Underwater anti-short circuit separate electric connector

An electric connector and anti-short-circuit technology, which is applied in the direction of connection, components of the connection device, circuits, etc., can solve the problems of no anti-short circuit mechanism, large underwater separation force, and no water pressure balance mechanism, etc., to achieve an anti-short circuit structure Simple, reliable, short-circuit proof, and poor maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

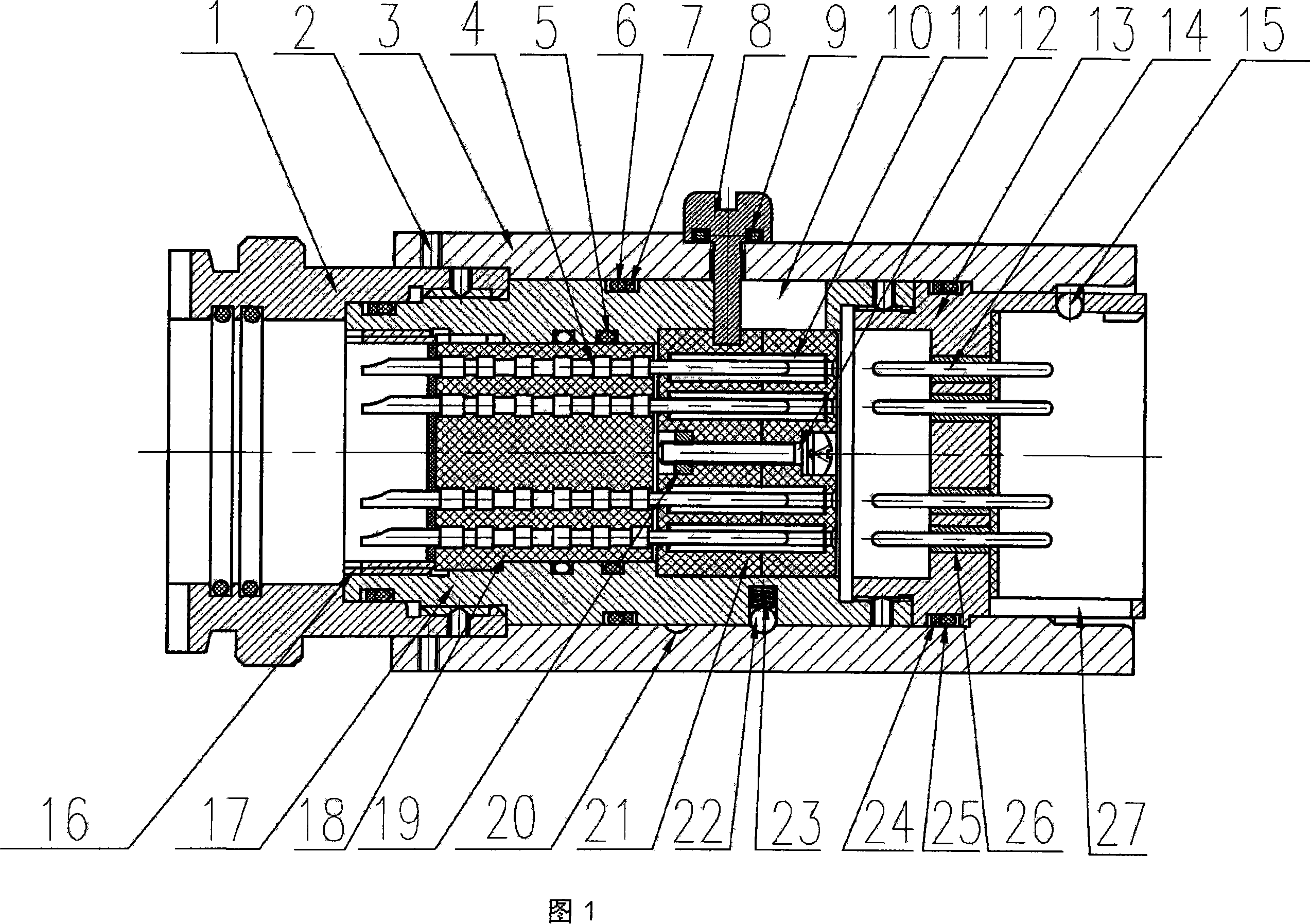

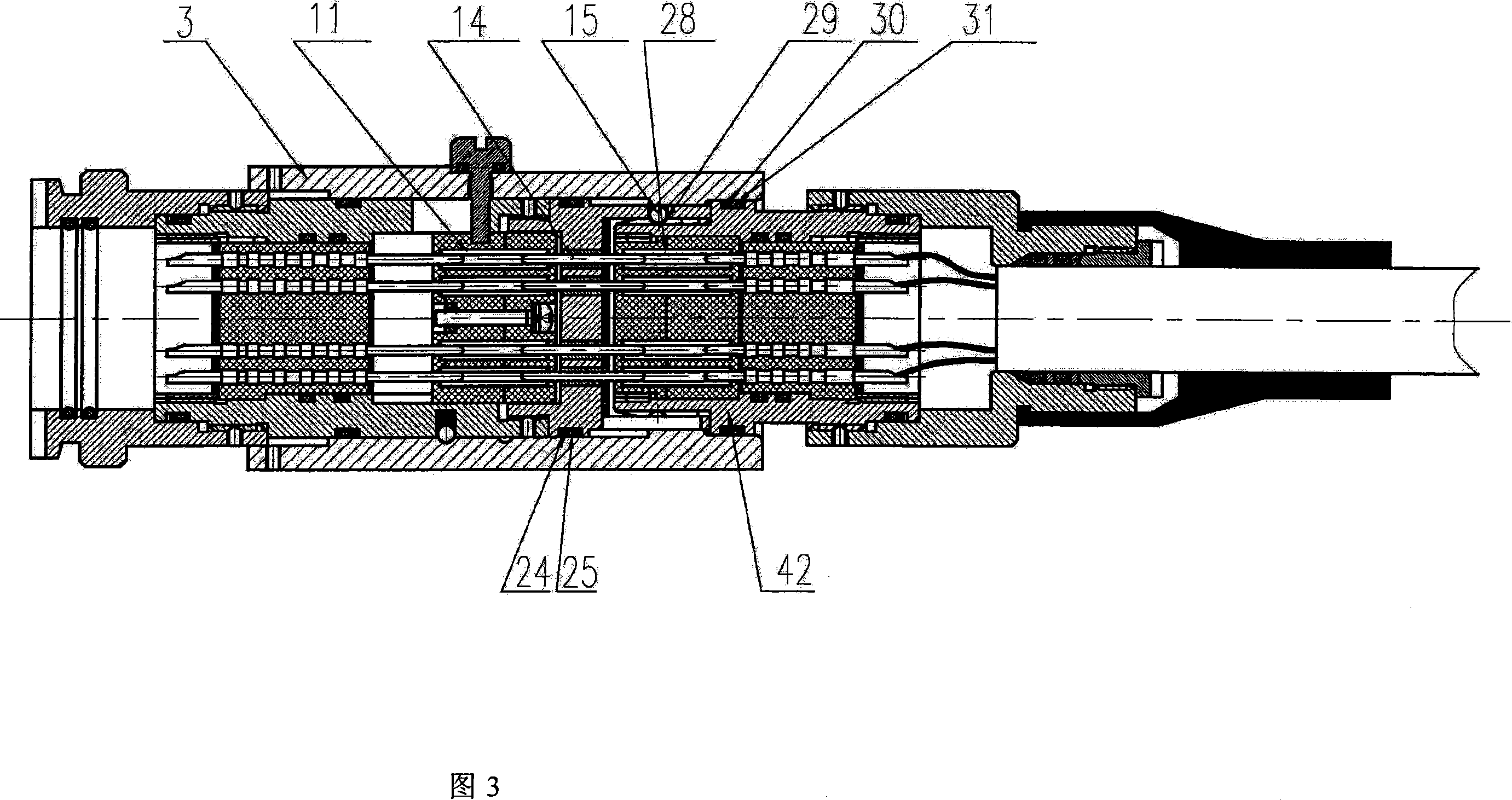

[0021] As shown in Figure 1, an unlocking sleeve 3 is arranged on the socket, and an installation hole 2 on the unlocking sleeve is connected with a release mechanism provided by the user, and the movement of the release mechanism can drive the unlocking sleeve 3 to move. The unlocking sleeve 3 is provided with a step matched with the socket housing, and the unlocking sleeve 3 can pull the socket front housing 13 and the socket rear housing 17 to move through the steps, so as to realize the complete separation of the head seat. The connecting rod 8 passes through the unlocking sleeve 3 and is connected to the socket intermediate insulator assembly 20. There are 4 grooves 10 on the socket rear housing 17, and the grooves 10 are arranged on the sealing assembly formed by the sealing ring 6 and the retaining ring 7, the sealing ring 25, the retaining ring Between the sealing components formed by the ring 24, there will be no contact with water. The connecting rod 8 can move in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com