Radiation detector

A technology for radiation detectors and detection elements, which can be used in semiconductor devices, electric solid state devices, radiation control devices, etc., and can solve problems such as diagnostic obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The overall structure of the X-ray detector

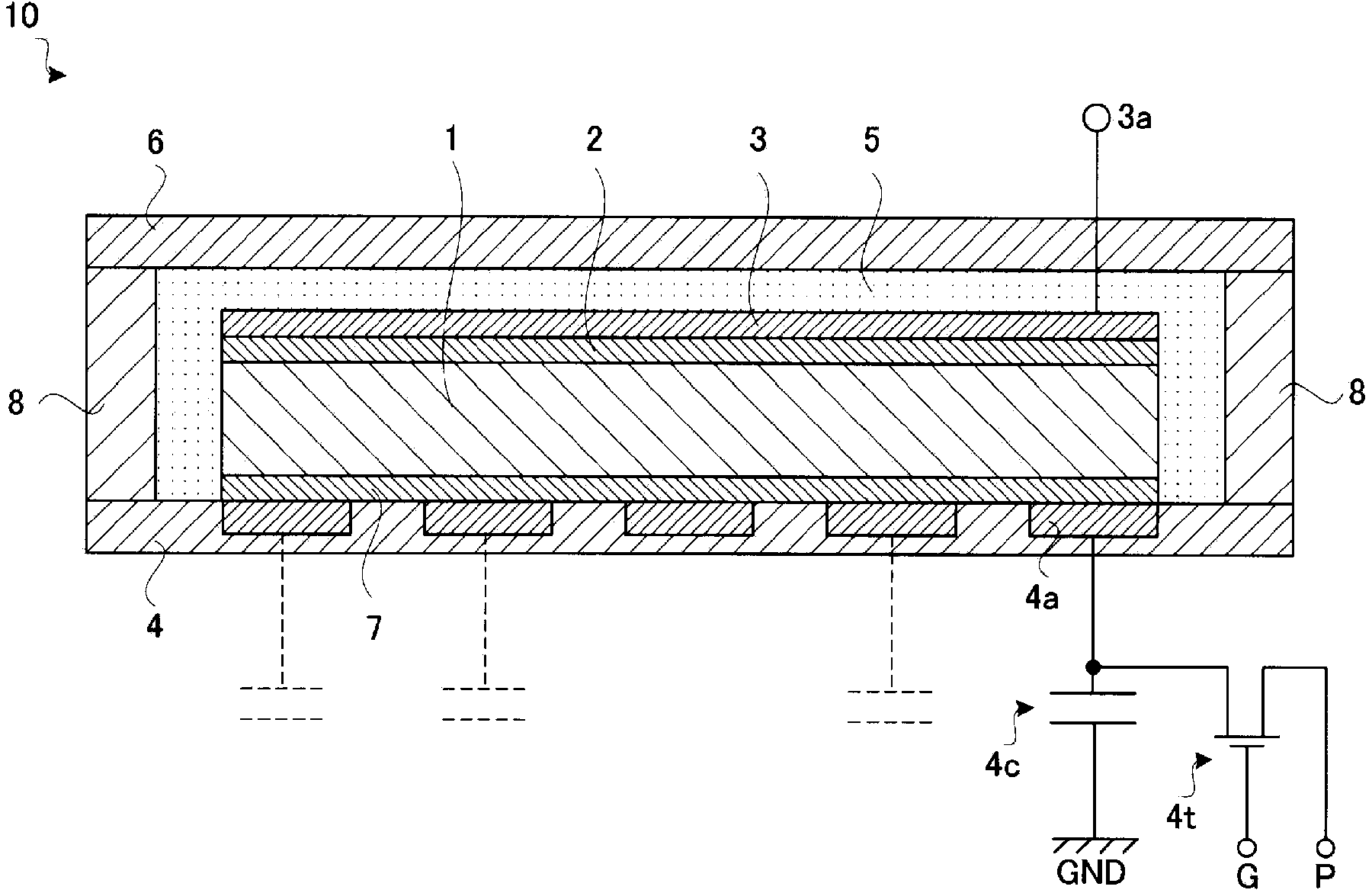

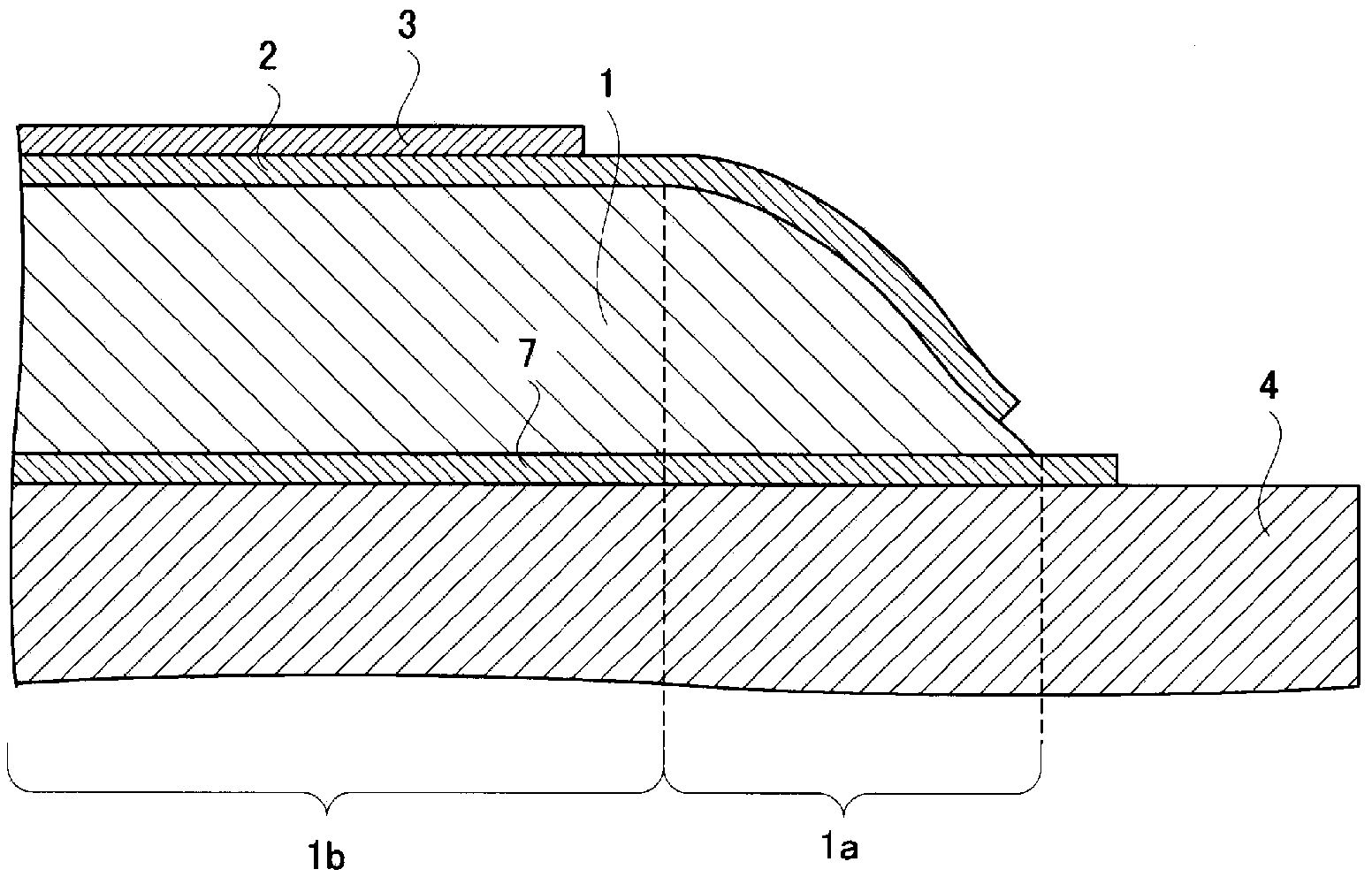

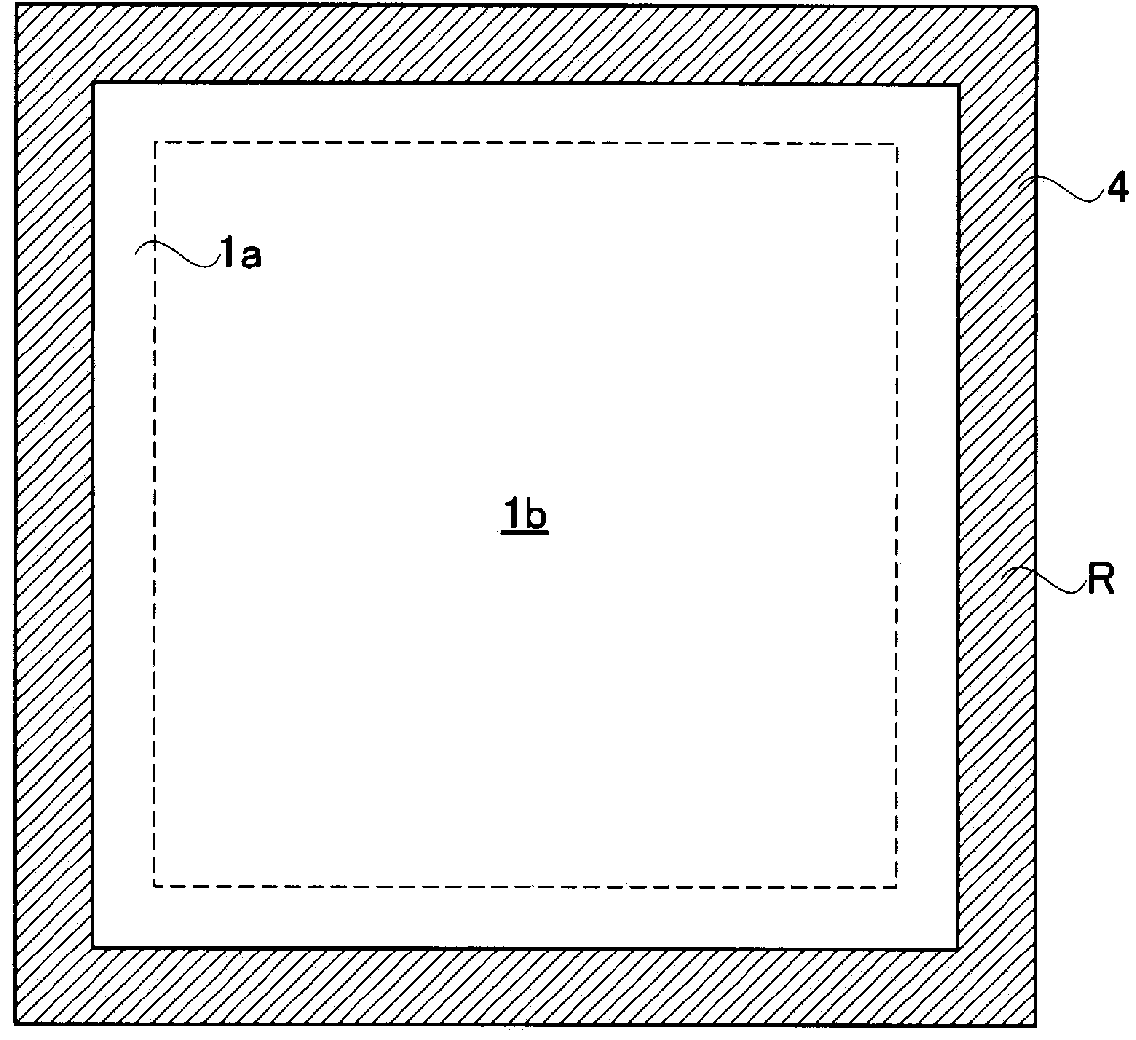

[0060] Such as figure 1 As shown, the X-ray detector 10 of Embodiment 1 has: an active matrix substrate 4, which is used to accumulate and read out the charges induced by the movement of carriers; an amorphous selenium layer 1, which is used to convert X-rays carrier pair; second high-resistance film 2; common electrode 3; epoxy resin layer 5, which is formed by curing epoxy resin at room temperature; and auxiliary plate 6, which is formed of glass. In addition, the X-ray detector 10 is configured by stacking an active matrix substrate 4, a first high-resistance film 7, an amorphous selenium layer 1, a second high-resistance film 2, a common electrode 3, an epoxy resin layer 5, and an auxiliary plate 6 in this order. . The X-ray detector corresponds to the radiation detector of the present invention.

[0061] The amorphous selenium layer 1 corresponds to the semiconductor layer of the present invention, and the second hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com