Patents

Literature

35results about How to "Short circuit will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

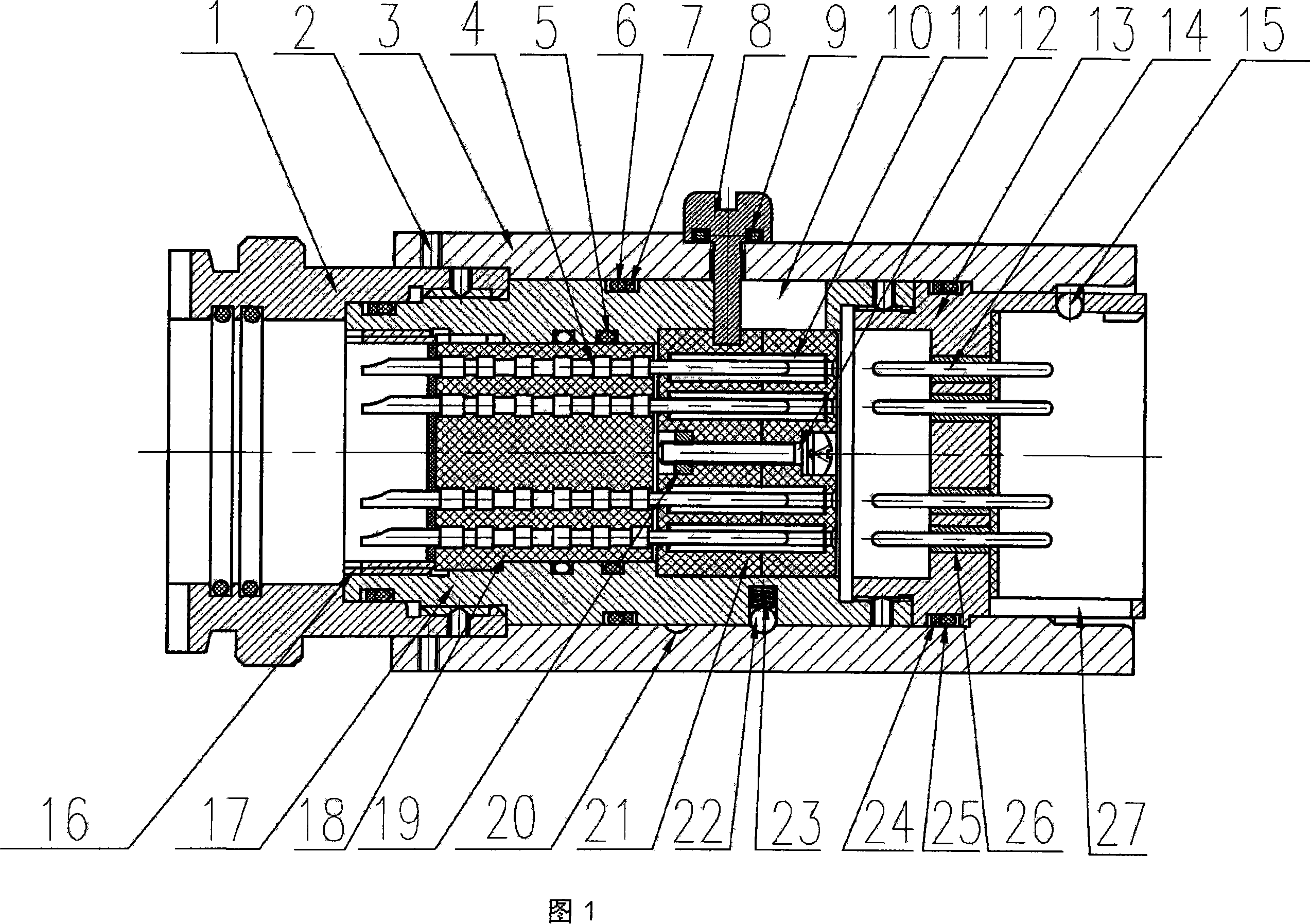

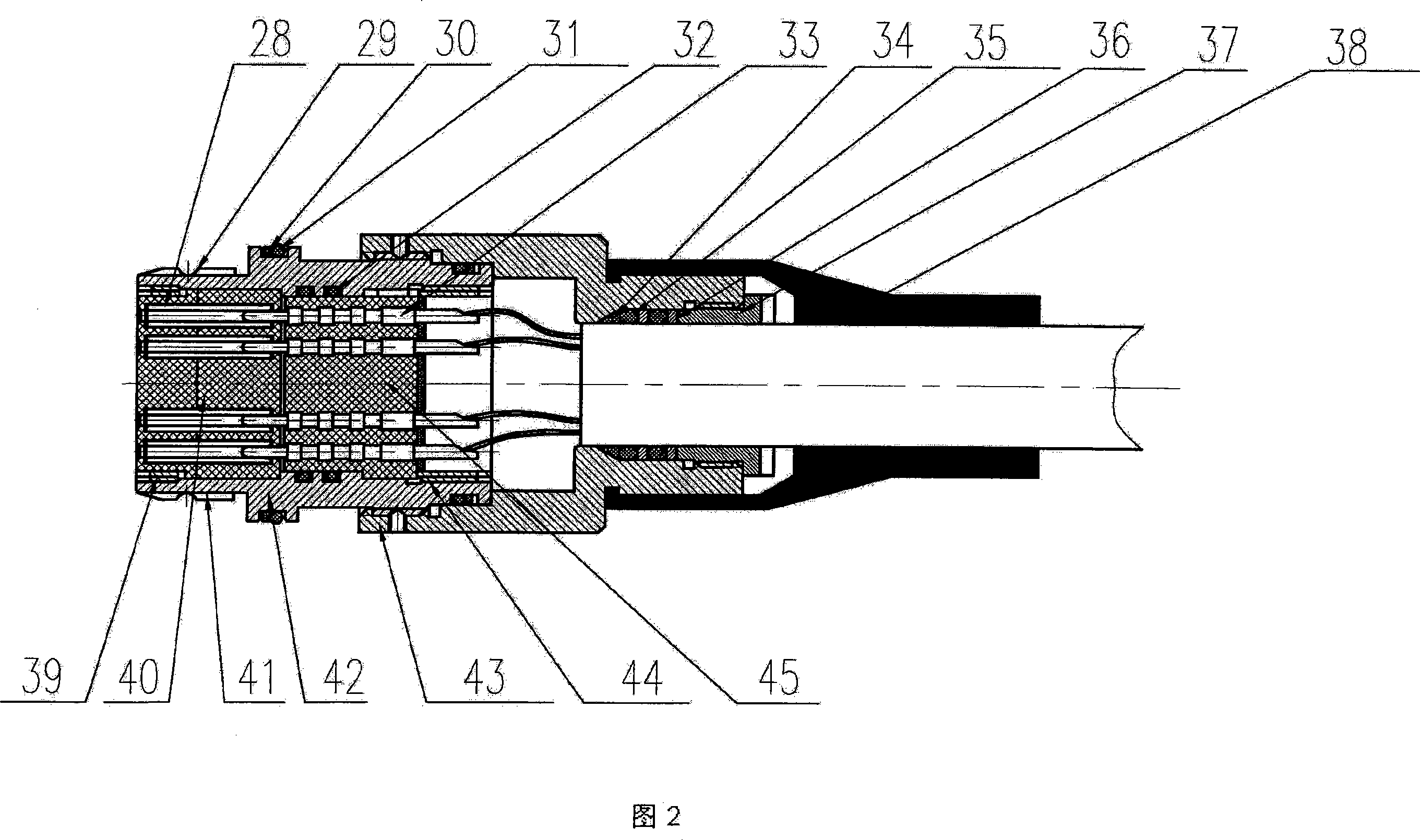

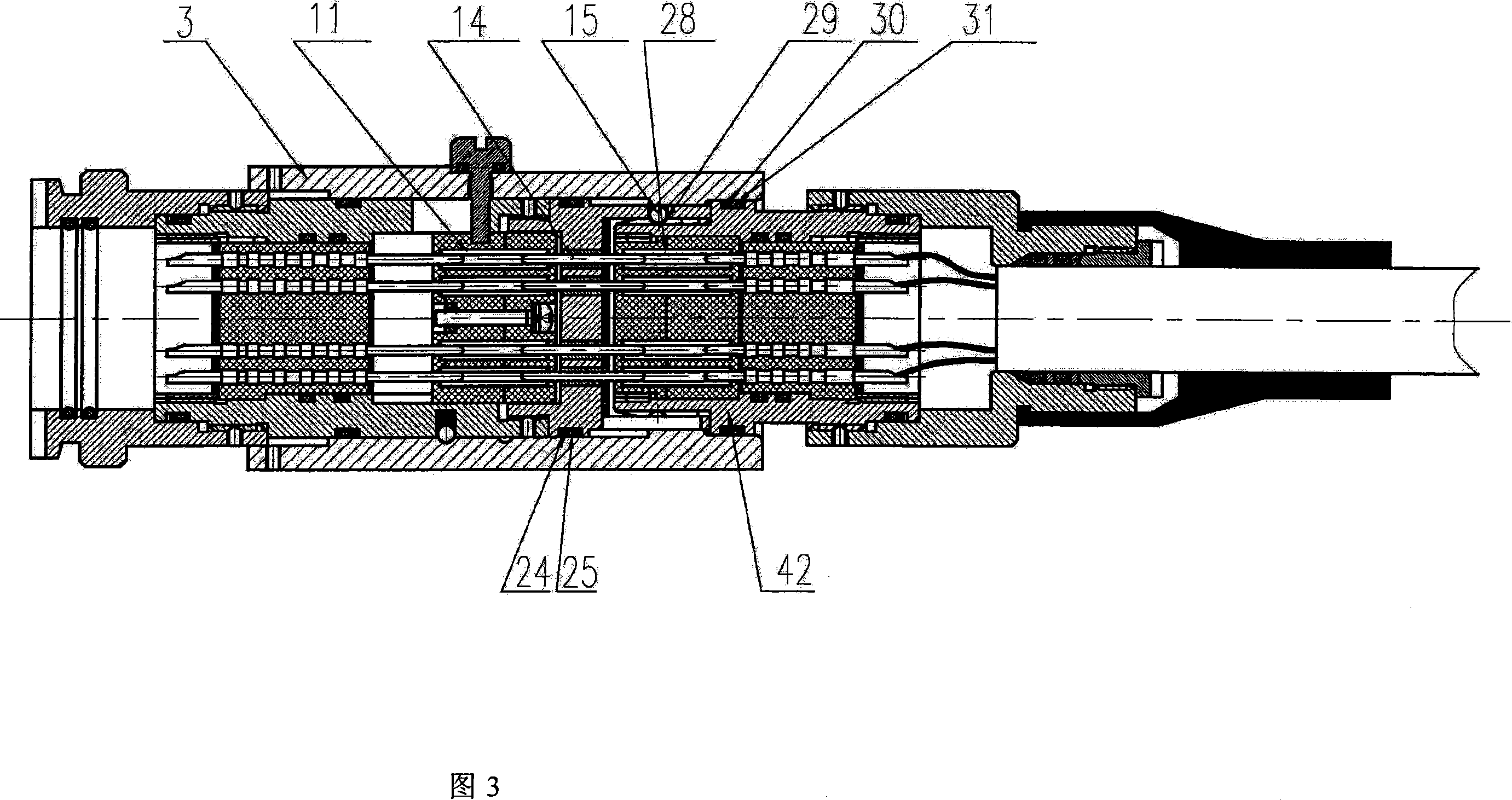

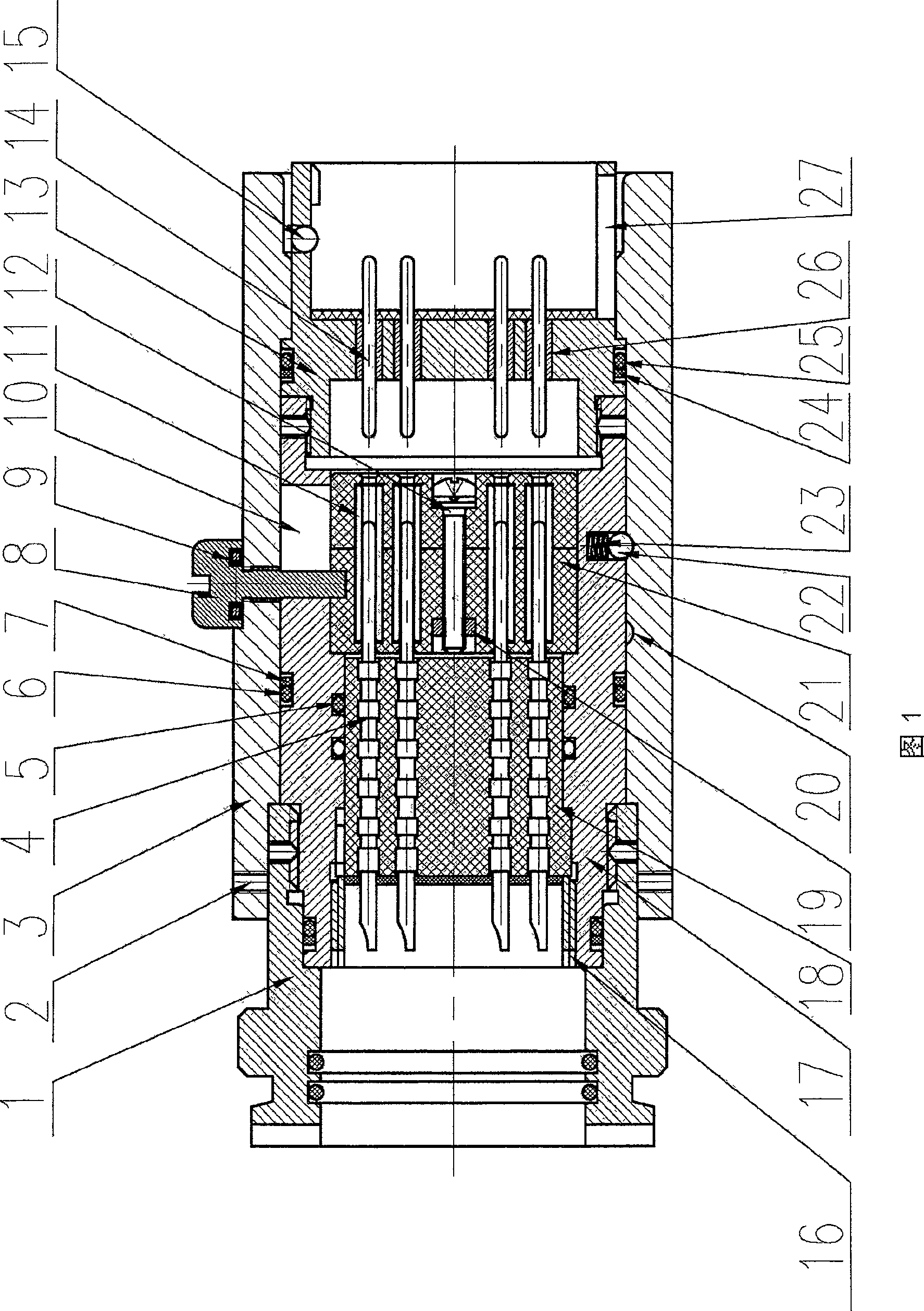

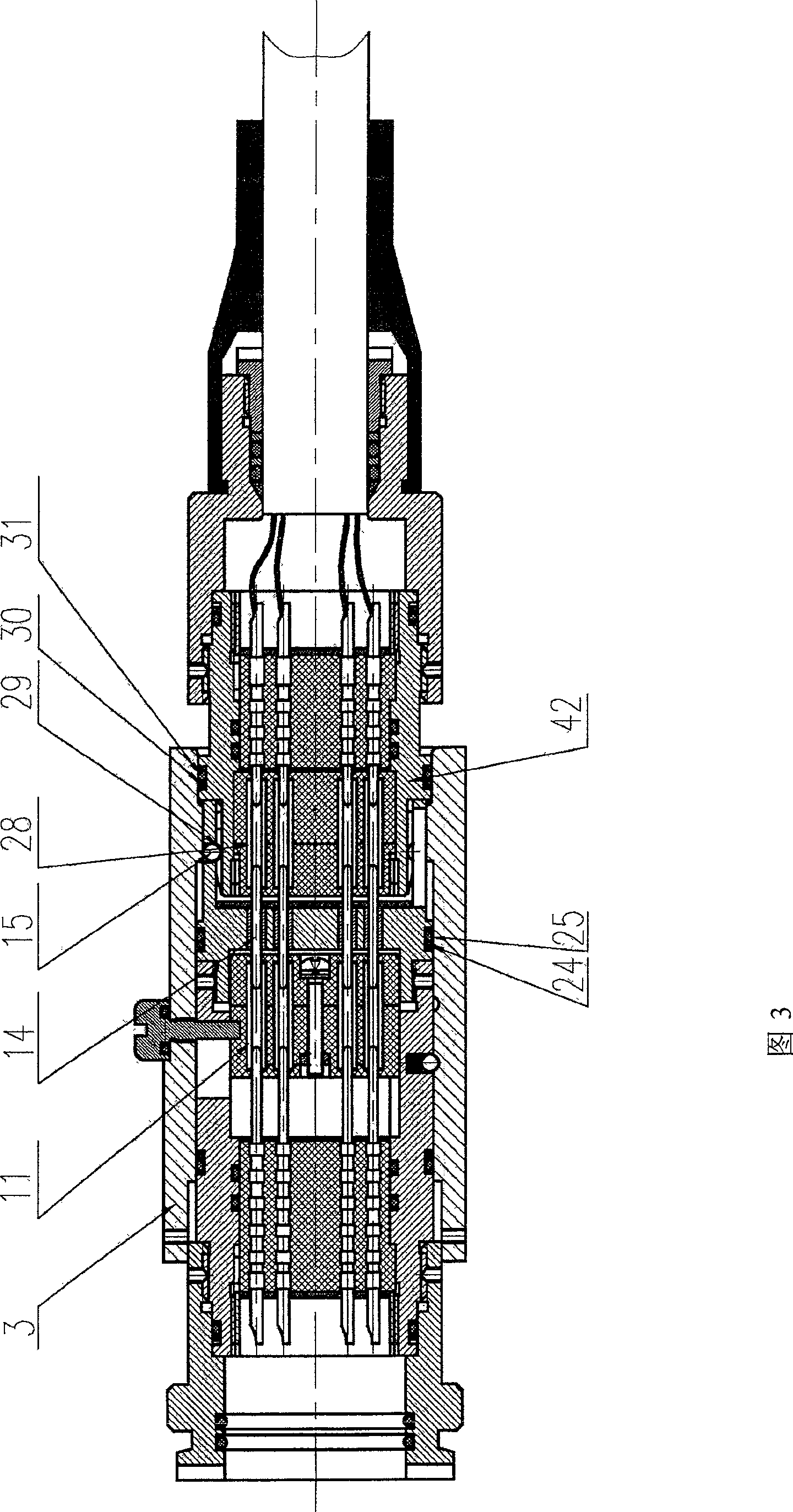

Underwater anti-short circuit separate electric connector

ActiveCN101051715ASimple anti-short circuit structureReliable anti-short circuitCoupling device detailsElectricityEngineering

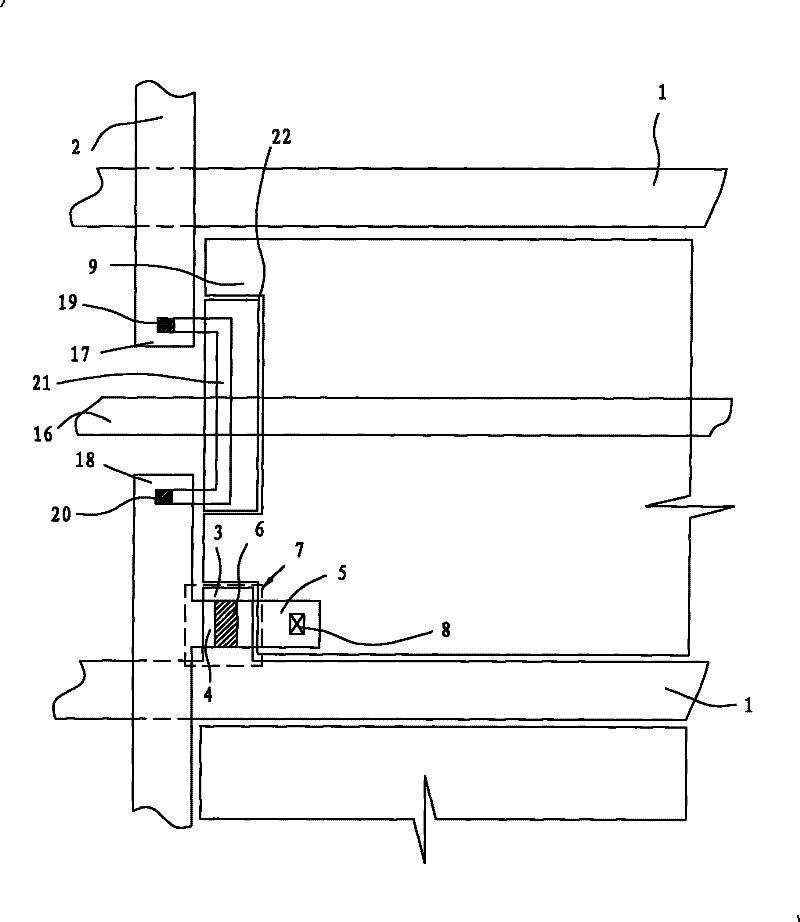

The electric connector is composed of socket and plug. Wire out port of the socket is connected to back shell body of the socket, and unlocking sheath is connected to releasing gear. The unlocking sheath via sidestep pulls movement of front shell body of the socket. Connecting rod connected to insulator module in middle of socket is setup on the unlocking sheath. Through the connecting rod, the unlocking sheath drives axial motion of the insulator to turn signal inside the socket on / off. After unlocking, through water inlet troughs on plug and socket, water enters into insertion face of the connector in order to realize balance between inner and outer hydraulic pressures. The plug with two jacks is installed in insulator module. One end of the plug is always contacted to connector pins, and the other end is assorted to connector pins to implement turning electric signal on / off. With simple structure, the invented electric connector prevents short circuit reliably.

Owner:杭州航天电子技术有限公司

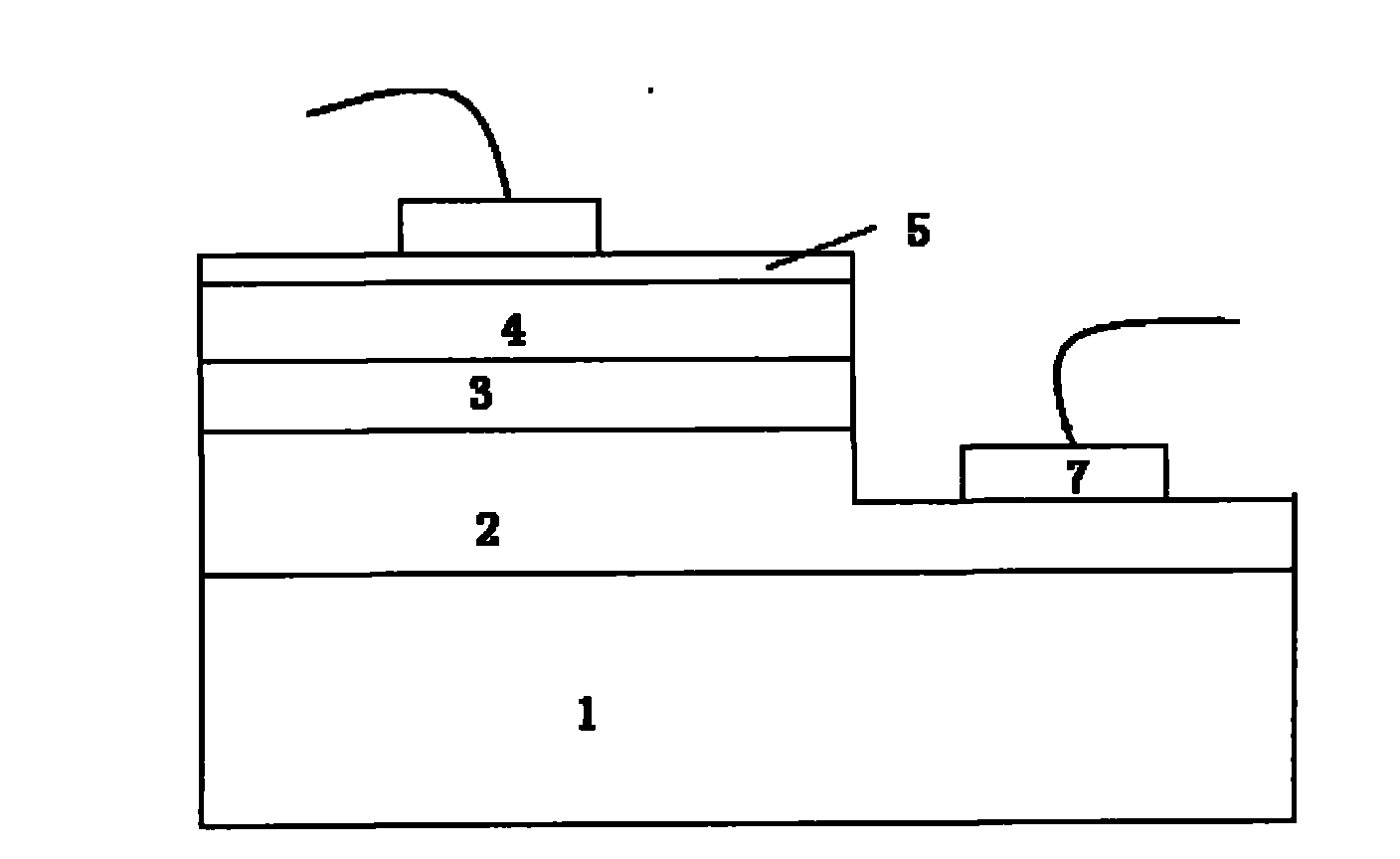

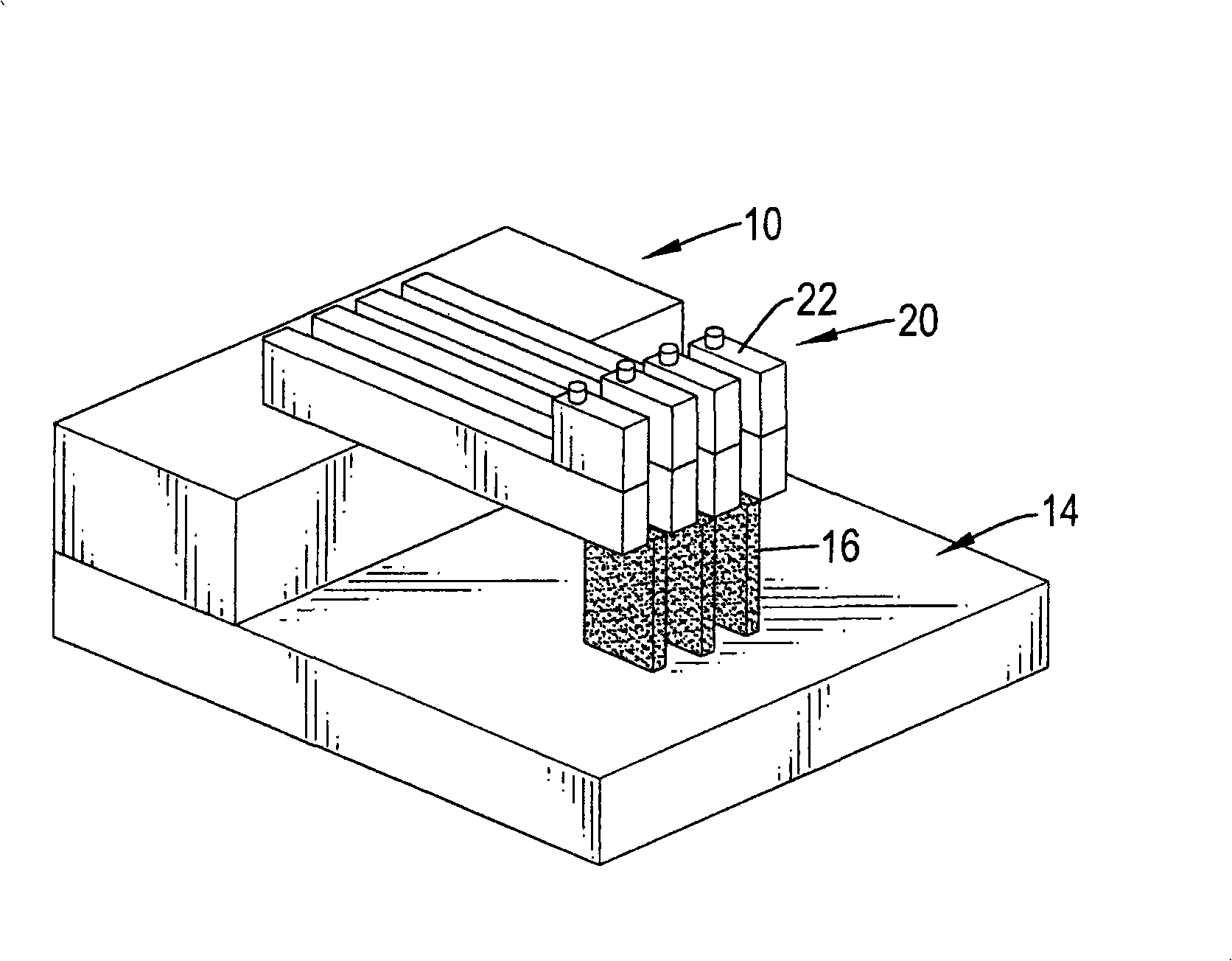

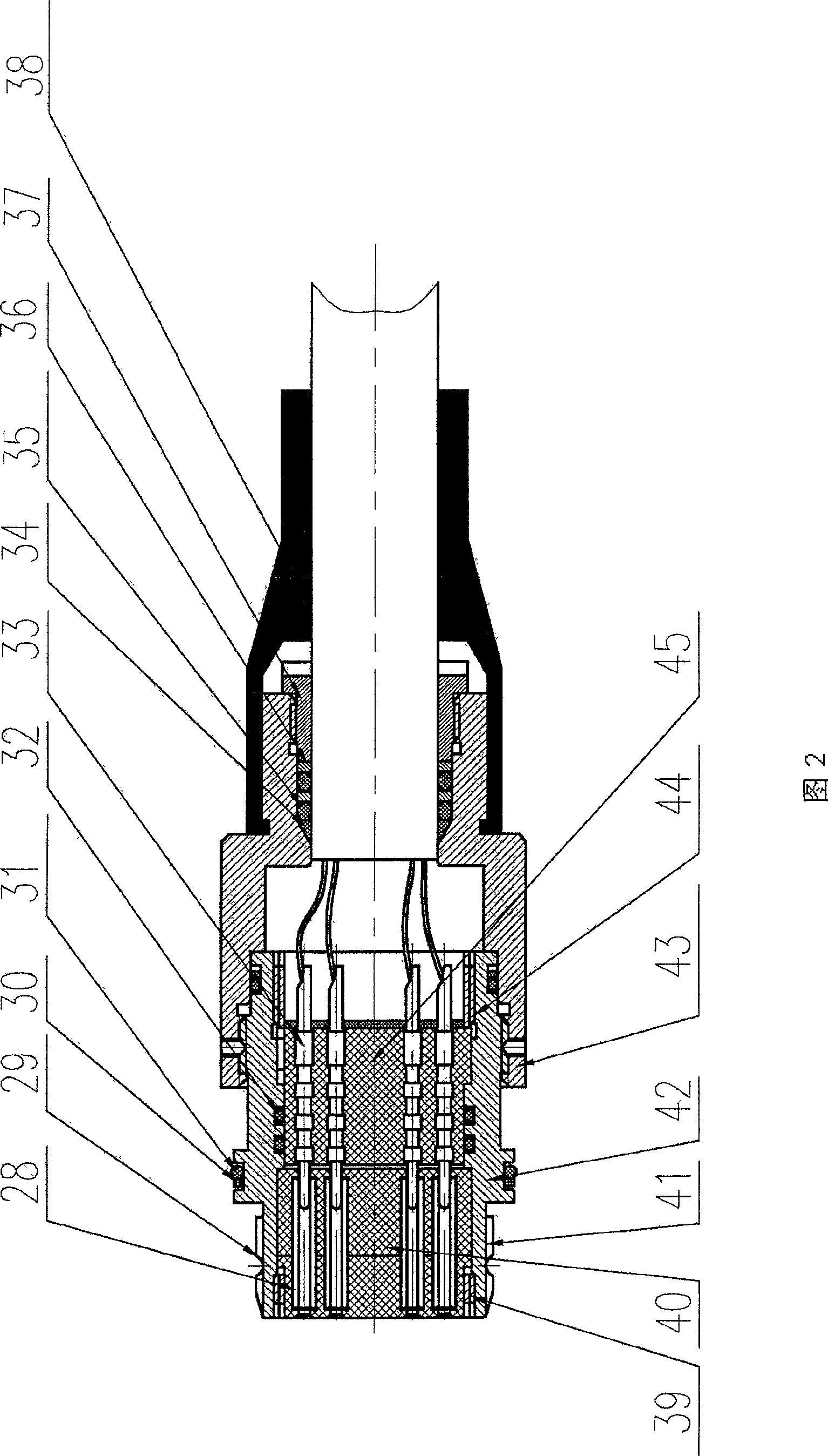

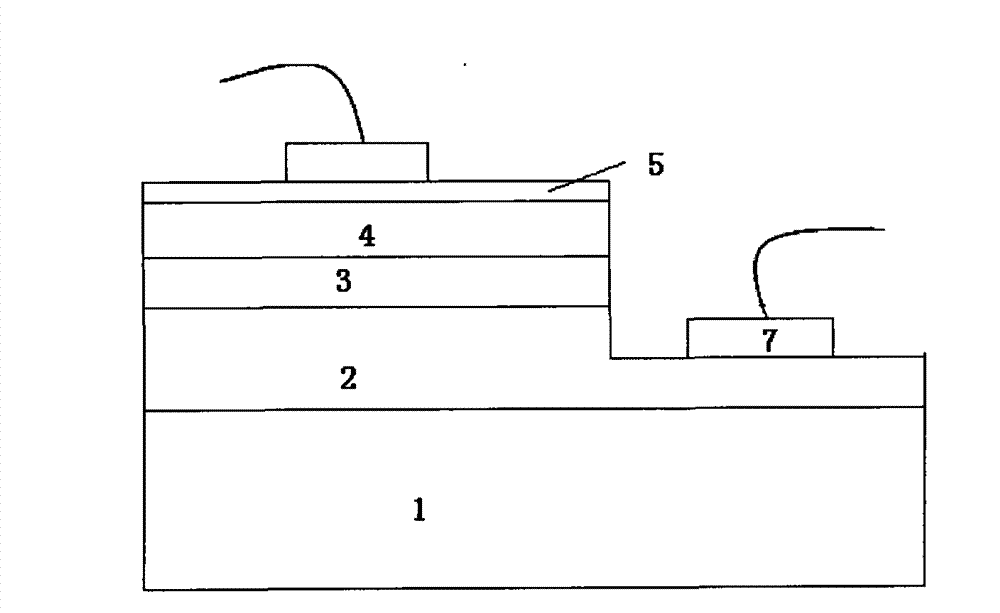

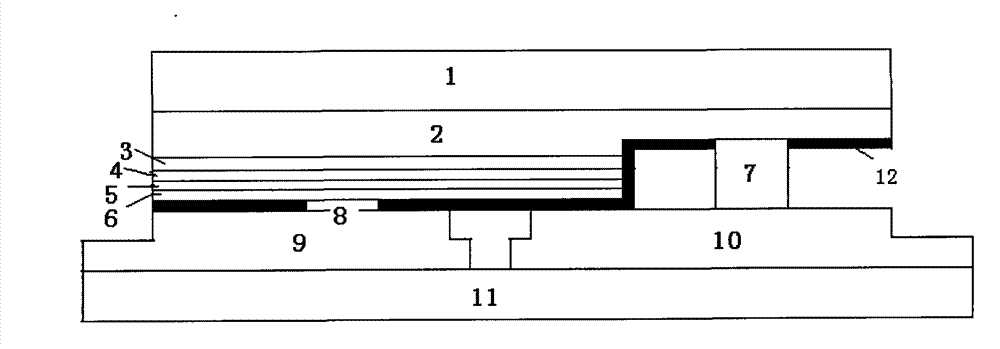

Flat FCB (Flip Chip Bonding) GaN-based LED (Light-Emitting Diode) chip structure

ActiveCN102034925APrevent short circuitAvoid short circuitSolid-state devicesSemiconductor devicesPower flowQuantum well

The invention provides a flat FCB (Flip Chip Bonding) GaN-based LED (Light-Emitting Diode) chip structure comprising a substrate. An N-type GaN layer, a QW (Quantum Well) active area, a P-type GaN layer, a current extension level and a light-reflecting layer are sequentially arranged below the substrate from top to bottom, a stepped surface to the N-type GaN layer is etched on the light-reflecting layer, an N electrode is made on the N-type GaN layer of the stepped surface, a P electrode is made on the light-reflecting layer and arranged on the same plane with the outer end of the P electrode, a transparent insulated medium film is coated on the plane of the P electrode bonding pad and the N electrode bonding pad except the regions of P electrode bonding pad and the N electrode bonding pad, a P bonding board is made at the outer end of the P electrode bonding spot, an N bonding board is made at the outer end of the bonding point of the N electrode, and the P bonding board and the N bonding board are bonded on a P electrode area and an N electrode area of a conductive Si or SiC substrate by cocrystallization or alloy. The insulated medium film is coated outside the PN bonding pads to prevent PN from being subjected to short circuits and a limit N-area electrode conductive flat is spliced to the P area desk.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

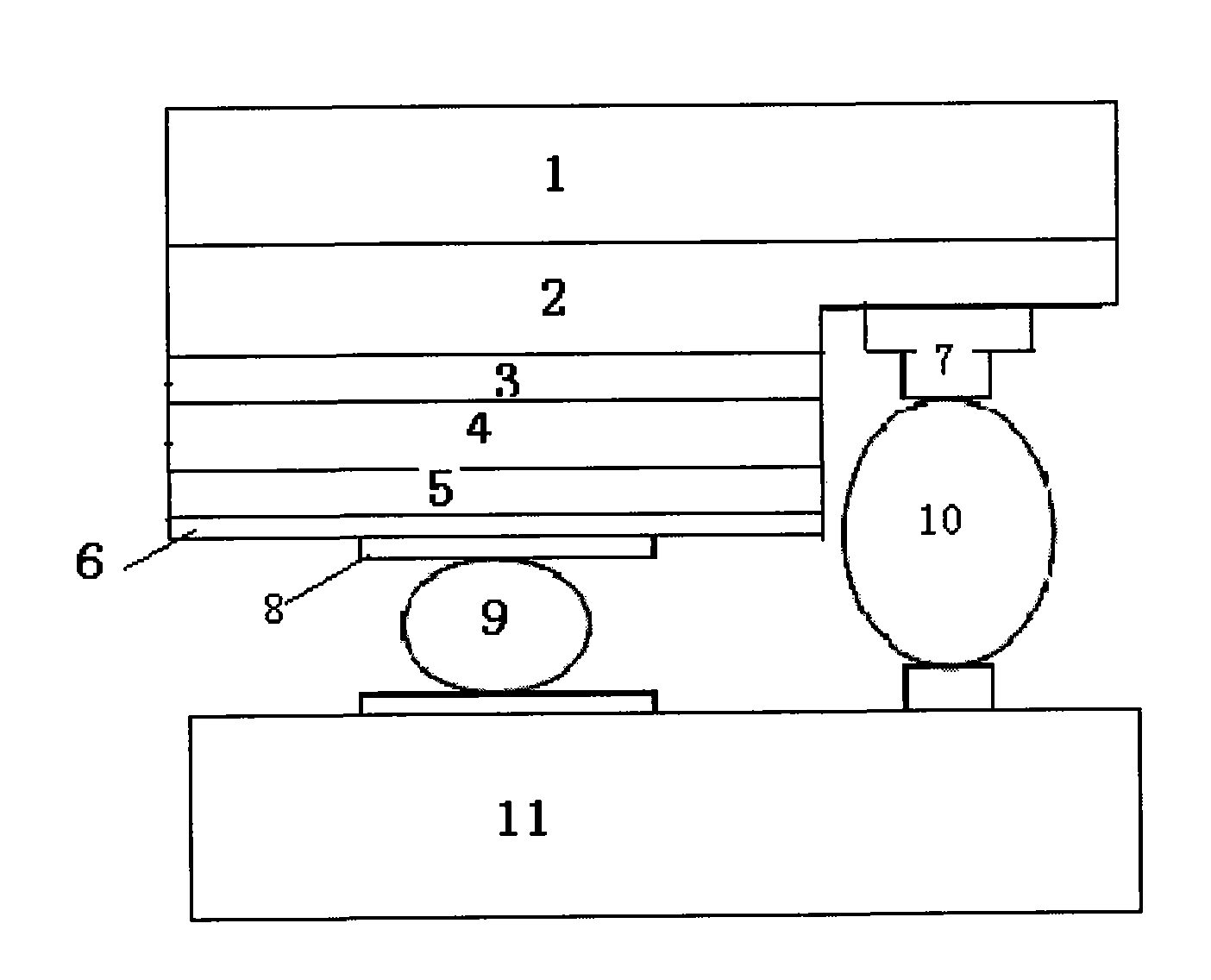

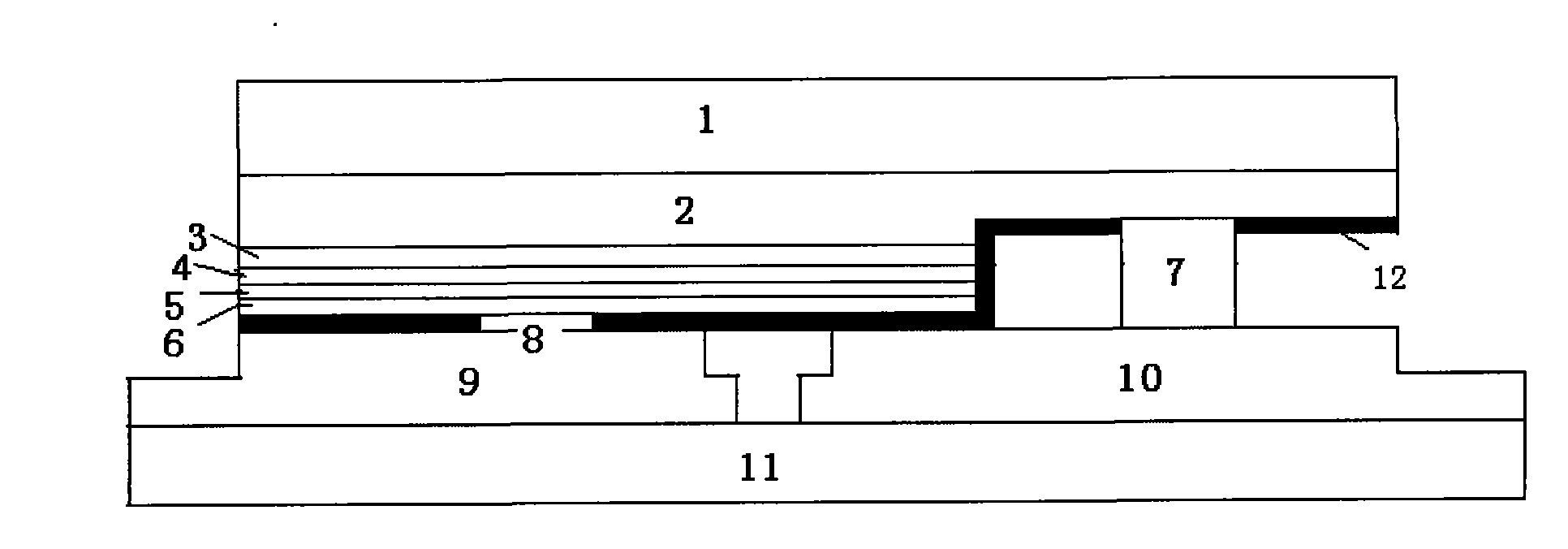

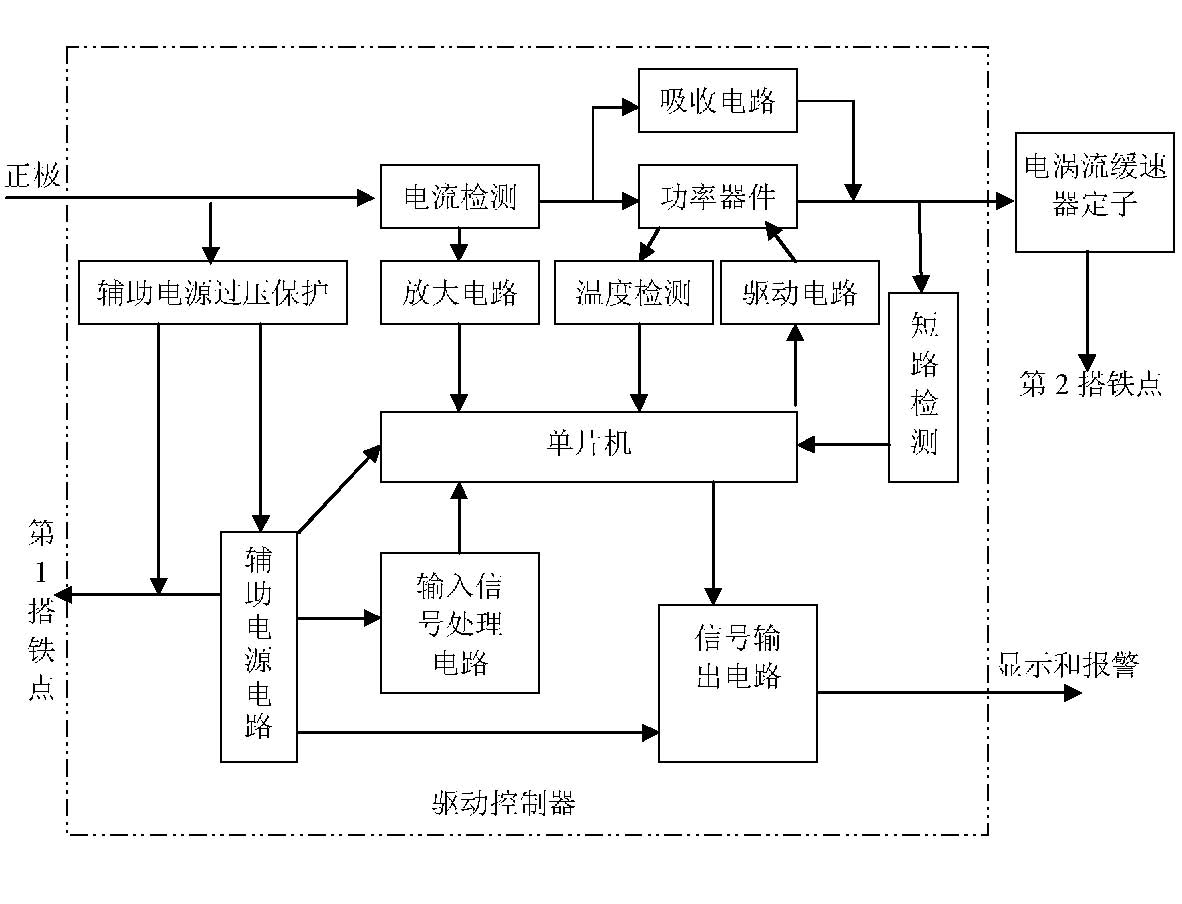

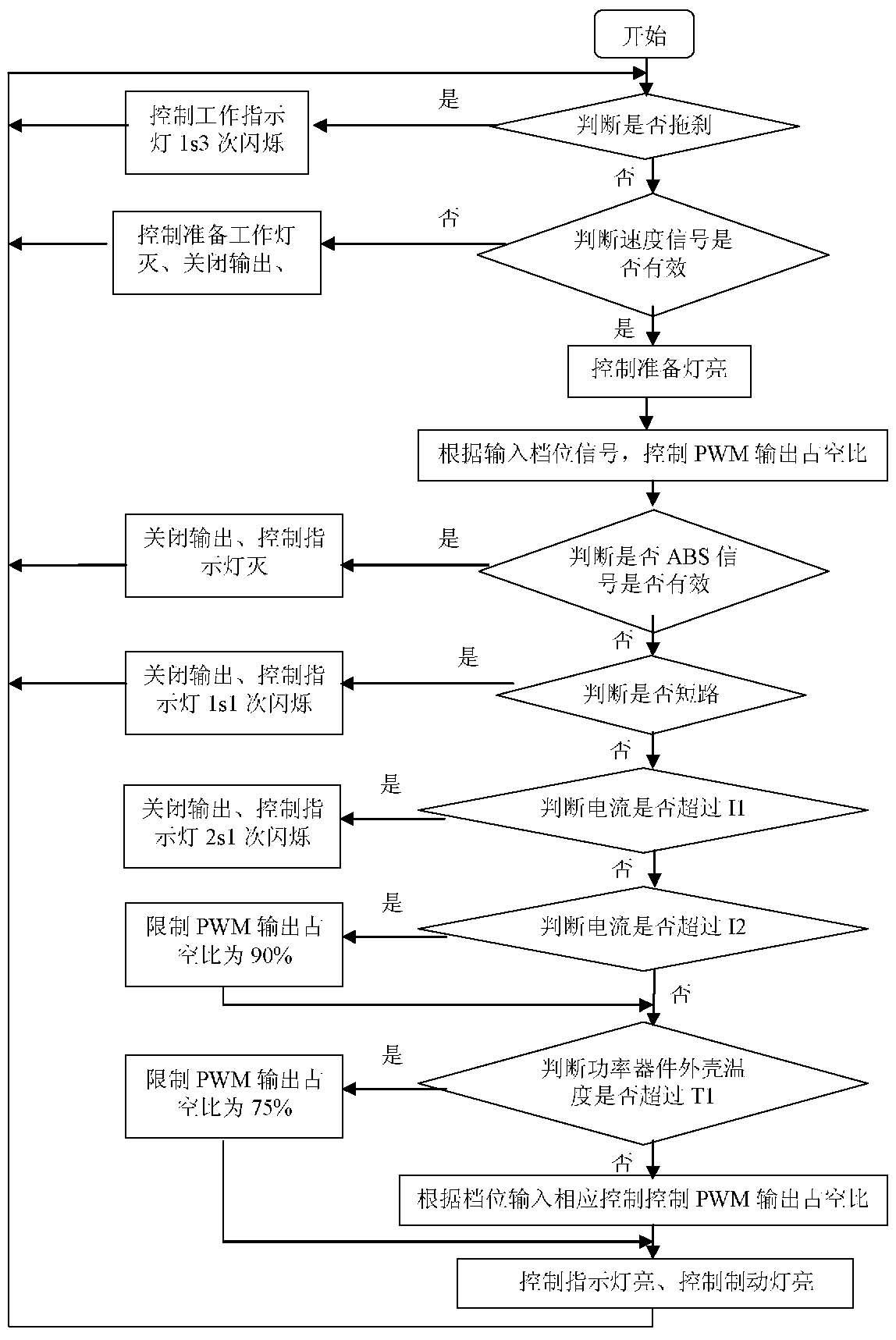

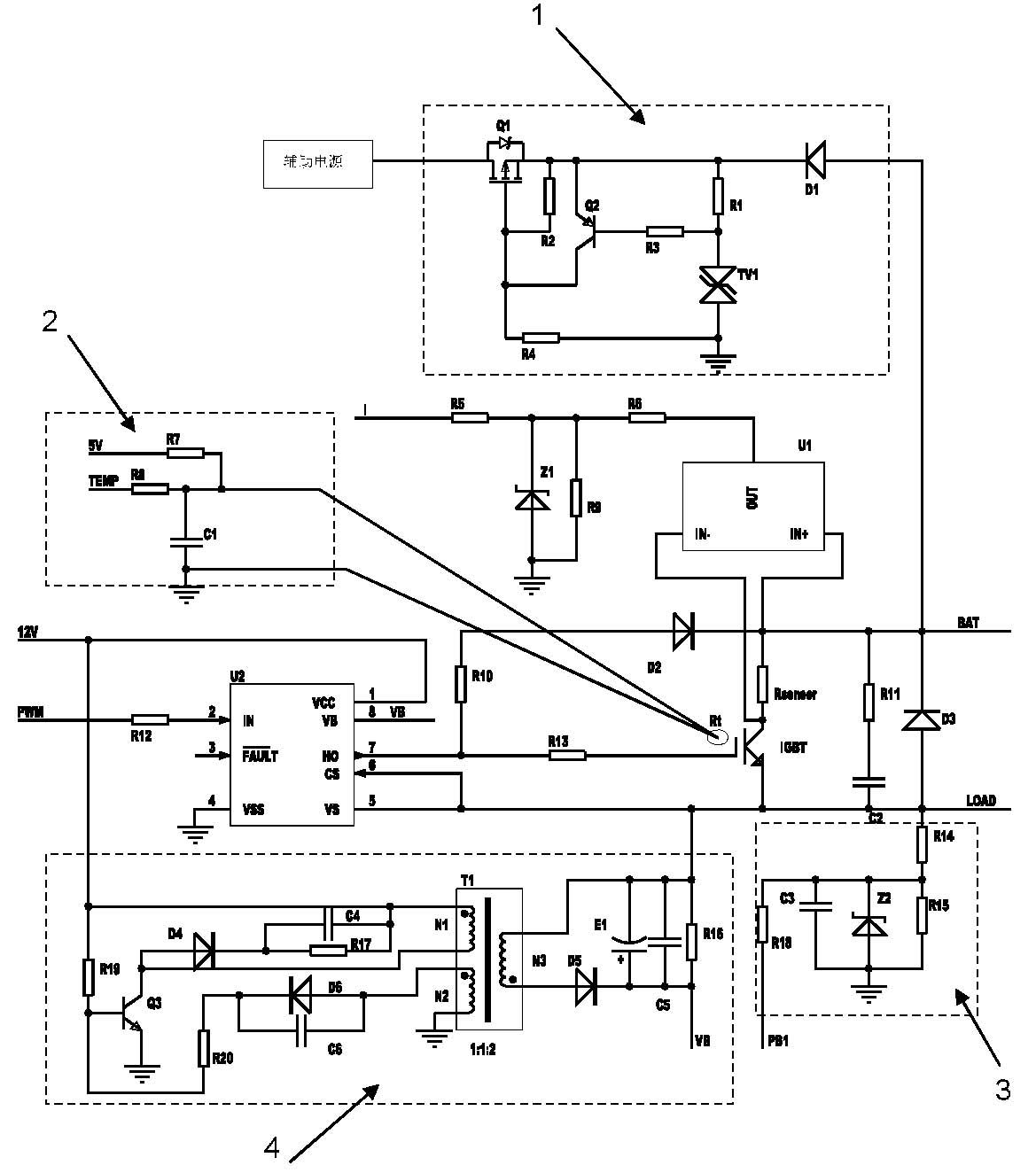

Driving controller of electric eddy current brake and control method thereof

InactiveCN101867336AAvoid failureAvoid short circuitElectrodynamic brake systemsElectric machinesDriver circuitElectricity

The invention relates to a driving controller of an electric eddy current brake and a control method thereof, wherein the controller comprises a control unit, a driving circuit and an insulated gate bipolar transistor IGBT with large current and high pressure resistance electrically connected in sequence, and a rectification unit, a transformer T1 and a power input thereof connected with an IGBT output grid electrode in sequence. The control method comprises the steps that the control unit controls the pulse width thereof according to the input gear to modulate the duty ratio of the PWM output under the condition of normal circuit detection, or else turns off the output or restricts the duty ratio of the PWM output; the driving circuit receives the PWM output and drives the IGBT output according to the PWM output. The driving controller of the electric eddy current brake and the control method thereof has the high pressure resistance of 300V, and basically avoids the over-voltage failure used on cars, the controller can not be failed under various abnormal conditions combining a detection and protection circuit, thereby greatly enhancing the reliability, and solving the industrial problem of poor reliability of electronic control mode in the electric eddy current brake industry.

Owner:深圳市大为创新科技股份有限公司

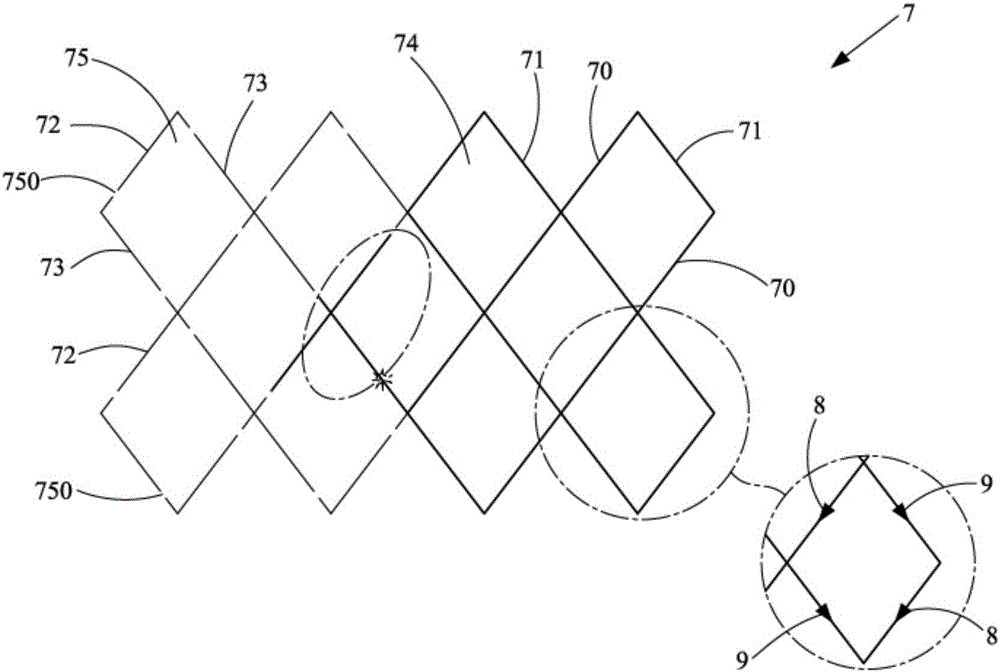

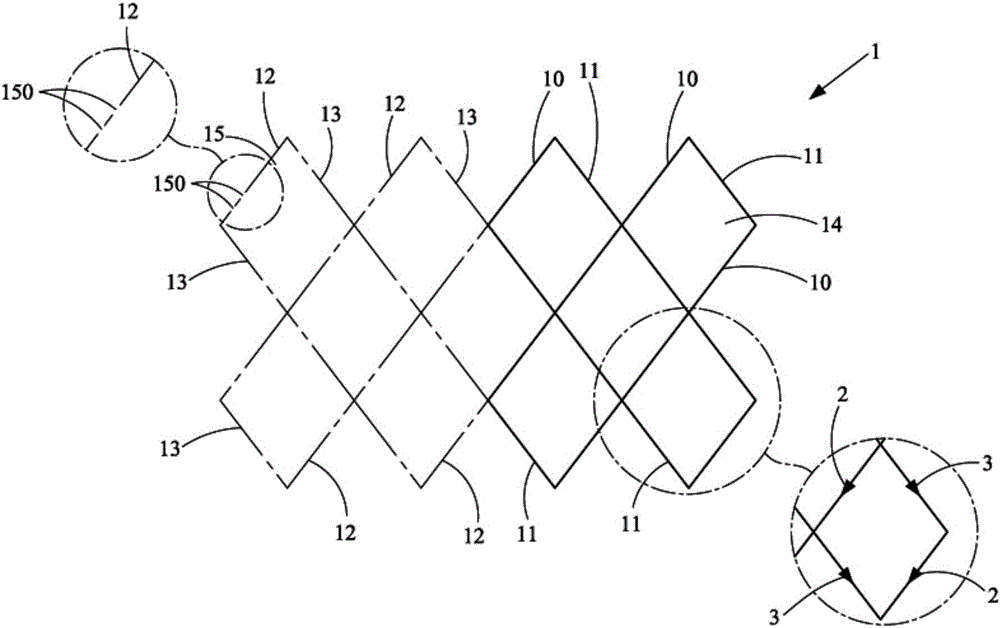

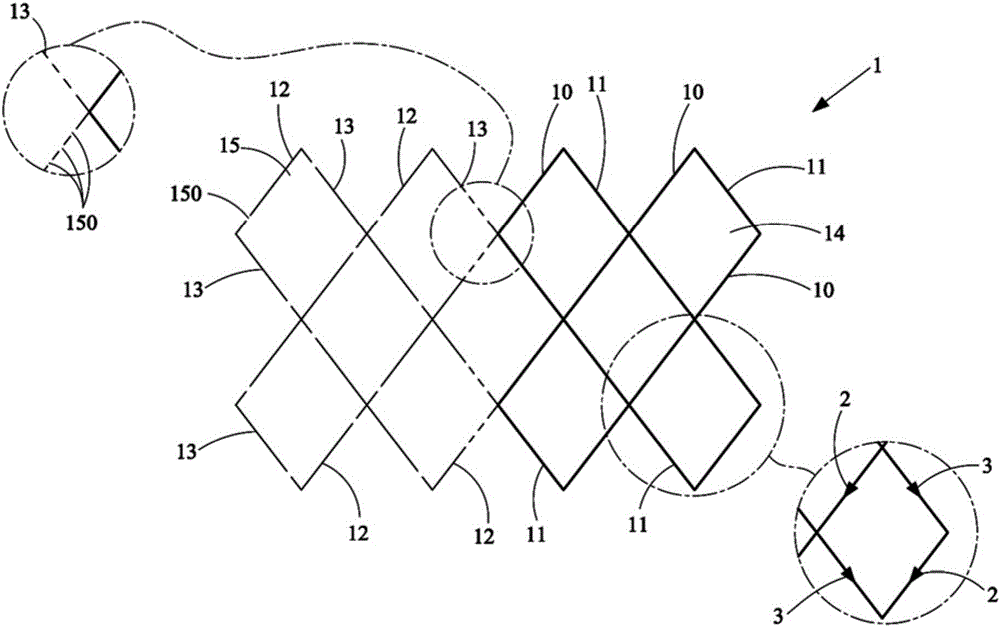

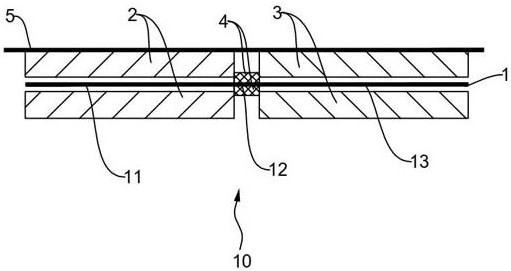

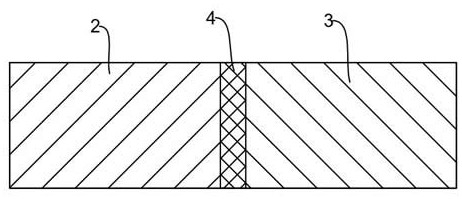

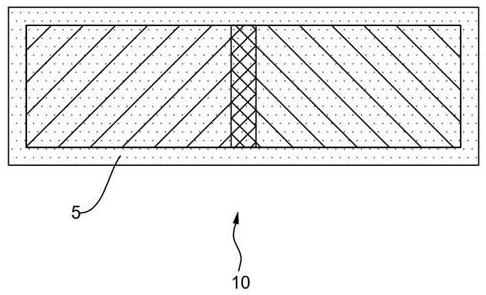

Metal mesh structure capable of reducing breakpoint short out and manufacturing method thereof

InactiveCN106020528AShort circuit will notNon-insulated conductorsCable/conductor manufactureMain channelMetal

The invention discloses a metal mesh structure capable of reducing breakpoint short out. The metal mesh structure includes a plurality of first main channel metal wires, a plurality of second main channel metal wires, a plurality of first nominal metal wires and a plurality of second nominal metal wires; the first main channel metal wires are mutually arranged in the first direction at intervals; the second main channel metal wires are mutually arranged in the second direction at intervals; and the second main channel metal wires and the first main channel metal wires are staggered to form a plurality of main channel meshes. The invention further discloses a manufacturing method of the metal mesh structure capable of reducing breakpoint short out. The metal mesh structure and the manufacturing method can effectively reduce breakpoint short out of metal meshes.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

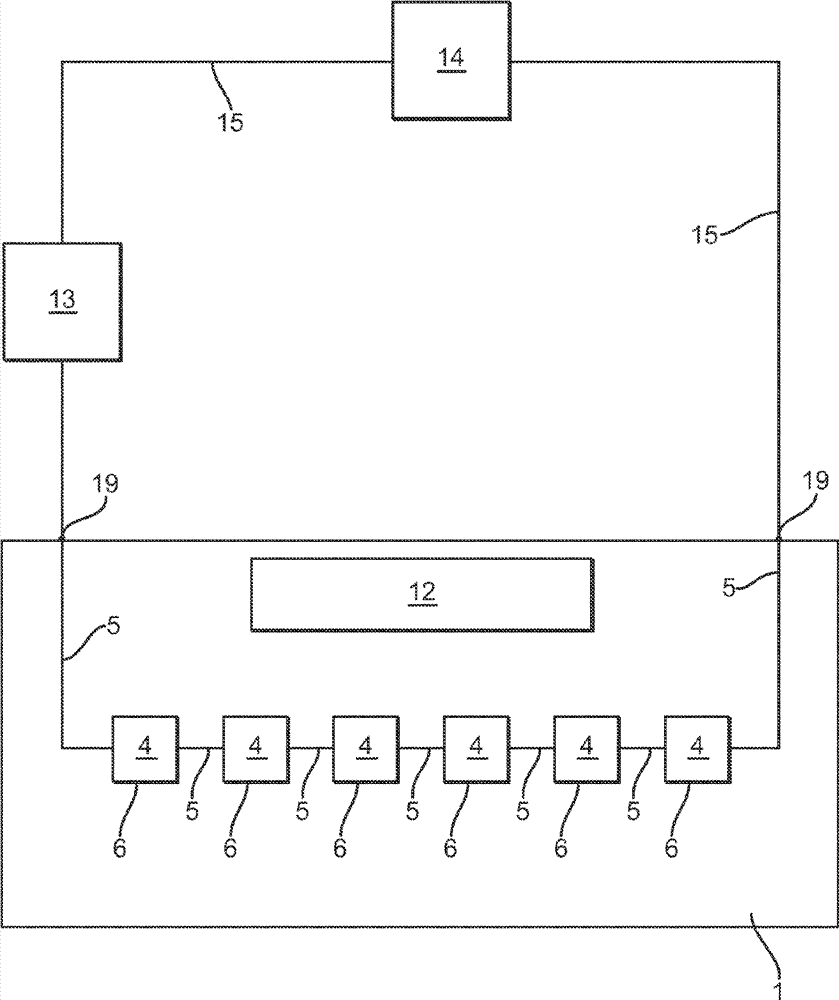

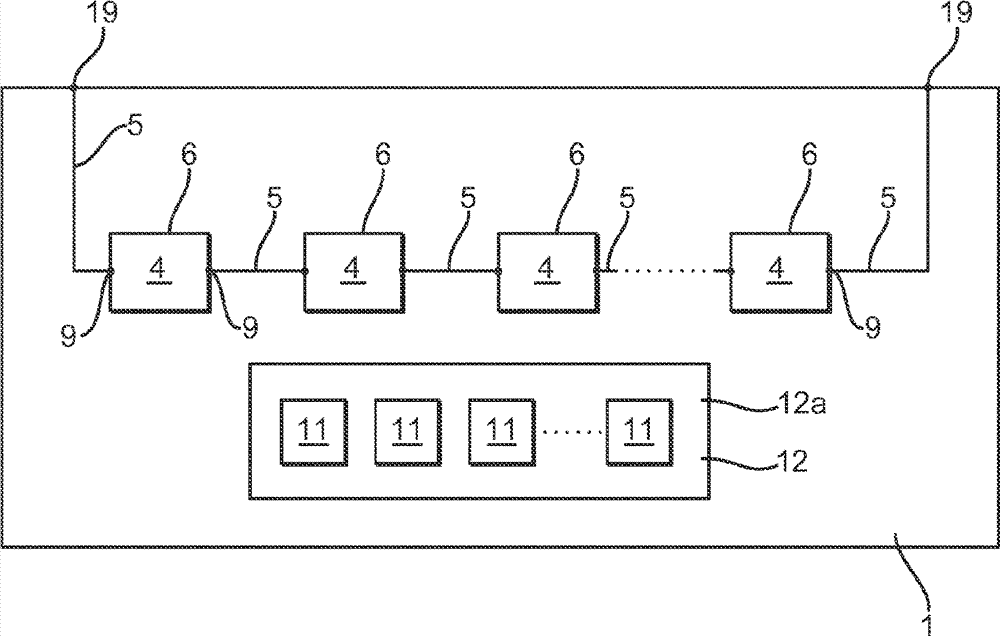

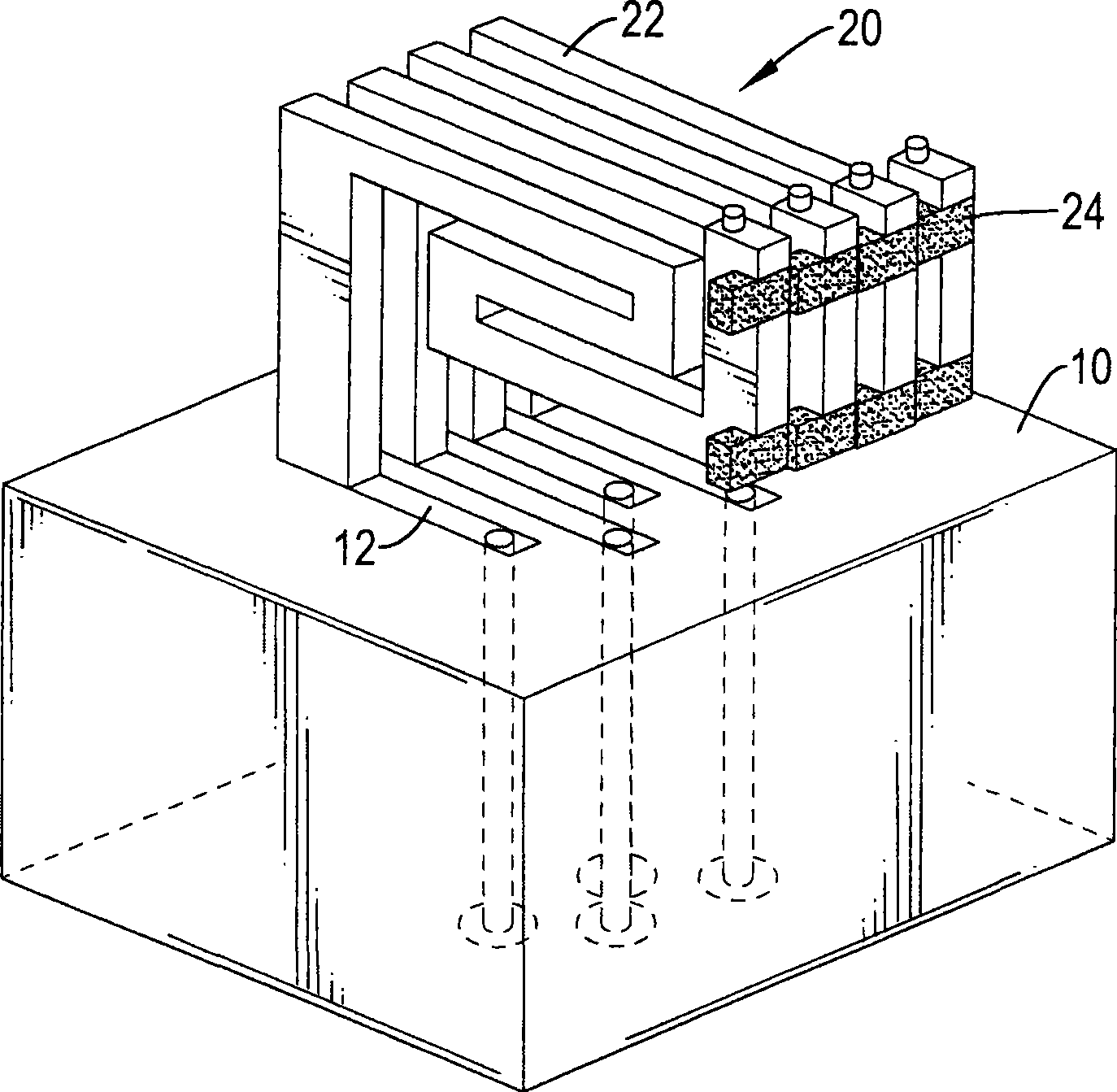

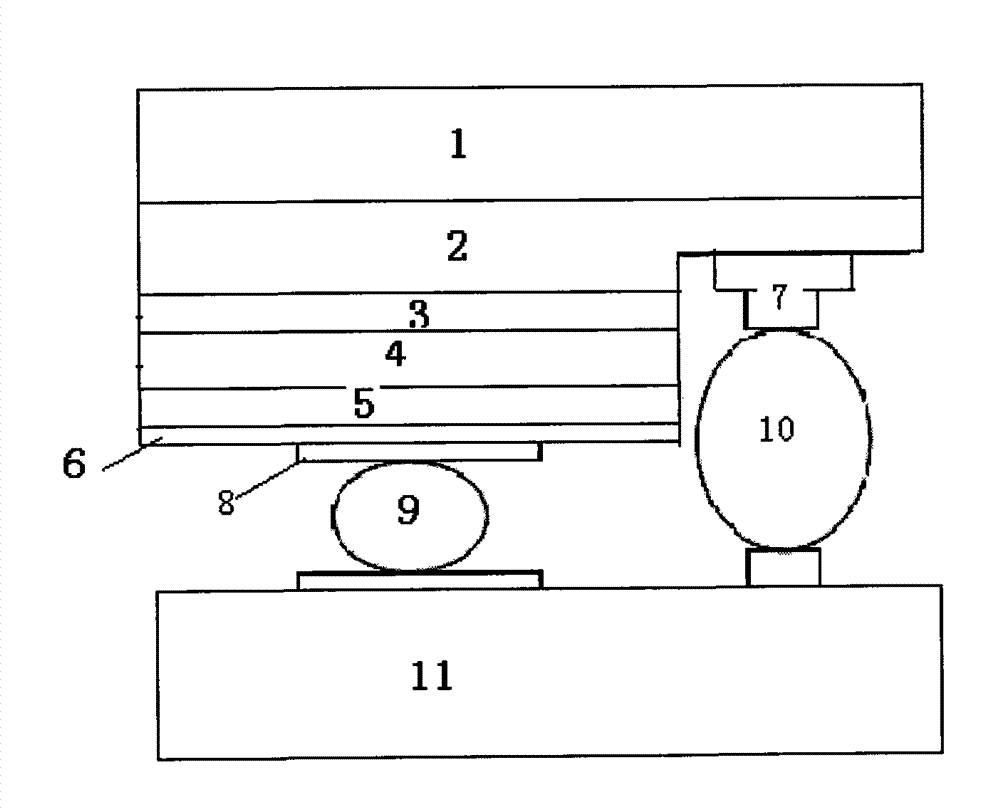

High-current battery system and method for controlling a high-current battery system

InactiveCN102742066AAvoid short circuitNo short circuitCircuit monitoring/indicationIndicating/monitoring circuitsElectricityComputer module

The present invention relates to a high-current battery system (1) in which a high operating current flows, in particular for vehicle drives. The high-current battery system (1) has a battery system monitoring electronics unit (12) and a plurality of battery modules (4), each module including at least one rechargeable battery cell (10) and being electrically connected in series by means of an operating current line (5) such that an operating current flows through the operating current line (5) during operation. At least one of the battery modules (4) is designed as a bypass battery module (6) which comprises a bypass switch (7) and a bypass line (8), which are designed and disposed such that the battery module (6) is electrically bridged by the bypass line (8) after the bypass switch (7) is switched from a normal operating position into a bypass position, so that the operating current flows through the bypass line (8). For each bypass battery module (6), the battery system monitoring electronics unit (12) incorporates a module monitoring unit (11) which monitors the associated battery module (6) and detects a fault state of the module (6). Upon detection of a fault state of a battery module (6) by one of the module monitoring units (11), the battery system monitoring electronics unit (12) measures the current flow in the operating current line (5) and switches the bypass switch (7) of the battery module (6) in question from the normal operating position into the bypass position at a time at which the current flow in the operating current line (5) is less than a predetermined limit value.

Owner:INNOLITH ASSESTS AG

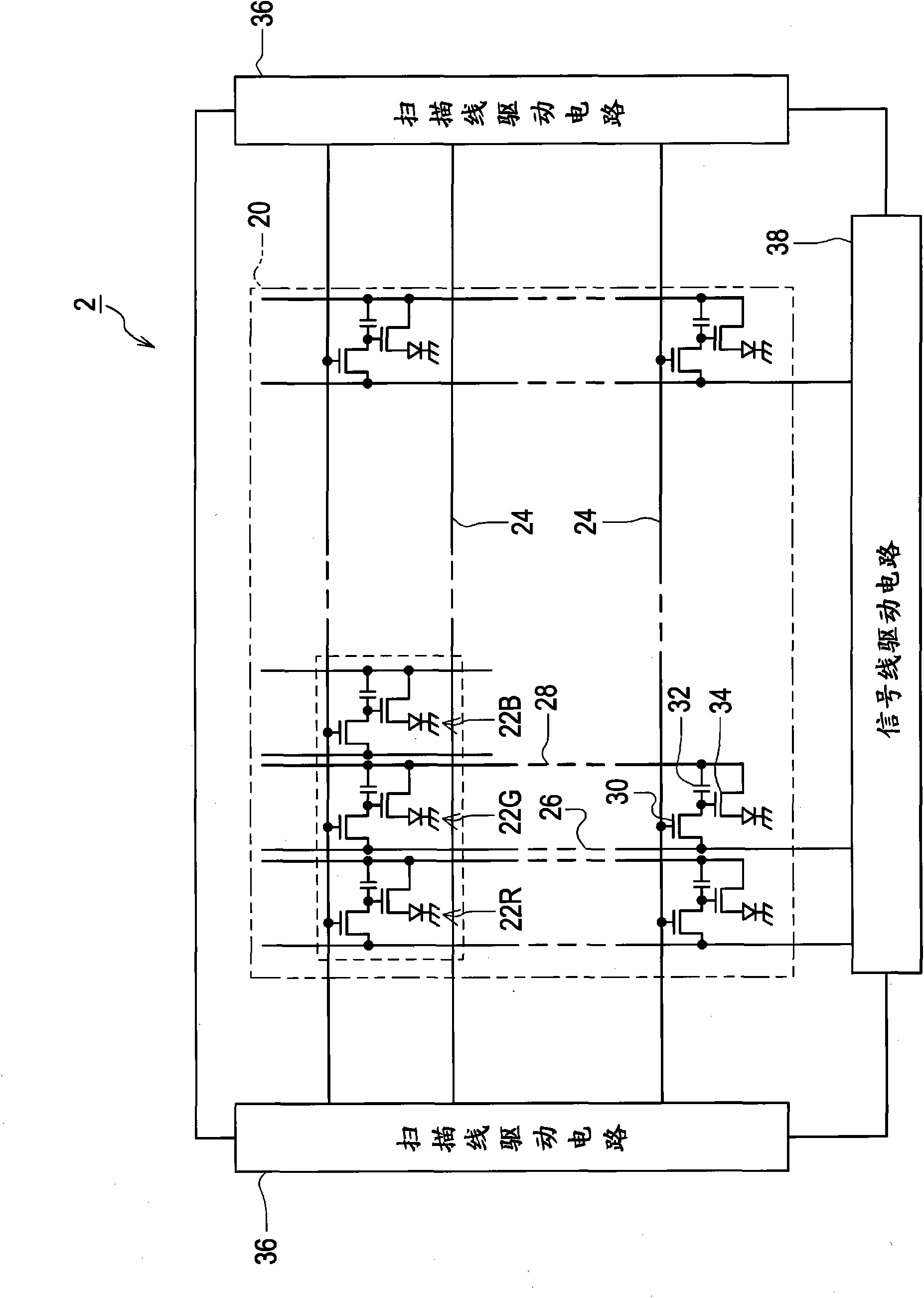

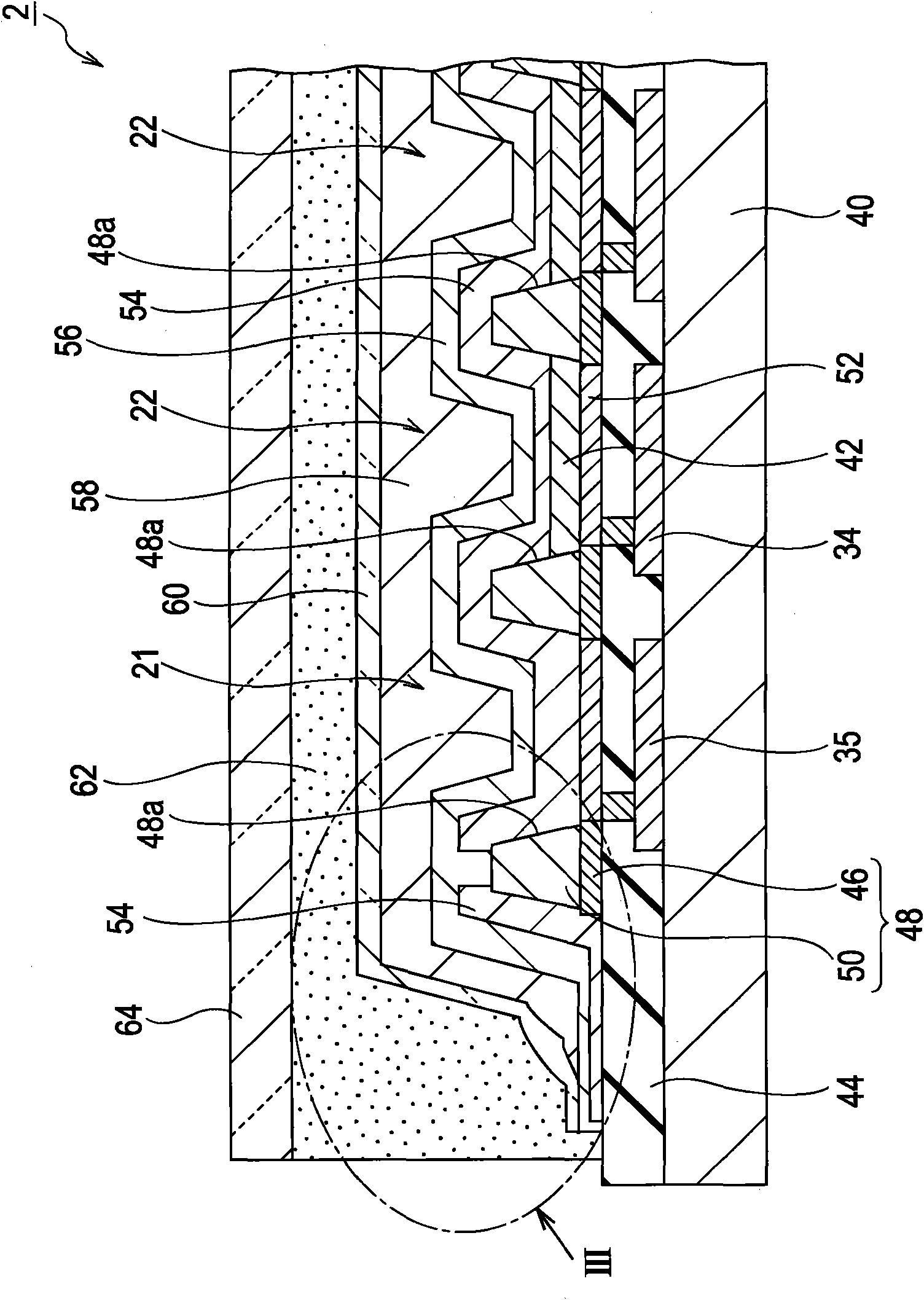

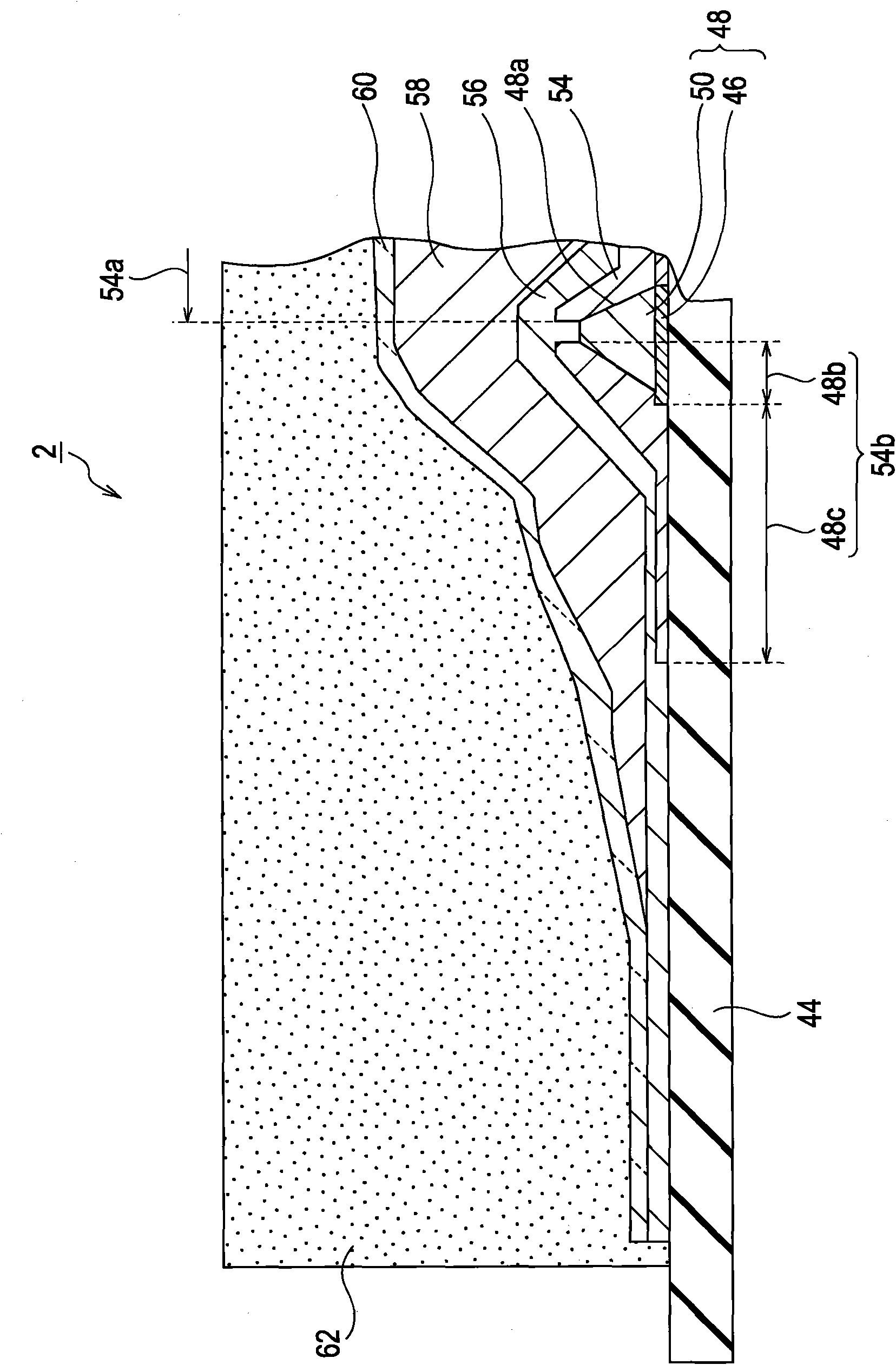

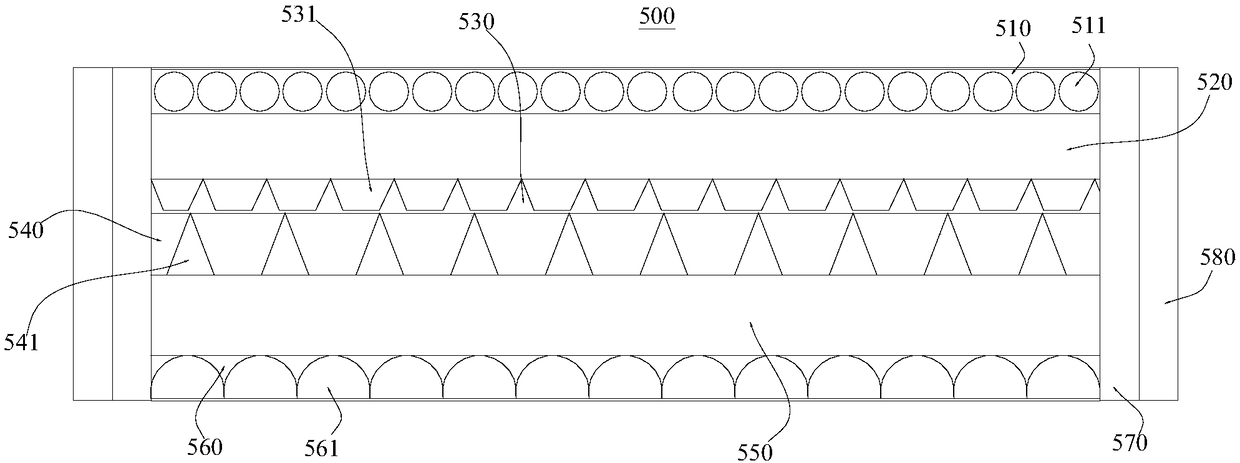

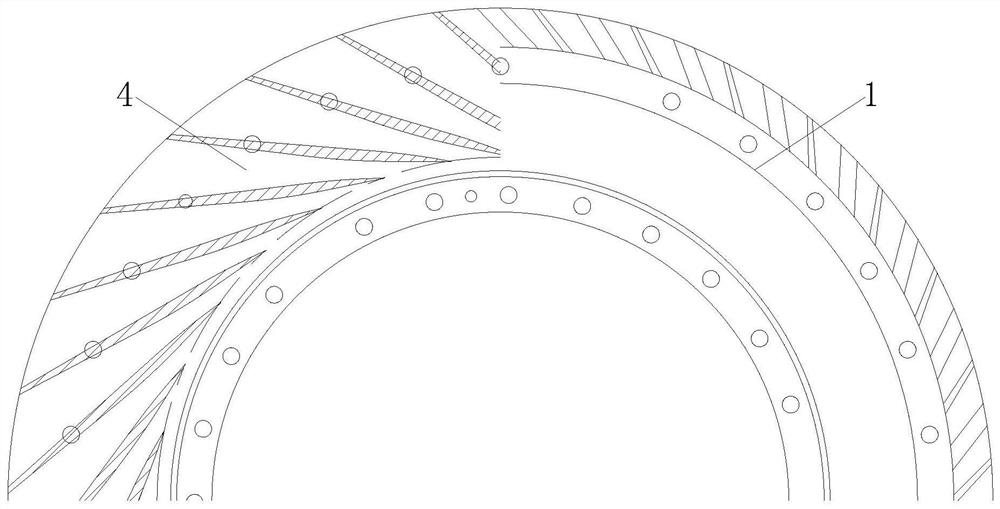

Organic electroluminescence device

InactiveCN101859876AShort circuit will notSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOrganic electroluminescence

The present invention provides an organic electroluminescence device which can improve humidity resistance performance and narrow a frame. The organic electroluminescence device includes on a substrate a plurality of first electrodes (52), a partition structure (48) having a plurality of openings (48a) corresponding to the positions of the first electrodes, an organic luminescent layer (42), a second electrode (54) covering the partition structure and the organic luminescent layer, and a sealing layer or a sealing member covering the second electrode. The second electrode includes a first portion (54a) and a second portion (54b) that are separate from each other. The first portion covers the entire partition structure (48b) except the outer portion from the edge of the partition structure, and the organic luminescent layer. The second portion covers the outer portion from the edge of the partition structure and at least part of the external region (48c) around the partition structure.

Owner:SEIKO EPSON CORP

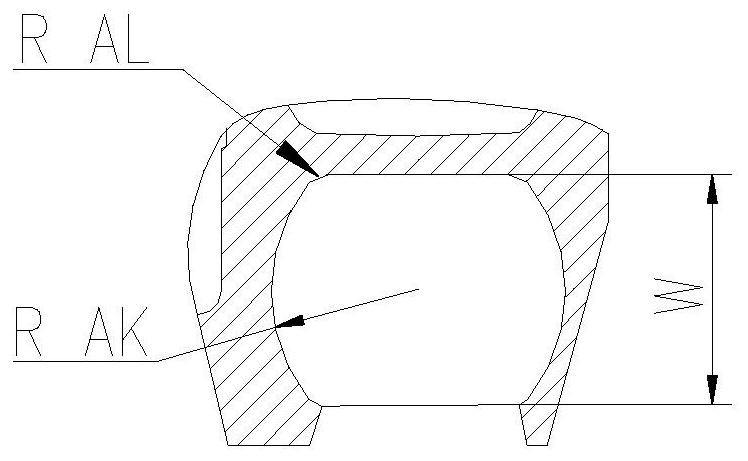

Probe short circuit preventing structure

InactiveCN101329366AEliminate short circuitShort circuit will notElectrical measurement instrument detailsElectrical testingPhysicsShort circuit

The invention provides a probe short-circuit prevention structure which is an insulated separation structure; each separation structure can be embedded in a probe body or a corresponding position of a probe seat, which is at the interval of the probes, thus causing each probe to have the efficacy of mutual separation when in use.

Owner:MICROELECTRONICS TECH INC

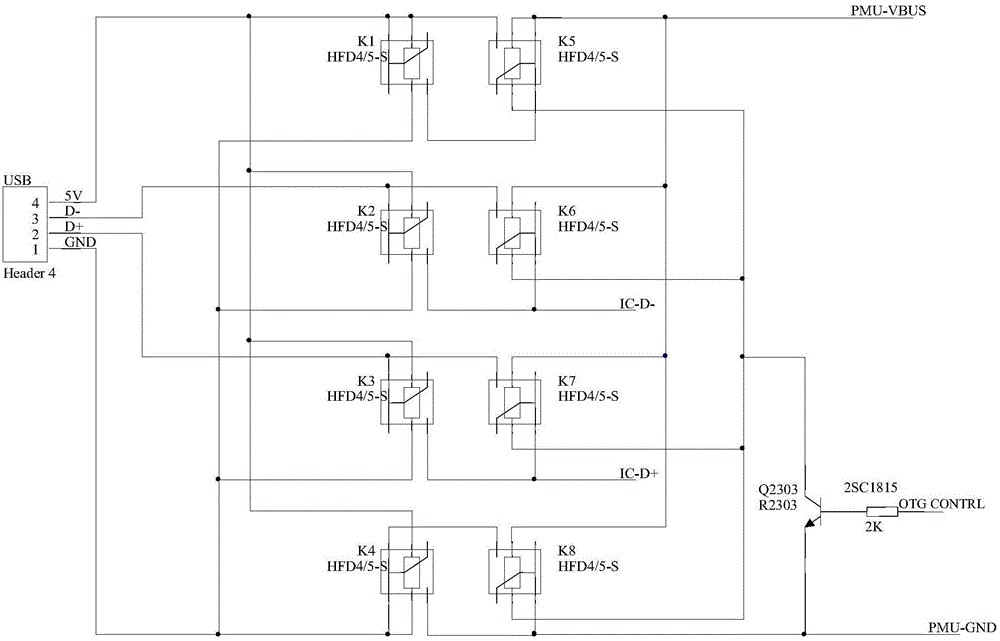

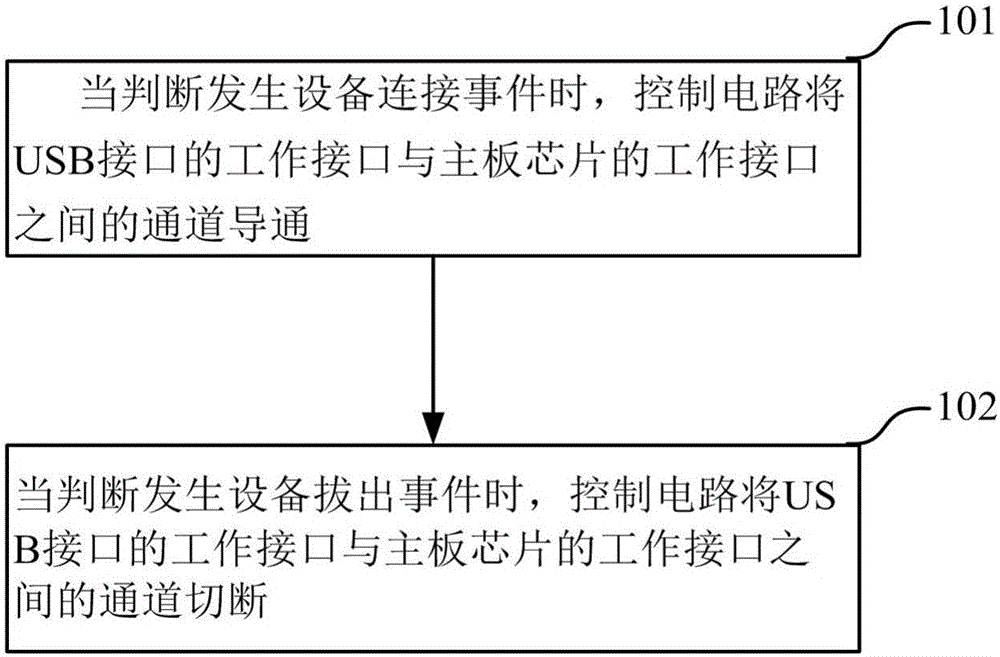

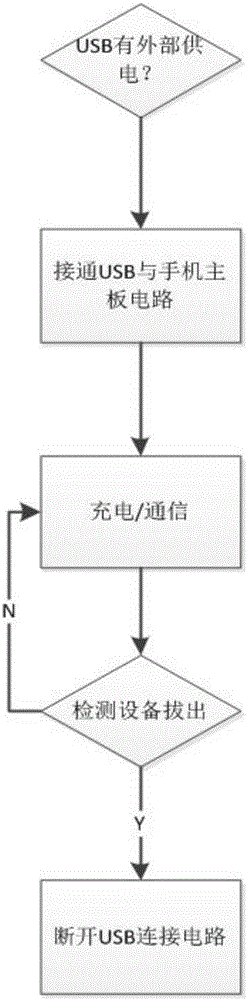

Waterproof method for USB interface and mobile terminal

ActiveCN106412245AShort circuit will notAvoid influenceSubstation equipmentTransmissionUSBPower circuits

The invention discloses a waterproof method for a USB interface. A control circuit is arranged between the USB interface and a mainboard chip of a mobile terminal, and the control circuit is used for controlling a connected state of a channel between a working interface of the USB interface and a working interface of the mainboard chip. When an equipment connection event is judged to occur, the control circuit makes the channel between the working interface of the USB interface and the working interface of the mainboard chip conductive; when an equipment pull-out event is judged to occur, the control circuit cuts off the channel between the working interface of the USB interface and the working interface of the mainboard chip. When no equipment is connected, the channel between the working interface of the USB interface and the working interface of the mainboard chip is cut off, so that even if conducting liquid enters, the working interface of the USB has short circuit, and the conduction of the whole power circuit of the mobile terminal cannot occur to cause short circuit of the power circuit.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

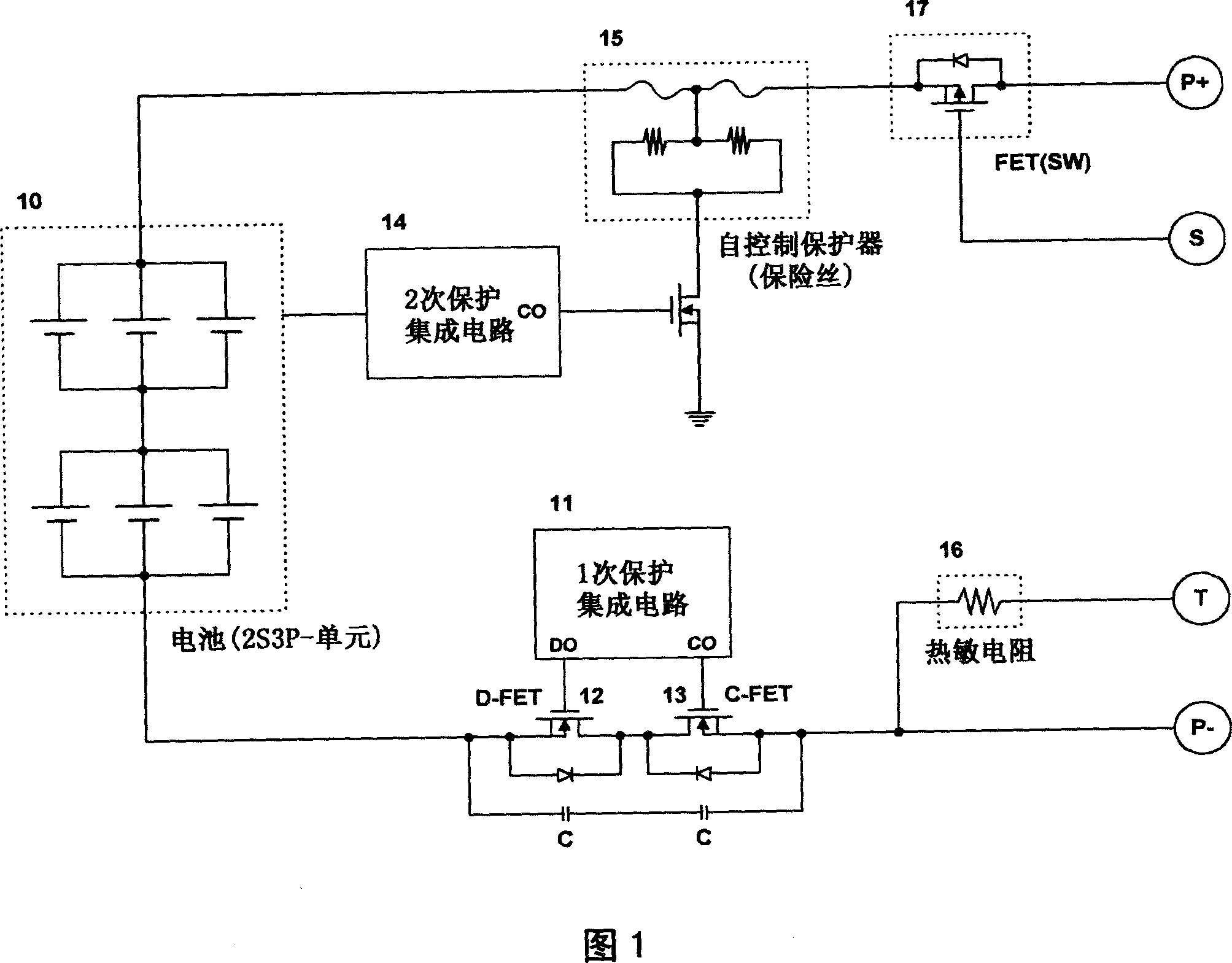

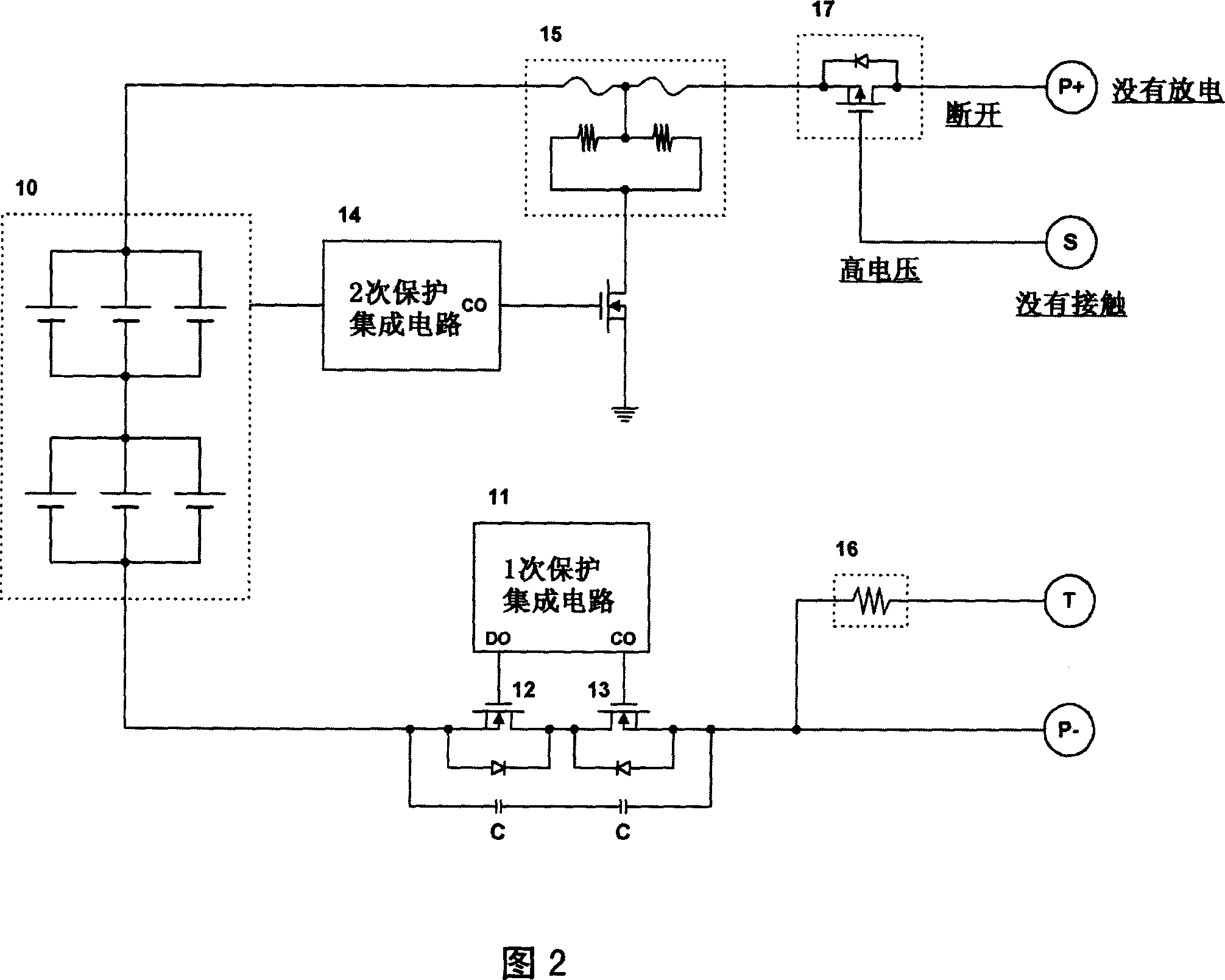

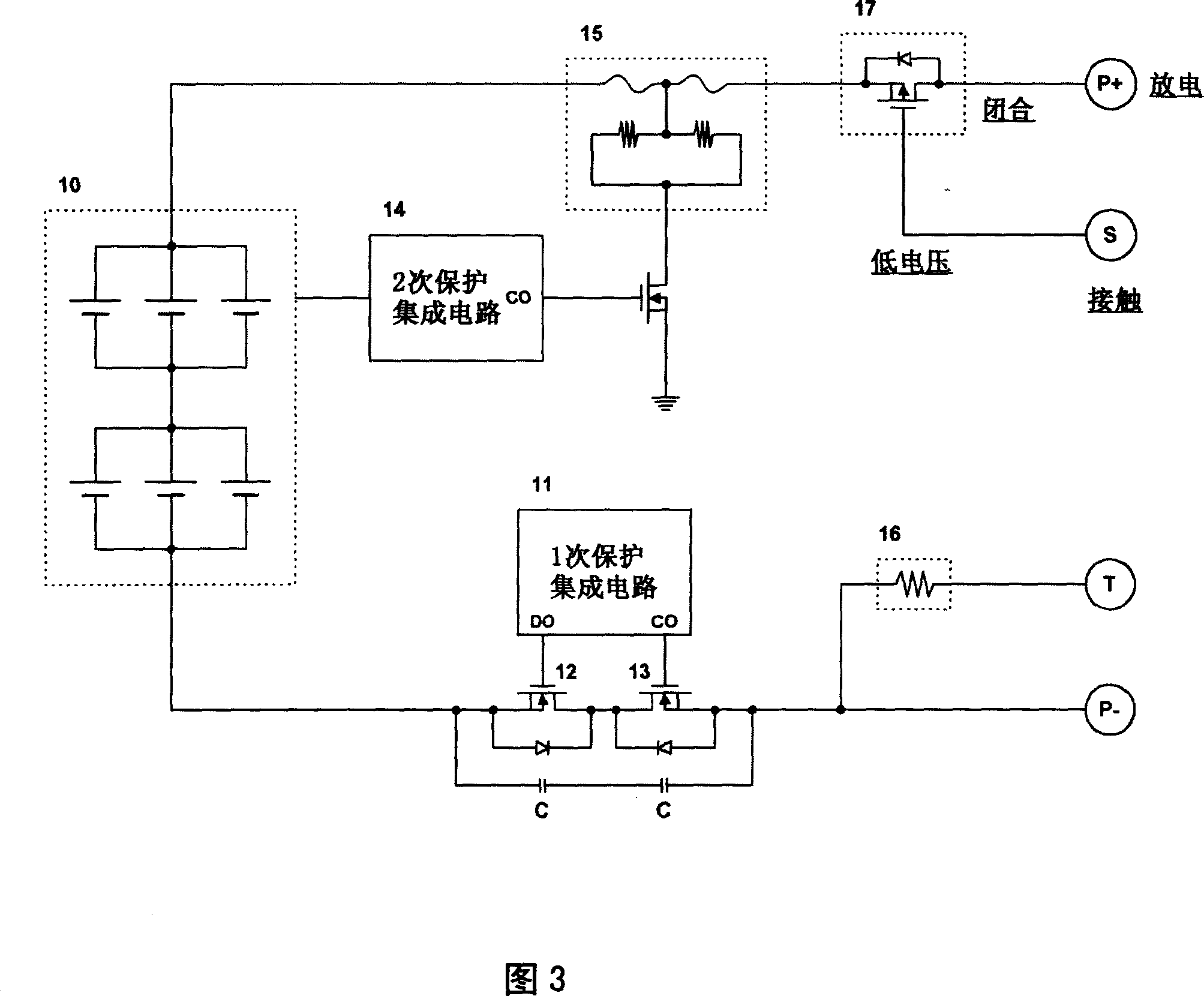

Battery pack for short circuit prevention

InactiveCN101101983AAvoid short circuitShort circuit will notBatteries circuit arrangementsElectric powerElectrical conductorThermistor

The invention is concerned with the battery group to prevent short-circuit for portable type DVD player, PDA or other electron equipment. It is to install the machinery switch at the front tip of the of the battery group discharge terminal that stays off when connecting with the electron equipment to keep it without short-circuit even connect with any other metal or conductor, which can reduce the damage of the battery group greatly. It is also to install circuit protection and thermal resistor to insure charging or discharging of the battery group safely.

Owner:LEJIN ELECTRONICS KUNSHAN COMPUTER CO LTD

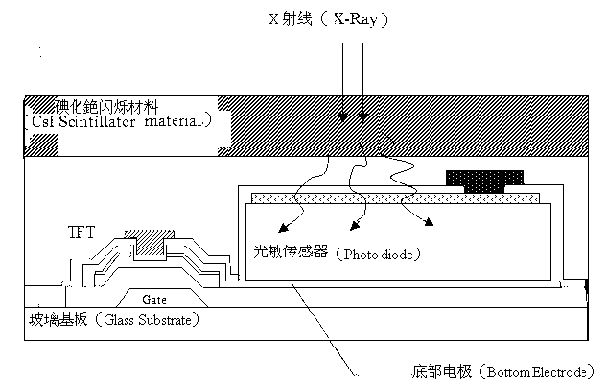

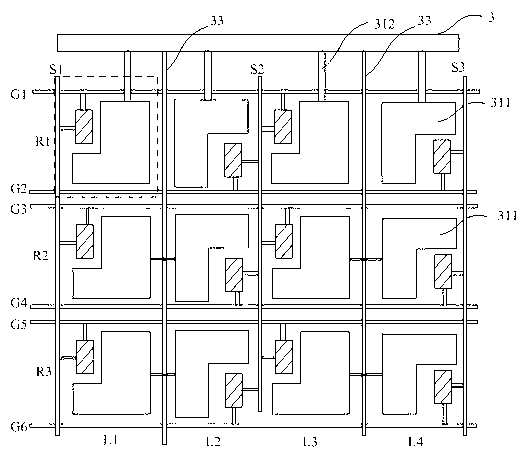

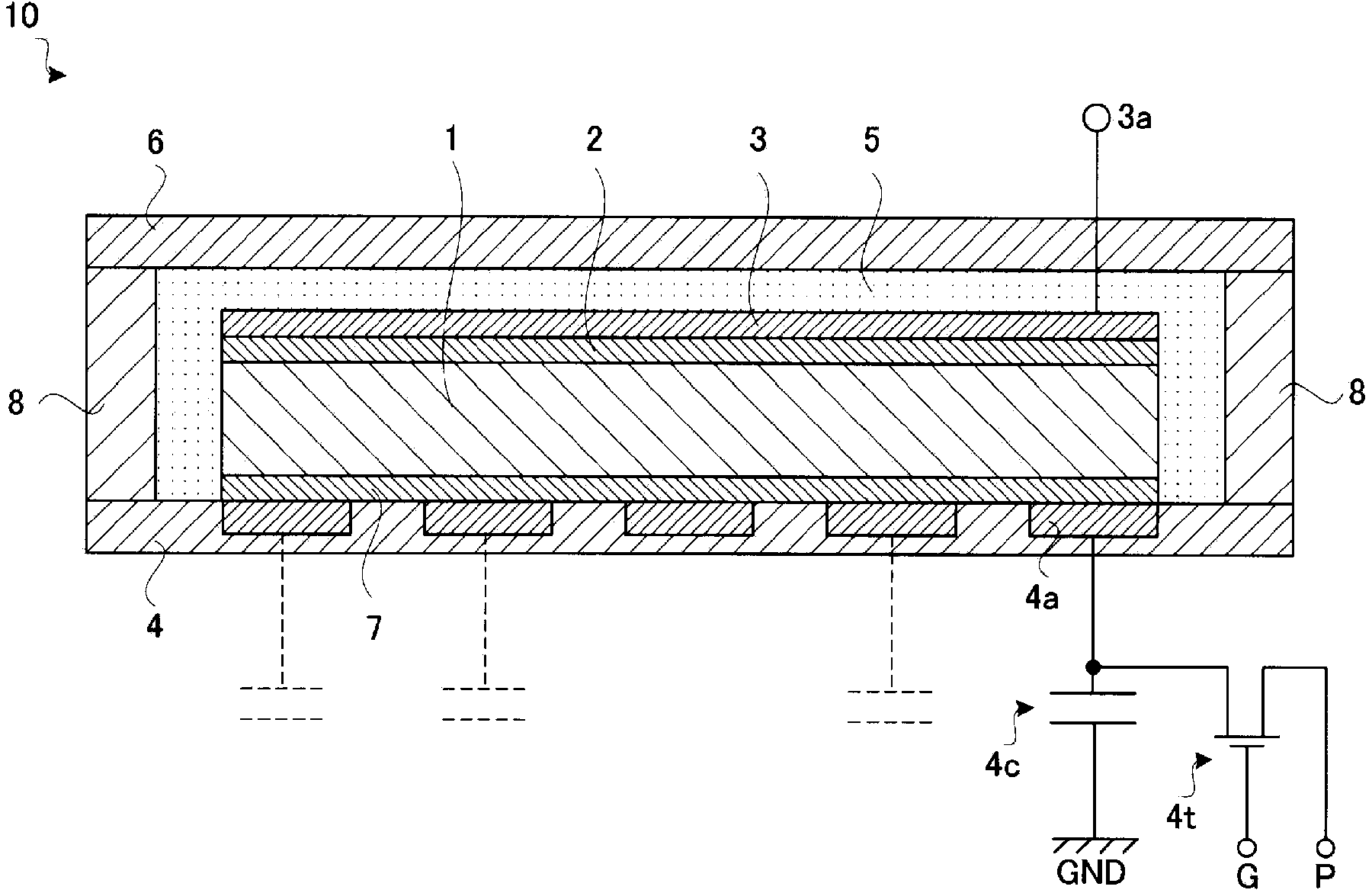

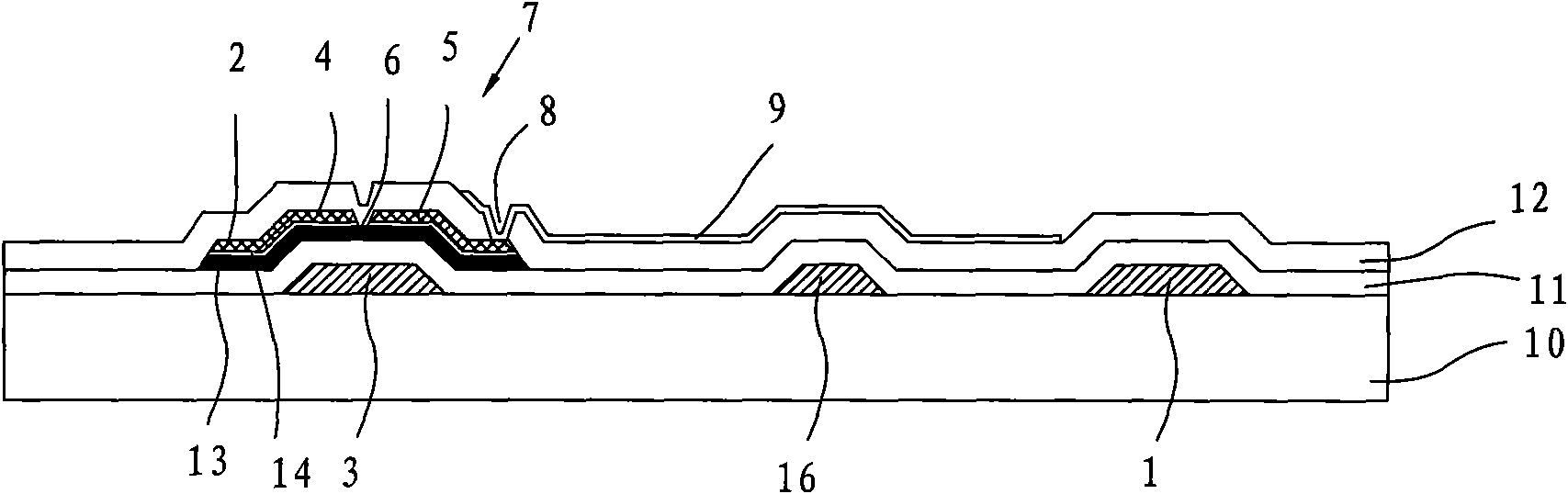

Flat plate type X-ray image sensor

ActiveCN103165629AShort circuit will notTelevision system detailsColor television detailsElectricityPower flow

The invention discloses a flat plate type X-ray image sensor. Due to the fact that protective pixels are arranged on a pixel array, when a large current which is caused by static electricity passes through a data line, short-circuit of a data line and public electrode wires which are located on two sides of the data line can be avoided. The flat plate type X-ray image sensor comprises the pixel array which is formed in a base plate and a public electrode bus which is located on the periphery of the pixel array. The pixel array comprises a plurality of data lines, scanning lines which cross with the plurality of data lines and pixel units which are located in an area of the scanning lines and the data lines. The pixel array further comprises at least one line of protective pixels, each protective pixel comprises a public electrode, and the public electrode is electrically connected with the public electrode bus through a conducting layer.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

TVS device chip and manufacturing method thereof

PendingCN109698171AShort circuit will notFire won'tSemiconductor/solid-state device detailsSolid-state devicesEngineeringNanocrystal

The invention discloses a TVS device chip in the technical field of TVS devices. The TVS device chip comprises a package casing, a TVS chip layer, an overcurrent chip layer, a first pin and a second pin. The inner cavity of the package casing is provided with the TVS chip layer and the overcurrent chip layer, the bottom of the TVS chip layer is connected to one end of the first pin by a wire, andthe top of the overcurrent chip layer is connected to one end of the second pin through a wire. Through the novel design of two chips in a TVS, one chip can satisfy a transient voltage clamp protection function, the other chip is automatically disconnected when over-current is continuous, through a high-molecular polymer in a reset over-current filler, when power-off and fault are removed, the collection temperature is reduced, the density of states is increased, the phase transition recovers, nanocrystals are reduced to a chain-like conductive path, the TVS device is restored to a normal state, therefore, the circuit is not short-circuited, and the fire of a circuit is not caused.

Owner:SHANGHAI LEIDITECH ELECTRONICS TECH

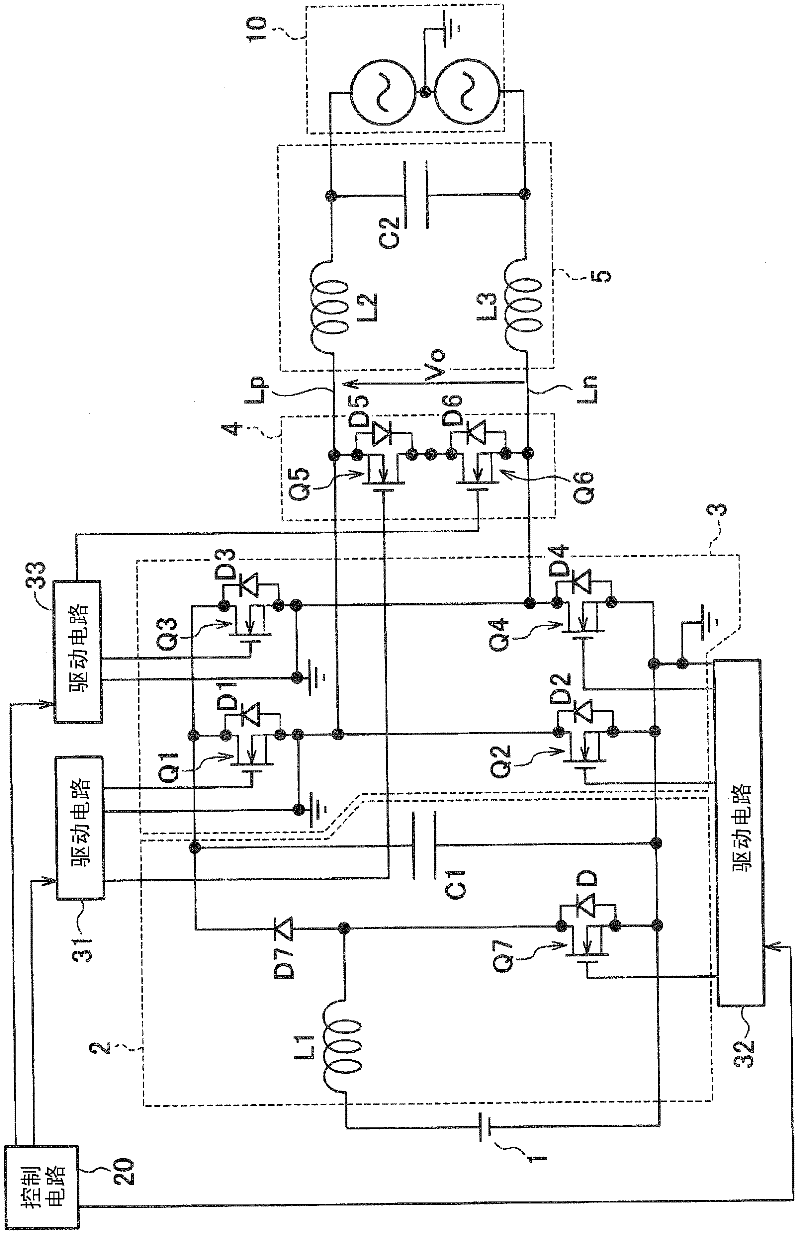

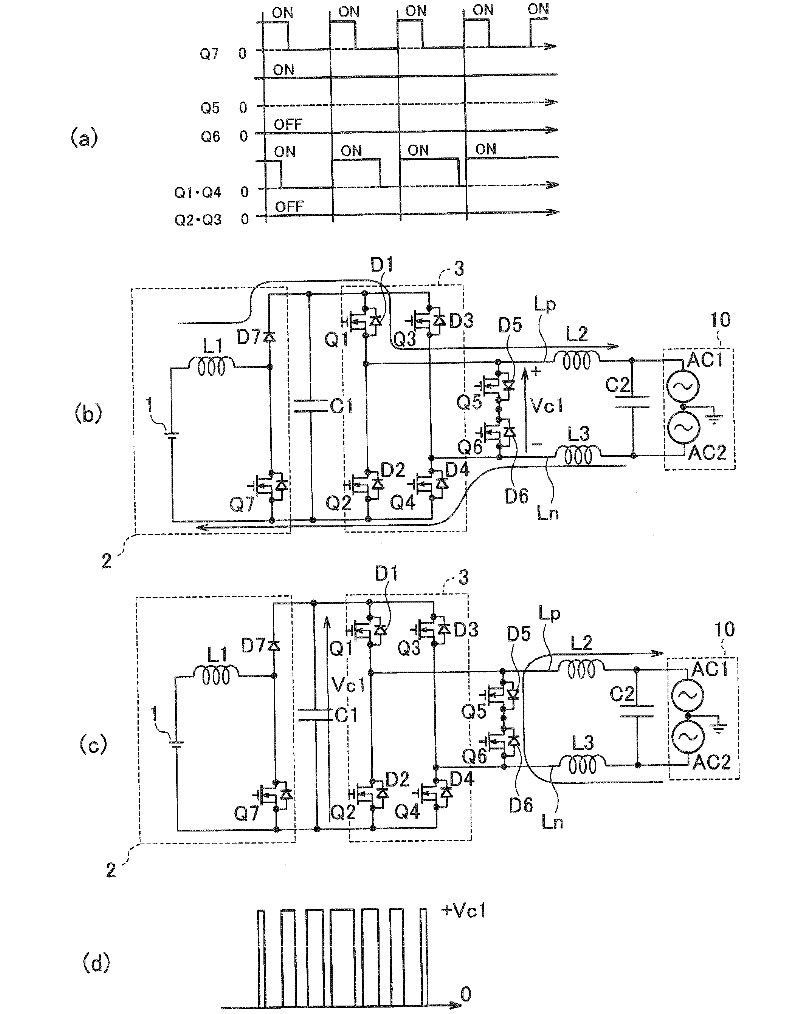

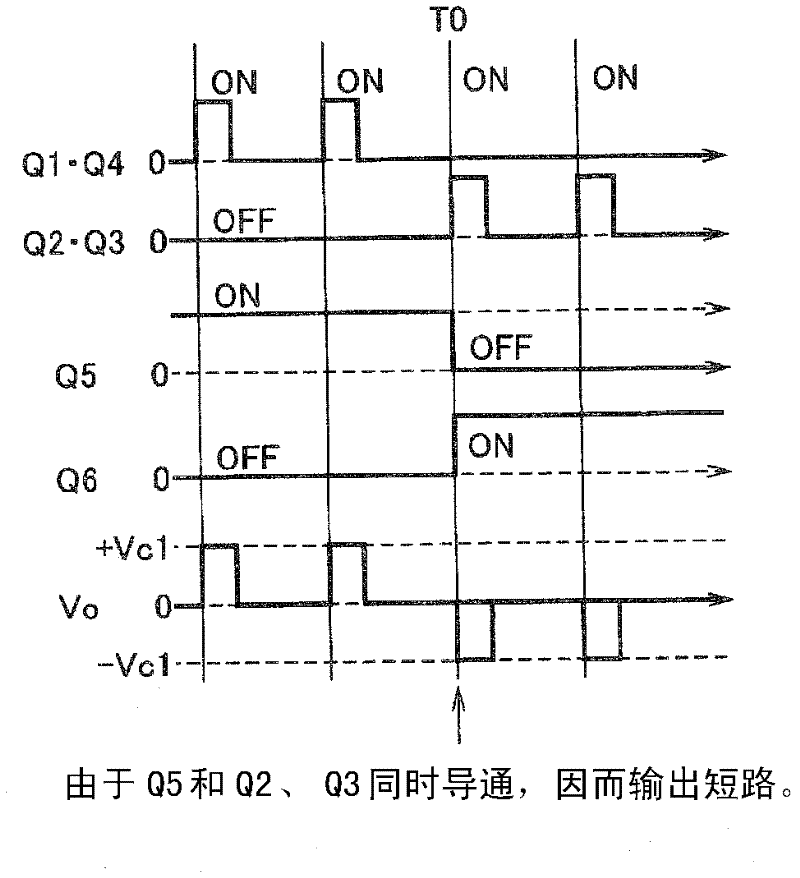

Power conversion apparatus, grid connection apparatus, and grid connection system

InactiveCN102474200AShort circuit will notImprove reliabilityEfficient power electronics conversionDc-dc conversionPower inverterElectrical polarity

A power conversion apparatus is provided with an inverter circuit, an output short-circuiting circuit, and a control circuit. The inverter circuit comprises a first inverter switch that is configured so as to generate a first polarity voltage from DC voltage, and a second inverter switch that is configured so as to generate a second polarity voltage from the DC voltage. The output short-circuiting circuit comprises a first short-circuiting switch that is configured so as to short-circuit a power supply line that outputs the first polarity voltage, out of a pair of power supply lines, and a second short-circuiting switch that is configured so as to short-circuit a power supply line that outputs the second polarity voltage, out of the pair of power supply lines. Upon switching the polarity from the first polarity to the second polarity, the control circuit turns off the first short-circuiting switch before the timing whereby the second inverter switch is turned on.

Owner:SANYO ELECTRIC CO LTD

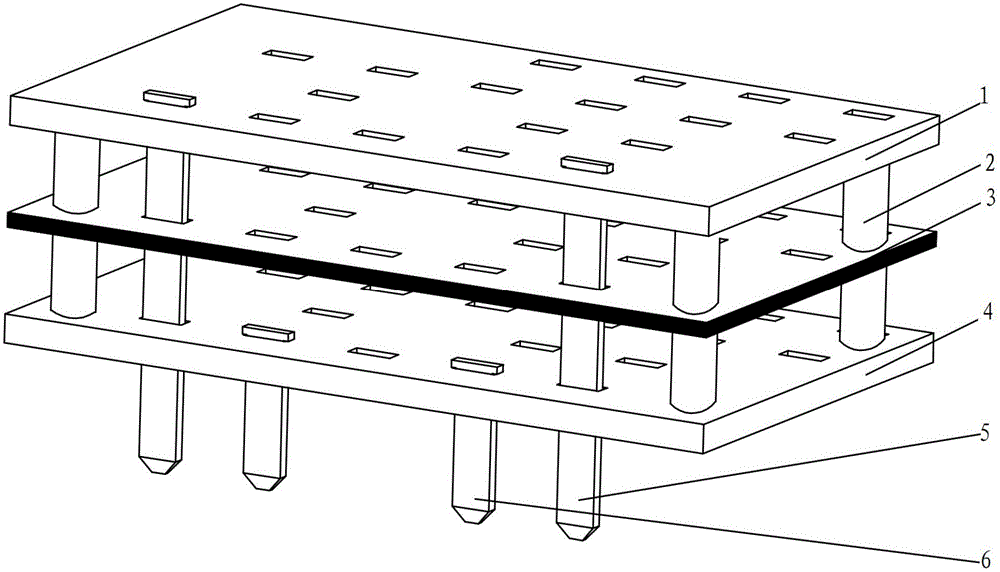

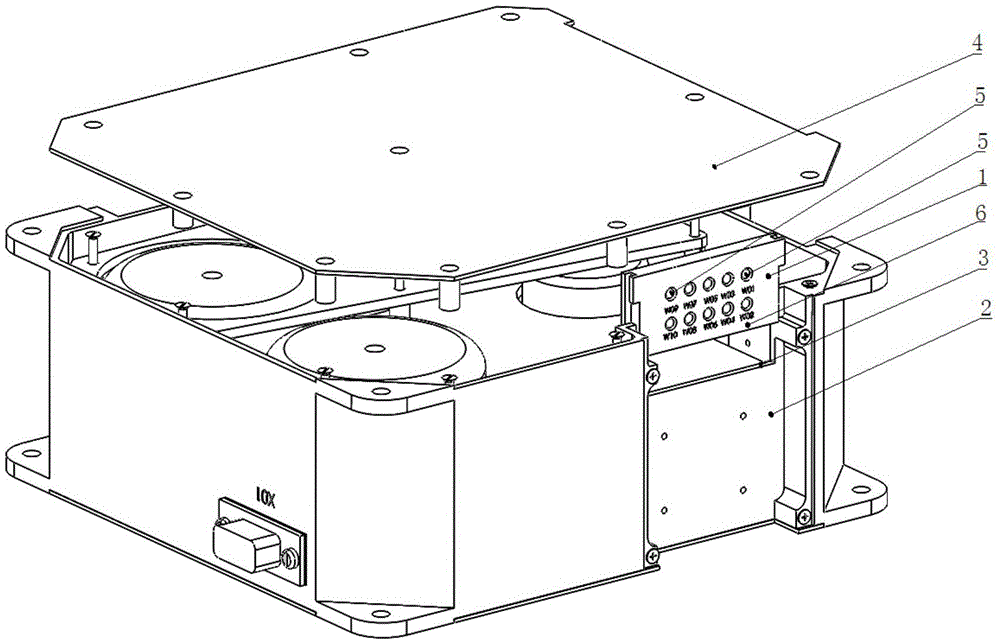

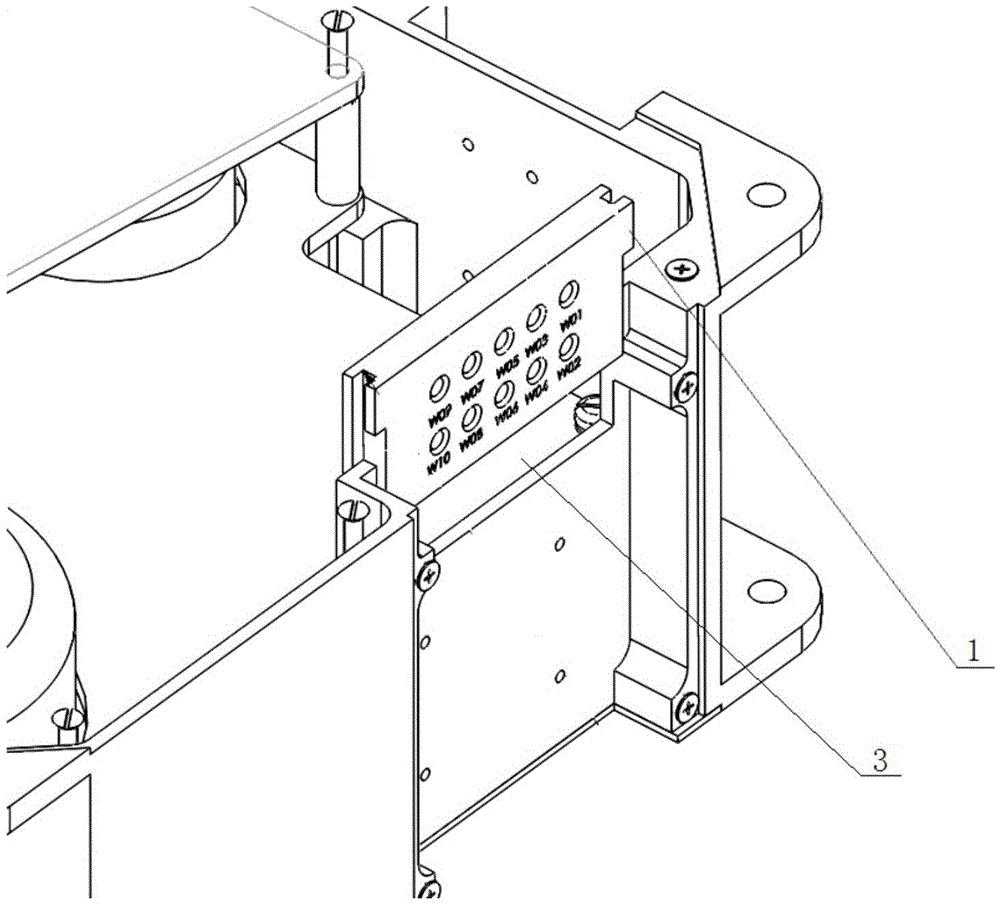

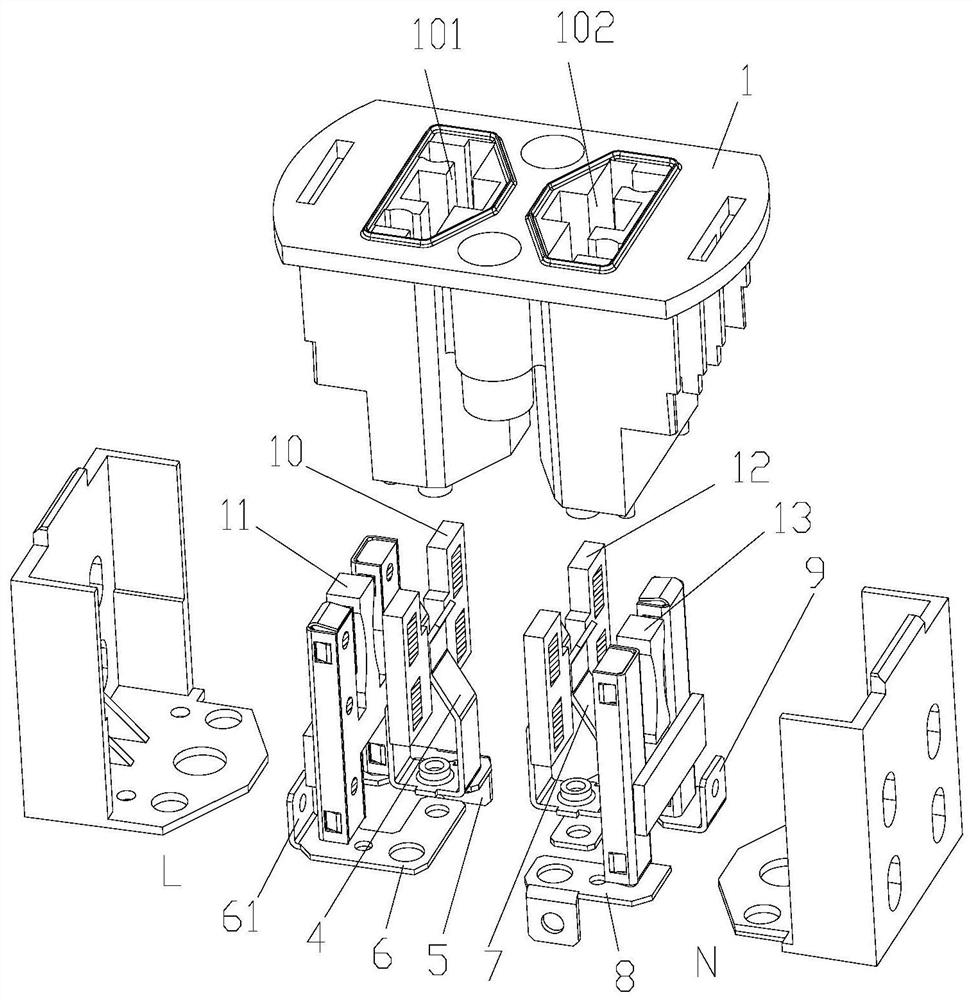

Multilayer PCB (Printed Circuit Board) central distribution box

PendingCN105161879AReduce manufacturing costEasy wiringPrinted circuits structural associationsFixed connectionsWeak currentPrinted circuit board

The invention relates to a multilayer PCB (Printed Circuit Board) central distribution box. The multilayer PCB central distribution box comprises an insulated box body, a plurality of PCBs positioned inside the insulated box body and at least one pair of conductive pins; the plurality of PCBs are arranged in parallel and layer by layer, and the two adjacent layers of PCBs are insulated by insulating paper and connected by insulating screws; one end of each of the two conductive pins in every pair of conductive pins is connected to the different layer of PCB, and the other end extends out from the outermost PCB. A common PCB design in weak current is introduced to the multilayer PCB central distribution box, and the plurality of PCBs are applied to high-current wiring, so that high tidiness, high safety, high safety and minimum cost of wiring are achieved.

Owner:SHANGHAI ALSON ELECTRIC

Radiation detector

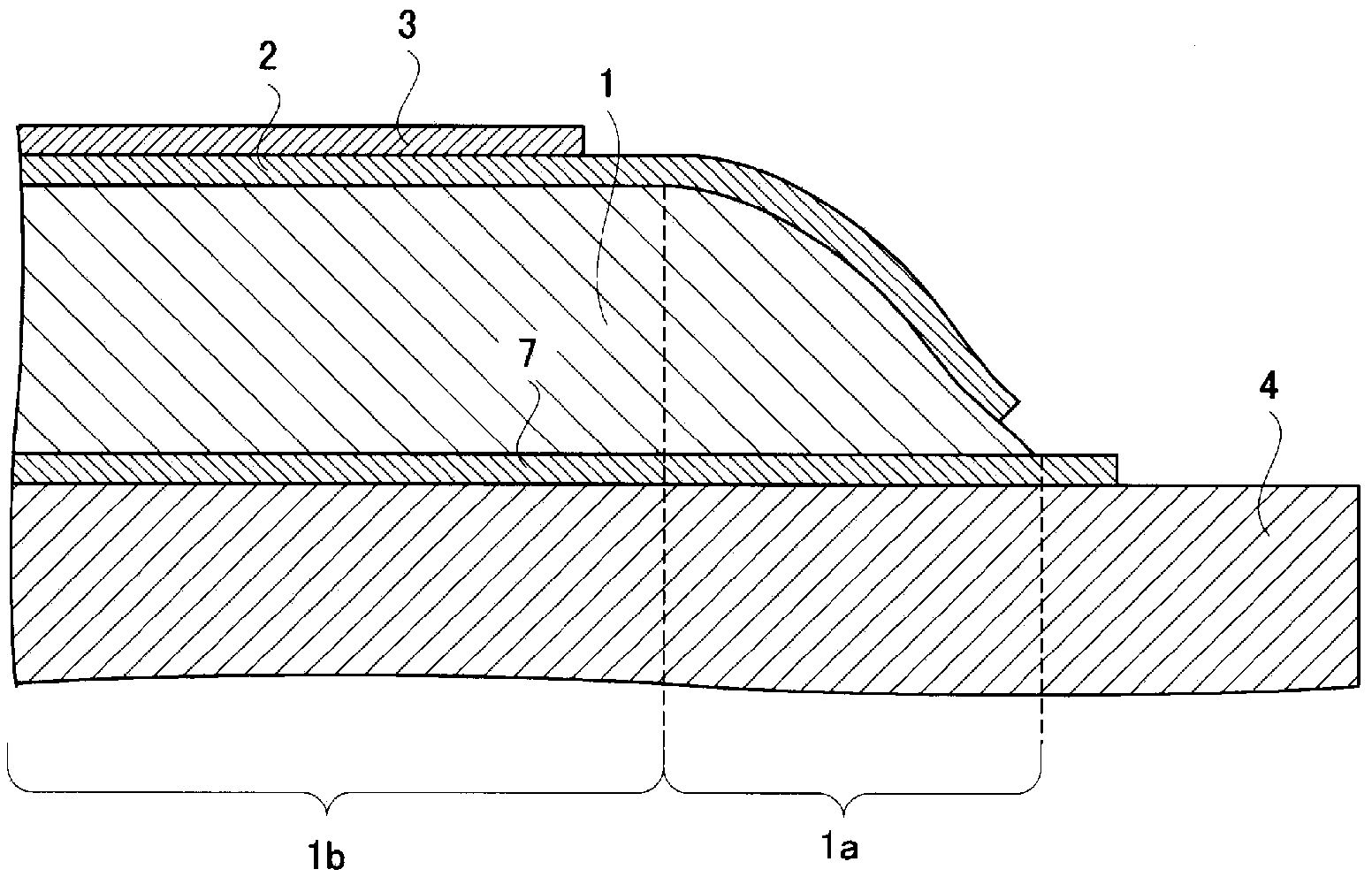

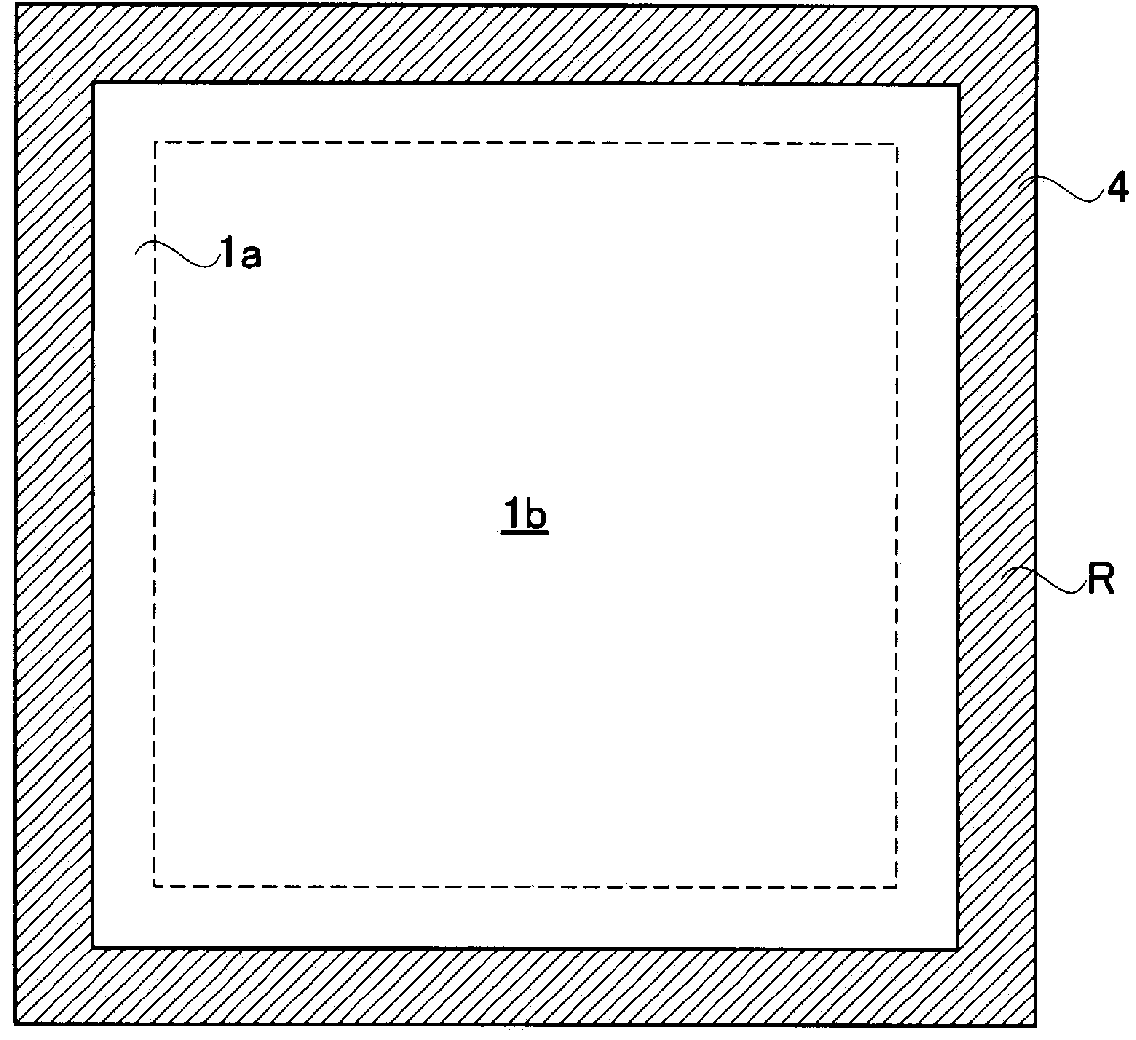

InactiveCN103534808AAvoid defectsShort circuit will notSolid-state devicesRadiation controlled devicesElectricityAmorphous selenium

Provided is a radiation detector that prevents shorting of electrical wirings that intersect with an inter-layer insulating layer there between, and wherein the occurrence of detector element failure is suppressed. By means of the present configuration, an amorphous selenium layer (1) and the electrical wiring of an active matrix substrate (4) are contrived in a manner so as to not short. Namely, the electrical wiring is provided to the position at which the layer thickness of the amorphous selenium layer (1) is covered by a thick central portion. As a result, the electrical wiring is reliably isolated from an electrode layer, and so it is possible to provide a radiation detector that can withstand long-term use.

Owner:SHIMADZU SEISAKUSHO CO LTD

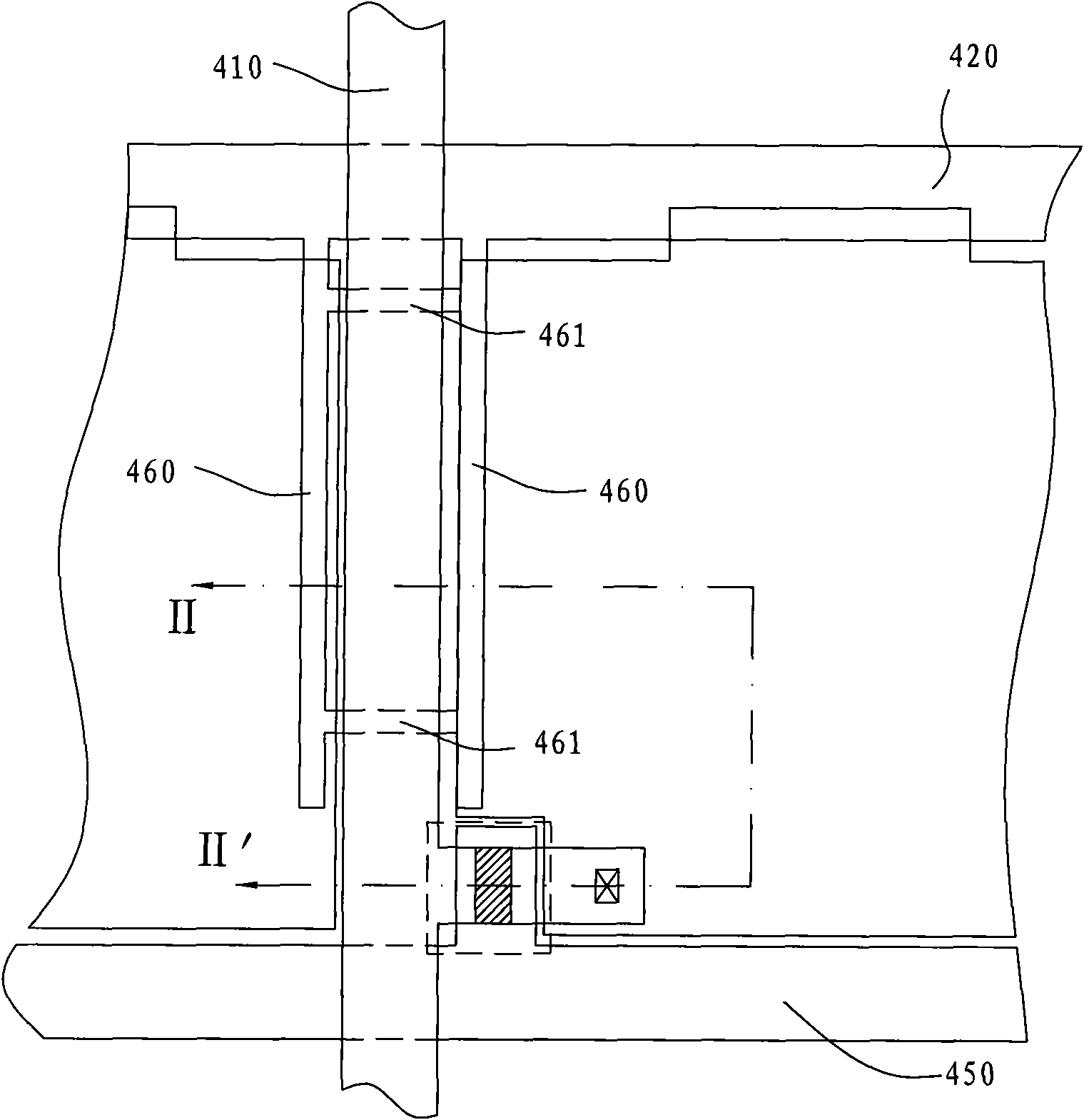

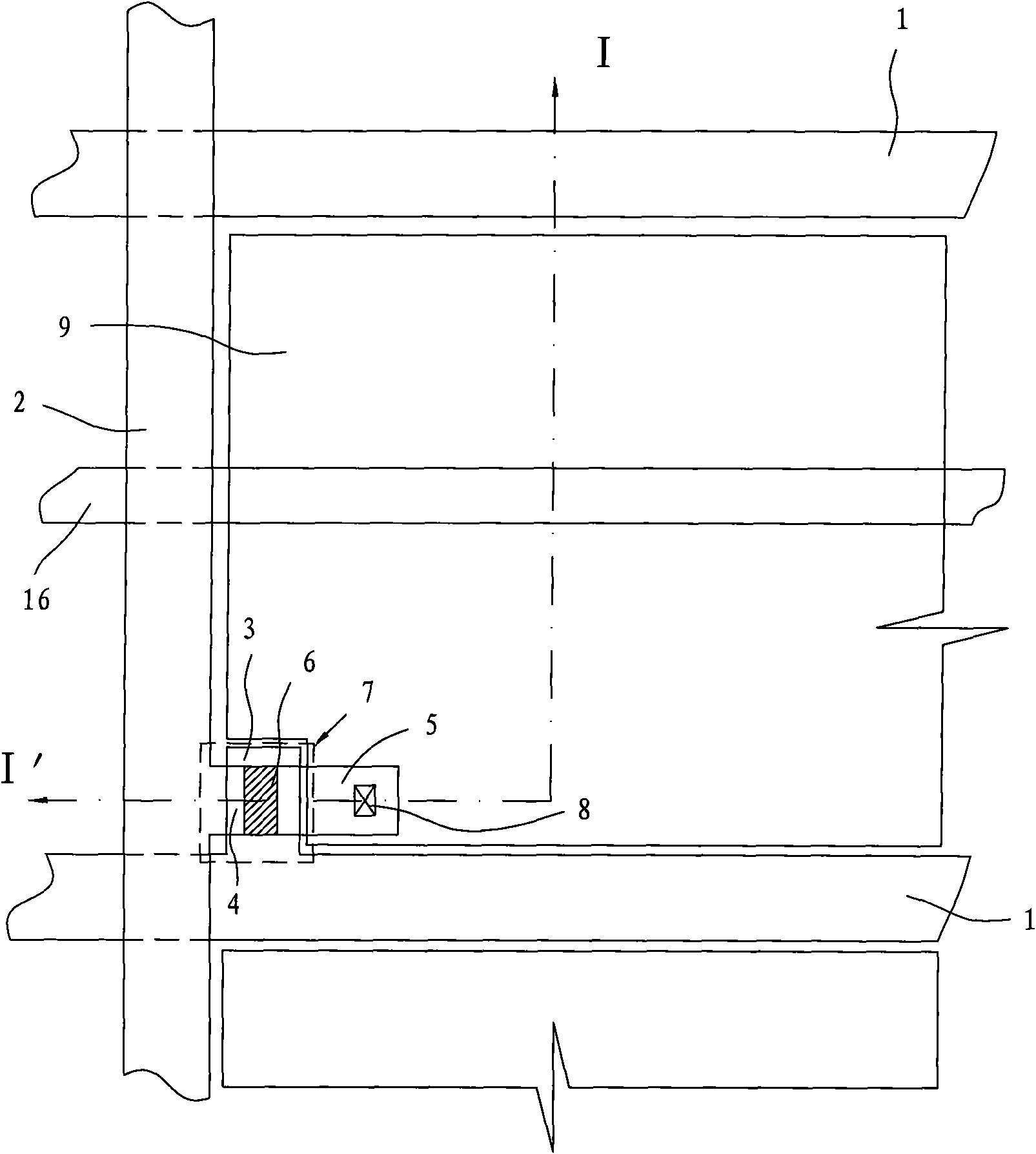

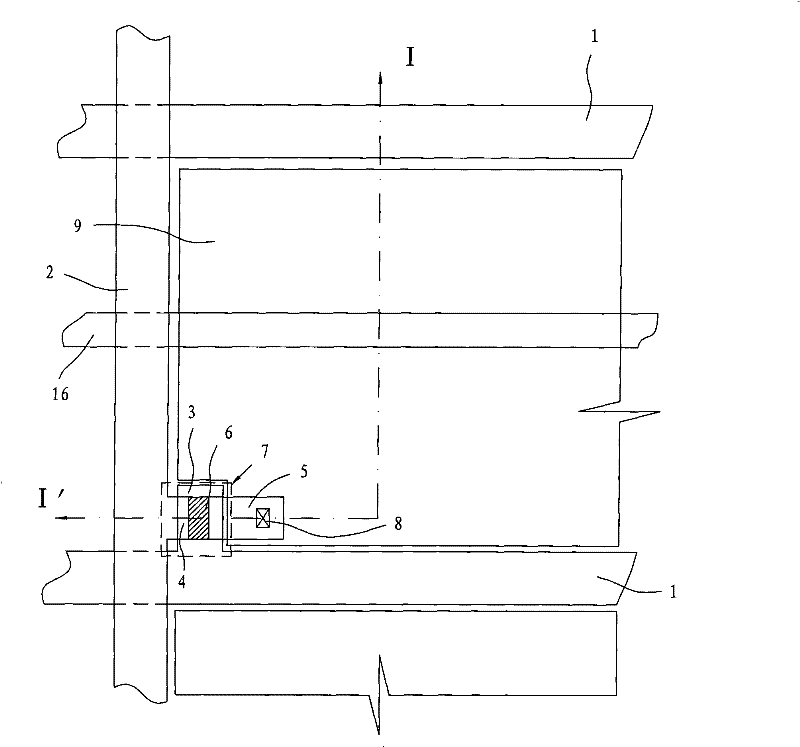

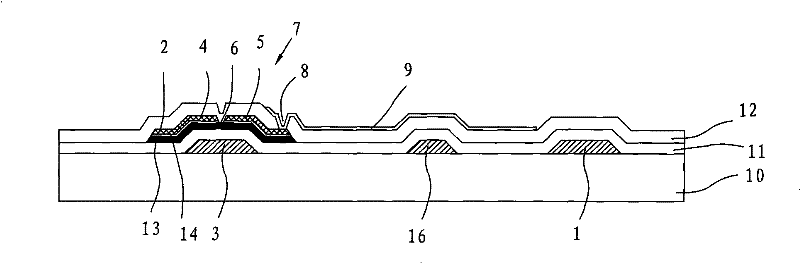

Pixel structure and maintenance method thereof

ActiveCN101813858AGuaranteed normal transmissionNo need to replaceNon-linear opticsManufacturing technologyLiquid-crystal display

The invention discloses a pixel structure and a maintenance method thereof, which relates to the technical field of liquid crystal display and solves the problems of complex maintenance progress and necessary maintenance device replacement for the traditional pixel structure. The invention embodiment is provided with a light shading part corresponding to data scanning lines on a grid and a grid layer of grid scanning lines. The light shading part is of a sealed structure and is connected to the grid scanning lines. The invention embodiment is mainly applied to the liquid crystal display, in particular to the liquid crystal display adopting TFT manufacture technology.

Owner:BOE TECH GRP CO LTD +1

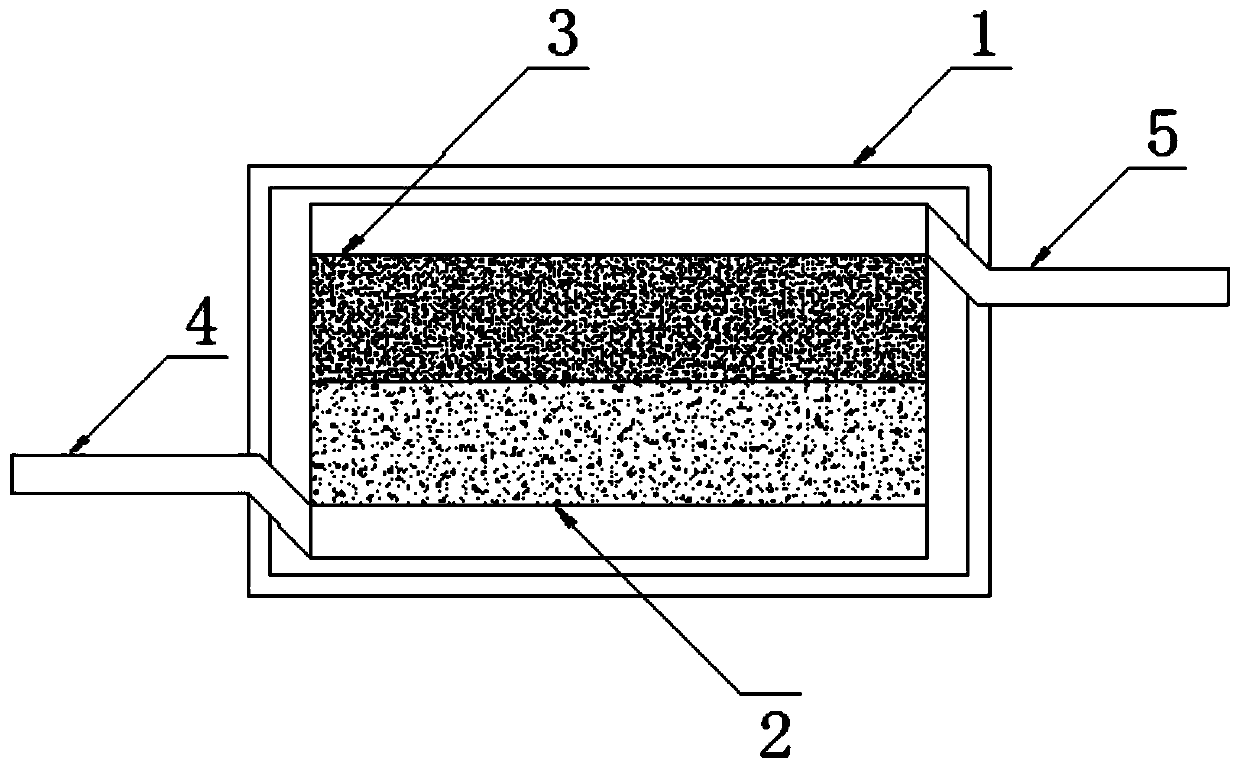

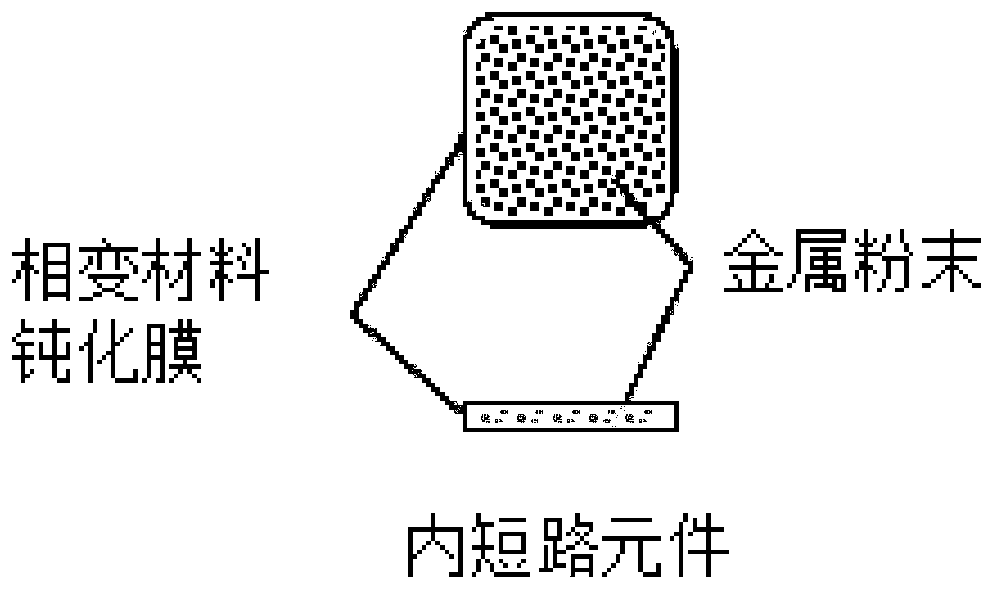

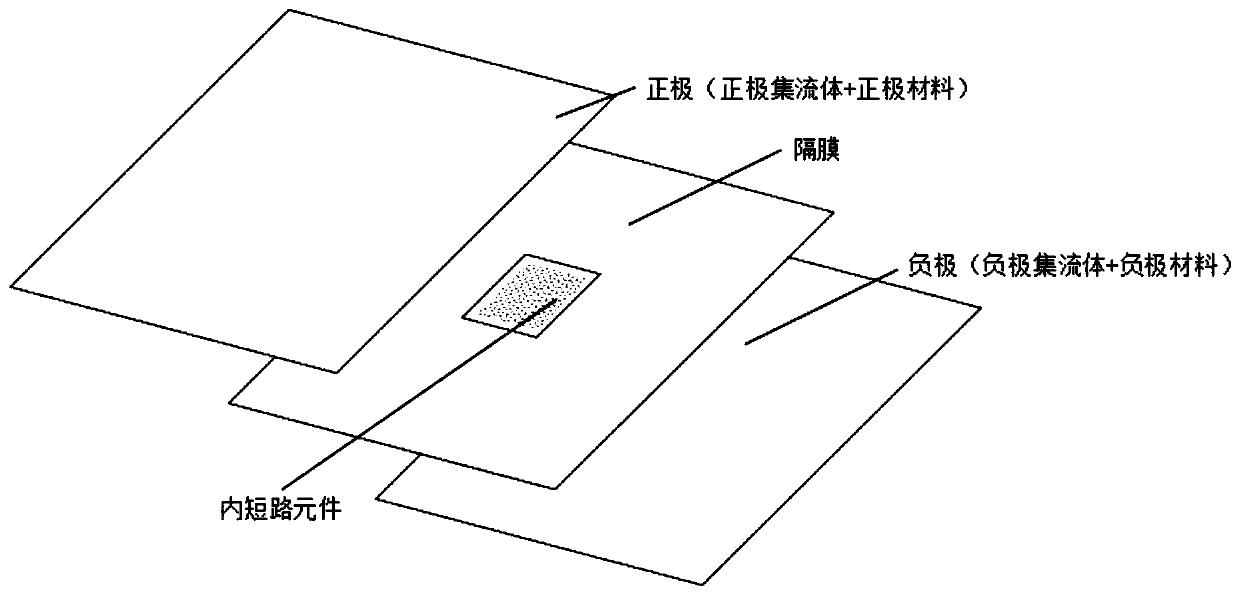

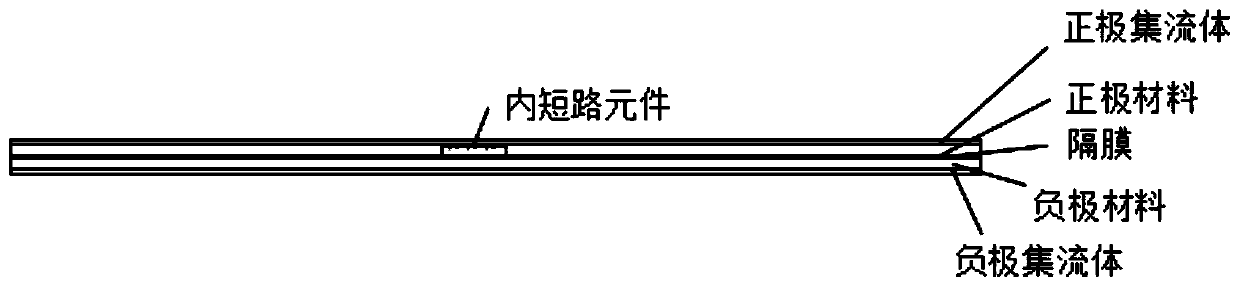

Internal short circuit triggering element, internal short circuit triggering battery and internal short circuit triggering method

InactiveCN110867605AShort circuit will notHigh simulationFinal product manufactureElectrical testingBattery degradationElectrical battery

The invention provides an internal short-circuit triggering element, an internal short-circuit triggering battery and an internal short-circuit triggering method. The internal short-circuit triggeringelement is characterized in that metal powder is isolated in a battery through a phase-change material before the element is not activated, so that the internal short circuit of the battery will notbe triggered; after the element is activated, the internal short circuit of the battery can be triggered through circulation, and the method is a good method for simulating the self-initiated internalshort circuit of the battery. The phase-change material does not react with the internal material of the battery, especially an electrolyte, and does not react under the action of voltage, so that the phase-change material can stably exist in the battery for a long time. The internal short-circuit trigger element occupies a small space, has small influence on normal charging and discharging and circulation of the battery, and is flexible in arrangement position. According to the internal short-circuit triggering method provided by the invention, the internal short-circuit triggering of the battery in a full life cycle can be realized, the thermoelectric characteristics of the battery can be acquired, and the internal short-circuit safety after aging of the battery can be evaluated.

Owner:TSINGHUA UNIV

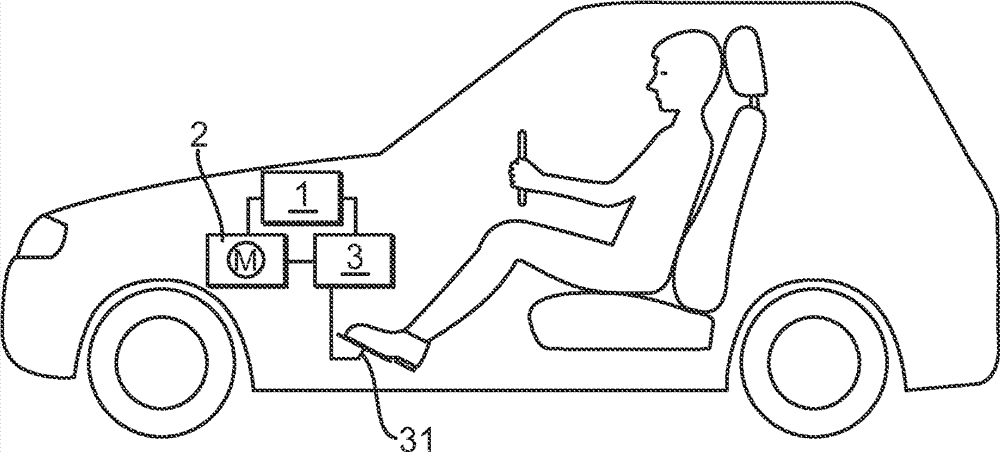

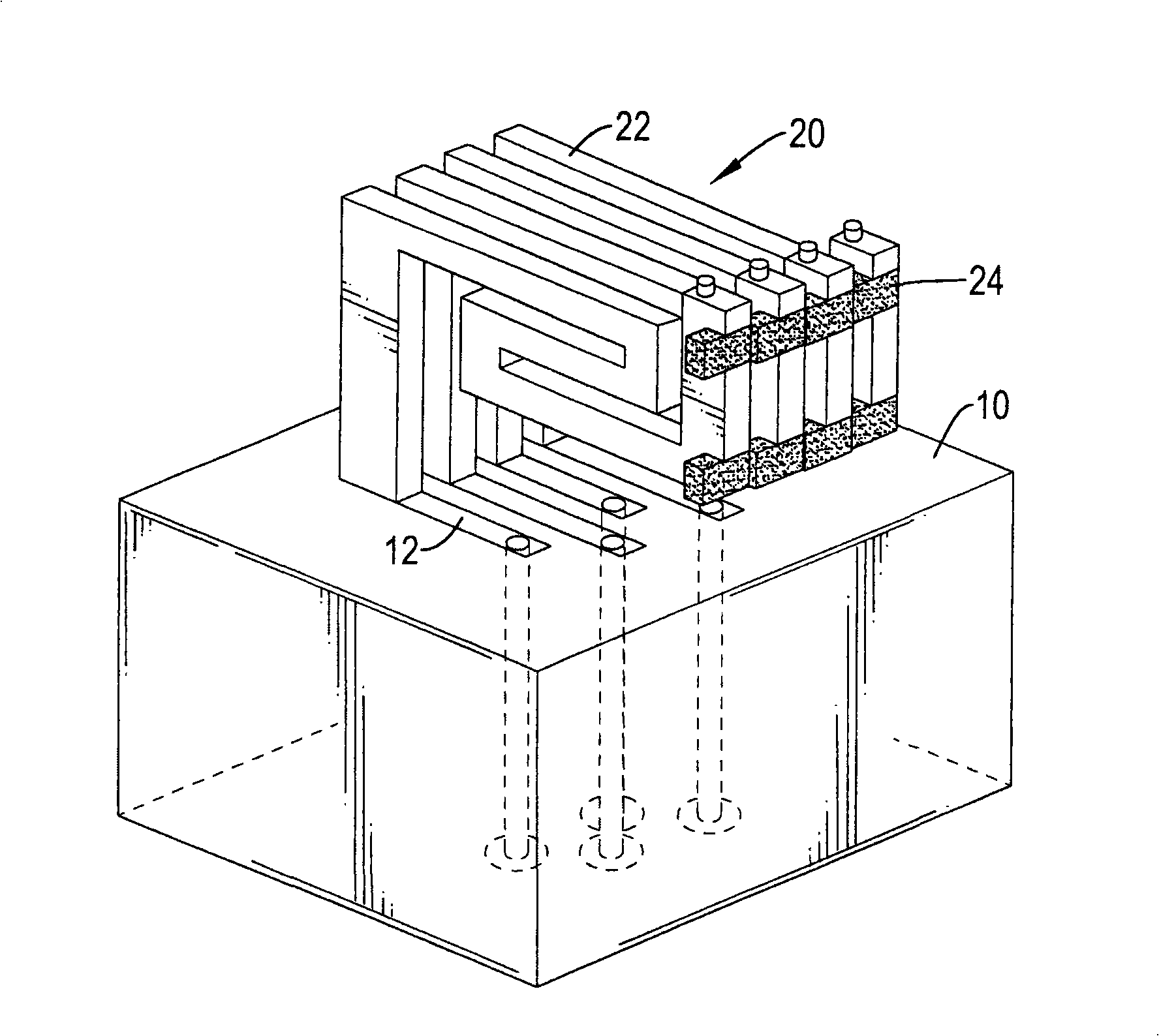

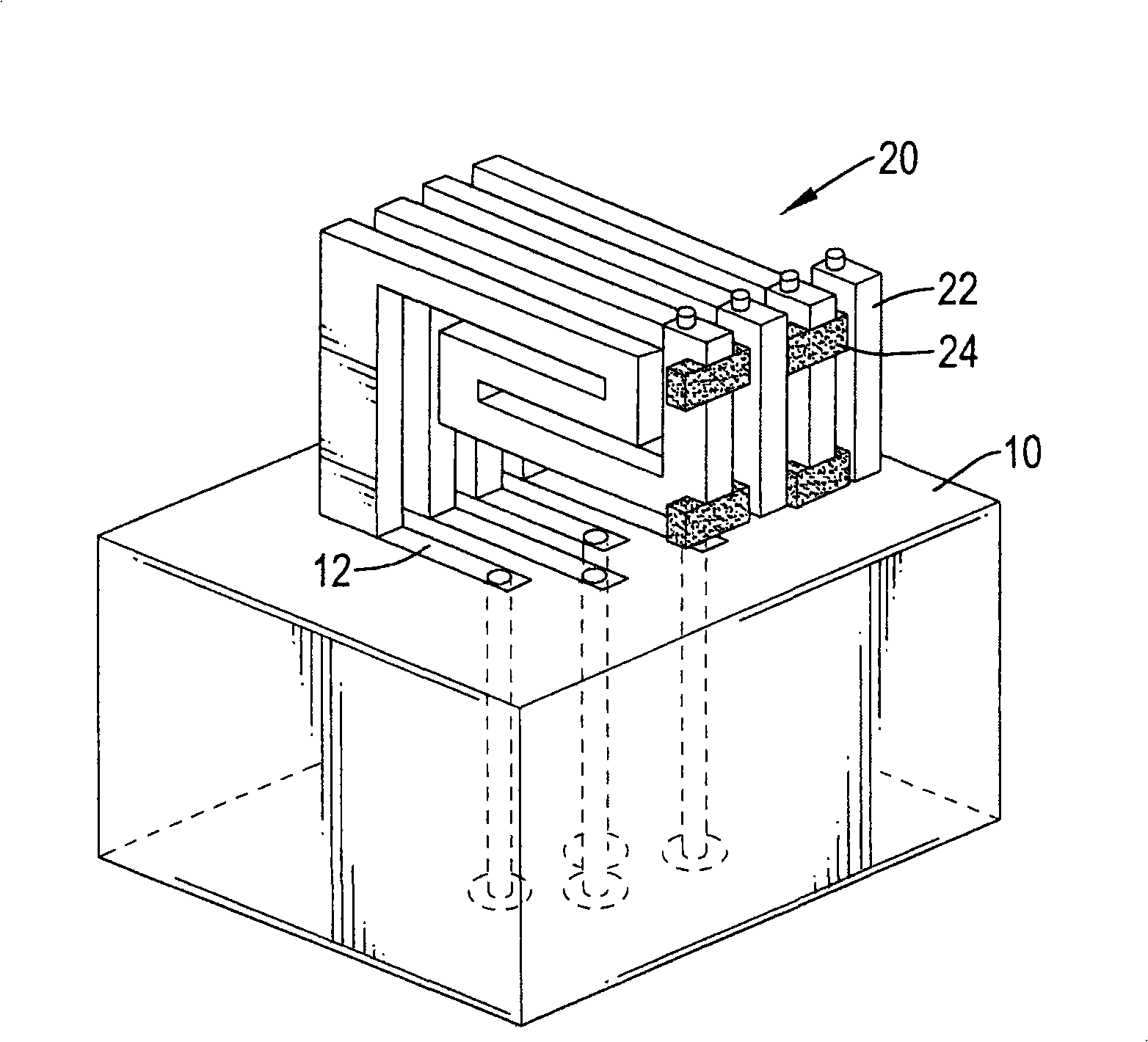

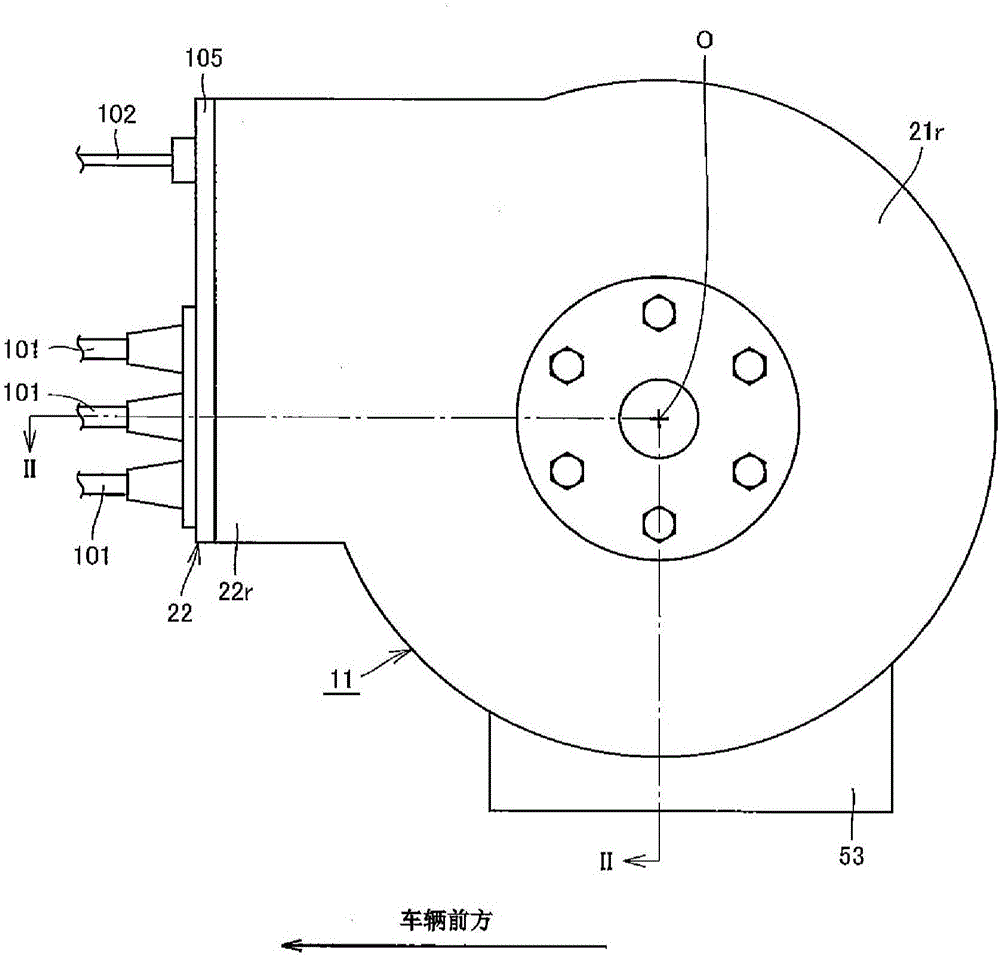

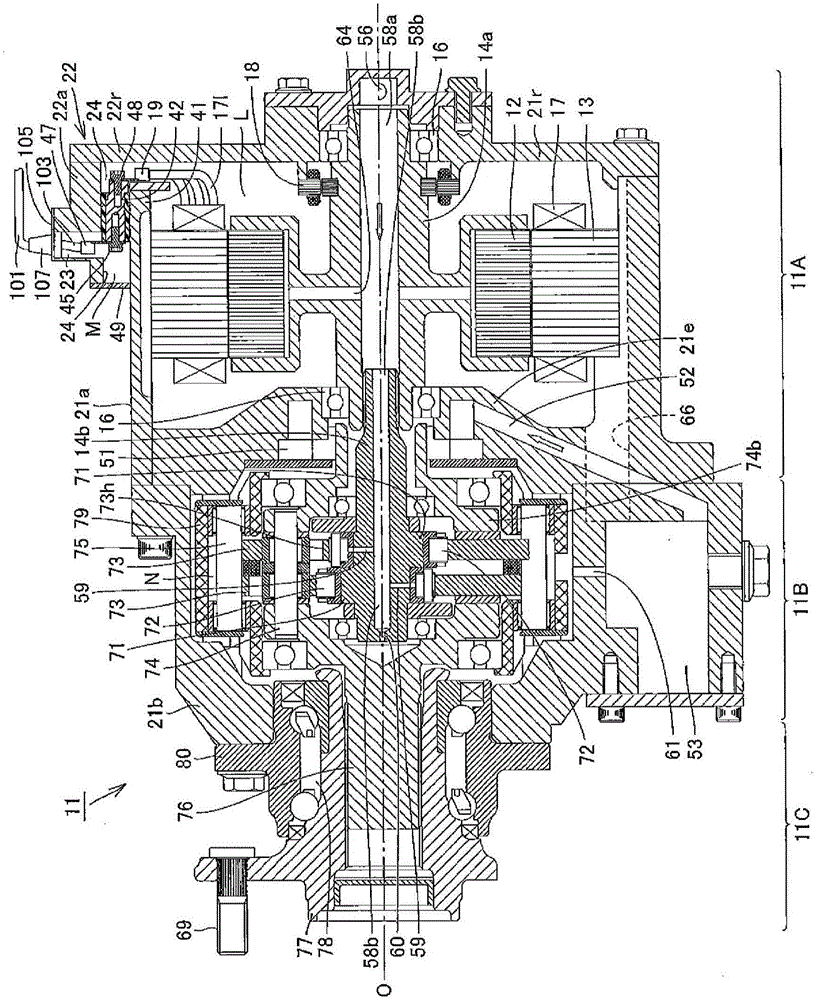

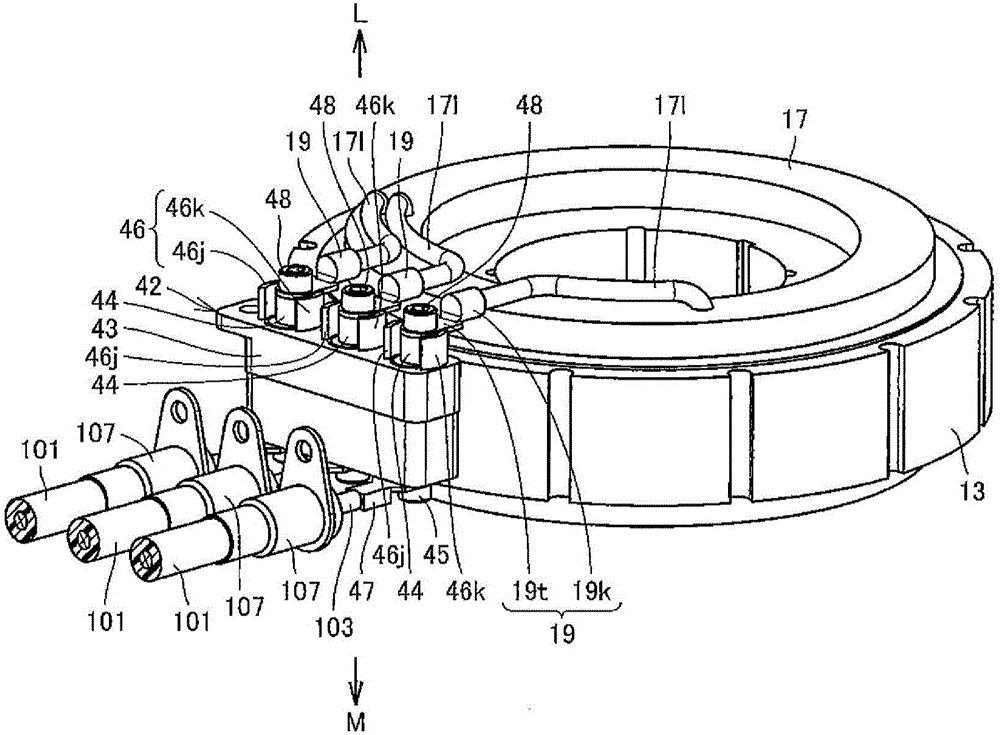

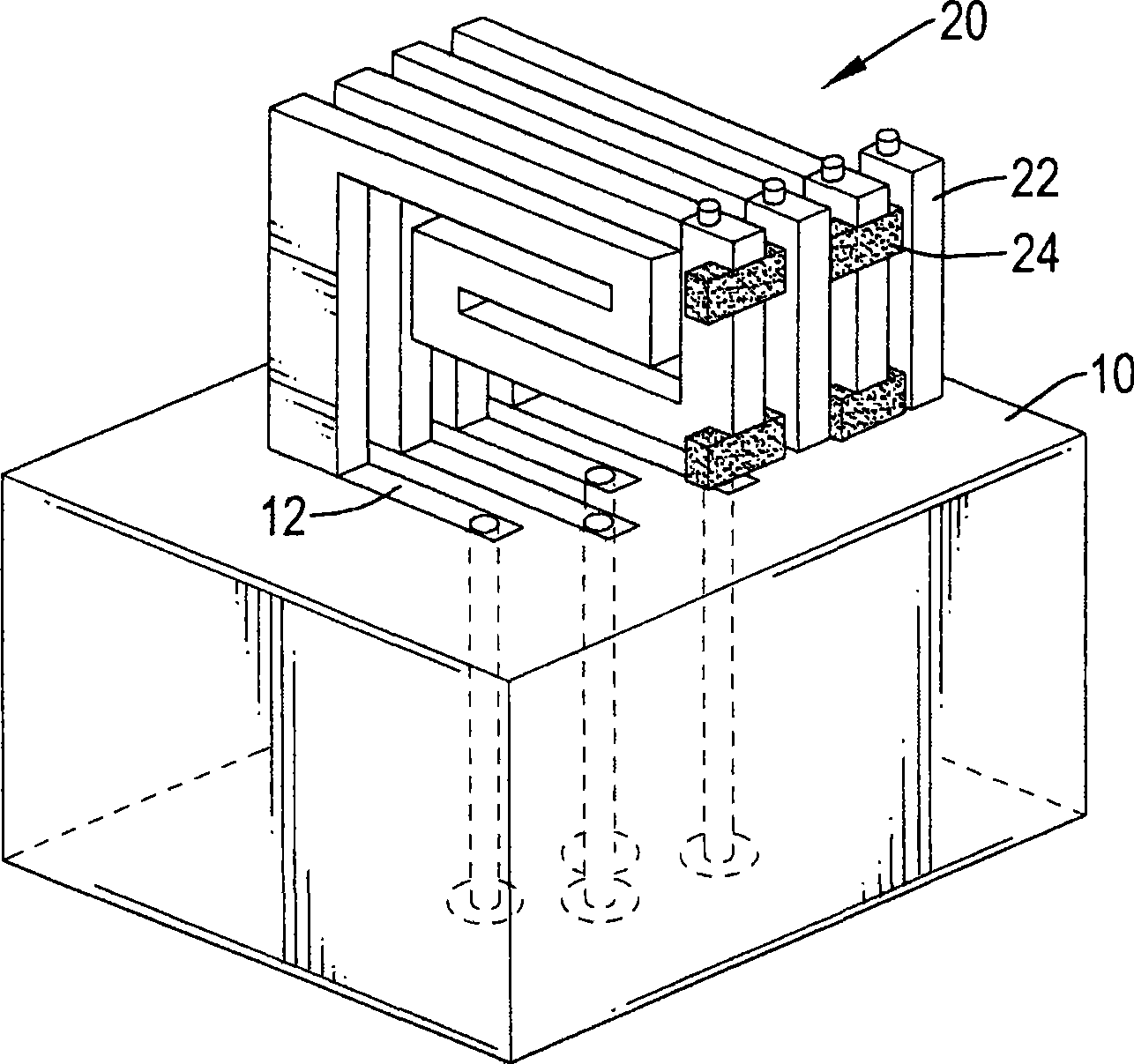

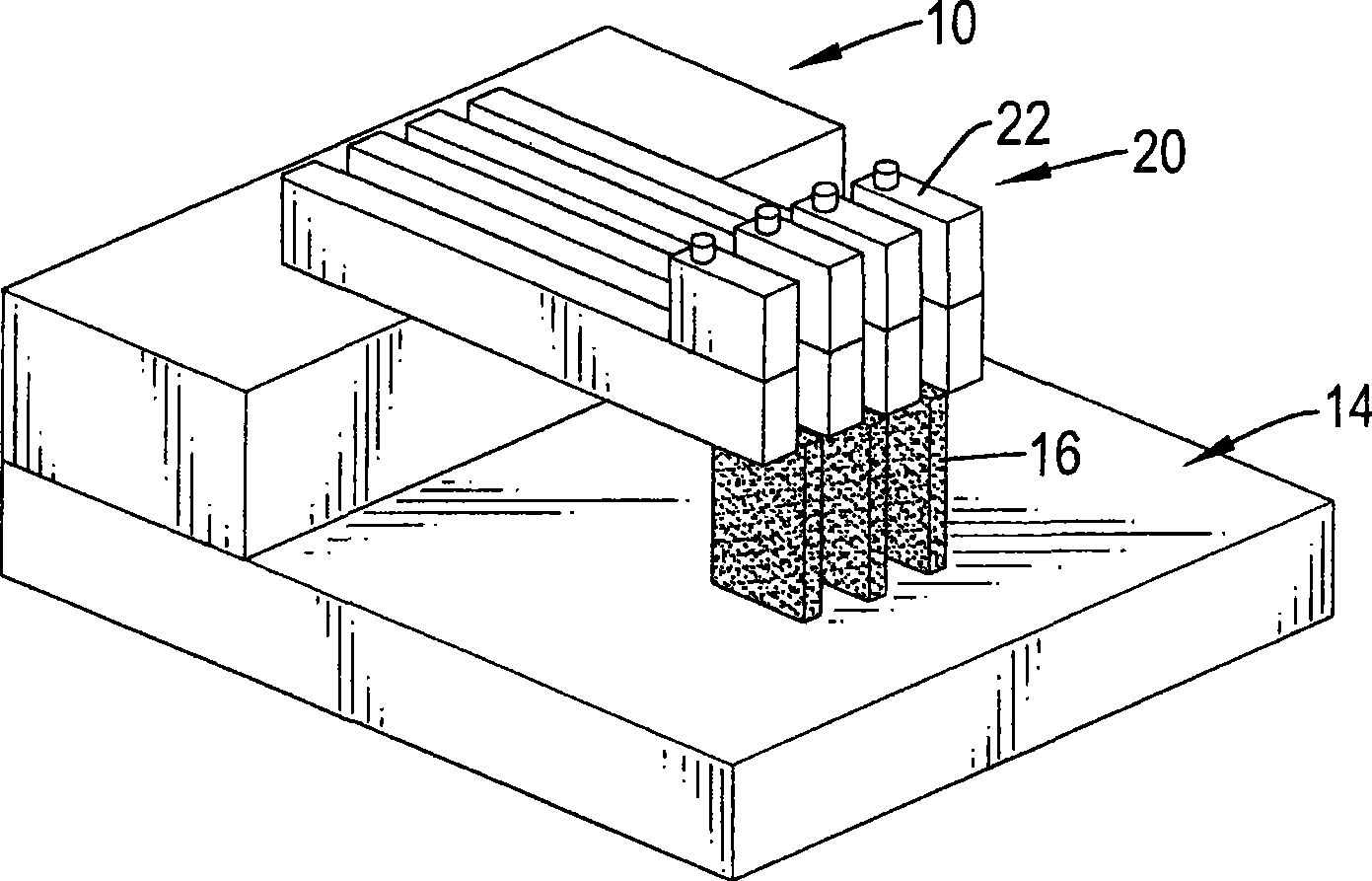

Terminal mounting structure for vehicle motor drive device

ActiveCN106575900AAvoid short circuitShort circuit will notVehicle connectorsPropulsion by batteries/cellsEngineeringMotor drive

This terminal mounting structure is provided with: a plurality of recipient-side terminals (19) extending from respective distal ends of electrical leads (171); a mount (42) having an electrically insulating base material (43) and a plurality of supply-side conductive bars (44) that are disposed at an interval from one another and extend through the base material; a plurality of screws (48) that are screwed into screw holes formed in ends of the supply-side conductive bars through the recipient-side terminals in a direction intersecting with the direction of extension of the recipient-side terminals, thus fixedly contacting each of the recipient-side terminals to the respective corresponding supply-side conductive bars; and a contact prevention mechanism (46) that is provided to the mount and prevents contact between adjacent recipient-side terminals.

Owner:NTN CORP

Manufacture method of probe short circuit preventing structure

InactiveCN101329366BEliminate short circuitShort circuit will notElectrical measurement instrument detailsElectrical testingBiomedical engineeringShort circuit

Owner:MPI CORP

Pixel structure and maintenance method thereof

ActiveCN101813858BGuaranteed normal transmissionWill not short circuitNon-linear opticsManufacturing technologyLiquid-crystal display

The invention discloses a pixel structure and a maintenance method thereof, which relates to the technical field of liquid crystal display and solves the problems of complex maintenance progress and necessary maintenance device replacement for the traditional pixel structure. The invention embodiment is provided with a light shading part corresponding to data scanning lines on a grid and a grid layer of grid scanning lines. The light shading part is of a sealed structure and is connected to the grid scanning lines. The invention embodiment is mainly applied to the liquid crystal display, in particular to the liquid crystal display adopting TFT manufacture technology.

Owner:BOE TECH GRP CO LTD +1

Multi-adaptive electric fusion welding device

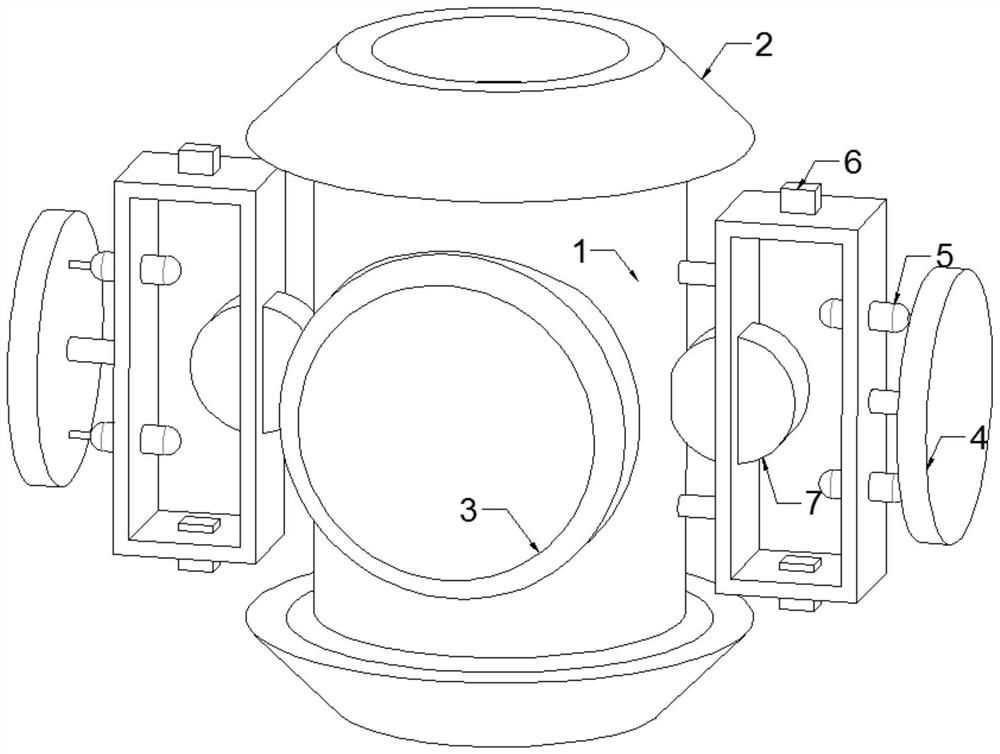

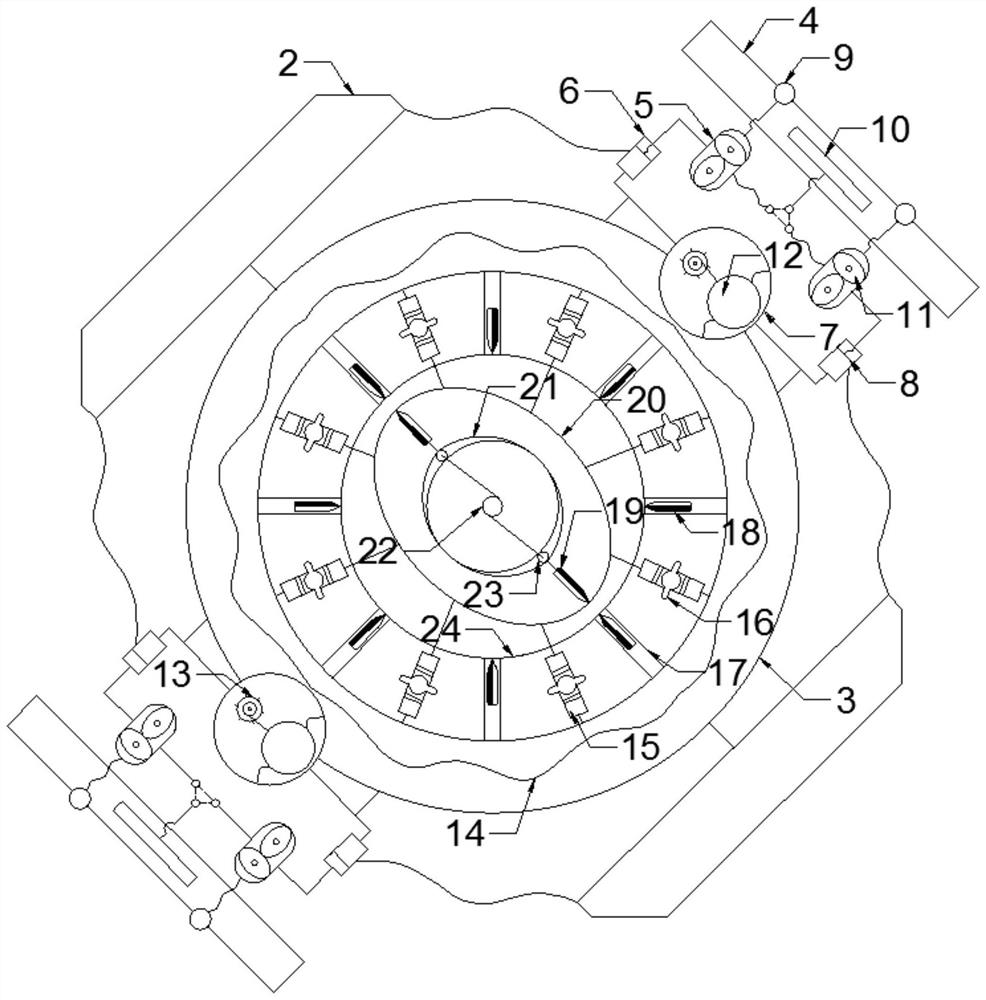

InactiveCN113070610AEasy to pushDetect disengagementWelding/cutting auxillary devicesAuxillary welding devicesPhysicsSevere weather

The invention discloses a multi-adaptive electric fusion welding device which comprises a cylindrical shell and is characterized in that a rain sheltering mechanism is arranged at the top of the cylindrical shell, a cleaning mechanism is installed on one side of the cylindrical shell, welding mechanisms are arranged on the two sides of the cylindrical shell, short circuit prevention mechanisms are arranged in gaps between the two sides of the cylindrical shell and the welding mechanisms, a deformation bag is connected into each welding mechanisms through a bearing, four first air cylinders are evenly arranged on the periphery of each deformation bag, first pistons are slidably connected into the four first air cylinders in a sleeved mode, a connecting rod is welded to one side of the first piston, a push rod is welded to the top end of each connecting rod, an elastic pipeline is installed on the other side of each first piston, an extrusion plate is welded to the top end of each elastic pipeline, and four contacts are arranged on the periphery of each welding mechanism. The multi-adaptive electric fusion welding device has the functions of automatically welding breakpoints and preventing mosquitoes and has the characteristic of resisting various severe weathers.

Owner:夏传斌

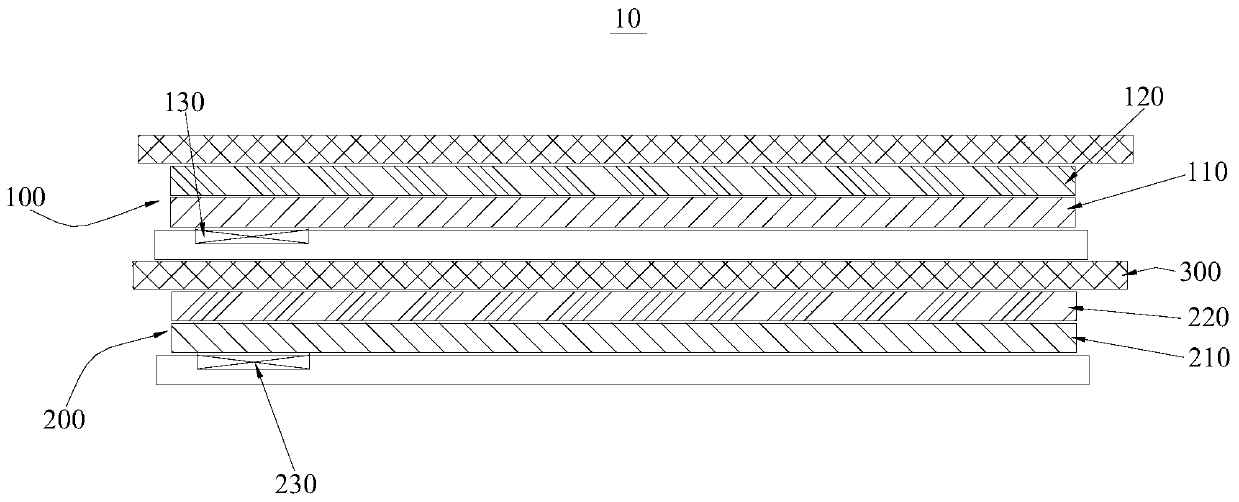

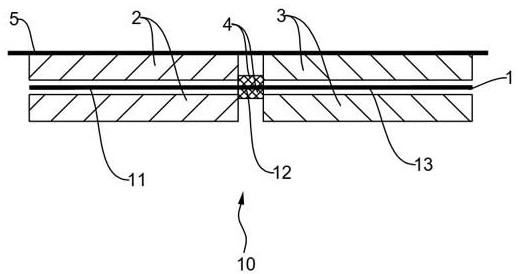

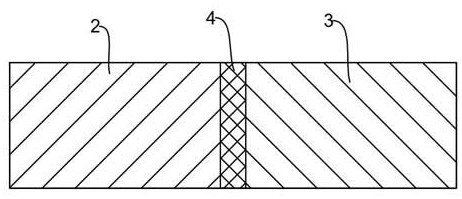

Bipolar electrode, laminated battery and preparation method of laminated battery

ActiveCN114094116AExtended service lifeIncrease profitElectrode manufacturing processesFinal product manufactureElectrical batteryElectrical polarity

The invention relates to a bipolar electrode, a laminated battery and a preparation method of the laminated battery, the bipolar electrode comprises a flexible conductive substrate, an insulating strip and an insulating layer, the flexible conductive substrate has a first surface and a second surface which are oppositely arranged, each of the first surface and the second surface comprises a positive electrode region, a bending region and a negative electrode region which are sequentially arranged, the positive electrode region is coated with a positive electrode active material, and the negative electrode region is coated with a negative electrode active material; the positive electrode region of the first surface is opposite to the positive electrode region of the second surface, and the negative electrode region of the first surface is opposite to the negative electrode region of the second surface; the bending region of the first surface is opposite to the bending region of the second surface; the bending region can be bent, so that the flexible conductive substrate is bent from an unfolded state to a folded state, and the folded state is that the positive electrode region and the negative electrode region are arranged oppositely; an insulating strip is arranged in the bending region; and the insulating layer is interposed between the positive electrode active material and the negative electrode active material. The bipolar electrode is simple in processing technology and low in processing cost, the energy density of the laminated battery is improved, and the service life of the laminated battery is prolonged.

Owner:深圳市睿赛新能源科技有限公司 +1

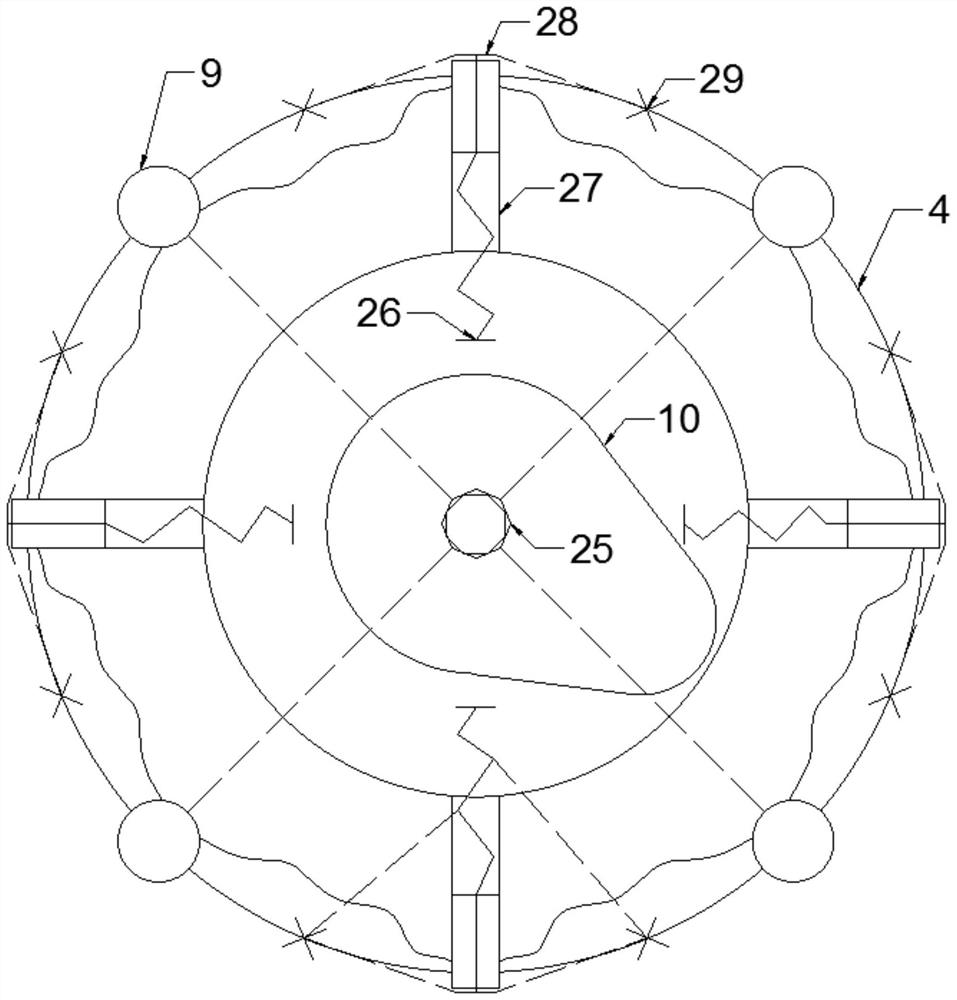

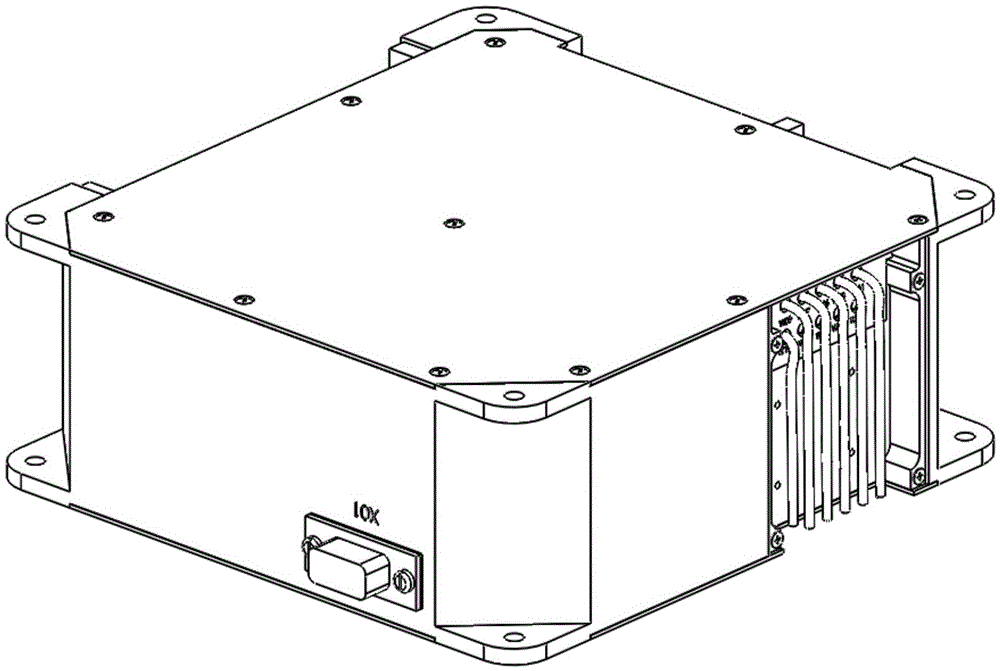

A high-voltage power supply lead casing for a magnetic deflection mass spectrometer for space

ActiveCN103700993BAchieve insulationShort circuit will notFlexible lead accommodationEnvironment effectPunching

The invention relates to a high-reliability leading-out mode of a high-voltage power supply lead machine case of a spatial magnetic deflection mass spectrograph. The mode comprises the steps that the machine case punching is carried out in a high-voltage lead leading-out position, an insulation lead board with a fixing clamp groove is processed, the punching is carried out for each leading-out wire on the insulation lead board according to requirements, and a high-voltage power supply cabin body is led out by a high-voltage lead through a hole formed in an insulation board. The leading-out mode has the advantages that the side wall in the leading-out position of the high-voltage lead of a high-voltage power supply is made of insulation materials, so the failure mode caused by the short circuit of the high-voltage lead on a metal casing after a high-voltage lead insulation layer is abraded or scraped by the metal casing under the cruel mechanical environment effect is radically avoided, and the reliability of the high-voltage power supply in the space application is powerfully guaranteed.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

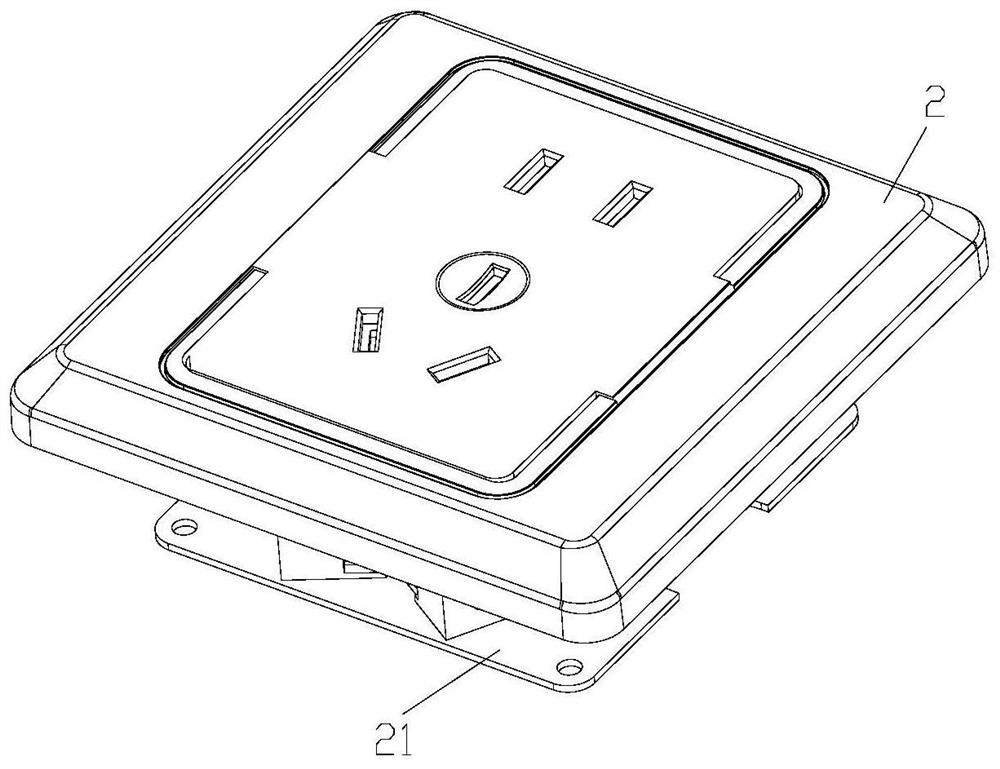

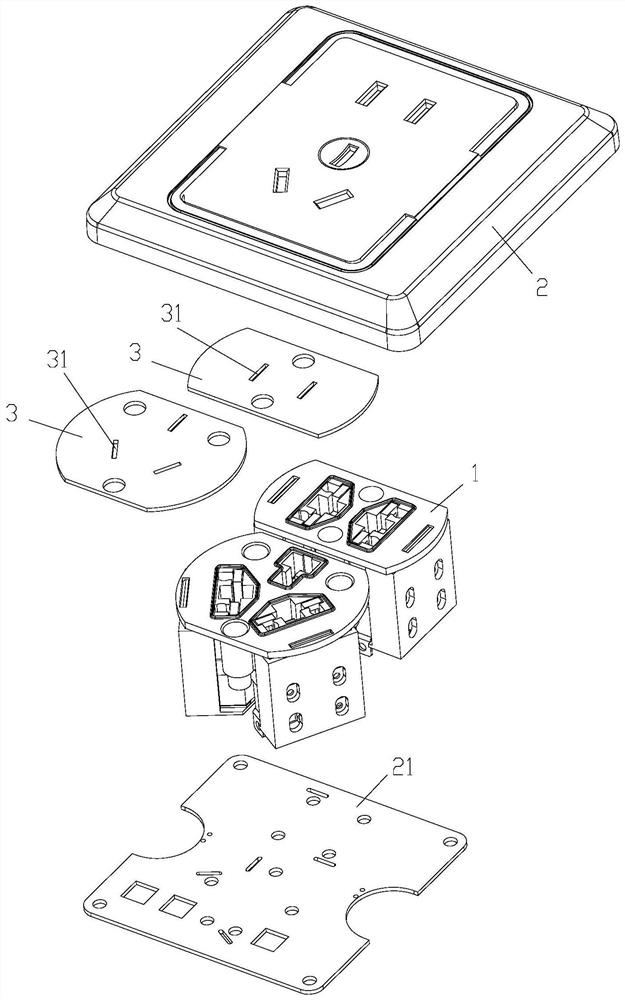

A waterproof socket

ActiveCN110224271BAchieve conductionAchieve short circuitCouplings bases/casesStructural engineeringNeutral line

Owner:深圳市龙迈源科技发展有限公司

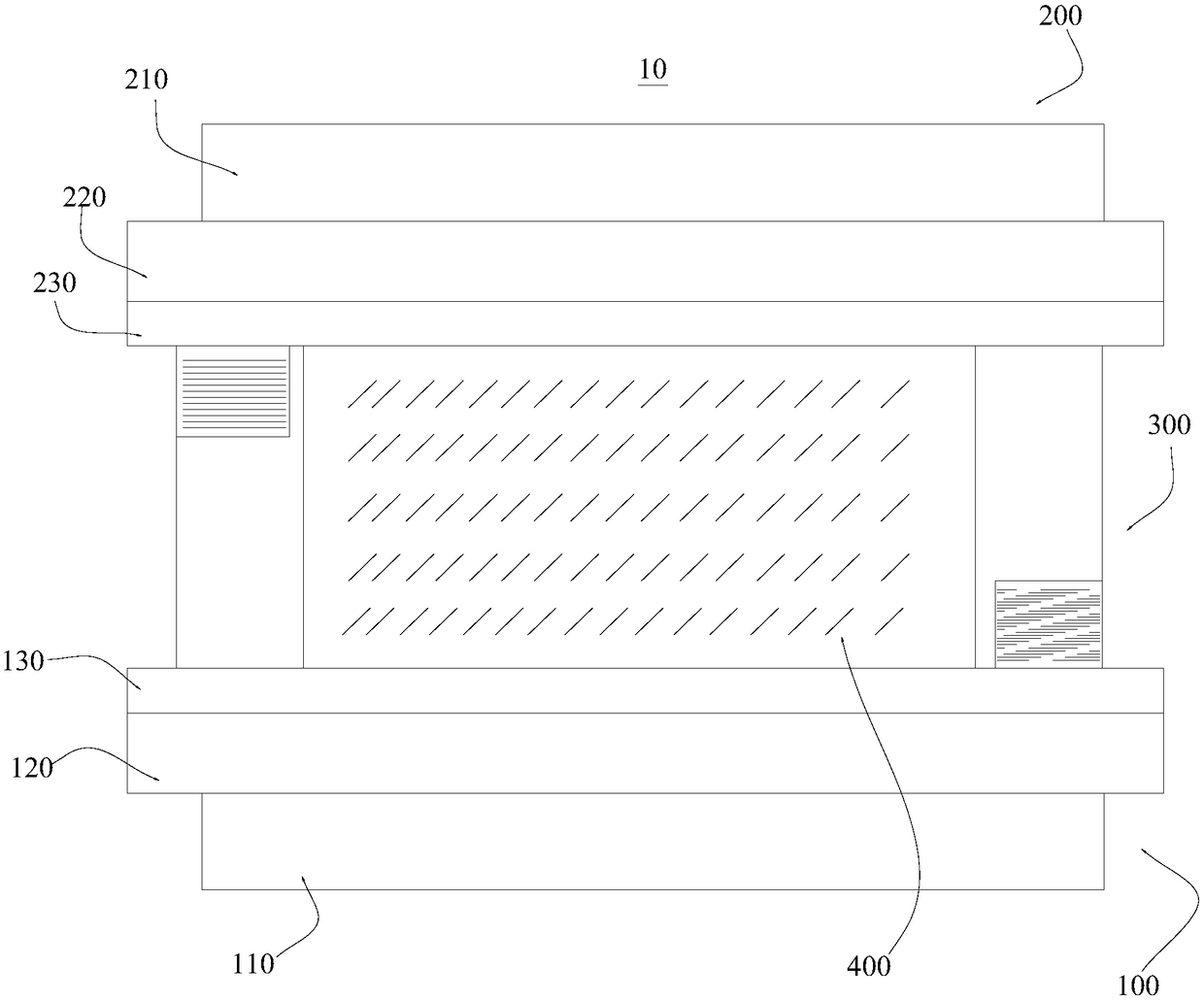

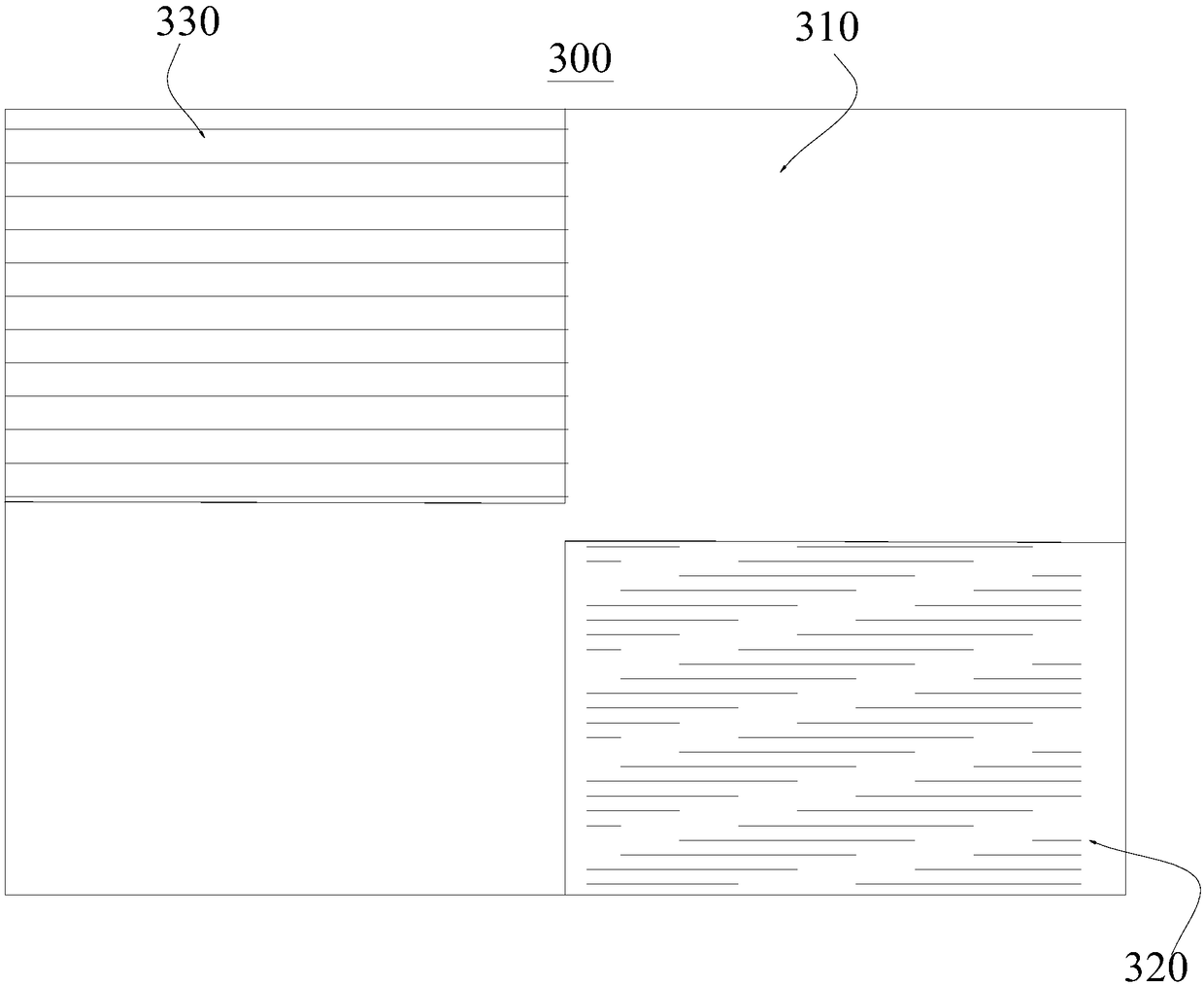

Liquid crystal display capable of preventing short circuit

PendingCN108445662AInput stableShort circuit will notStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

An liquid crystal display capable of preventing short circuit comprises a first display component, a second display component, a sealing element, a liquid crystal filling body and a driving module. Inthe actual application of the liquid crystal display capable of preventing short circuit, a first output end of the driving module outputs a first voltage to a first conductive portion, a second output end of the driving module outputs a second voltage to a second conductive portion, and the first conductive portion is electrically connected with the first display component, the second conductiveportion is electrically connected with the second display component, and the first conductive portion and the second conductive portion are separated by an insulating sealant portion, the first conductive portion and the second conductive portion are not shorted by the sealant portion, that is, no short circuit occurs, so that the first voltage can be stably input into the first display component, the second voltage can be stably input into the second display component, and the first display component and the second display component stably exist voltage difference to form an internal electric field to cause the liquid crystal filling body to rotate.

Owner:CONHUI HUIZHOU SEMICON

Underwater anti-short circuit separate electric connector

ActiveCN100502161CImprove connectivityShort circuit will notCoupling device detailsElectricityUnderwater

The electric connector is composed of socket and plug. Wire out port of the socket is connected to back shell body of the socket, and unlocking sheath is connected to releasing gear. The unlocking sheath via sidestep pulls movement of front shell body of the socket. Connecting rod connected to insulator module in middle of socket is setup on the unlocking sheath. Through the connecting rod, the unlocking sheath drives axial motion of the insulator to turn signal inside the socket on / off. After unlocking, through water inlet troughs on plug and socket, water enters into insertion face of the connector in order to realize balance between inner and outer hydraulic pressures. The plug with two jacks is installed in insulator module. One end of the plug is always contacted to connector pins, and the other end is assorted to connector pins to implement turning electric signal on / off. With simple structure, the invented electric connector prevents short circuit reliably.

Owner:杭州航天电子技术有限公司

Flat FCB (Flip Chip Bonding) GaN-based LED (Light-Emitting Diode) chip structure

ActiveCN102034925BPrevent short circuitAvoid short circuitSolid-state devicesSemiconductor devicesQuantum wellAlloy

The invention provides a flat FCB (Flip Chip Bonding) GaN-based LED (Light-Emitting Diode) chip structure comprising a substrate. An N-type GaN layer, a QW (Quantum Well) active area, a P-type GaN layer, a current extension level and a light-reflecting layer are sequentially arranged below the substrate from top to bottom, a stepped surface to the N-type GaN layer is etched on the light-reflecting layer, an N electrode is made on the N-type GaN layer of the stepped surface, a P electrode is made on the light-reflecting layer and arranged on the same plane with the outer end of the P electrode, a transparent insulated medium film is coated on the plane of the P electrode bonding pad and the N electrode bonding pad except the regions of P electrode bonding pad and the N electrode bonding pad, a P bonding board is made at the outer end of the P electrode bonding spot, an N bonding board is made at the outer end of the bonding point of the N electrode, and the P bonding board and the N bonding board are bonded on a P electrode area and an N electrode area of a conductive Si or SiC substrate by cocrystallization or alloy. The insulated medium film is coated outside the PN bonding pads to prevent PN from being subjected to short circuits and a limit N-area electrode conductive flat is spliced to the P area desk.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

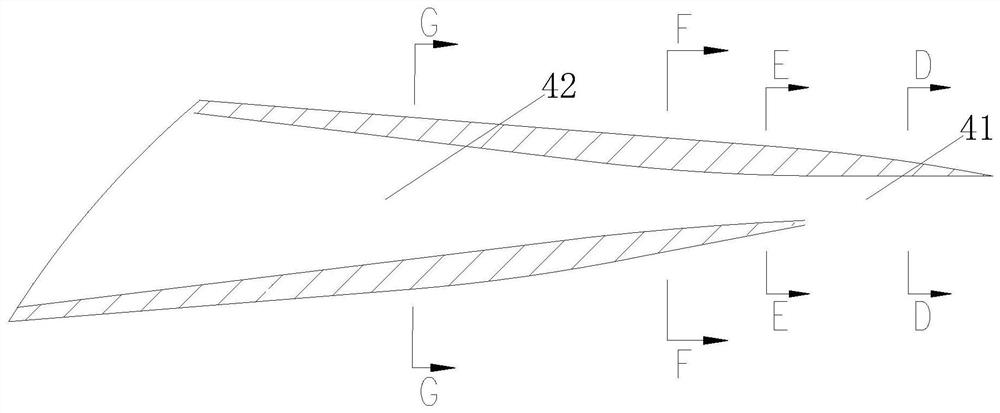

Radial diffuser channel pretreatment method

ActiveCN110076408BEliminate to get throughAvoid getting burnedElectrochemical machining apparatusPretreatment methodMachining

The invention provides a radial diffuser channel pretreatment method. The method comprises the following steps that S21, an electrolytic machining environment is prepared; S22, a through-hole cathodeis used for carrying out vibration feeding electrolytic machining on a channel of a radial diffuser at the feeding speed of 5mm / min-6mm / min, and the channel is broken through by using a burr working section of the through-hole cathode; and S23, the through-hole cathode is used for carrying out vibration feeding electrolytic machining on the channel of at the feeding speed of 3mm / min-4mm / min, uneven allowance on the inner wall of the channel is eliminated by using an inner wall working section of the through-hole cathode. Burrs can be eliminated through the burr working section of the through-hole cathode to break through the channel, the problem that a short circuit is generated by contact between a forming cathode and burrs when the forming cathode carries out vibration feeding electrolytic machining on the channel is avoided, the uneven allowance on the inner wall of the channel can be eliminated by using the inner wall working section of the through-hole cathode, and the problem that a short circuit is generated by contact between a forming cathode and the inner wall of the channel when the forming cathode carries out vibration feeding electrolytic machining on the channel is avoided.

Owner:CHINA HANGFA SOUTH IND CO LTD

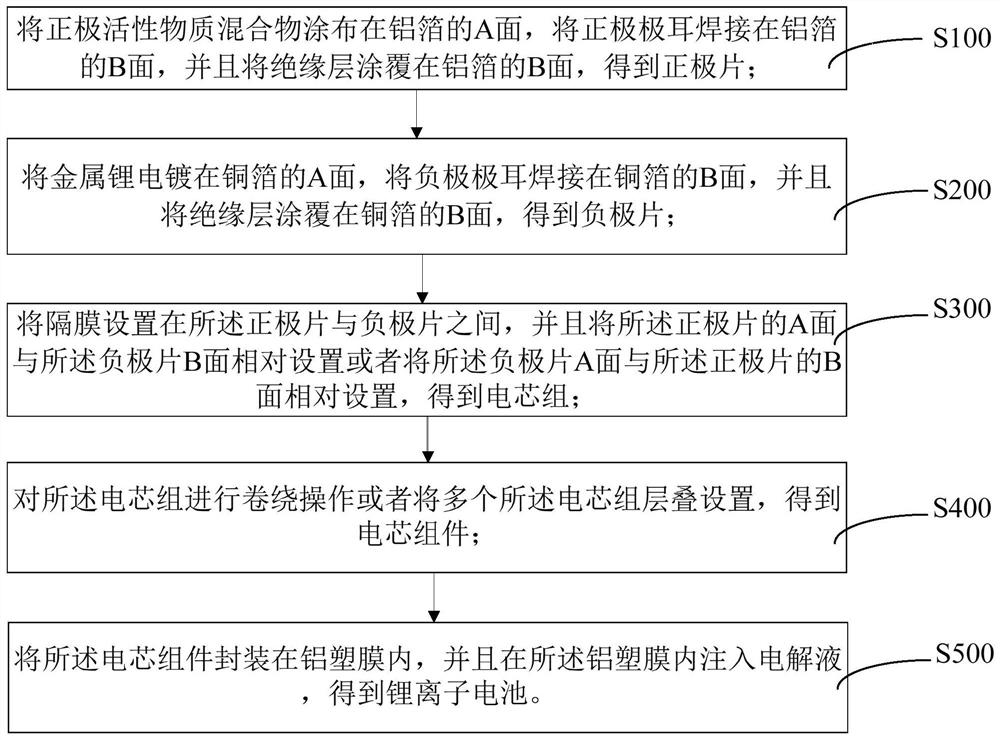

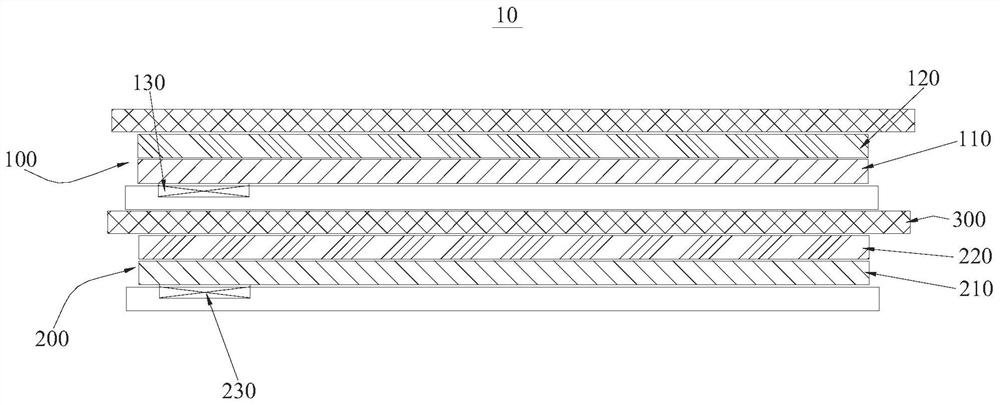

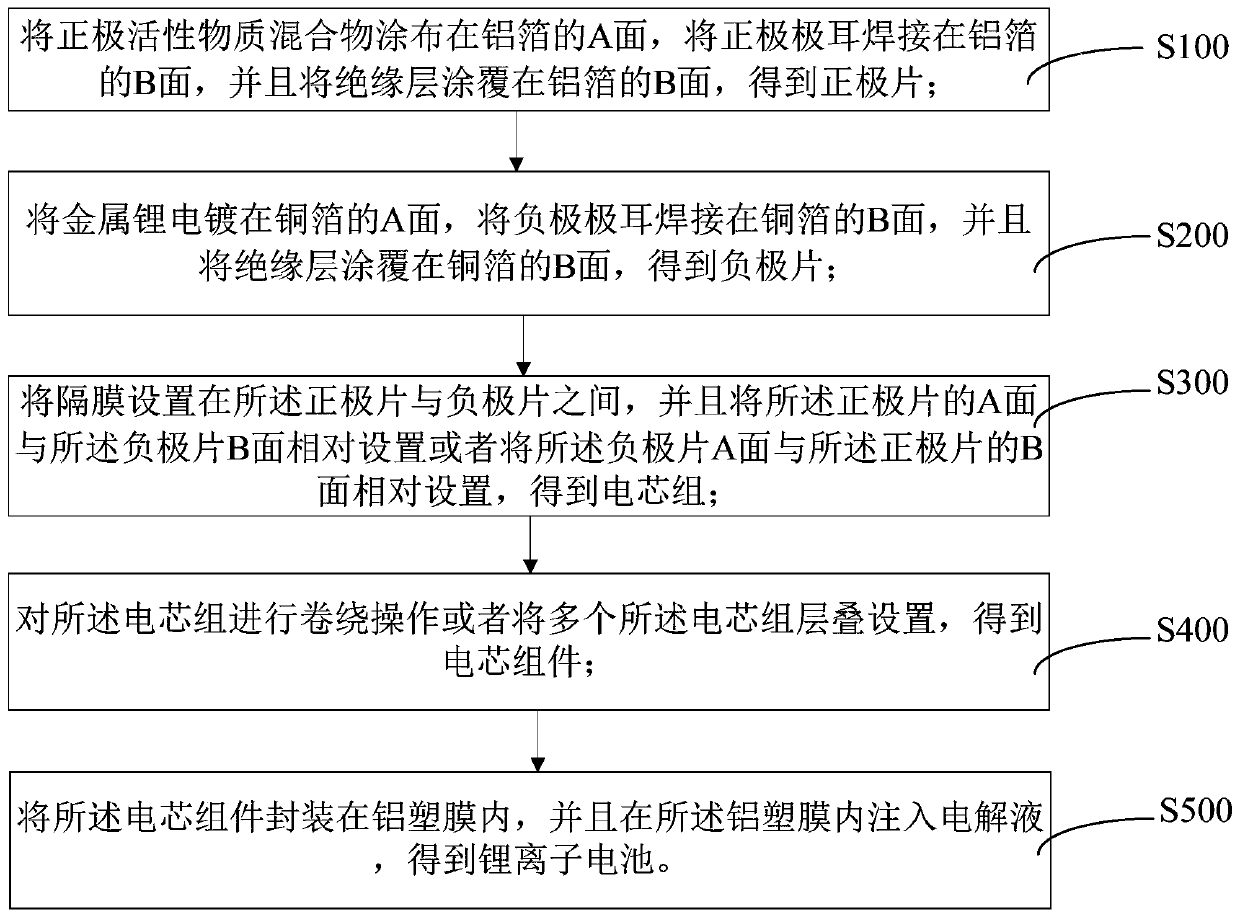

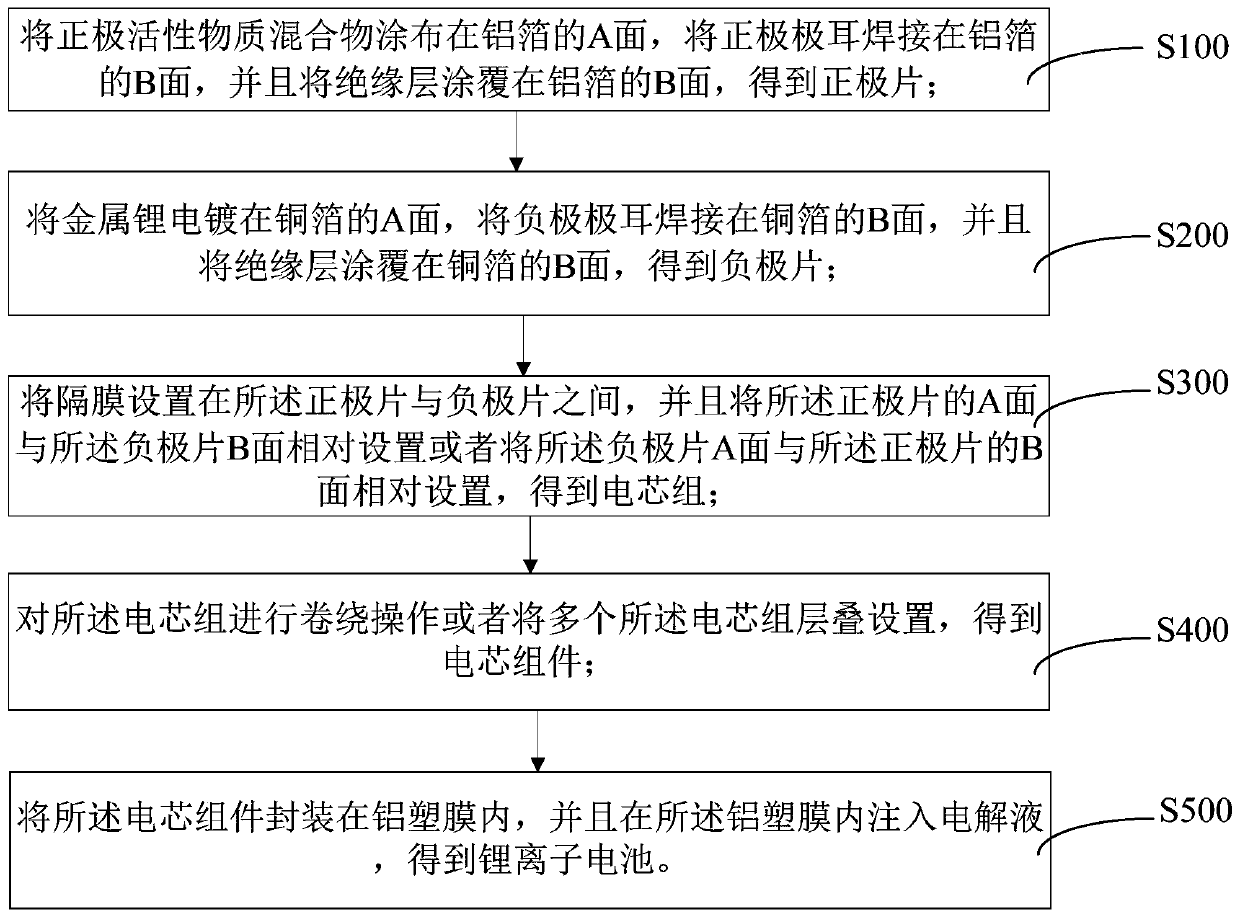

Preparation method of lithium ion battery and lithium battery thereof

ActiveCN111146504BIncrease energy densityAvoid short circuitFinal product manufactureNegative electrodesMetallic lithiumPhysical chemistry

A preparation method of a lithium ion battery and the lithium battery thereof. The preparation method of the lithium ion battery comprises the following steps: coating a positive electrode active material mixture on the A side of the aluminum foil, and coating an insulating layer on the B side of the aluminum foil; electroplating metal lithium On the A side of the copper foil, and the insulating layer is coated on the B side of the copper foil; the separator is arranged between the positive electrode sheet and the negative electrode sheet, and the A surface of the positive electrode sheet is opposite to the B surface of the negative electrode sheet or the negative electrode sheet The A side is arranged opposite to the B side of the positive electrode sheet; the battery pack is wound or a plurality of battery packs are stacked. The preparation method of the lithium ion battery of the present invention can improve the energy density of the battery by arranging a positive electrode sheet of a single-sided active material and a negative electrode sheet using lithium metal as the negative electrode, and at the same time, an insulating layer is arranged on the positive electrode sheet and the negative electrode sheet , so that the generated lithium dendrites can be blocked, thereby preventing the short circuit caused by the contact between the lithium dendrites and the positive electrode sheet.

Owner:EVE ENERGY CO LTD

Lithium ion battery preparation method and lithium battery thereof

ActiveCN111146504AIncrease energy densityAvoid short circuitFinal product manufactureNegative electrodesMetallic lithiumCopper foil

The invention relates to a lithium ion battery preparation method and a lithium ion battery thereof. The lithium ion battery preparation method comprises the following steps: coating a cathode activematerial mixture on the A surface of an aluminum foil, and coating an insulating layer on the B surface of the aluminum foil; electroplating metal lithium on the surface A of the copper foil, and coating the insulating layer on the surface B of the copper foil; arranging a diaphragm between the positive plate and the negative plate, and oppositely arranging the surface A of the positive plate andthe surface B of the negative plate or oppositely arranging the surface A of the negative plate and the surface B of the positive plate; and carrying out winding operation on the battery cell groups or stacking a plurality of battery cell groups. According to the preparation method of the lithium ion battery, the positive plate with the single-sided active material and the negative plate with thelithium metal as the anode are arranged, the insulating layers are arranged on the positive plate and the negative plate, so that the generated lithium dendrites can be blocked, and the lithium dendrites are prevented from being in contact with the positive plate to cause short circuit.

Owner:EVE HYPERPOWER BATTERIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com