Manufacture method of probe short circuit preventing structure

A technology of probe short circuit and manufacturing method, which is applied to parts, instruments, and measuring devices of electrical measuring instruments, and can solve problems such as complex structure of probes and inability of probes to contact measuring contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

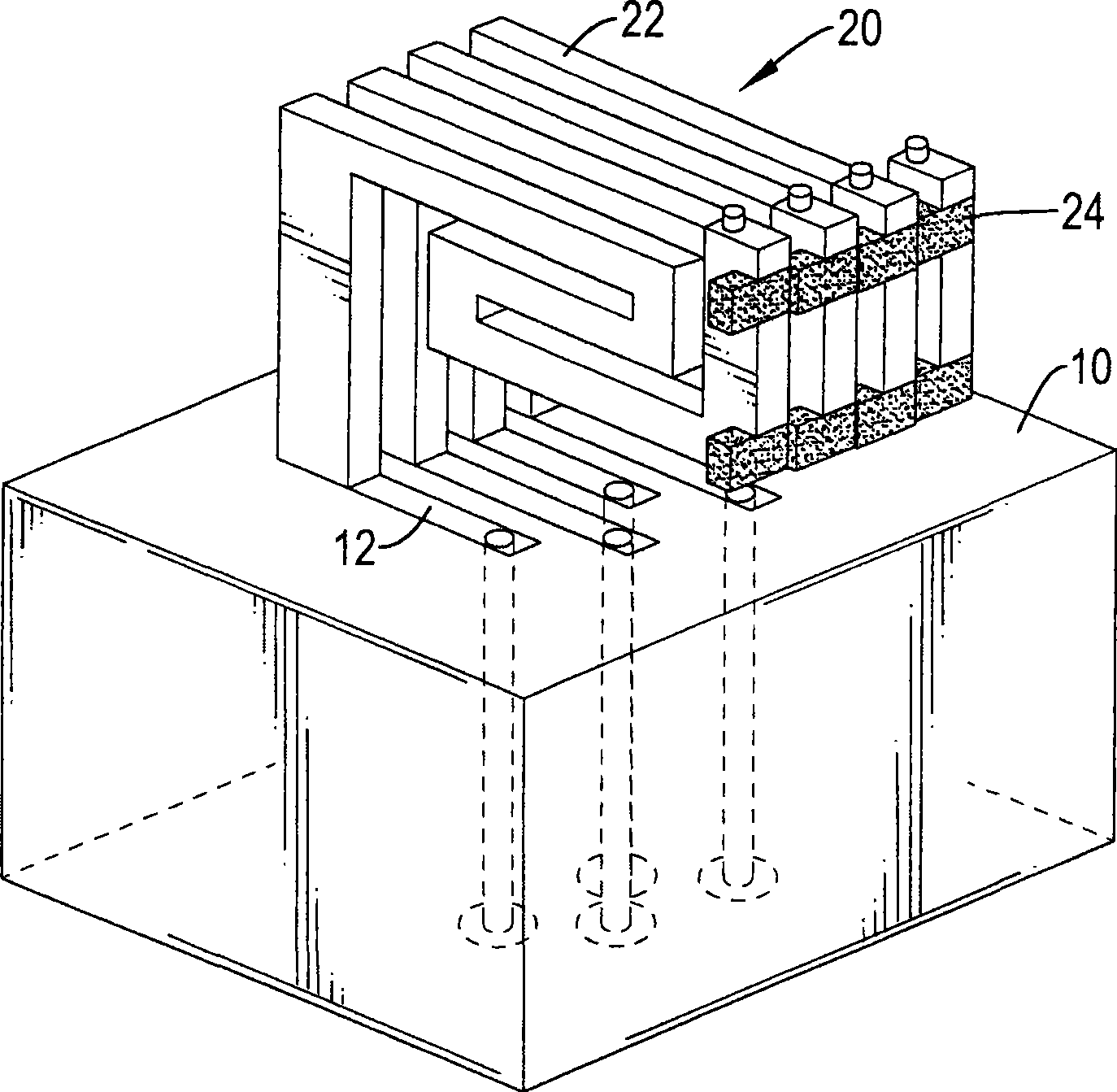

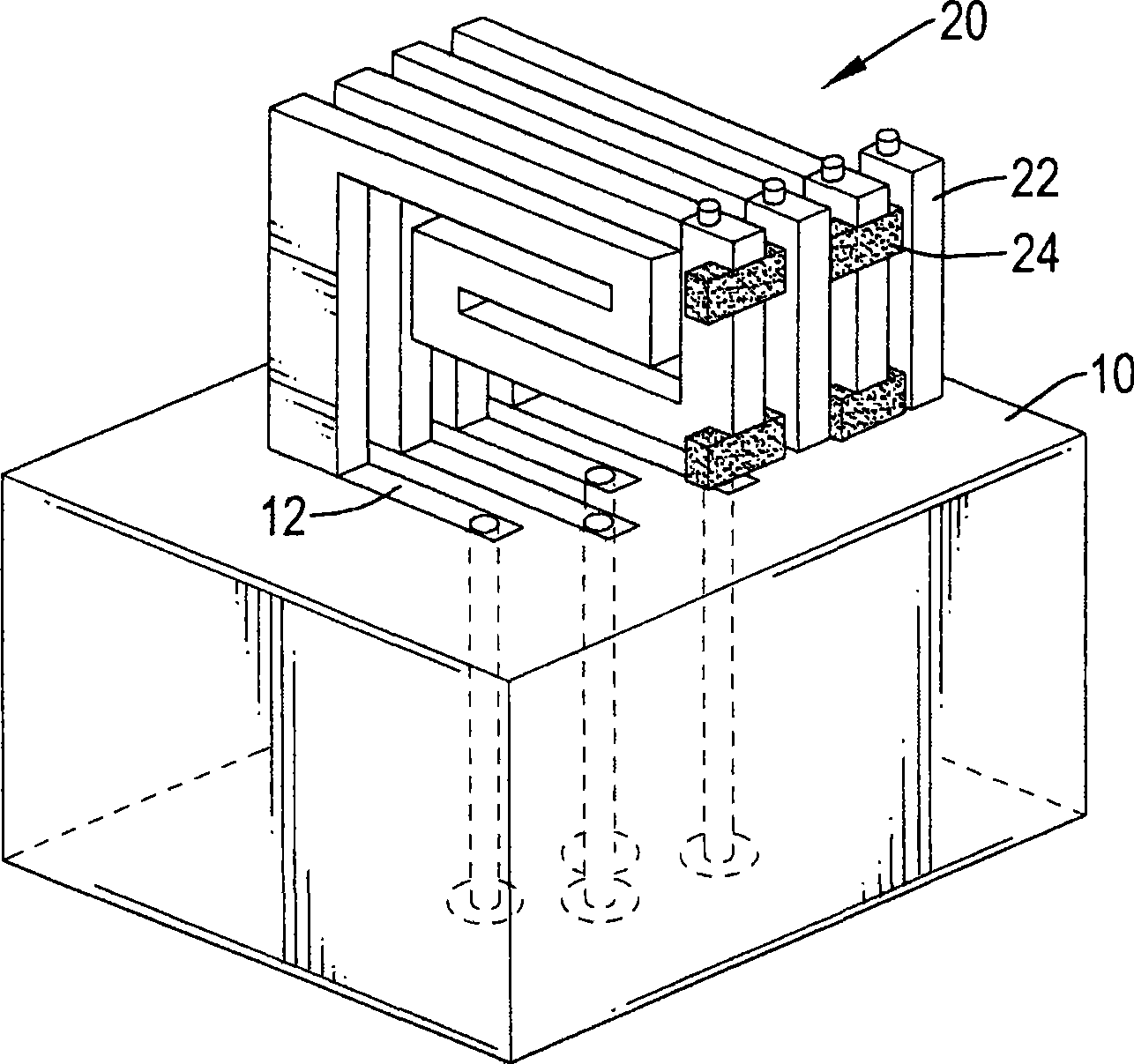

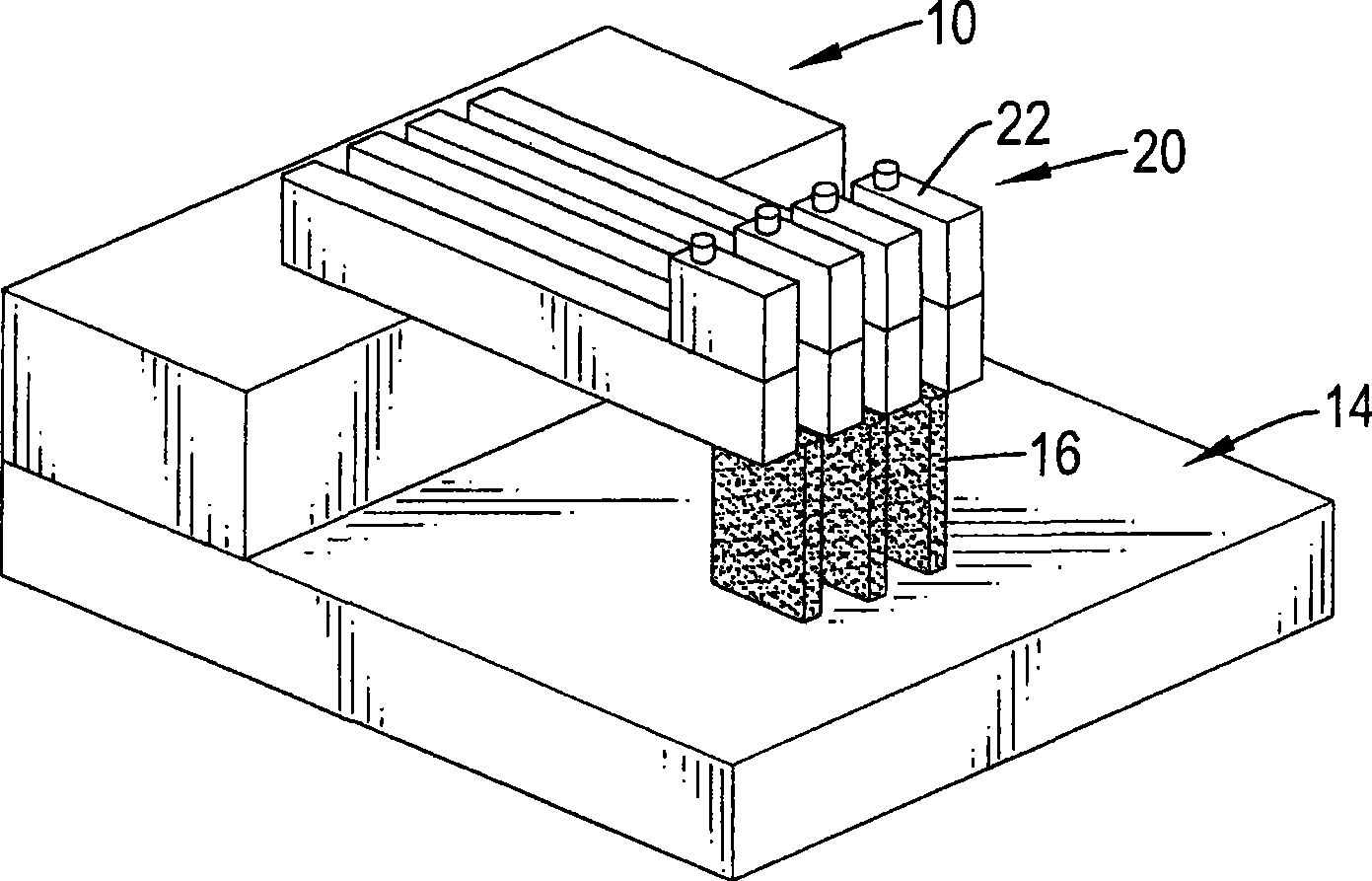

[0058] Please refer to figure 1 , is a first preferred embodiment of a probe short circuit prevention structure of the present invention, which includes a probe base 10 and a probe array 20, wherein the probe array 20 includes a plurality of probes 22 and a plurality of isolation Block 24.

[0059] The probe base 10 includes a plurality of conductive parts 12, each conductive part 12 is isolated from each other, and can be used as a contact point for connecting external signal lines (not shown in the figure).

[0060] The plurality of probes 22 have electrical conductivity and elastic deformation capability, and can be shaped into any shape, such as L-shape, long rod shape, etc. Taking this preferred embodiment as an example, the length direction has multiple bent L-shape , each probe 22 includes a cantilever portion and a contact portion, and the contact portion of each probe 22 is electrically connected and fixed to a conductive portion 12, and the cantilever portion of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com