Internal short circuit triggering element, internal short circuit triggering battery and internal short circuit triggering method

A technology of triggering element and internal short circuit, which is applied to electrical components, secondary batteries, circuits, etc., can solve the problems of large structural modification of the battery, unsuitable internal short circuit safety evaluation, and inability to simulate the internal short circuit state of the battery. Small, small impact on charge and discharge and cycle, flexible layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

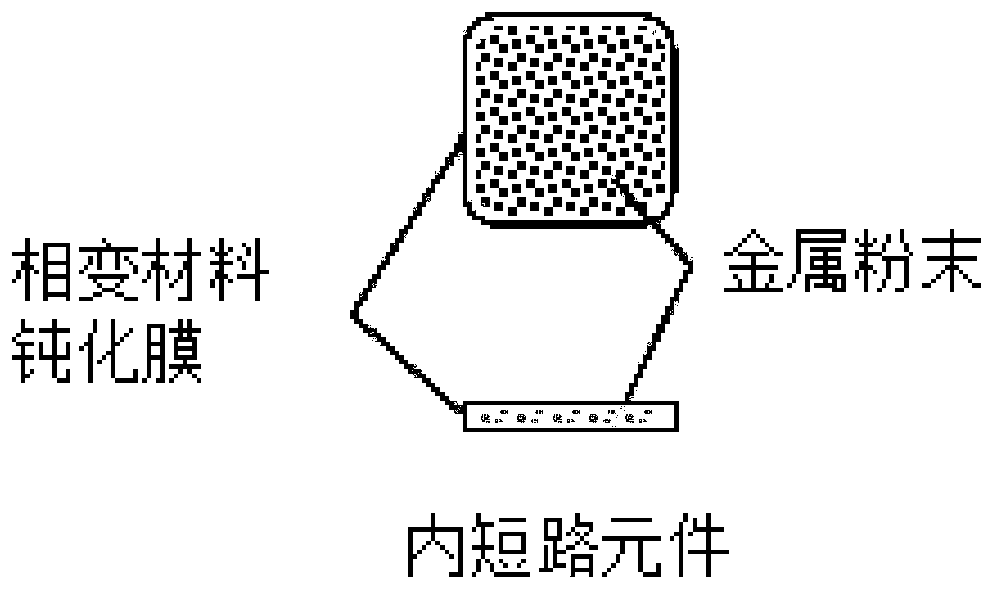

[0044] A preparation method of the internal short-circuit trigger element provided by the present invention comprises the following steps:

[0045] On a layer of melted phase-change material, add metal powder, then add a layer of melted phase-change material, and obtain the internal short-circuit trigger element after cooling;

[0046] or;

[0047] The molten phase-change material is mixed with metal powder to prepare a uniform suspension liquid, poured into a mold, and after cooling, excess metal powder on the surface is removed to obtain the internal short-circuit trigger element.

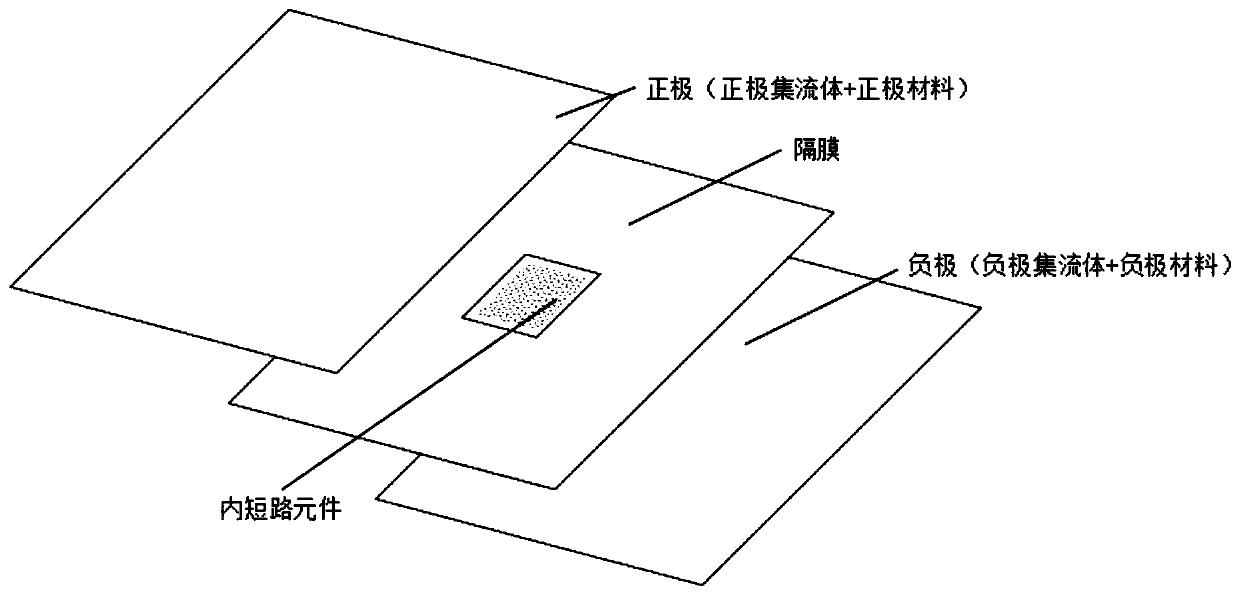

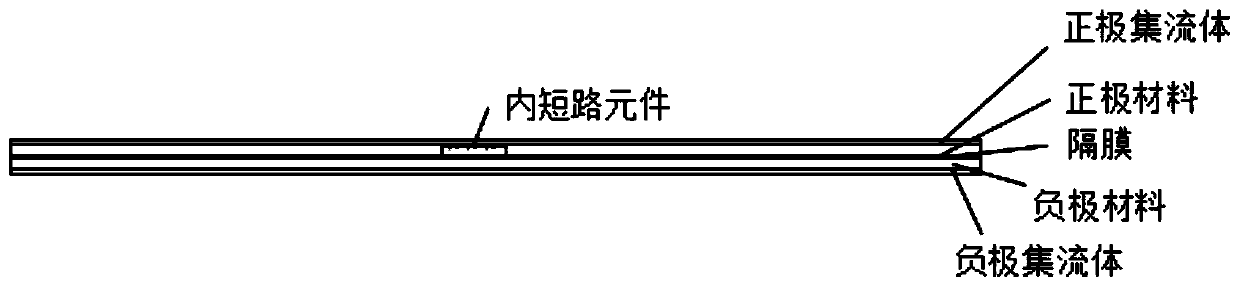

[0048] An internal short circuit trigger battery, the battery is a stacked battery or a wound battery, the battery includes a negative electrode current collector, a negative electrode material, a separator, a positive electrode material and a positive electrode current collector arranged in sequence, and the internal short circuit trigger element is set between the cathode material and the sepa...

Embodiment 1

[0079] An internal short-circuit trigger element, in a circular mold with a diameter of 6mm, add a layer of melted paraffin, then add iron powder with a diameter between 50 and 200 microns, and then add a layer of melted paraffin, and get the thickness after cooling 400 µm internal short circuit trigger element.

Embodiment 2

[0081] Blend melted paraffin with nickel powder with a diameter of 50-200 microns to make a uniform suspension, inject it into the mold, remove excess nickel powder on the surface after cooling, and demould to obtain an internal short-circuit trigger with a thickness of 480 microns. element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com