An underwater anti-short-circuit separation electrical connector that can be unlocked synchronously

An electrical connector, anti-short-circuit technology, applied in the direction of connection, connecting device components, circuits, etc., can solve the problems of unable to achieve synchronous unlocking, unable to achieve short-circuit prevention, no waterproof function, etc., to achieve small structural size, reliable Electrical connection, effect of preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

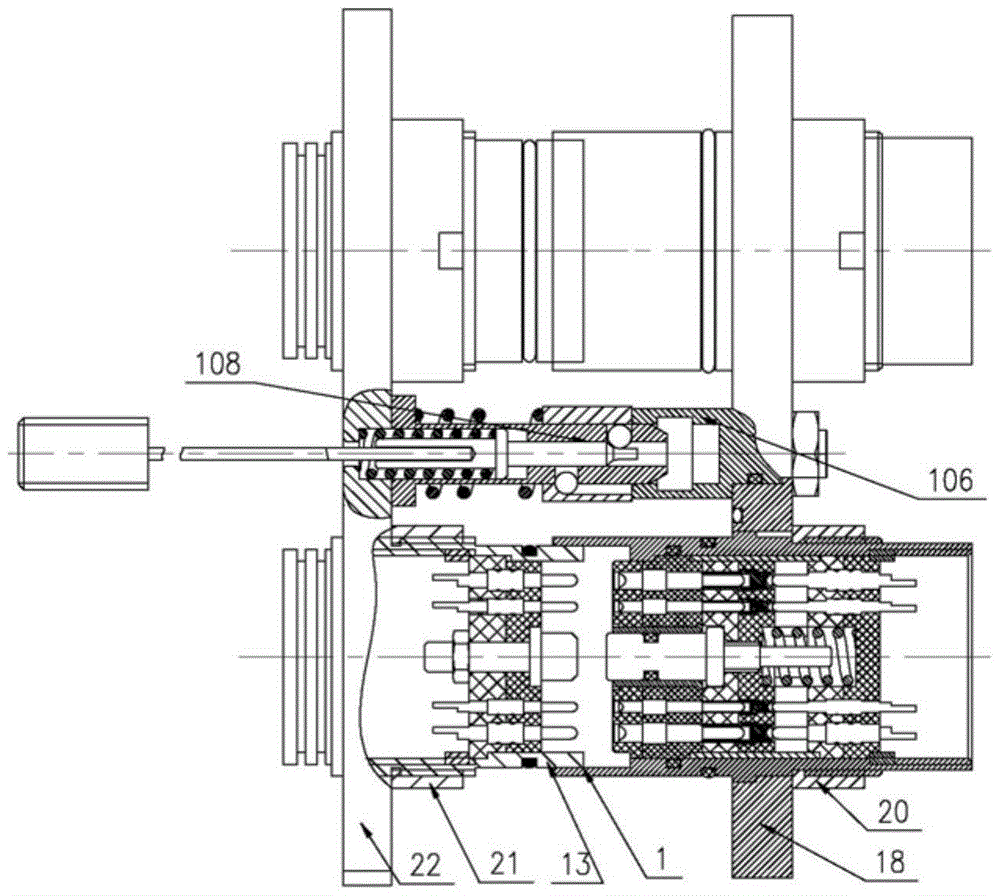

[0024] Such as figure 1 As shown, it is the first stage (state 1) of the mating process of the electrical connector: the connection mechanism 108 fixed at the center of the plug flange 22 enters the interior of the lock sleeve 106 fixed at the center of the socket flange 18 . The connection mechanism 108 includes a pull rod 23, a steel ball 24, and an unlocking spring 25. There is a groove inside the lock sleeve 106. Correspondingly, the plug shells of the two split plugs on both sides of the plug flange 22 are fixed symmetrically with the plug parallel tightening ring 21. The body 13 contacts and extends into the socket housing 1 of the split socket on both sides of the socket flange 18, which is symmetrically fixed on the socket flange 18 with a socket tightening ring 20, to complete the synchronous guiding.

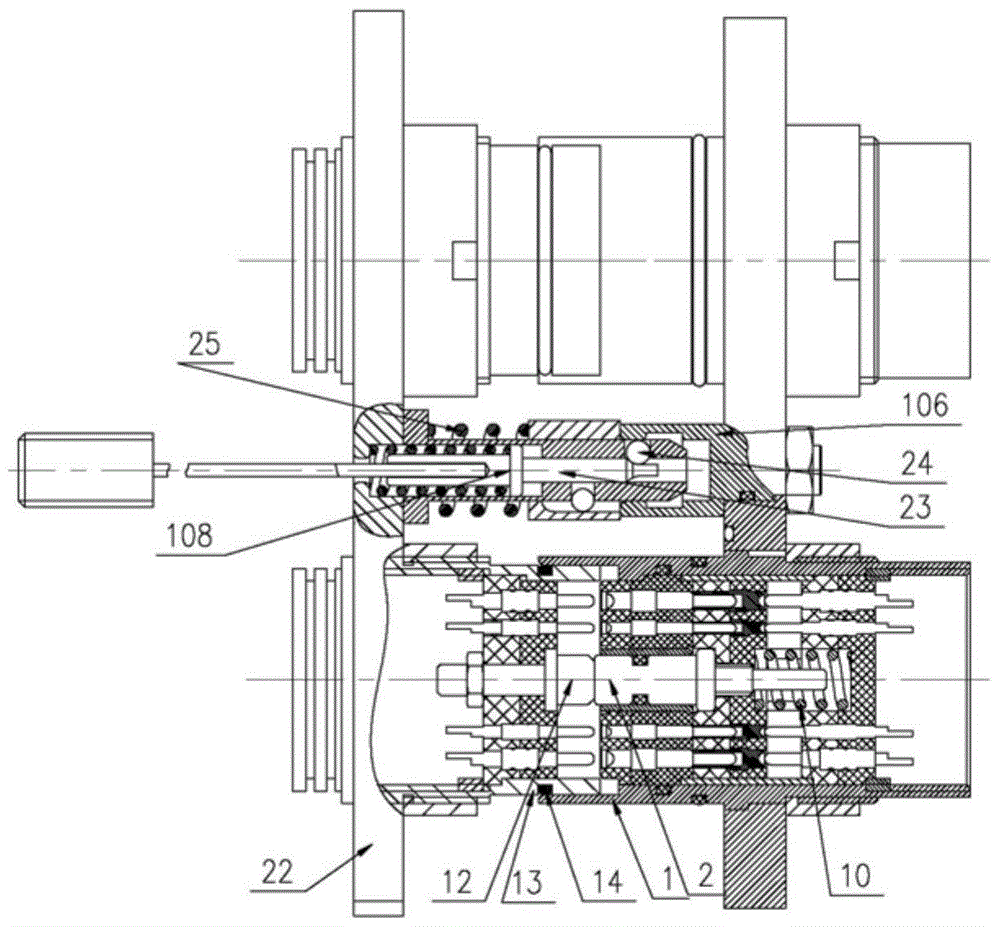

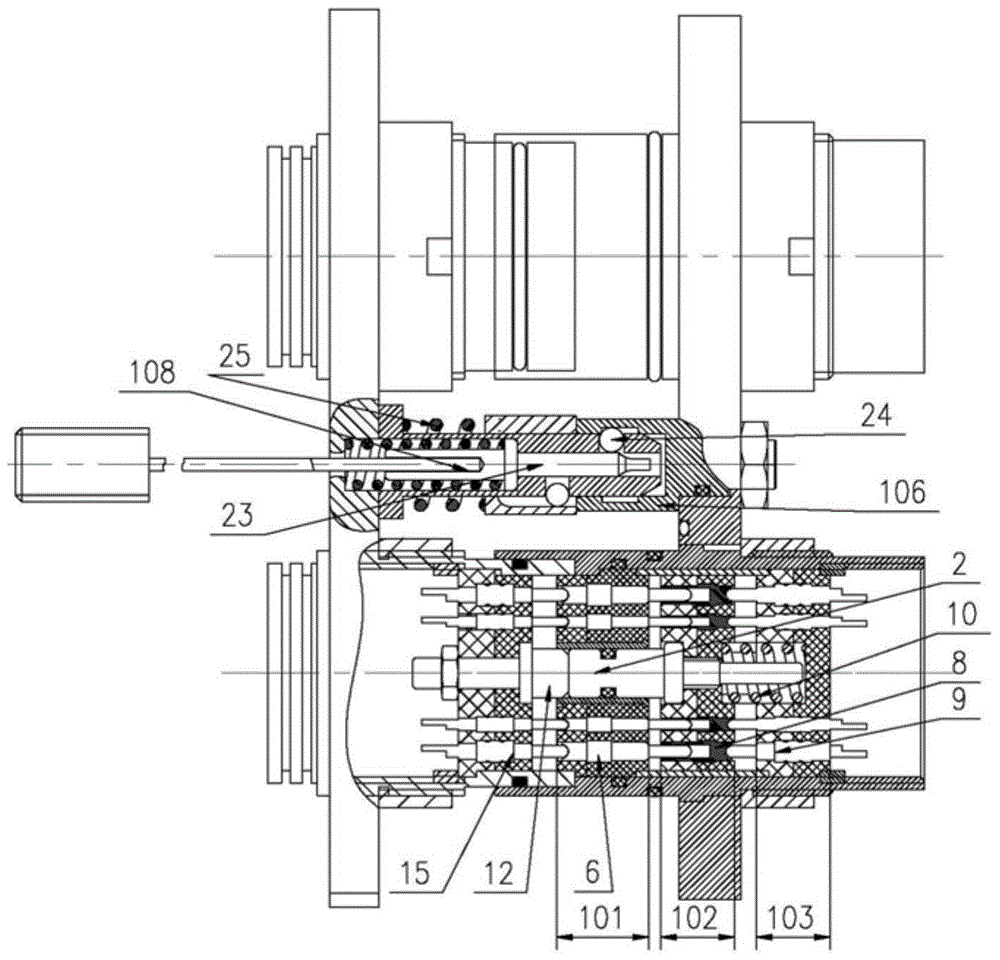

[0025] Such as figure 2 As shown, it is the second stage (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com