Pixel structure and maintenance method thereof

A technology of pixel structure and pixel unit, applied in nonlinear optics, instruments, optics, etc., can solve the problems of complex maintenance process and damage to common electrode lines, and achieve the effect of simple maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

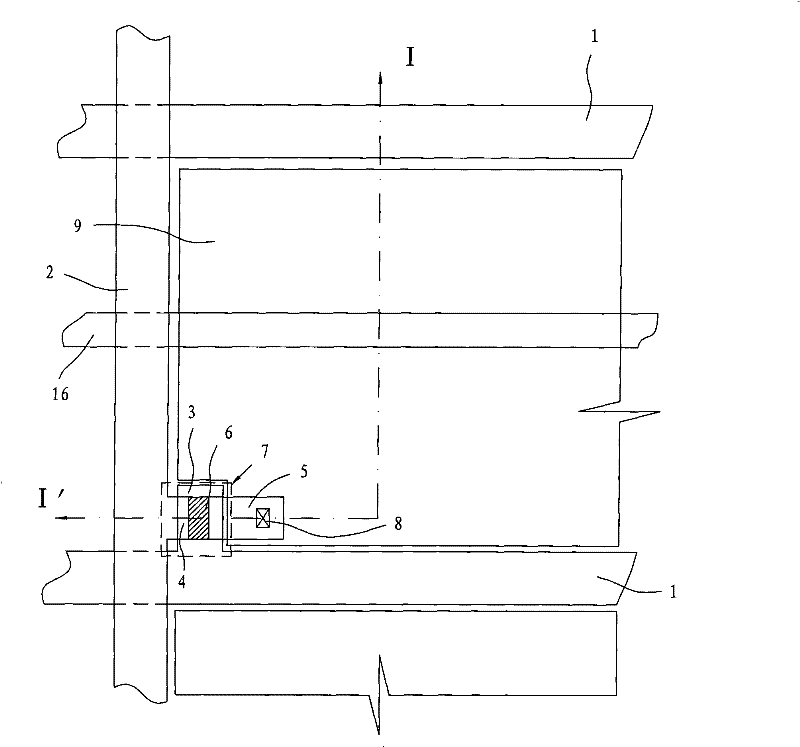

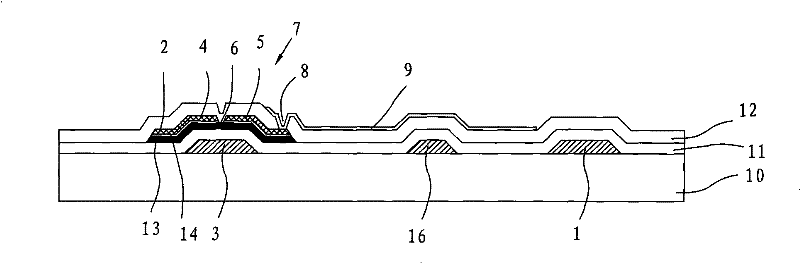

[0033] An embodiment of the present invention provides a pixel structure, such as Figure 5 As shown, the pixel structure includes gate scan lines 420 , 450 and data scan lines 410 intersecting each other on a substrate 470 , and the intersections of the gate scan lines 450 and data scan lines 410 define pixel units.

[0034] In order to facilitate maintenance after the data scanning line is disconnected, the pixel structure of the embodiment of the present invention also needs to set a light shielding part, which is a closed structure and connected to the gate scanning line 450, and the light shielding part and the gate scanning line 450 are located at the same layer. Specifically, as Figure 6 As shown, the light-shielding portion includes vertical light-shielding strips 460 and horizontal light-shielding strips 461 parallel to the data scanning lines. The specific arrangement of the vertical light-shielding strip 460 is as follows: vertical light-shielding strips 460 resp...

Embodiment 2

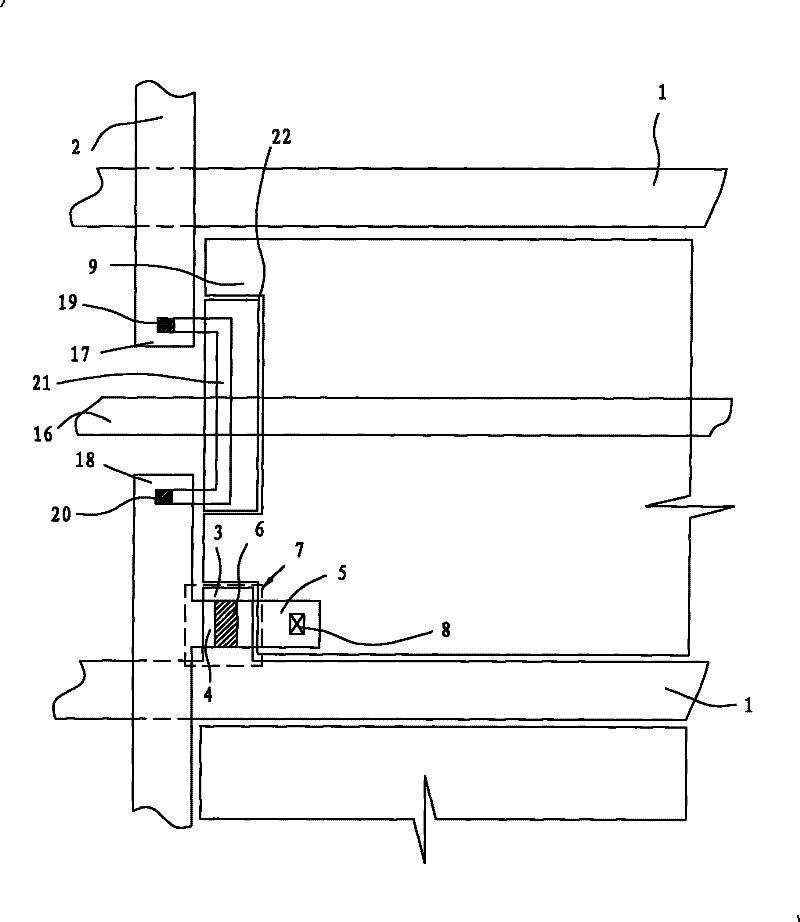

[0041] The embodiment of the present invention also provides a method for repairing the pixel structure, the repair method is mainly aimed at the following two situations:

[0042] First, the data scanning line at the corresponding position between the two ends of the shading strip is disconnected.

[0043] For the maintenance under this situation, the specific operation of the embodiment of the present invention is as follows: Figure 7 As shown, holes 510 and 511 are punched at the overlapping position of the data scanning line 410 and the horizontal light-shielding strip. Filling with metal (that is, welding operation); in this way, the horizontal light-shielding strips of the light-shielding portion and the data scanning lines 410 are connected together through the metal in the holes 510 and 511, so that the disconnected data scanning lines 410 are connected through the light-shielding portion.

[0044] If the vertical light-shielding strip 460 in the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com