Organic electroluminescence device

An electroluminescent device and organic light-emitting layer technology, applied in organic semiconductor devices, circuits, electrical components, etc., can solve problems such as moisture ingress and cracks at the ends of pixel partition layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

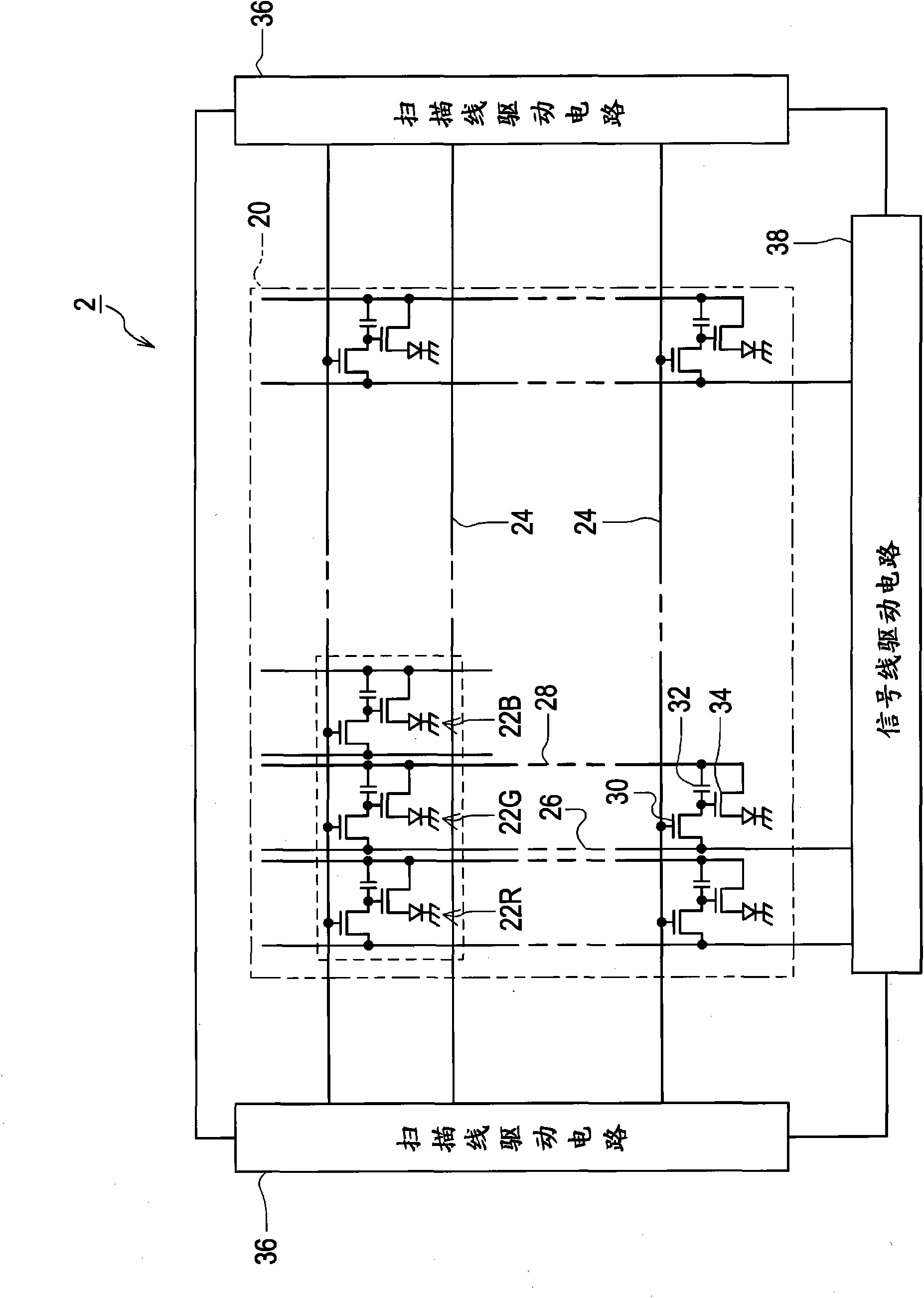

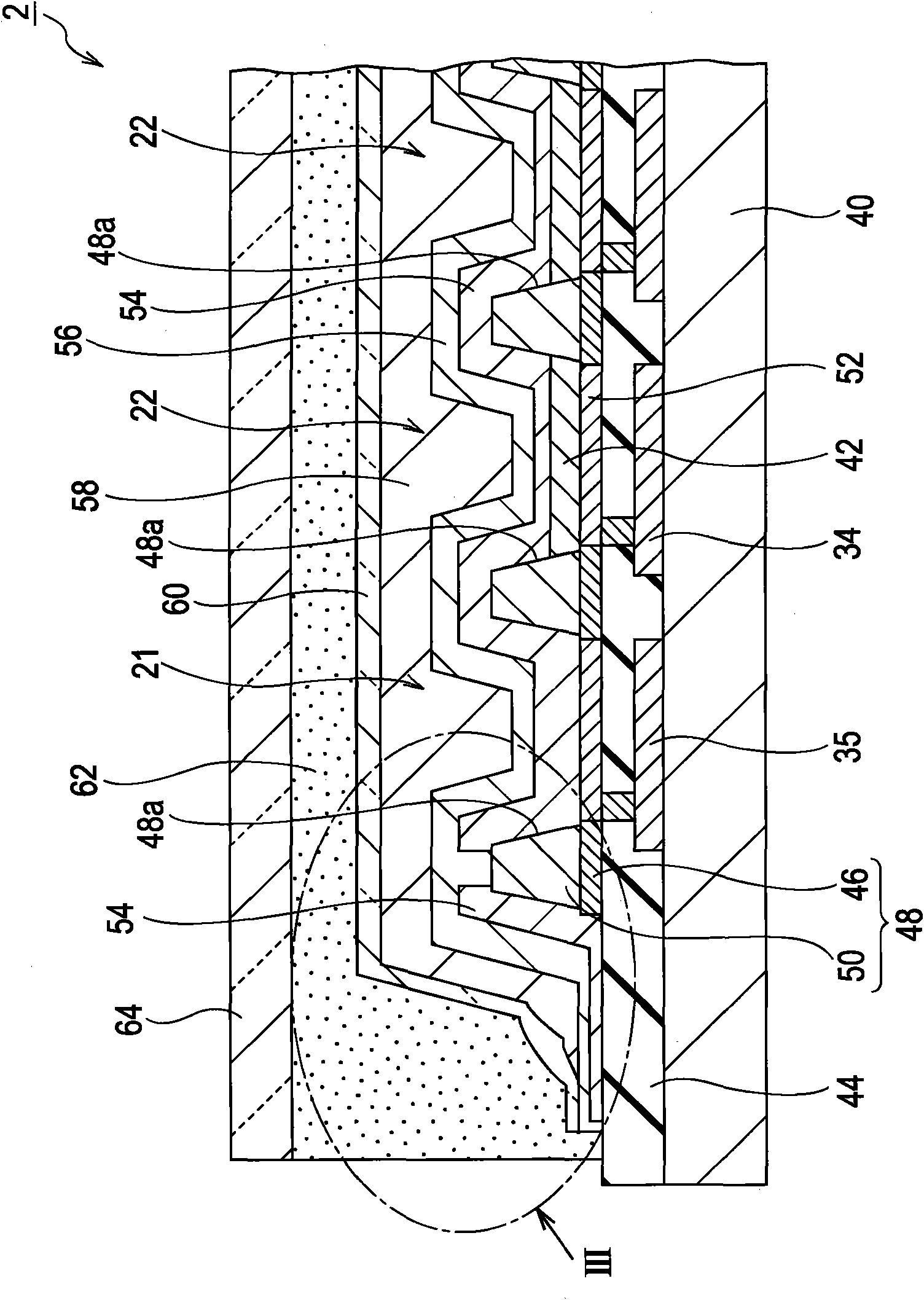

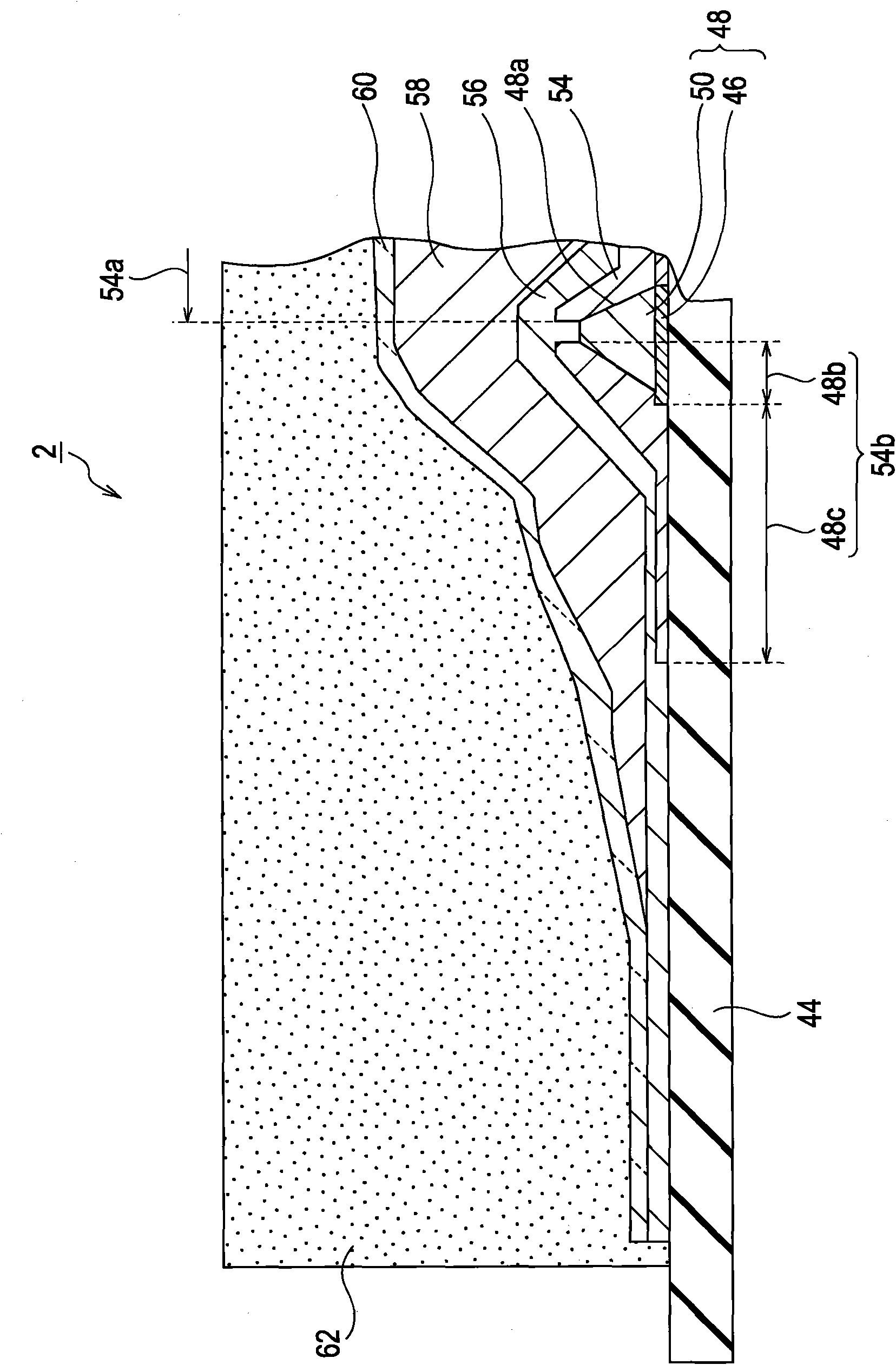

[0040] figure 1 It is an equivalent circuit diagram of various elements, wiring, and the like of the organic EL device 2 according to the present embodiment. In the display region 20 of the organic EL device 2, three types of organic EL elements, namely, a red organic EL element 22R emitting red light, a green organic EL element 22G emitting green light, and a blue organic EL element 22B emitting blue light, are regularly arranged. twenty two. Hereinafter, when the light emission color is not distinguished, it is simply referred to as the organic EL element 22 . In addition, as will be described later, the organic EL elements 22 differ only in the organic EL material that is the electro-optical material.

[0041] The organic EL device 2 is an active matrix type device that controls light emission of the organic EL elements 22 individually to form an image in the display area 20 including a plurality of organic EL elements 22 . A plurality of scanning lines 24 , a plurality ...

no. 2 approach

[0082] The structure of the organic buffer layer of the organic EL device according to this embodiment is the same as that of the common cathode layer in the first embodiment. However, the organic EL device according to this embodiment is a full-color panel using a low-molecular-weight organic EL material described later, and can perform full-color display using an organic EL element and a color filter that emit white light.

[0083] Figure 8 is a cross-sectional view of the organic EL device 4 according to this embodiment, Figure 9 will be Figure 8 Part B is an enlarged cross-sectional view shown. This organic EL device 4 includes a flat substrate 72 . The substrate 72 is made of glass or plastic, and a plurality of organic EL elements 74 are formed on the upper surface of the substrate 72 . The organic EL element 74 is an element that emits white light. The organic EL element 74 has an organic light-emitting layer 76 formed using a low-molecular-weight organic EL mate...

no. 3 approach

[0104] The organic EL device according to this embodiment is the same as the organic EL device 2 according to the first embodiment except for the structure of the organic buffer layer.

[0105] Figure 10 It is an enlarged cross-sectional view showing a part of the organic EL device 6 according to the present embodiment. In this organic EL device 6 , the first organic buffer layer 102 is formed on the cathodic protection layer 56 so as to overlap all of the plurality of organic EL elements 22 in order to flatten unevenness due to pixel partition walls. On the first organic buffer layer 102 , the second organic buffer layer 104 is formed so as to overlap all of the plurality of organic EL elements 22 . The gas barrier layer 60 is formed on the cathode protection layer 56 , the first organic buffer layer 102 , and the second organic buffer layer 104 so as to completely cover the terminals of the first organic buffer layer 102 and the second organic buffer layer 104 .

[0106] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com