Multilayer PCB (Printed Circuit Board) central distribution box

A central power distribution box, PCB circuit board technology, applied in the direction of circuit, printed circuit components, printed circuit structural connection, etc., can solve the problems of difficult wiring design, large product size, cumbersome wiring, etc., and achieve simple and detachable features , low production cost, simplified wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] The structure and principle of the multi-layer PCB central distribution box are described in detail below by taking two PCB circuit boards as examples.

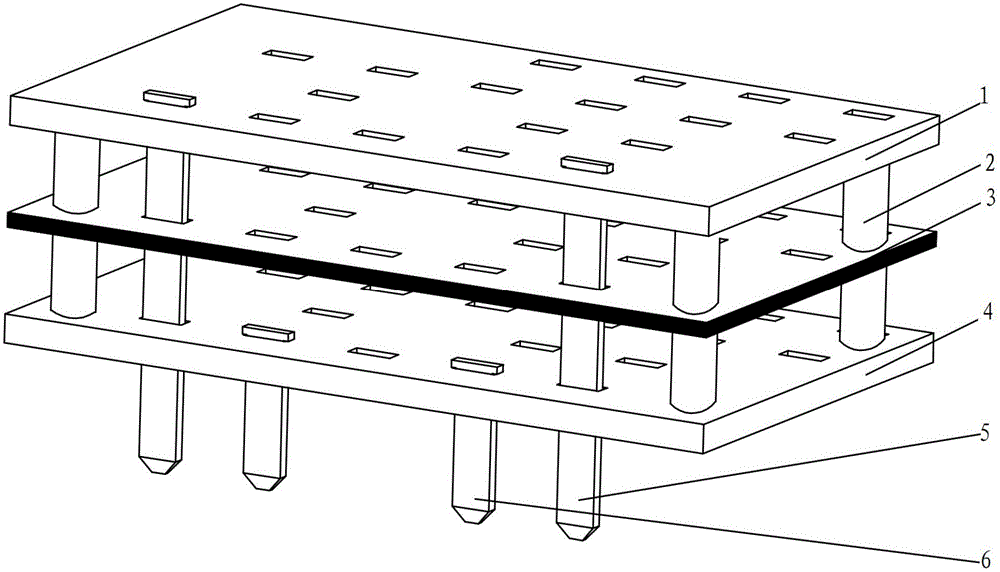

[0018] see figure 1 , the multi-layer PCB central distribution box includes an insulating box body, two PCB circuit boards located in the insulating box body and at least one pair of conductive pins. During specific implementation, the insulating box body may adopt a plastic insulating box body.

[0019] The PCB circuit boards are arranged parallel to each other by layers, an insulating paper insulation 3 is provided between the upper PCB circuit board 1 and the lower PCB circuit board 4, and the upper PCB circuit board 1 and the lower PCB circuit board 4 are connected by insulating screws 2; The screw 2 can be a plastic screw. During specific implementation, there can be four insulating screws 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com