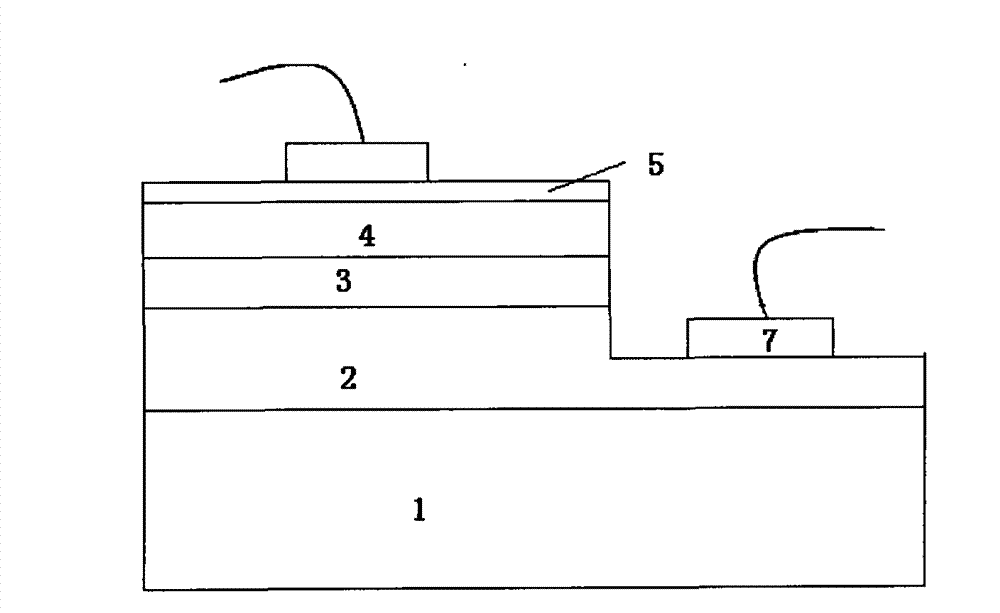

Flat FCB (Flip Chip Bonding) GaN-based LED (Light-Emitting Diode) chip structure

A LED chip, flip-chip welding technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of heat-conducting metal bumps limited, chip PN short circuit, etc., to achieve better heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

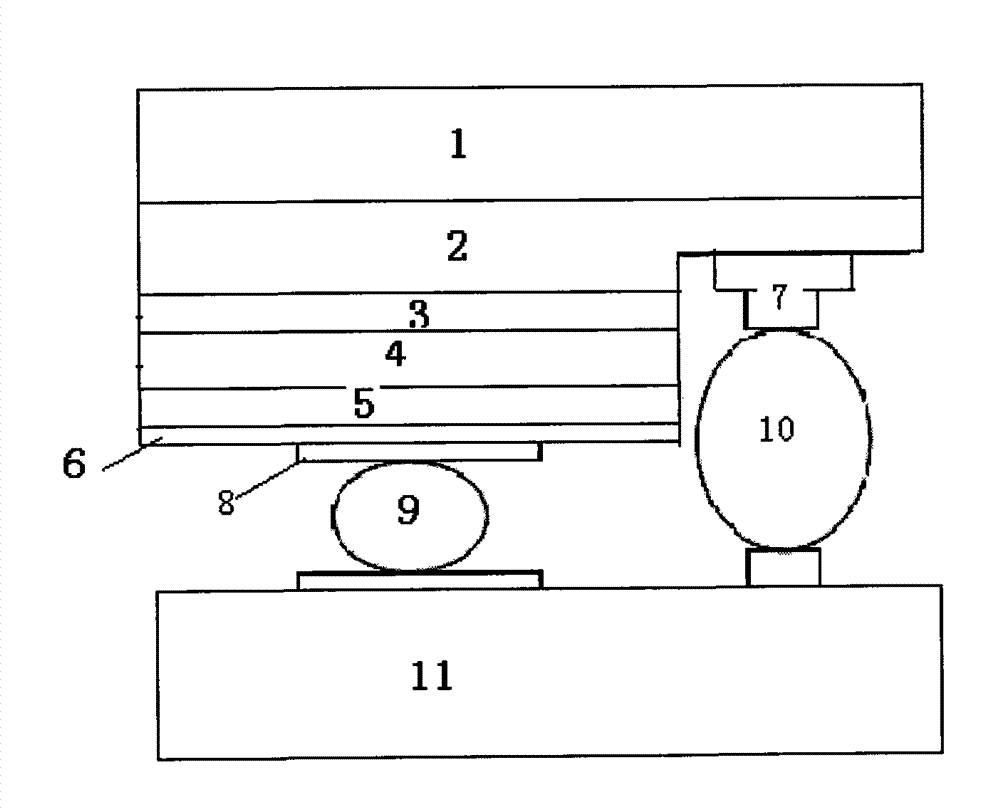

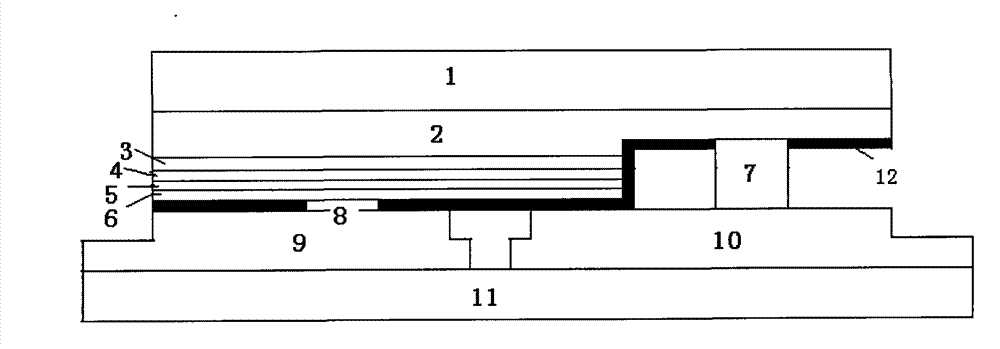

[0015] The structure of the flat panel flip-chip GaN-based LED of the present invention is figure 2 Improvements based on the flip-chip structure shown, such as image 3 with Figure 4 As shown, the light reflection layer 6 is etched with a step surface to the N-type GaN layer 4, an N electrode 7 is formed on the N-type GaN layer 4 of the step surface, and a P electrode 8 is formed on the light reflection layer 6. The outer ends of the N electrode 7 and the P electrode 8 are on the same horizontal plane. A layer of transparent insulating dielectric film 12 is plated on other areas on the surface where the P electrode pad and the N electrode pad are located except for the P electrode pad and the N electrode pad. A P welding plate 9 is made on the outer end of the P electrode solder joint, and an N welding plate 10 is made on the outer end of the N electrode solder joint. The P welding plate 9 and the N welding plate 10 are welded to the P electrode area and N of the thermally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com