Hatch cover interlocking mechanism and hatch cover system

A lock mechanism and hatch cover technology, which is used in building locks, building structures, and non-mechanical transmission-operated locks, can solve the problems of hatch cover unlocking, difficulty in locking, and easy sticking of connecting rods, and achieves strong adaptability. , to achieve the effect of concealed design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

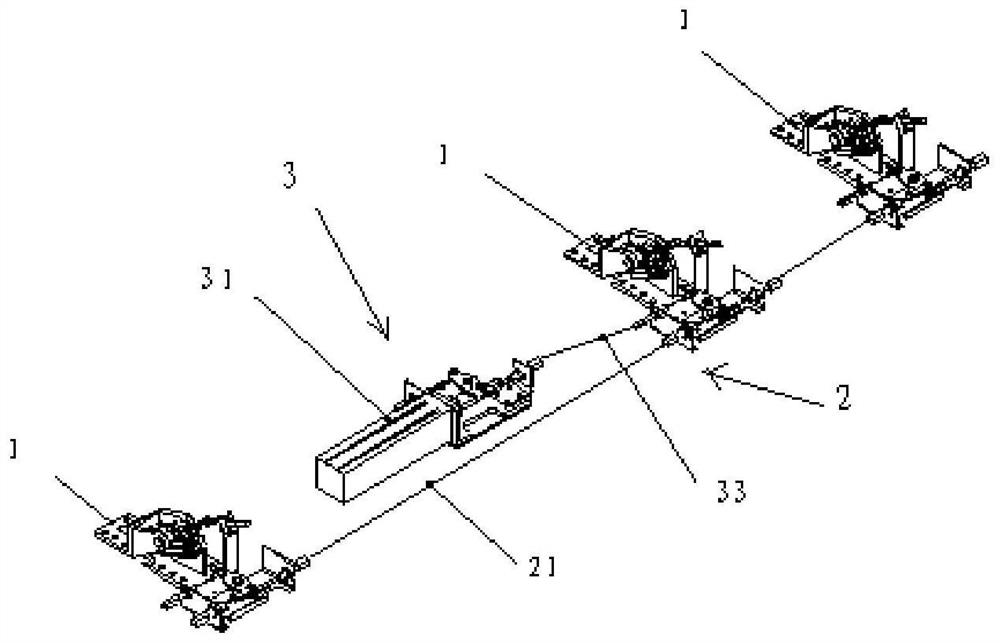

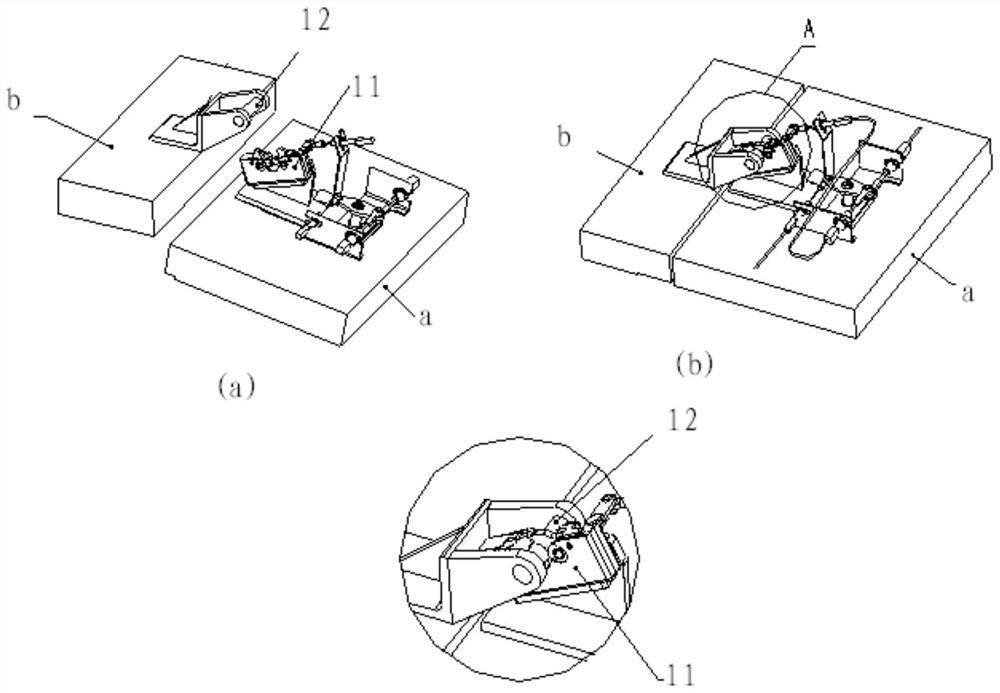

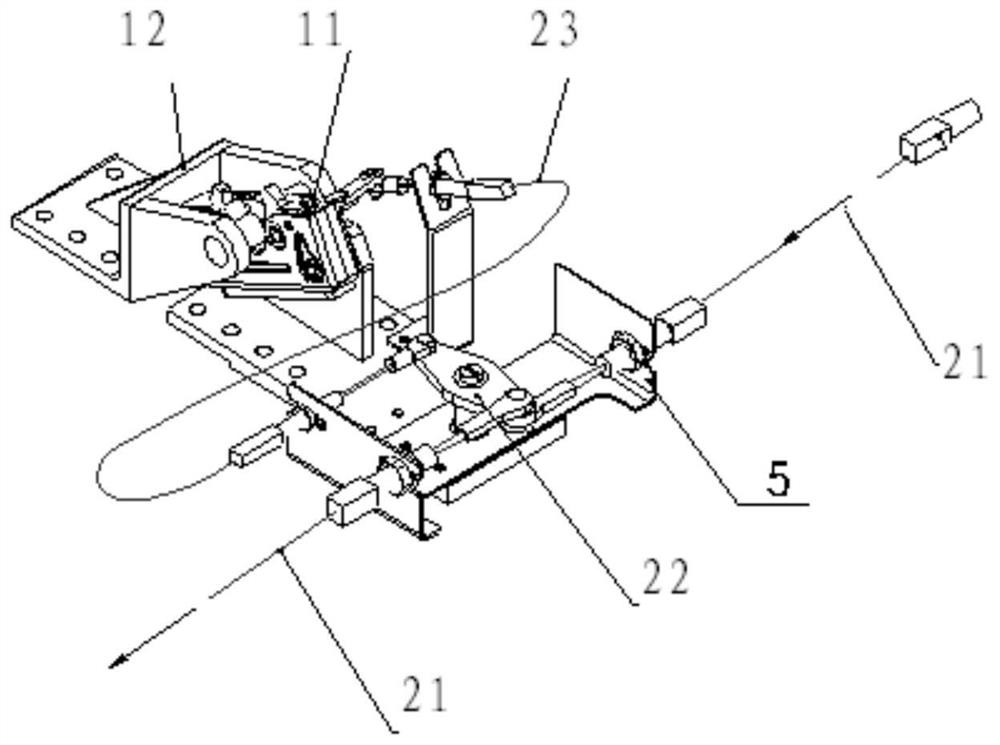

[0042] Such as Figure 4 and 5 As shown, the present embodiment provides a hatch system, including a composite hatch cover and a hatch interlocking mechanism arranged on the hatch cover. Such as Figure 5As shown, the hatch cover includes a first cover body a and a second cover body b, and the hatch cover interlocking mechanism includes six sets of lock mechanism units 1, flexible shaft assembly 2 and drive assembly 3, as figure 1 As shown, the drive assembly 3 includes a motor 31 and a drive flexible shaft 32, such as figure 2 As shown, the lock mechanism unit 1 includes a lock body 11 and a lock pin shaft 12 that are matched with each other. The six lock bodies 11 are evenly distributed on the central axis of the first cover a. One-to-one correspondence, and set at the corresponding position of the second cover b, multiple lock bodies 11 are connected in parallel through the flexible shaft assembly 2, the lock bodies 11 are set on the first cover a, and the matching lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com