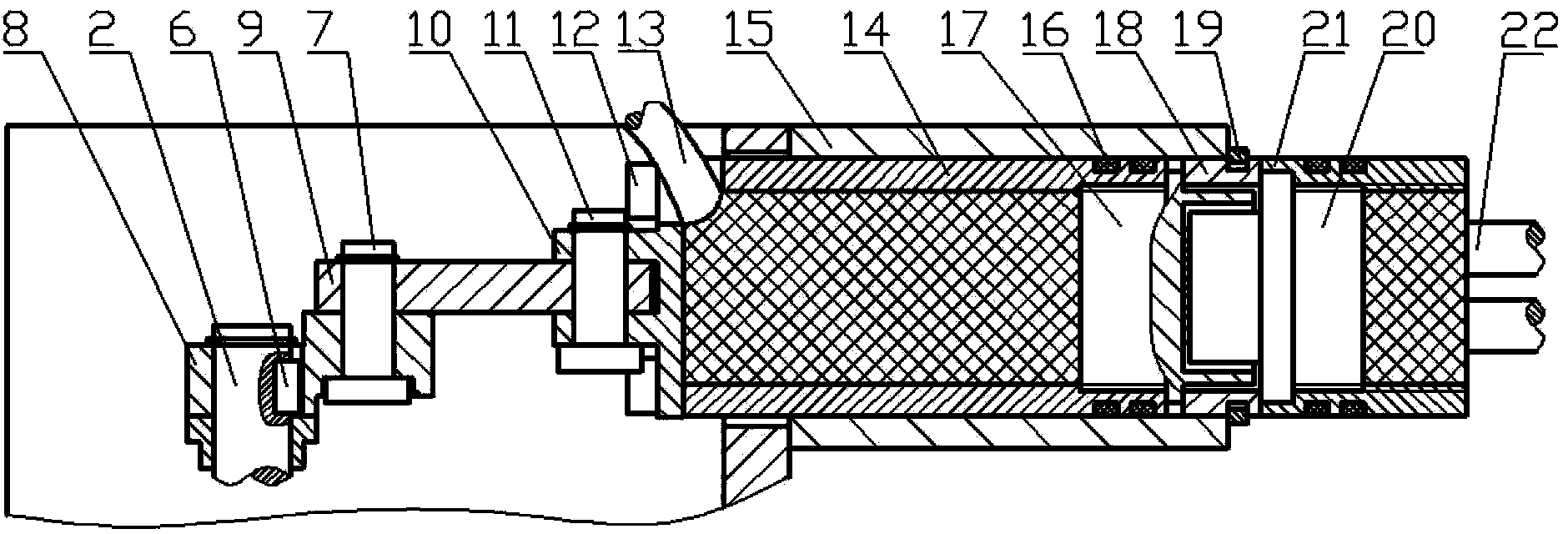

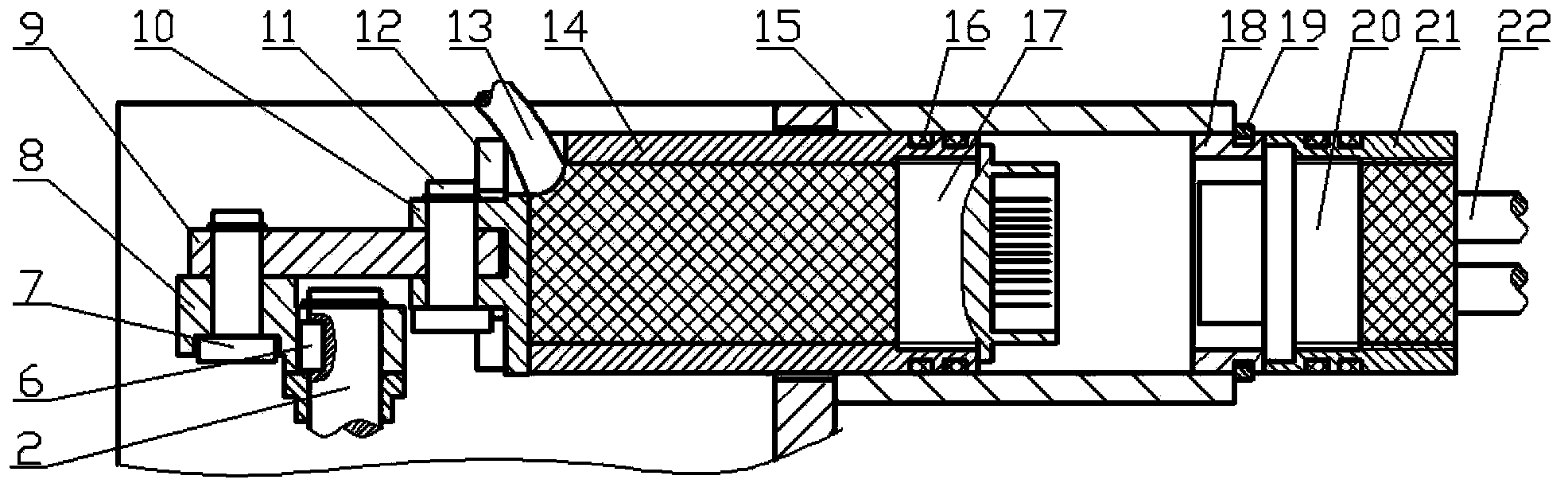

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0018] combine Figure 1~2 , the power shaft 2 is connected to the crank 8 through the key 6, the crank 8 is connected to the connecting rod 9 through the pin 7, the connecting rod 9 is connected to the socket plate 10 through the pin 11, the socket plate 10 is connected to the socket sleeve 14 through the screw 12, and the socket The sleeve 14 can slide back and forth in the cable-off sleeve 15, and a cable-off sleeve 18 is installed between the socket sleeve 14 and the plug sleeve 21, and a C-ring 19 is installed on the cable-off sleeve 18. Wherein, the cable socket 17 is connected with the socket sleeve 14 through threads, and the underwater cable 13 is vulcanized and sealed with the socket sleeve 14 after being connected with the cable socket 17. The cable plug 20 is connected with the plug sleeve 21 through threads, and the underwater cable 22 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com